In the realm of heavy machinery, comprehending the layout and organization of various components is essential for effective maintenance and repair. A clear representation of the individual elements within these powerful machines aids technicians and operators in swiftly identifying issues and ensuring optimal performance.

By analyzing the arrangement of the elements, users can gain valuable insights into the functionality and interconnectivity of each section. This understanding not only enhances troubleshooting capabilities but also promotes more efficient handling of repairs and upgrades.

With a focus on specific models, the study of component layouts becomes a vital resource for professionals in the field. Mastery of these visual representations allows for a deeper appreciation of the intricacies involved in machinery operation, ultimately leading to improved reliability and longevity of the equipment.

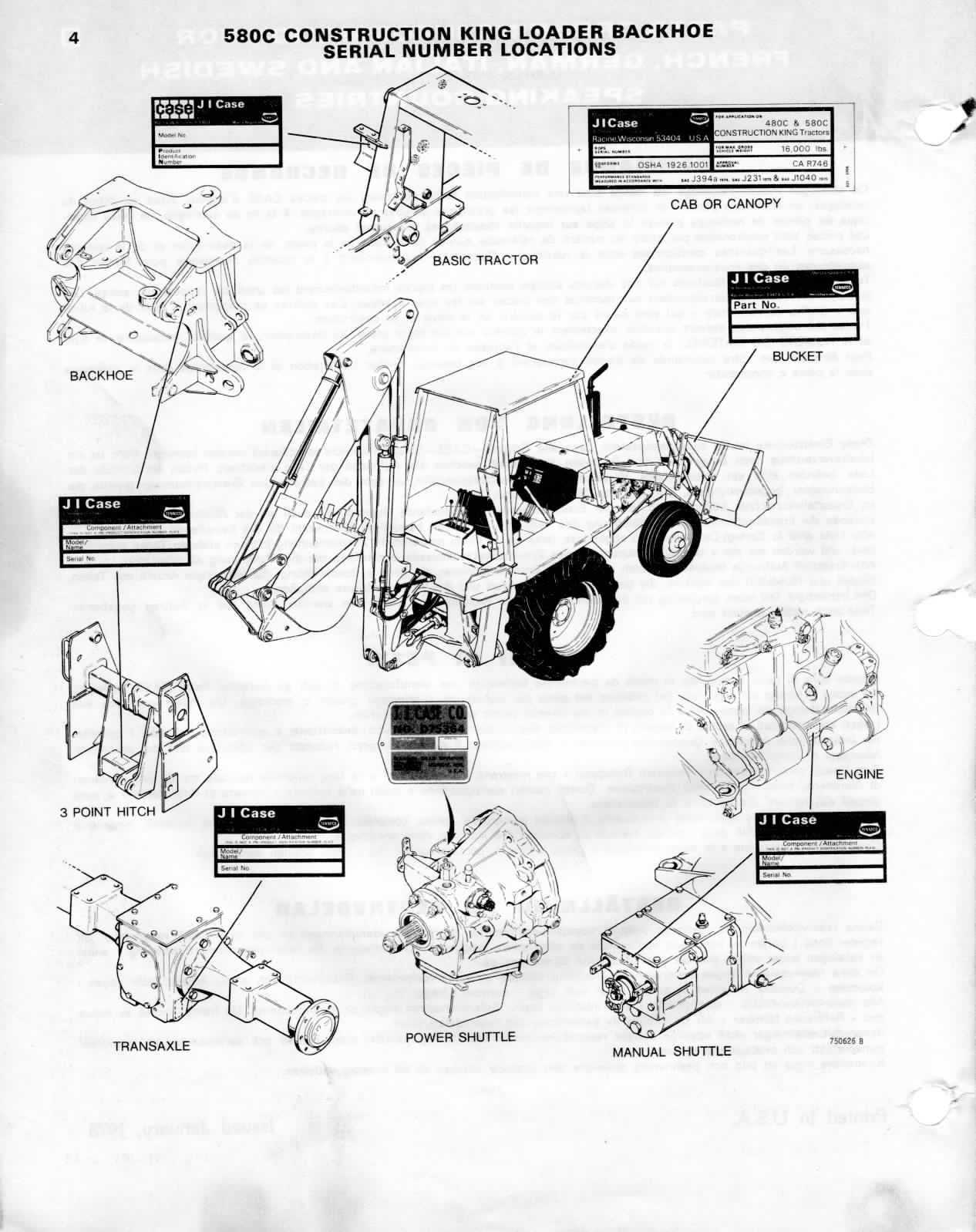

Understanding the Case 580C Parts Diagram

The visual representation of machinery components is essential for maintenance and repair. Grasping the layout of these elements helps operators and technicians ensure optimal functionality and longevity of their equipment. Such illustrations provide clarity on how different sections interact, facilitating troubleshooting and efficient servicing.

Comprehending the layout enables users to identify specific sections and their roles within the system. Each part is typically labeled, making it easier to locate components when replacements or repairs are necessary. This organized approach not only simplifies the repair process but also aids in understanding the overall mechanics at play.

