Maintaining outdoor tools in proper working condition is crucial for ensuring their longevity and efficiency. One important aspect of this is familiarizing yourself with the internal structure and individual elements that make up the device. By understanding how different segments connect and function together, you can easily identify potential issues and take necessary steps to resolve them.

Exploring the layout of the mechanical components provides insights into the operation of the equipment, enabling a more straightforward approach to troubleshooting and upkeep. Identifying the precise configuration of each element allows for more effective repair and replacement processes, ensuring the equipment continues to operate smoothly.

Comprehending the assembly of specific elements is not just useful for repairs; it also contributes to the overall understanding of how the tool functions as a whole. This knowledge empowers users to maintain their equipment effectively and address any complications that may arise over time.

Understanding the Ames Reel Easy Mechanism

The mechanism in question is designed to simplify the task of winding and unwinding flexible lines, making it more efficient and user-friendly. By employing a smart internal structure, this system allows for smoother operation and reduces the effort needed during use. The design focuses on ensuring that the line feeds out and retracts consistently without tangling or jamming, enhancing the overall experience.

Key Features of the Mechanism

This winding system incorporates an automatic adjustment feature that keeps tension on the line as it is pulled. This helps maintain an even distribution, ensuring that the flexible line remains organized. Additionally, the built-in locking component allows for secure placement when adjustments are needed, offering greater control and ease of use.

Effortless Line Replacement

Replacing the line is made more convenient by a quick-loading function. The system allows the line to be inserted and secured rapidly, reducing downtime and frustration. With an intuitive process, users can effortlessly change the line without needing special tools or extensive knowledge. This ensures a smooth transition for continued use and upkeep.

