Understanding the detailed structure and individual elements of construction equipment is crucial for ensuring its efficient performance and longevity. Each component within the system plays a vital role in the overall operation, and being familiar with these elements allows for better maintenance and troubleshooting.

In this guide, we will dive into the specific elements and layout of heavy machinery systems. By gaining insight into the positioning and functionality of each element, users can optimize performance and address any potential issues with greater accuracy.

Whether for routine maintenance or complex repairs, a thorough grasp of these mechanical systems helps technicians keep the equipment in top condition, ensuring long-term reliability and operational efficiency.

Understanding the Case 580K Components

When analyzing the key systems and mechanisms of heavy machinery, it’s essential to break down the various assemblies that work together to ensure efficient operation. Each component plays a specific role in maintaining the overall functionality, from the engine to the hydraulic systems, contributing to the machine’s performance in challenging environments.

Engine and Powertrain Systems

The driving force behind the machine lies in its power generation system. This includes:

- The power unit, which generates the required energy for all operations.

- The transmission, responsible for distributing that energy effectively across different parts.

- Cooling mechanisms that ensure consistent performance even under heavy load.

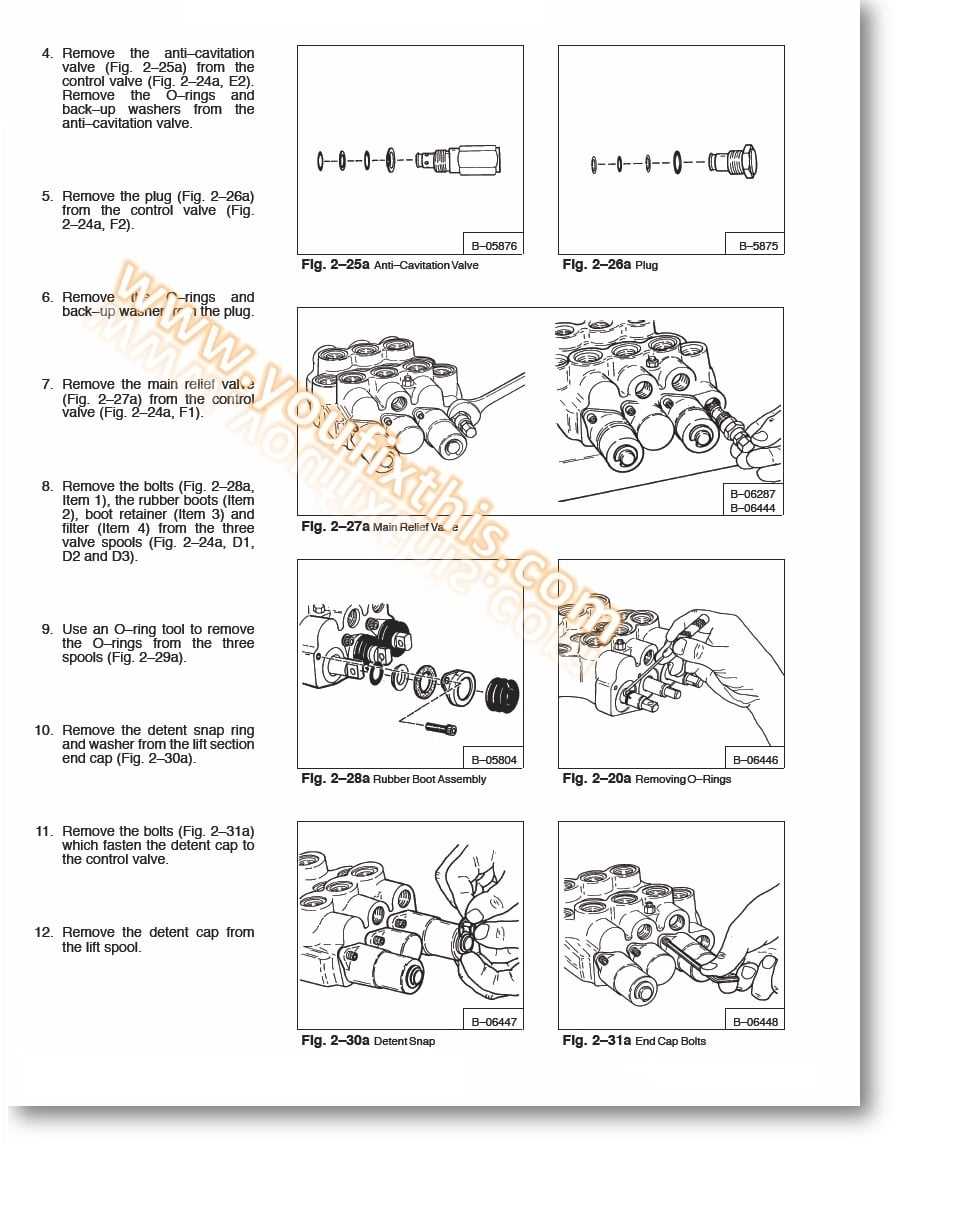

Hydraulic and Control Systems

Precision and control are critical in operating machinery. These systems are responsible for:

- Providing fluid power to various attachments.