Additionally, familiarity with the schematic fosters confidence in handling the equipment. It empowers users to perform regular inspections and maintenance, ultimately leading to better performance and reduced downtime. Engaging with these visuals transforms a complex machine into a more manageable system, enhancing the operator’s experience and efficiency.

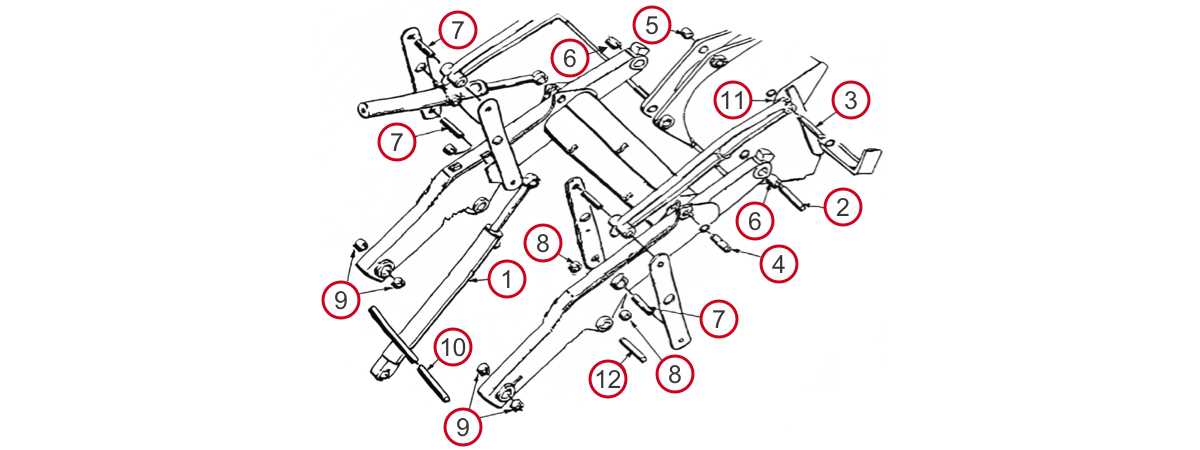

Key Components of the Case 580C

This section delves into the essential elements that contribute to the functionality and efficiency of a well-known piece of heavy machinery. Understanding these fundamental components is crucial for anyone looking to maintain, repair, or operate this equipment effectively.

Core Functional Parts

The machinery consists of several vital parts that work in unison to perform various tasks. Each element plays a specific role in ensuring smooth operation and high performance.

| Component | Function |

|---|---|

| Engine | Drives the machine and powers its various functions. |

| Transmission | Transfers power from the engine to the wheels and implements. |

| Hydraulic System | Operates attachments and provides lifting capabilities. |

| Frame | Supports all components and provides structural integrity. |

Additional Critical Elements

Beyond the core components, several additional features enhance usability and efficiency. Familiarity with these elements can significantly improve operational knowledge.

| Element | Purpose |

|---|---|

| Cab | Provides operator comfort and control. |

| Bucket | Facilitates digging and material handling. |

| Stabilizers | Ensure stability during operation, especially when digging. |

| Wheels | Allow for mobility and maneuverability on various terrains. |

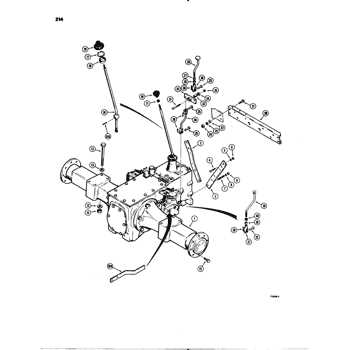

How to Read the Parts Diagram

Understanding the visual representation of components is crucial for effective maintenance and repair. This guide will help you navigate through the various sections and symbols commonly used in these illustrations, allowing for efficient identification and ordering of necessary elements.

Familiarizing Yourself with Symbols

Each representation contains specific icons and notations that denote various elements. Here’s how to interpret them:

- Shapes: Different shapes indicate specific types of components, such as circular for gears and rectangular for housing.

- Lines: Solid lines typically represent connections, while dashed lines may indicate optional or auxiliary parts.

- Labels: Each item is usually accompanied by a unique code or number for easy reference.

Identifying Component Relationships

Understanding how components interact is vital for a holistic view of the machinery. Follow these steps:

- Locate the main assembly on the illustration.

- Trace connections to secondary parts, noting their functions.

- Refer to the accompanying list to confirm part specifications.

Common Issues and Replacement Parts

When operating heavy machinery, various challenges can arise over time, leading to the need for specific components to be replaced. Understanding these frequent problems and the corresponding replacements can help maintain the efficiency and longevity of the equipment.

