Exploring the intricate structure of construction equipment reveals the essential elements that contribute to their functionality and efficiency. Knowledge of these components not only aids in maintenance but also enhances operational skills, ensuring that users can maximize the potential of their machinery.

Each segment of these powerful machines plays a vital role in their overall performance. By gaining insights into the specific roles and arrangements of these elements, operators can troubleshoot issues more effectively and make informed decisions regarding repairs and upgrades.

In this section, we will delve into a comprehensive overview of the various components, providing a clear visual representation that illustrates their interconnections. This ultimate guide will serve as a valuable resource for both enthusiasts and professionals seeking to deepen their understanding of heavy equipment mechanics.

Understanding Case 580 Backhoe Parts

When working with heavy machinery, comprehending the various components is essential for effective operation and maintenance. Each element plays a crucial role in the overall functionality of the equipment, ensuring that tasks are performed efficiently and safely. Familiarity with these elements can significantly enhance both performance and longevity.

Key Components and Their Functions

Every piece of machinery consists of multiple sections, each designed for specific tasks. The main body provides stability, while the attachment systems allow for versatility in operations. Hydraulic systems are vital for movement and power, enabling the machine to perform heavy lifting and digging activities.

Maintenance and Care

Regular inspection and upkeep of the machinery are vital to prevent breakdowns. Understanding the wear and tear of individual components helps in planning timely replacements. Implementing a routine maintenance schedule ensures optimal performance and reduces operational costs.

In summary, having a solid grasp of the various components is essential for anyone operating or maintaining heavy machinery. This knowledge not only aids in effective management but also contributes to a safer working environment.

Importance of Accurate Diagrams

Accurate representations play a crucial role in the maintenance and repair of complex machinery. They serve as vital resources for technicians, providing a clear overview of components and their interconnections. This clarity ensures that professionals can perform their tasks efficiently, minimizing the risk of errors that could lead to costly downtime or further complications.

Enhancing Efficiency

Well-structured visuals allow for quick identification of parts and systems, streamlining the repair process. By having a reliable reference, technicians can swiftly locate necessary components, reducing the time spent troubleshooting. This efficiency not only saves labor costs but also increases the productivity of the entire operation.

Preventing Misunderstandings

Clear illustrations help to mitigate misinterpretations that may arise from vague instructions. When details are accurately depicted, the likelihood of mistakes decreases significantly. Comprehension of the intricate workings of machinery becomes easier, fostering confidence in the technician’s abilities and ensuring that repairs are executed correctly the first time.

Common Components of Backhoe Loaders

Understanding the fundamental elements of these versatile earth-moving machines is essential for efficient operation and maintenance. Each component plays a critical role in ensuring functionality and performance, contributing to the overall effectiveness of the equipment.

Key Parts Overview

The machinery comprises several integral sections, each designed to perform specific tasks. Below is a table that highlights the main components and their functions.

| Component | Function |

|---|---|

| Loader Bucket | Used for lifting and transporting materials. |

| Excavator Arm | Enables digging and precise material removal. |

| Stabilizers | Provide balance during operation to prevent tipping. |

| Transmission | Facilitates movement and power transfer to wheels or tracks. |

Maintenance and Care

Regular maintenance of these essential components ensures longevity and reliability. Keeping an eye on wear and tear can significantly enhance performance and reduce downtime.