- Managing the movements with high accuracy through the control valves.

- Ensuring safe operation via pressure regulation and distribution of hydraulic fluids.

Key Engine Parts and Their Functions

The engine is a complex system made up of several critical components, each playing an essential role in its overall operation. Understanding these components and how they work together ensures efficient performance and longevity.

Cylinder Block: The cylinder block serves as the foundation, housing the main components that produce power. It must withstand extreme pressure and temperature while maintaining structural integrity.

Pistons: Pistons are essential for converting fuel energy into mechanical movement. Positioned inside the cylinders, they move up and down, creating the force necessary to turn the engine’s crankshaft.

Crankshaft: The crankshaft converts the linear motion of the pistons into rotational energy. This energy is then transferred to other parts of the vehicle’s drivetrain to create movement.

Camshaft: The camshaft controls the opening and closing of the engine’s valves, ensuring precise timing for fuel intake and exhaust expulsion, which is critical for optimal combustion.

Valves: Valves regulate the flow of fuel and air into the engine and control the exhaust gases leaving the combustion chambers. Their accurate operation is essential for maintaining power and efficiency.

Hydraulic System Overview

The hydraulic system plays a crucial role in the functionality of many heavy-duty machines, powering essential components through the use of pressurized fluid. This system is responsible for transmitting energy, allowing the machine to perform tasks that require significant force and precision. Understanding how this system operates can help ensure its efficiency and longevity.

At the core of the system, a powerful pump generates the pressure needed to move the hydraulic fluid through various lines and valves. These elements work in harmony to transfer force from one point to another, enabling precise control over movements like lifting, digging, or steering.

Regular maintenance of the system, including fluid checks and component inspections, is essential to prevent wear and ensure that the system remains responsive and effective. Any disruption or damage to the hydraulic system can lead to decreased performance or complete failure of the machine’s operations.