-

Hydraulic System Failures:

Issues in the hydraulic system are common due to wear and tear. Symptoms include reduced lifting capacity and slow operation. Key replacements may involve:

- Hydraulic hoses

- Seals and gaskets

- Hydraulic pumps

-

Engine Overheating:

Overheating can lead to severe engine damage. This can often be traced to coolant leaks or a malfunctioning radiator. Consider replacing:

- Thermostats

- Water pumps

- Radiators

-

Transmission Problems:

Transmission issues may manifest as slipping or difficulty in shifting. Regular checks and replacements of components can prevent major failures. Key items include:

- Transmission filters

- Fluid

- Gaskets

-

Electrical Failures:

Electrical components are vital for operation and often experience faults. Common repairs involve:

- Wiring harnesses

- Starter motors

- Batteries

By identifying these prevalent issues and understanding which components to replace, operators can ensure their machinery runs smoothly and efficiently for years to come.

Maintenance Tips for Case 580C

Regular upkeep is essential for ensuring the longevity and efficient operation of any heavy machinery. Implementing a consistent maintenance routine not only enhances performance but also reduces the likelihood of unexpected breakdowns. Below are some valuable tips to keep your equipment in optimal condition.

Routine Inspections

Perform frequent checks on all major components, including hydraulic systems, engine oil levels, and filters. Inspect hoses for signs of wear and replace them if necessary. Ensure that all connections are secure and free of leaks, as this can prevent more significant issues down the line.

Lubrication and Fluid Management

Maintain proper lubrication for moving parts to minimize friction and wear. Regularly check and replenish fluids such as transmission oil, coolant, and hydraulic fluid. Keeping these levels topped off will not only enhance performance but also extend the lifespan of the machinery.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for ensuring optimal performance and longevity. High-quality elements not only enhance the efficiency of operations but also provide peace of mind, knowing that replacements are reliable and durable. This section outlines various avenues to source original items effectively.

Several key places can be explored when searching for these essential elements:

| Source | Description |

|---|---|

| Authorized Dealers | Official representatives offer a wide range of genuine components with the assurance of quality and warranty. |

| Manufacturer’s Website | Directly purchasing from the original producer ensures that you receive the most up-to-date and genuine items. |

| Specialized Retailers | Stores focusing on industrial machinery often carry a selection of authentic components, providing expert advice and support. |

| Online Marketplaces | Reputable platforms can connect you with genuine parts, but it’s vital to verify seller ratings and product authenticity. |

| Local Repair Shops | Experienced technicians may have access to original items and can assist in identifying the right components for your needs. |

By exploring these options, you can ensure that you acquire the necessary items that maintain the integrity and functionality of your equipment.

Assembly and Disassembly Instructions

This section provides essential guidance on how to carefully put together and take apart machinery components, ensuring both efficiency and safety. Understanding the correct procedures is vital for maintaining optimal performance and longevity of the equipment.

Preparation Steps

- Gather all necessary tools and equipment.

- Ensure a clean and organized workspace.

- Review the assembly and disassembly guidelines thoroughly.

Disassembly Process

- Start by disconnecting power sources to prevent accidents.

- Remove any external covers or guards.

- Carefully take out individual components in reverse order of assembly.

- Store removed parts securely to avoid damage.

Assembly Process

- Begin with the base component and secure it in place.

- Follow the reverse order of the disassembly process.

- Ensure all fasteners are tightened to the manufacturer’s specifications.

- Reattach any covers or guards before reconnecting power.

Aftermarket vs. OEM Components

The choice between original equipment manufacturer components and alternative aftermarket options is a significant consideration for many in the machinery sector. Each type offers distinct advantages and disadvantages, influencing performance, cost, and longevity. Understanding these differences can help users make informed decisions tailored to their specific needs and preferences.

Quality and Reliability

OEM components are typically manufactured to the exact specifications set by the original equipment producer, ensuring a high level of quality and reliability. These parts often come with warranties, providing peace of mind to users. In contrast, aftermarket alternatives can vary widely in quality, with some offering exceptional performance while others may fall short. It is essential to research and choose reputable brands when considering these options.

Cost Considerations

One of the most compelling reasons for opting for aftermarket options is the potential for significant cost savings. These components often come at a lower price point compared to their OEM counterparts, making them an attractive choice for budget-conscious users. However, it is crucial to weigh the initial savings against potential long-term costs, such as repairs or replacements, which may arise from using inferior alternatives.

Ultimately, the decision between original components and aftermarket solutions depends on individual priorities, including budget, performance requirements, and the importance of warranty coverage.

Resources for Repair Manuals

Accessing quality repair documentation is essential for effective maintenance and troubleshooting of machinery. Comprehensive guides provide vital information on assembly, disassembly, and component specifications, ensuring that users can carry out repairs efficiently and safely. Various resources are available for individuals seeking detailed instructions and illustrations to aid in their repair endeavors.

Online Platforms

Numerous websites specialize in providing repair manuals for a wide range of equipment. These platforms often feature downloadable content, which may include PDF files, instructional videos, and community forums for additional support.

Printed Manuals

For those who prefer traditional methods, printed manuals can be acquired through various retailers. These resources often come in the form of comprehensive handbooks that provide step-by-step guidance along with helpful diagrams.

| Resource Type | Examples | Accessibility |

|---|---|---|

| Online Manuals | Manufacturer websites, dedicated repair sites | Instant download |

| Printed Guides | Bookstores, online retailers | Shipping required |

| Community Forums | User-generated content, discussion boards | Free access |