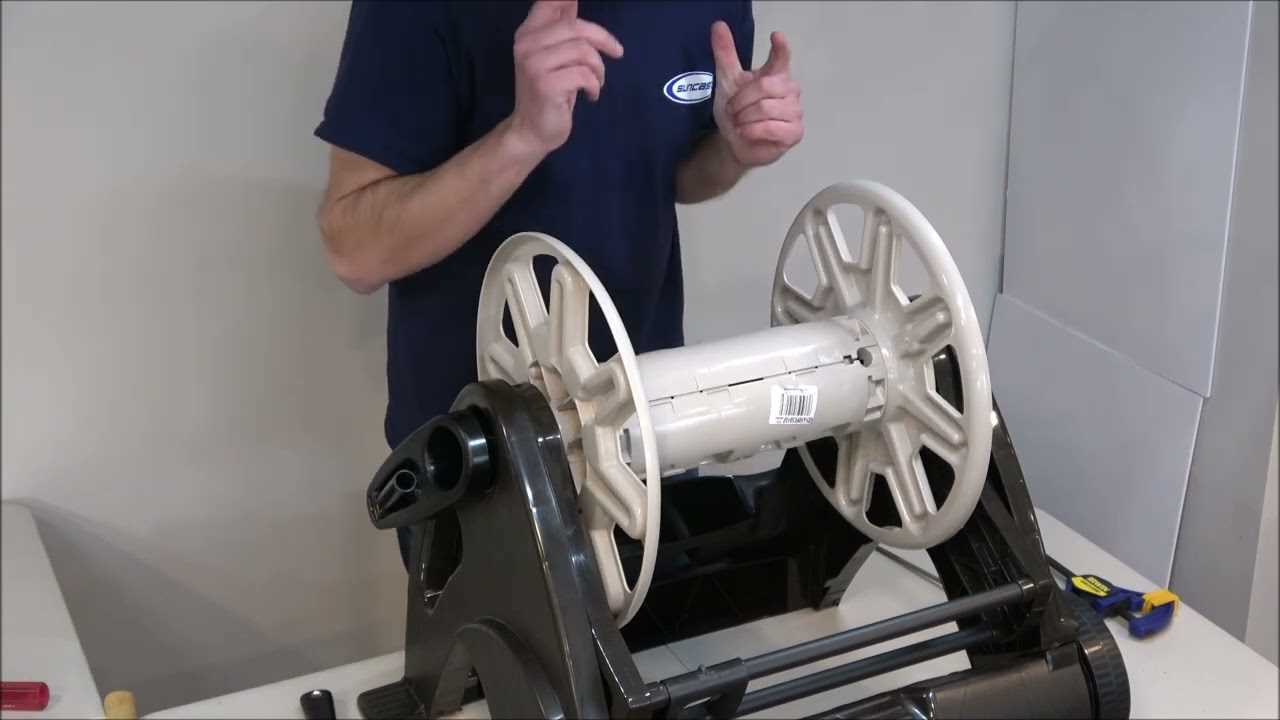

Key Features of the Hose Reel

The hose storage solution offers practical benefits that simplify watering tasks and help keep outdoor areas organized. With a design focused on user convenience, it aims to make handling and storing hoses more efficient while extending their longevity. Here are some of the main attributes that make this garden tool an essential addition for anyone looking to maintain a tidy yard.

Automatic Winding Mechanism

One standout feature is the built-in mechanism that allows the hose to retract smoothly with minimal effort. This function prevents tangling and kinking, ensuring the hose remains in top condition. It also saves time by eliminating the need to manually roll up the hose after each use.

Sturdy Construction and Durability

Designed for long-term use, the unit is built with robust materials that withstand exposure to various weather conditions. Its durable casing protects the internal components, while the reinforced hose can endure frequent usage without wear. This ensures consistent performance and a longer lifespan.

Enhanced Mobility is another advantage, allowing the user to move the unit effortlessly across the yard. This makes it easy to water different areas without carrying the hose manually. Additionally, the compact design helps save space when storing the unit in a garage or shed.