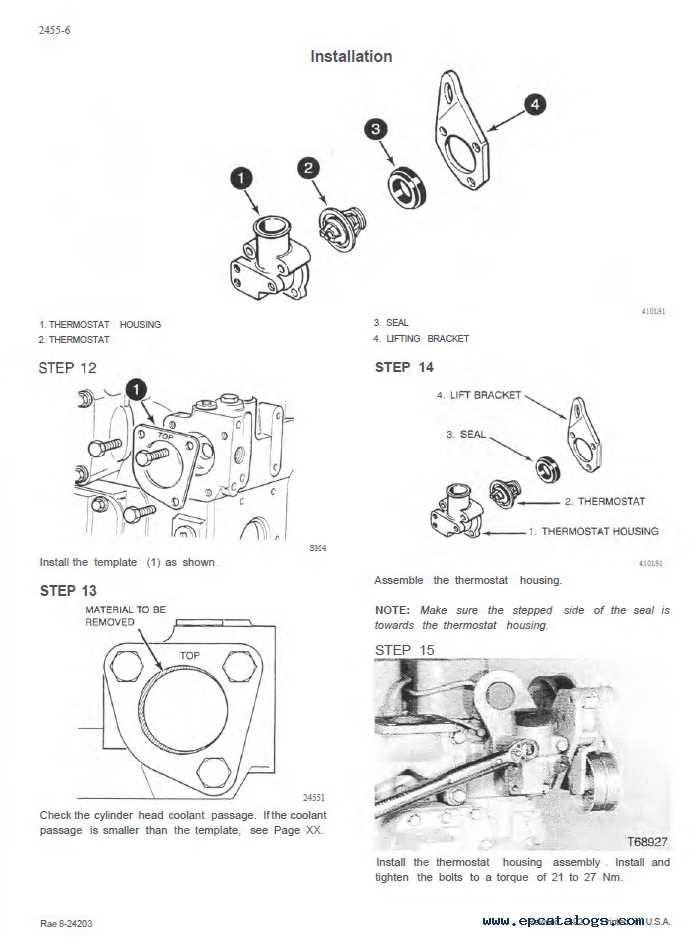

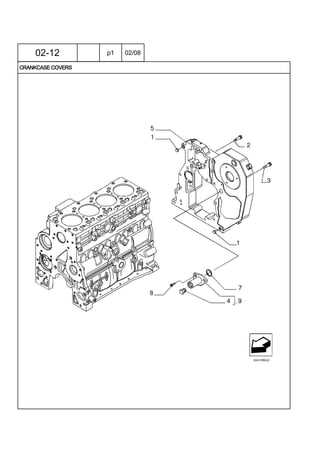

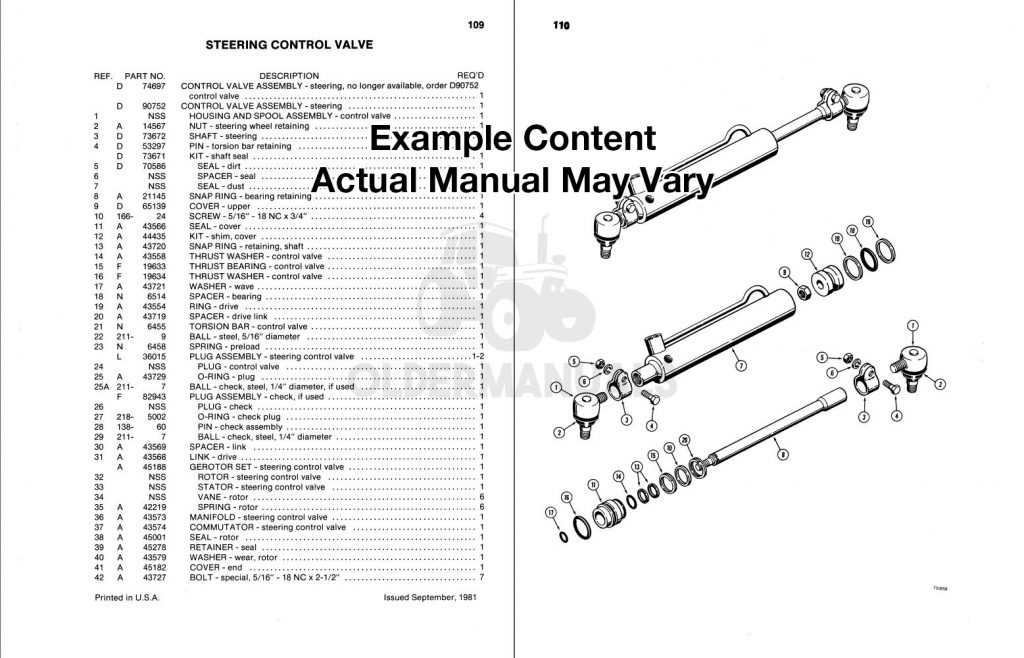

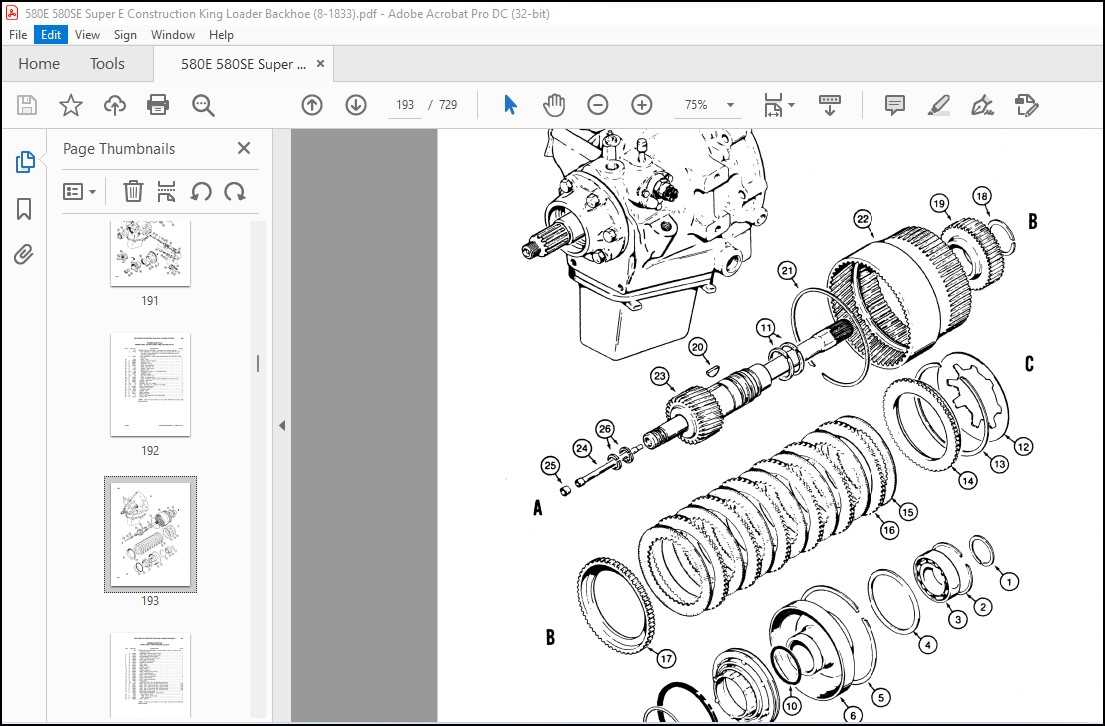

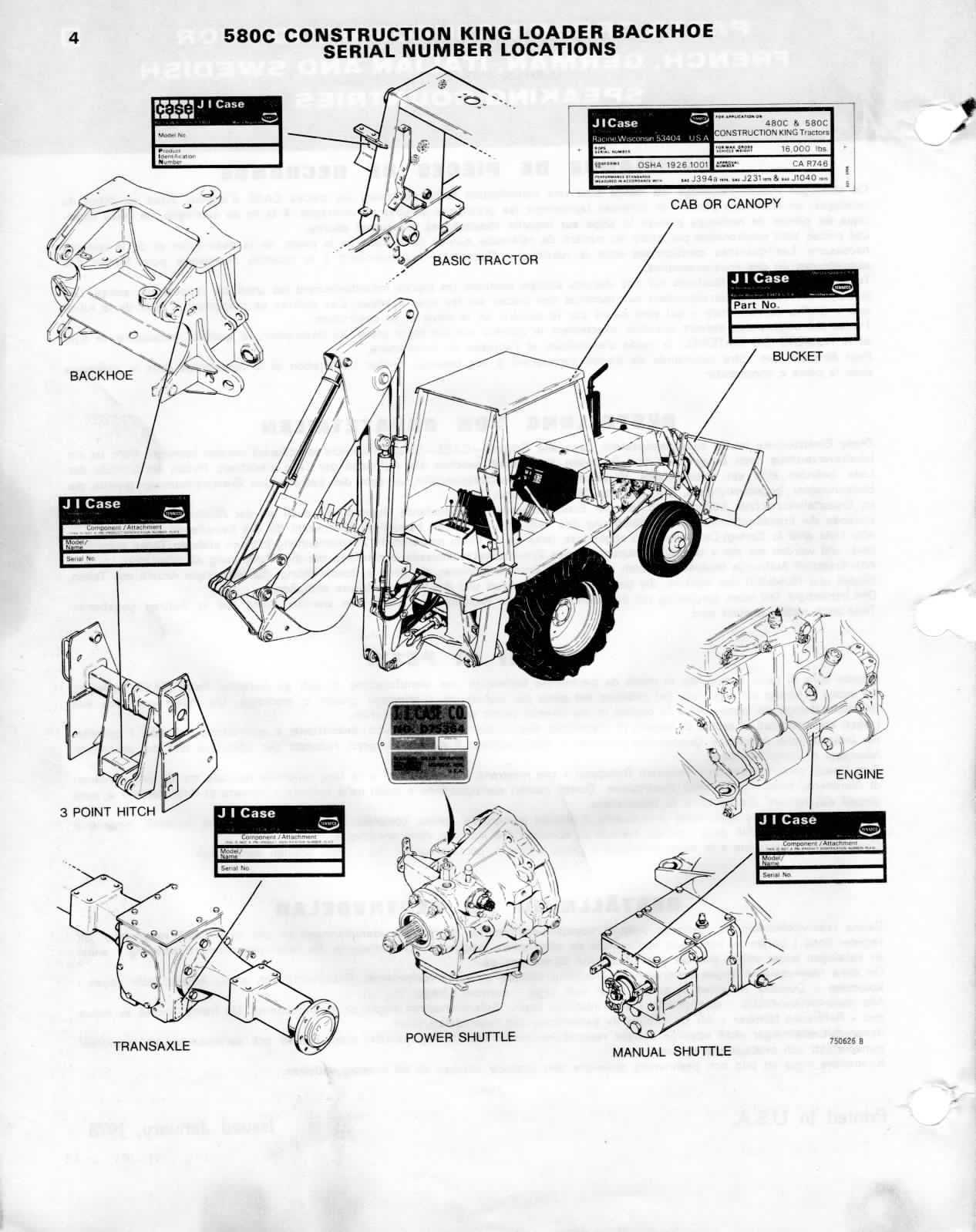

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone involved in machinery maintenance or repair. These visual aids provide a clear representation of components and their relationships within a system, allowing users to identify specific elements and their functions. Familiarity with how to interpret these illustrations can significantly enhance the efficiency of your work.

First, familiarize yourself with the overall layout. Typically, these visuals are organized to showcase different sections of the machinery. Pay attention to labels and numbers, which correspond to a list of components. This reference list is crucial for locating parts and understanding their placement.