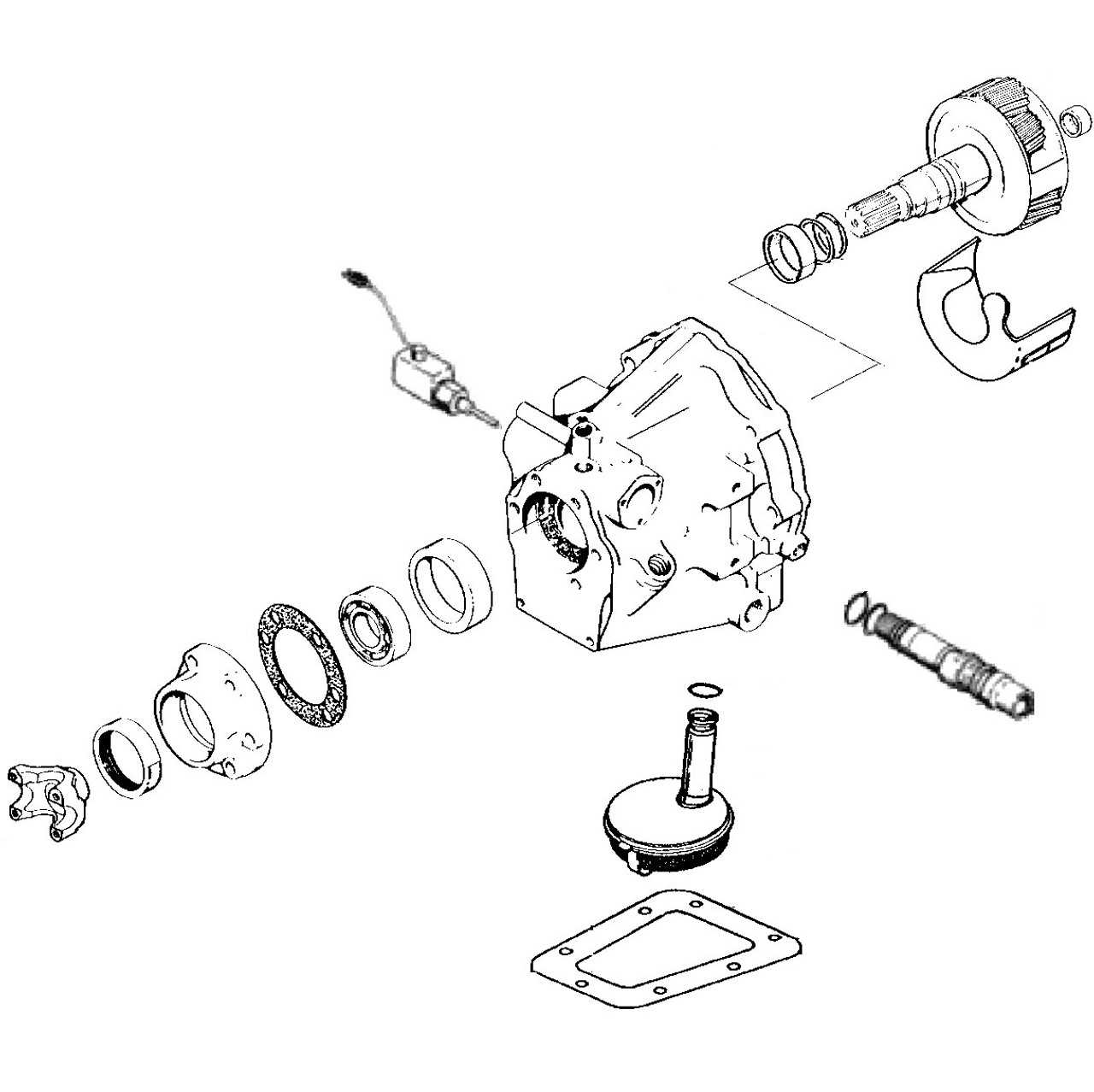

Transmission and Drive System Breakdown

The transmission and drive system are critical components that ensure smooth power delivery and vehicle movement. A deep understanding of their inner workings allows for effective maintenance and troubleshooting. This section provides an overview of the mechanisms involved, focusing on key elements that contribute to efficient operation.

| Component | Function |

|---|---|

| Gearbox | Transfers engine power to the wheels through a series of gears, adjusting speed and torque. |

| Differential | Distributes engine power between wheels, allowing for smooth turns by enabling different wheel speeds. |

| Clutch System | Engages and disengages the power flow from the engine to the transmission, facilitating gear changes. |

| Axles | Transmit power from the differential to the wheels, providing the necessary traction for movement. |

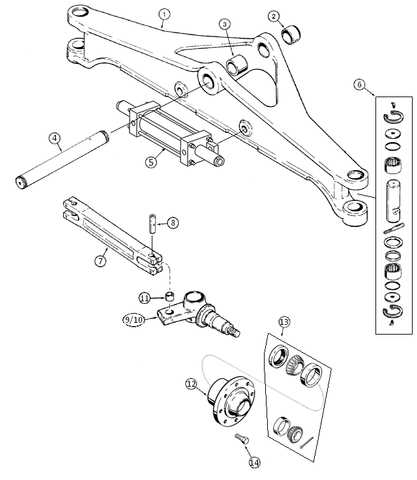

Front and Rear Axle Components

The axle system plays a crucial role in the overall operation of both front and rear sections, ensuring optimal movement and stability. Understanding the key elements of this mechanism is essential for maintaining balance and performance during various tasks.

Key Components of the Front Axle

- Axle shaft: Transmits power from the differential to the wheels, allowing smooth rotation.

- Steering knuckles: Critical for managing the steering functions by connecting the wheels to the axle.

- Hub assembly: Houses the wheel bearings and ensures the wheels rotate freely.

Primary Elements of the Rear Axle

- Differential: Distributes torque to the wheels, enabling different speeds for each wheel during turns.

- Axle housing: Protects the internal components from debris and damage while providing structural support.

- Wheel bearings: Ensure smooth and efficient rotation of the wheels by reducing friction.

Steering Mechanism and Control

The steering system is a crucial component in any heavy machinery, facilitating maneuverability and precision in movement. This section explores the various elements that contribute to effective steering control, ensuring optimal performance and safety during operation.

The steering mechanism consists of several key components that work together harmoniously:

- Steering Wheel: The primary interface for the operator, allowing for directional input.

- Steering Column: Connects the steering wheel to the gearbox and transmits the operator’s movements.

- Gearbox: Translates the rotational motion of the steering wheel into lateral movement, enhancing responsiveness.

- Linkage System: Consists of rods and joints that connect the gearbox to the wheels, allowing for the transfer of motion.

