Modern agricultural machinery relies on a complex assembly of interconnected elements, each serving a crucial role in ensuring efficient operation in the field. From the cutting blades to the frame, every piece works in harmony to provide optimal performance. Knowing the arrangement and function of these elements helps users maintain and troubleshoot the equipment more effectively.

In this section, we will explore the key elements that form the backbone of heavy-duty field machinery. We’ll take a closer look at how different parts interact and how they contribute to smooth operation and longevity. By understanding the inner workings, users can make informed decisions when it comes to maintenance and replacements.

Each component is carefully designed for durability and precision, ensuring that the machinery can handle the tough demands of fieldwork. Whether you’re focusing on blade assemblies or the supporting structures, understanding these elements will give you a better grasp of how to keep the machinery in optimal condition.

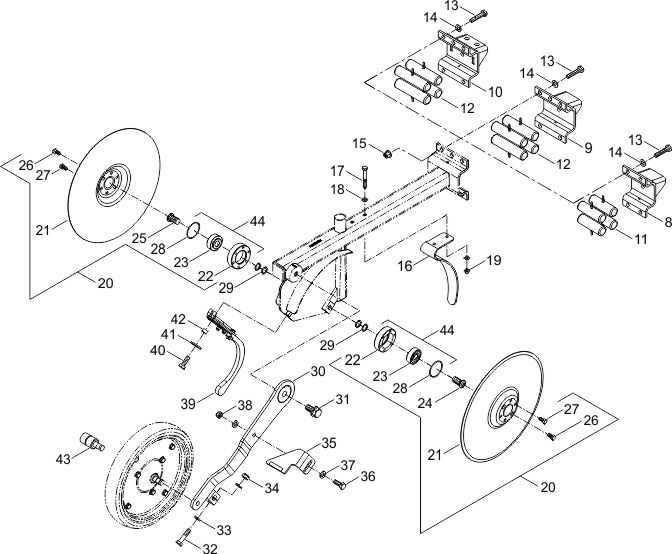

Understanding the Main Components of Case IH 496 Disc

The agricultural tool in question is composed of various essential elements that work together to ensure efficient soil preparation. Each component is designed to serve a specific function, contributing to the overall performance and durability of the equipment. Knowing these core elements is crucial for maintaining proper operation and optimizing field results.

Cutting Blades: These are designed to slice through the earth, ensuring a smooth and even cut. Their arrangement and sharpness play a vital role in breaking up the soil and crop residues effectively.

Frame Structure: The solid framework holds all the components together. Its durability and balance allow for consistent performance even under challenging conditions. The strength of the structure ensures the equipment can withstand the strain of large-scale fieldwork.

Hubs and Bearings: These are essential for the smooth rotation of the cutting blades. Properly maintained hubs and bearings reduce friction and wear, ensuring longer service life and better efficiency in the field.

Hydraulic System: The hydraulic system allows the operator to adjust the depth and angle of the equipment for varying field conditions. This adaptability is key to achieving uniform soil preparation, regardless of the terrain.

Understanding these components helps in ensuring regular maintenance and efficient operation,

Key Features of the Disc Assembly

The configuration of this agricultural equipment is designed for effective soil preparation. Its structure ensures optimal ground penetration and efficient mixing of soil layers, promoting better soil health. The following section highlights the core components and the role they play in achieving effective performance in a variety of field conditions.

Blade Configuration

The cutting elements are arranged in a specific pattern, allowing for uniform soil cultivation. These elements are engineered to cut through different soil types, ensuring proper tillage. Their spacing and depth can be adjusted, providing flexibility for varying agricultural needs. This adaptability contributes to the overall efficiency of the machine.

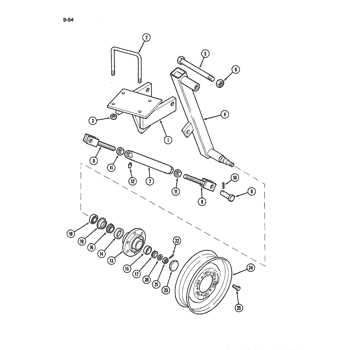

Frame and Axle Mechanism

The robust support structure maintains stability during operation. The axles connecting the individual elements are designed for smooth rotation and even weight distribution. This ensures consistent performance across diverse terrains, minimizing strain on the equipment and enhancing durability.

| Feature | Description |

|---|---|

| Blade Material | Hardened steel for long-lasting performance |

| Adjustable Depth | Customizable for different soil conditions |

| Blade Type | Function |

|---|---|

| Smooth Edge | Ideal for cutting through soft, less resistant materials, offering a clean and precise cut. |

| Serrated Edge | Designed for tougher surfaces, these blades can break through hard or uneven layers more effectively. |

| Notched Edge | Offers increased penetration into dense or compacted materials, ensuring deeper action with each pass. |

| Fluted Edge | Allows for improved soil flow, reducing resistance while maximizing movement efficiency. |