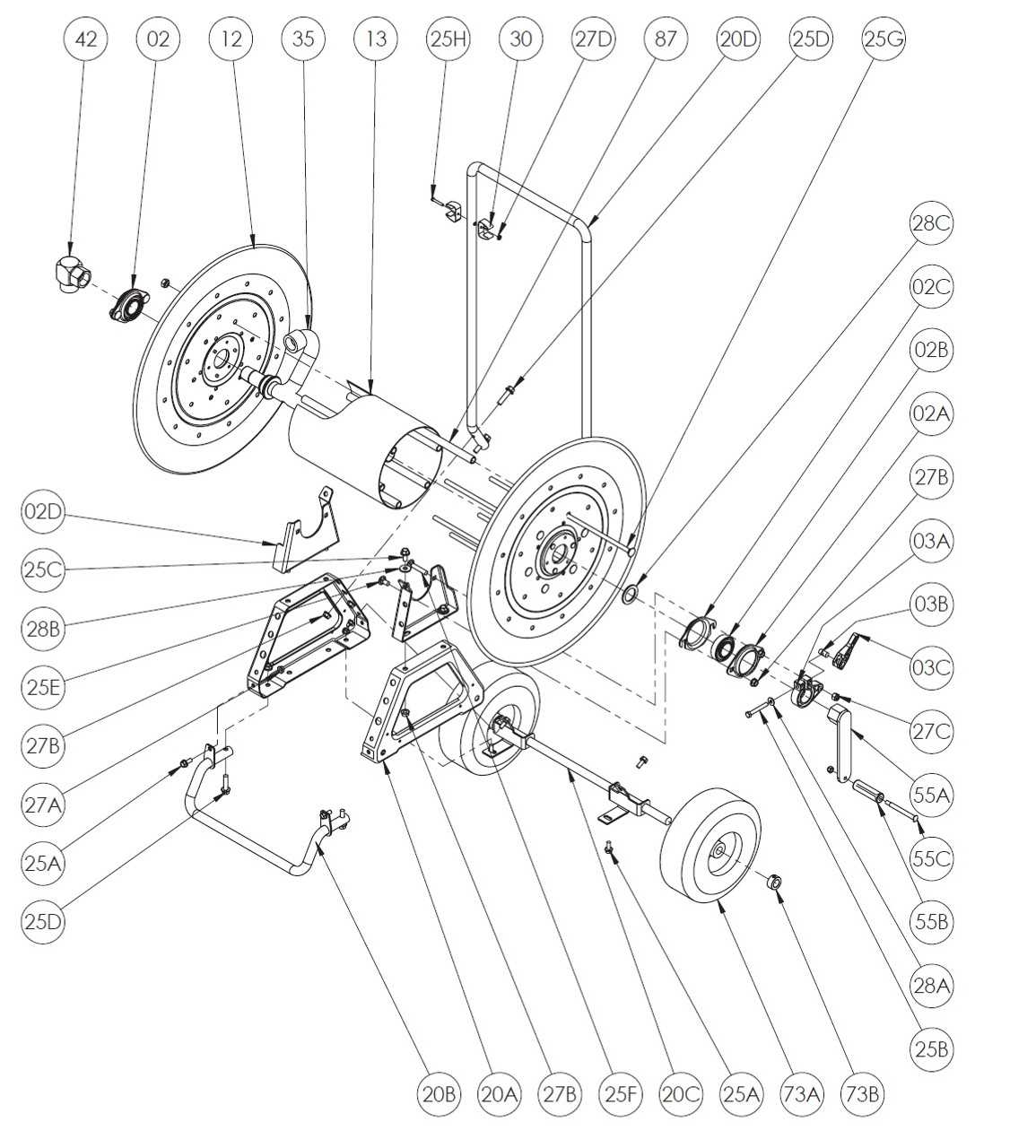

Parts Identification and Their Functions

Understanding the various components of the device is essential for efficient use and maintenance. Each element has a distinct role, ensuring smooth operation and reliable performance. Familiarizing oneself with these components helps in troubleshooting issues and replacing elements when needed.

Handle: The grip section provides control and stability during use. It allows for a comfortable hold, reducing strain on the user while guiding the tool.

Locking Mechanism: This feature secures the device in place, preventing unwanted movement. It ensures the tool remains steady, enhancing safety during operation.

Spindle: The central rotating component facilitates the winding or unwinding motion. It enables smooth rotation and supports the main function of the equipment.

Fasteners: These small but vital elements hold various parts together, maintaining the structural integrity of the device. They need to be checked regularly to avoid loosening over time.

Knowing the purpose of each component aids in efficient handling and extends the lifespan of the equipment.

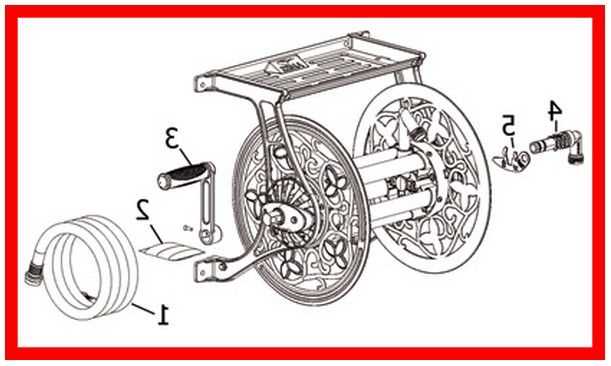

How to Assemble the Reel Properly

Properly putting together the equipment is crucial to ensure smooth functionality and prevent future issues. Following the correct steps will help you achieve a secure and efficient setup. Here’s a straightforward guide to getting it right.

- Start by arranging all the components and tools you need for the assembly. Make sure you have everything on hand to avoid interruptions during the process.

- Connect the central axis to the main frame. Make sure it fits snugly and use any provided fasteners to secure it firmly in place.

- Attach the winding drum to the axis, ensuring it spins freely. Check for any obstructions that might hinder its rotation and adjust as necessary.

- Secure the handles or knobs on each side, which will allow for better grip and control during use. Tighten any bolts or screws that keep them attached.

- Finally, double-check all connections and components for stability. Give the assembled device a few test turns to confirm everything is in working order.

Following these steps will help ensure that your setup is reliable and ready for regular use.

Troubleshooting Common Issues with the Reel

Addressing frequent problems with this type of equipment is essential for maintaining optimal performance. Users may encounter various difficulties that can affect the functionality, such as tangled lines, uneven winding, or difficulties in retracting. Understanding these issues and their potential causes can help resolve them quickly and efficiently.

Tangled Lines often occur due to improper winding or blockage within the mechanism. To fix this, ensure the cord is clean and free from debris. Gently unwind it and straighten any twists before rewinding carefully.

Uneven Winding can result from an improperly balanced load or incorrect guiding. Inspect the alignment and ensure the cord is distributed evenly across the spool during retraction. Regularly check for signs of wear on the guides that could impact the smoothness of operation.