- Hydraulic Assist: Enhances steering effort, making it easier for the operator to maneuver the machine.

Each of these components plays a vital role in the overall functionality of the steering system. Regular maintenance and inspection are essential to ensure that all parts are in good working condition, preventing any potential issues during operation.

Understanding the intricacies of the steering mechanism enables operators to maximize efficiency and safety while handling heavy machinery.

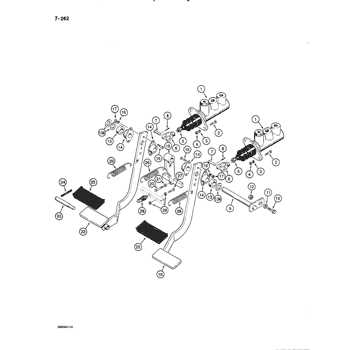

Brake System Layout and Parts

The braking mechanism is a crucial component of any machinery, ensuring safe operation and control. Understanding its structure and function is essential for maintenance and troubleshooting. This section outlines the various elements of the braking system, emphasizing their roles and interconnections.

Key Components

The primary elements of the braking mechanism include hydraulic cylinders, brake pads, and rotors. Each component works together to generate the necessary force for stopping the machine effectively.

Component Overview

| Component | Description |

|---|---|

| Hydraulic Cylinder | Converts hydraulic pressure into mechanical force, activating the brake pads. |

| Brake Pads | Friction material that presses against the rotor to create stopping power. |

| Rotor | A rotating disc that the brake pads clamp down on to halt movement. |

| Brake Lines | Transfer hydraulic fluid from the reservoir to the hydraulic cylinders. |

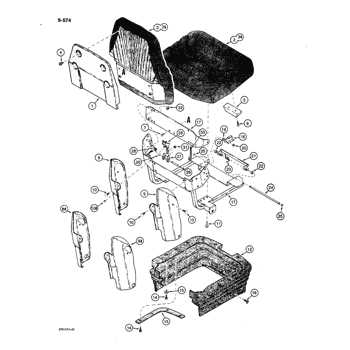

Cabin Controls and Interior Elements

The functionality and comfort of any machinery heavily rely on the design and arrangement of its operator’s area. This section focuses on the essential components that enhance user experience and operational efficiency within the enclosed space. From control interfaces to seating arrangements, each element plays a crucial role in ensuring smooth operation and ease of access for the operator.

Control Interfaces

Control interfaces are vital for navigating and managing various functions of the equipment. These elements are typically designed for intuitive usage, allowing the operator to focus on tasks without distraction. The placement and layout of buttons, switches, and levers can significantly impact the effectiveness of the operator’s interaction with the machine.

Seating and Comfort Features

Comfort is paramount in the design of the operator’s space, as prolonged use demands a well-structured seating arrangement. Adjustable seats, armrests, and ergonomic designs contribute to reducing fatigue and improving focus during operations. The materials used in seating can also enhance the overall experience, providing both support and durability.

| Feature | Description |

|---|---|

| Control Layout | Strategically placed buttons and levers for ease of access. |

| Adjustable Seating | Seats that can be modified for height and angle to suit the operator. |

| Visibility Enhancements | Design elements that ensure clear sightlines to surroundings and equipment. |

| Storage Compartments | Accessible spaces for tools and personal items to keep the area organized. |

Cooling System Structure and Elements

The cooling mechanism plays a crucial role in maintaining optimal operating temperatures within machinery. It consists of several interconnected components designed to efficiently dissipate heat generated during operation. Understanding this system is essential for effective maintenance and troubleshooting.

Core Components: The primary elements include a radiator, water pump, thermostat, and hoses. Each of these parts works collaboratively to regulate temperature and ensure proper circulation of coolant throughout the engine.

Radiator: The radiator serves as the primary heat exchanger, transferring heat from the coolant to the surrounding air. It is essential for preventing overheating and maintaining engine efficiency.

Water Pump: This component circulates the coolant, allowing it to flow through the engine and back to the radiator. A malfunctioning water pump can lead to inadequate coolant flow and potential overheating.

Thermostat: The thermostat regulates the temperature of the coolant by controlling its flow based on the engine’s temperature. It ensures that the engine warms up quickly and operates within the optimal temperature range.

Hoses: These flexible tubes transport coolant between the engine, radiator, and other components. They must be in good condition to prevent leaks and ensure efficient operation.

Regular inspection and maintenance of the cooling system elements are vital for the longevity and performance of the machinery. Keeping an eye on these components can prevent serious issues and ensure smooth operation.