Next, look for symbols and color codes that indicate various types of components or their status. These may vary by manufacturer, so take a moment to review any accompanying legends or keys. Understanding these symbols will help you quickly navigate through the illustration.

Finally, use the diagram in conjunction with a service manual. The manual often provides additional details on each component, including specifications and maintenance tips. By combining the visual representation with descriptive text, you can gain a comprehensive understanding of the machinery.

Identifying Wear and Tear

Understanding the signs of deterioration is crucial for maintaining optimal functionality in heavy machinery. Regular inspection can help identify components that may be suffering from fatigue, ensuring that the equipment remains reliable and efficient over time.

Common Indicators

Look for visible signs such as cracks, rust, or unusual wear patterns. These markers often indicate that specific elements require immediate attention or replacement to prevent further damage and costly repairs.

Maintenance Recommendations

To prolong the lifespan of your equipment, implement a routine maintenance schedule. Regular lubrication and cleaning can significantly reduce wear and help detect issues early, allowing for timely interventions.

Finding Replacement Parts Online

In today’s digital age, sourcing components for machinery has become remarkably convenient. With just a few clicks, operators and mechanics can access a vast array of options to ensure their equipment remains functional and efficient. This section will guide you through the process of locating these crucial items on the internet.

Start by conducting thorough research. Use reliable search engines to identify reputable suppliers who specialize in heavy machinery components. Look for websites that provide detailed information about their offerings, including specifications, compatibility, and pricing.