If retraction problems arise, they may be linked to a weakened spring or internal friction. Clean the housing area and lubricate the moving parts as needed. If the problem persists, consider replacing the internal components that may have lost tension over time.

Maintenance Tips for Prolonged Usage

To ensure the longevity of your equipment, regular upkeep is essential. Proper maintenance helps prevent wear and extends the lifespan of the tool, allowing it to function optimally over time. By following some practical advice, you can keep the device in excellent condition, even with frequent use.

Regular Cleaning

Frequent cleaning is vital for maintaining efficiency. After each use, remove any dirt, grass, or other debris that may accumulate. Pay close attention to areas where particles tend to build up, as these can affect the overall performance. A simple rinse with water or a soft brush can go a long way in keeping the equipment functioning smoothly.

Lubrication of Moving Parts

Applying lubricant to the moving components periodically ensures that the device operates without unnecessary friction. This practice reduces the likelihood of parts wearing out prematurely. Use a high-quality oil designed for mechanical tools and follow the recommended application frequency for best results.

By integrating these straightforward practices into your routine, you can significantly extend the working life of the tool and avoid costly repairs or replacements in the future.

Replacement Parts Guide and Compatibility

Understanding the various components of your equipment and finding suitable substitutes can help extend its lifespan. This section provides insights into choosing appropriate replacements and ensuring they fit seamlessly with your existing setup. Proper selection of compatible pieces can enhance functionality and prevent potential mismatches that may affect performance.

When looking for substitutes, it’s important to verify the specifications and design features to match the original equipment. Compatibility checks, such as size, shape, and connection type, are crucial to ensure a smooth installation. Using components designed specifically for your model will improve durability and reliability.

Additionally, it is recommended to consult with the manufacturer’s guidelines or seek advice from knowledgeable sources. This can help identify suitable options that offer the same level of quality and function. Regular maintenance and timely replacements will contribute to the long-term efficiency and safety of your equipment.

Safety Precautions When Using the Reel

When operating any type of winding device, it is crucial to prioritize safety to prevent accidents and injuries. Understanding and adhering to safety guidelines not only protects the user but also enhances the overall performance and longevity of the equipment.

General Safety Guidelines

Before utilizing the equipment, ensure that you are familiar with the manufacturer’s instructions and specifications. Always inspect the device for any signs of wear or damage. Proper maintenance and regular checks can significantly reduce the risk of malfunction during use.

Proper Usage Techniques

When engaging with the apparatus, maintain a firm grip and steady stance. Avoid distractions and ensure that the work area is clear of obstacles. Additionally, wear appropriate personal protective equipment such as gloves and safety glasses to shield against potential hazards.

| Precaution | Description |

|---|---|

| Inspect Equipment | Check for any visible damage or wear before use. |

| Clear Work Area | Ensure the surrounding area is free from hazards. |

| Use PPE | Wear gloves and safety glasses to protect against injuries. |

| Follow Instructions | Adhere to the manufacturer’s guidelines for safe operation. |

Cleaning and Storage Recommendations

Proper maintenance is essential for ensuring longevity and optimal performance of gardening equipment. Regular cleaning helps prevent the buildup of dirt and debris, which can lead to operational issues. Furthermore, appropriate storage techniques protect tools from environmental factors and potential damage.

Cleaning should be conducted after each use to maintain functionality. Use a gentle brush or cloth to remove soil and residue from surfaces. For more stubborn buildup, a mixture of water and mild detergent can be employed. Avoid harsh chemicals, as they may damage materials.

After cleaning, ensure that all components are thoroughly dried to prevent rusting or corrosion. Once dried, consider applying a light lubricant to moving parts to enhance their performance. This practice not only ensures smooth operation but also extends the life of the equipment.

Storage plays a crucial role in preserving tools. Store them in a cool, dry place away from direct sunlight and extreme temperatures. Hanging equipment on a wall or placing it on shelves can help keep them organized and reduce the risk of damage. For added protection, consider using protective covers or cases.

By following these guidelines for cleaning and storage, you can maintain your tools in excellent condition, ensuring they are ready for use whenever needed.