Selecting the

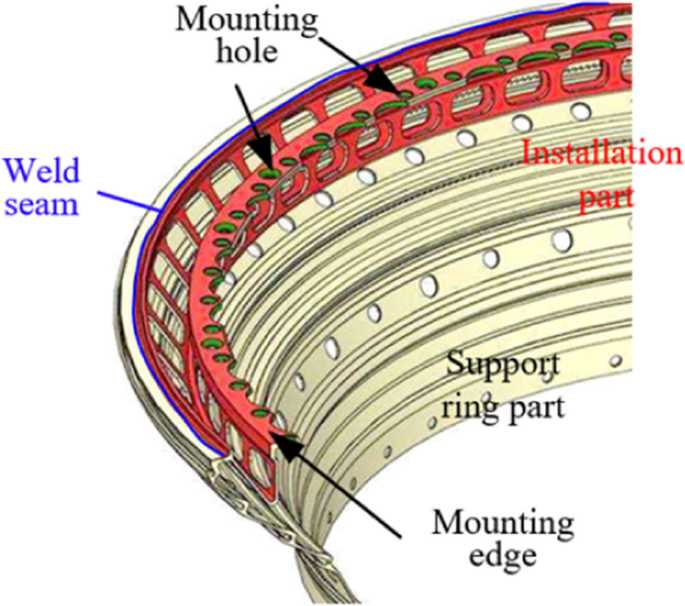

Exploring the Frame Structure

The foundational framework of agricultural equipment plays a crucial role in providing stability, durability, and support for its various components. Understanding this structural design is essential for ensuring long-lasting performance and efficient functionality in the field. By examining how different elements of the framework are arranged and connected, we can gain insights into how it withstands the rigorous demands of tough terrain and heavy loads.

Key Components of the Framework

- Main Beams: These form the backbone, providing overall rigidity and resistance to external forces.

- Cross Members: Positioned to distribute weight evenly, they enhance the balance and stability of the overall assembly.

- Connection Points: Critical joints where different segments are bolted or welded, ensuring a cohesive structure.

Benefits of a Well-Designed Frame

- Improved Durability: A strong framework reduces wear and tear on individual parts

Hydraulic System Parts and Functionality

The hydraulic system is a critical component that enhances the efficiency and effectiveness of agricultural machinery. It operates through the transmission of fluid pressure, enabling various mechanisms to perform their functions smoothly and reliably. Understanding the elements involved in this system is essential for maintaining optimal performance and ensuring longevity.

This system typically comprises several key components, each serving a specific role in the overall operation. The reservoir stores hydraulic fluid, ensuring a constant supply to the system. Pumps are responsible for generating pressure, while valves regulate the flow and direction of the fluid. Additionally, cylinders convert hydraulic energy into mechanical force, driving the equipment’s movements.

Maintenance of the hydraulic system is vital for preventing issues such as leaks or reduced efficiency. Regular checks of fluid levels, inspections of seals, and monitoring of the overall system can significantly contribute to the reliability and performance of the machinery. By understanding the functionality of each component, operators can make informed decisions regarding repairs and maintenance, ultimately enhancing productivity in their agricultural operations.

Adjusting and Maintaining Tillage Depth

Proper management of soil penetration is essential for achieving optimal agricultural outcomes. Adjusting and maintaining the appropriate depth of cultivation can enhance soil health, improve crop yields, and facilitate effective water management. Understanding how to fine-tune this aspect of tillage operations will lead to better results in both short-term productivity and long-term sustainability.

To achieve the desired soil working depth, it is crucial to consider various factors such as soil type, moisture levels, and crop requirements. Adjusting the equipment settings, including the angle and height of the implements, allows for precise control over how deeply the soil is disturbed. Regular checks and adjustments during operation ensure that the depth remains consistent, adapting to changes in field conditions.

Routine maintenance of the tillage equipment is equally important. Inspecting components for wear and tear, ensuring that blades and shares are sharp, and lubricating moving parts contribute to efficient performance. Keeping the machinery in top condition not only extends its lifespan but also ensures that it operates effectively at the desired depth, preventing issues like uneven soil disturbance and compaction.

Lastly, monitoring the results of tillage operations through field observations and soil testing can provide valuable insights. Adjustments based on these assessments will help in refining practices over time, leading to more effective cultivation strategies and healthier soils.

Common Issues with the Disc Harrow

Farm equipment designed for soil preparation often encounters a range of challenges that can affect its performance. Understanding these issues is essential for maintaining efficiency and ensuring effective land management. This section highlights some of the prevalent complications associated with such machinery.

Wear and Tear: Over time, the components of soil-tilling implements can experience significant wear. This degradation can lead to diminished effectiveness in cutting through the soil, making regular inspections and timely replacements crucial.

Soil Compaction: Inadequate operation can lead to compacted soil, reducing aeration and affecting plant growth. Ensuring proper depth and speed during use can help mitigate this issue.

Improper Alignment: If the equipment is not correctly aligned, it may not function optimally. Misalignment can result in uneven tilling, which can affect crop yields. Regular adjustments and calibrations are necessary to maintain proper functionality.

Hydraulic Problems: Hydraulic systems are essential for the operation of such implements. Issues such as leaks or inadequate pressure can hinder performance. Regular maintenance and checks can prevent hydraulic failures.

Maintenance Neglect: Lack of routine maintenance can lead to numerous issues, including increased wear, hydraulic failures, and operational inefficiencies. Establishing a regular maintenance schedule is vital for ensuring longevity and performance.

Addressing these common complications promptly can lead to improved efficiency and productivity in land cultivation, ultimately benefiting agricultural operations.

Where to Find Replacement Parts

Finding suitable components for your agricultural equipment is crucial for maintaining efficiency and performance. Various sources can provide the necessary elements to ensure your machinery operates smoothly. Whether you are looking for original items or compatible alternatives, there are multiple avenues to explore in your search for the right solutions.

Authorized Dealers

One of the most reliable places to source components is through authorized dealers. These distributors typically carry a wide range of authentic items and can offer expert advice on the best options for your specific model. In addition, purchasing from authorized vendors ensures that you receive quality products that meet the manufacturer’s standards.

Online Marketplaces

Online platforms have revolutionized the way individuals obtain machinery components. Numerous websites specialize in agricultural supplies, providing an extensive selection of items at competitive prices. Before making a purchase, check reviews and ratings to ensure the credibility of the seller. Additionally, many online stores offer user-friendly interfaces that simplify the search process, making it easier to locate the components you need.