Consider exploring online marketplaces as well. These platforms often feature a wide variety of sellers, giving you the opportunity to compare prices and find the best deals. Pay close attention to customer reviews and ratings to ensure you are purchasing from a trustworthy source.

Utilize forums and community groups dedicated to machinery enthusiasts. Engaging with others who share your interests can lead to valuable recommendations for online stores. Additionally, you may discover tips for specific components that can save you both time and money.

Lastly, always verify the return and warranty policies of any online vendor before making a purchase. This ensures that you are protected in case the item does not meet your expectations or is incompatible with your machinery.

Maintenance Tips for Backhoe Longevity

Ensuring the durability of heavy machinery requires consistent care and attention. Implementing a routine maintenance schedule not only extends the lifespan of your equipment but also enhances its efficiency and performance. Below are essential tips to maintain your construction vehicle effectively.

- Regular Inspections: Conduct thorough checks on all critical components, including hydraulics, electrical systems, and engine conditions.

- Fluid Levels: Frequently monitor and replace engine oil, hydraulic fluid, and coolant to prevent overheating and wear.

- Air Filters: Clean or replace air filters regularly to ensure optimal engine performance and fuel efficiency.

- Battery Maintenance: Inspect the battery connections and terminals for corrosion; clean them as needed to ensure proper power supply.

- Tire Care: Check tire pressure and tread wear to maintain traction and stability during operation.

In addition to these practices, keep a detailed maintenance log to track services performed and schedule future upkeep. Regular training for operators on proper handling techniques also contributes significantly to the longevity of the machinery.

- Proper Operation: Train operators to use the equipment correctly to avoid unnecessary stress and damage.

- Storage: When not in use, store the machine in a sheltered environment to protect it from harsh weather conditions.

By adhering to these guidelines, you can ensure your equipment remains reliable and efficient for years to come.

Resources for Repair Manuals

When it comes to maintaining and repairing heavy machinery, having access to reliable manuals is crucial. These resources provide detailed instructions, diagrams, and specifications that can guide you through various procedures, ensuring that tasks are completed efficiently and correctly. Utilizing the right manuals not only enhances the repair process but also helps in understanding the machinery’s components and their functions.

| Resource Type | Description | Access Method |

|---|---|---|

| Manufacturer Manuals | Official documentation from the equipment manufacturer, covering maintenance and repair. | Available online or through authorized dealers. |

| Online Forums | Community-driven platforms where users share experiences, tips, and unofficial guides. | Accessible through dedicated websites and social media groups. |

| Books and Publications | Printed or digital books providing comprehensive repair techniques and safety information. | Can be purchased online or found in local libraries. |

| Video Tutorials | Visual guides demonstrating repair procedures step-by-step. | Available on platforms like YouTube and specialized tutorial websites. |

By utilizing these resources, individuals can enhance their knowledge and skills, ensuring that they can tackle repairs with confidence and precision.

Upgrading vs. Replacing Parts

When it comes to maintaining heavy machinery, two main approaches arise: enhancement of existing components versus complete substitution. Each option carries its own set of advantages and considerations, influencing both performance and budget.

Upgrading often involves improving the current elements to boost efficiency and longevity. This strategy can lead to enhanced functionality without the need for a full overhaul. Some benefits of this approach include:

- Cost-effectiveness: Upgrading may require a lower financial investment compared to total replacement.

- Improved performance: Enhanced features can lead to better operation and output.

- Less downtime: Modifications can typically be completed more quickly than a full change-out.

On the other hand, replacing components can sometimes be the more prudent choice. This may be necessary when parts are worn out beyond repair or when seeking to integrate the latest technology. Considerations for this route include:

- Reliability: New components often offer warranties and assurance of quality.

- Compatibility: Full replacements ensure that all parts work harmoniously with each other.

- Long-term savings: While upfront costs may be higher, new components can lead to lower maintenance needs over time.

Ultimately, the decision between upgrading and replacing should be based on an assessment of current conditions, future goals, and financial implications. Making the right choice can significantly impact operational efficiency and overall satisfaction.