In the realm of outdoor equipment, particularly those designed for cutting and trimming, comprehending the intricate layout and individual elements is crucial. This section aims to provide insight into the various components that constitute a powerful cutting device, enhancing both its functionality and efficiency. By grasping the relationships between these elements, users can make informed decisions about maintenance, repair, and upgrades.

Every cutting machine comprises a series of interconnected pieces that work in harmony to achieve optimal performance. From the engine to the guide mechanisms, each element plays a vital role in the overall operation. A thorough examination of these components reveals how they contribute to the tool’s effectiveness, making it essential for users to familiarize themselves with their functions.

Understanding the configuration of these parts not only aids in troubleshooting potential issues but also empowers users to enhance their tool’s capabilities. By recognizing the significance of each component, operators can ensure their equipment remains in peak condition, ultimately extending its lifespan and improving its cutting prowess.

Understanding the Husqvarna 450 Chainsaw

This section aims to provide insights into a specific model of a powerful cutting tool commonly used for forestry and landscaping tasks. By delving into its features, components, and overall functionality, readers can gain a clearer understanding of how this tool operates and its various applications.

Key Features

The cutting tool in focus boasts several characteristics that make it a popular choice among users. Here are some of the most notable features:

- High-performance engine for efficient operation

- Ergonomic design for improved comfort during use

- Easy access to maintenance points for quick servicing

- Safety mechanisms to enhance user protection

Essential Components

Understanding the main elements of this tool is crucial for effective usage and maintenance. Below are the essential components that contribute to its performance:

- Power Unit: Responsible for driving the cutting mechanism

- Guide Bar: The long, flat piece that supports the chain and allows for cutting

- Chain: The serrated loop that performs the actual cutting

- Fuel Tank: Stores the mixture necessary for engine operation

- Air Filter: Prevents debris from entering the engine, ensuring efficient performance

By familiarizing oneself with these features and components, users can optimize their experience and ensure the longevity of their cutting tool.

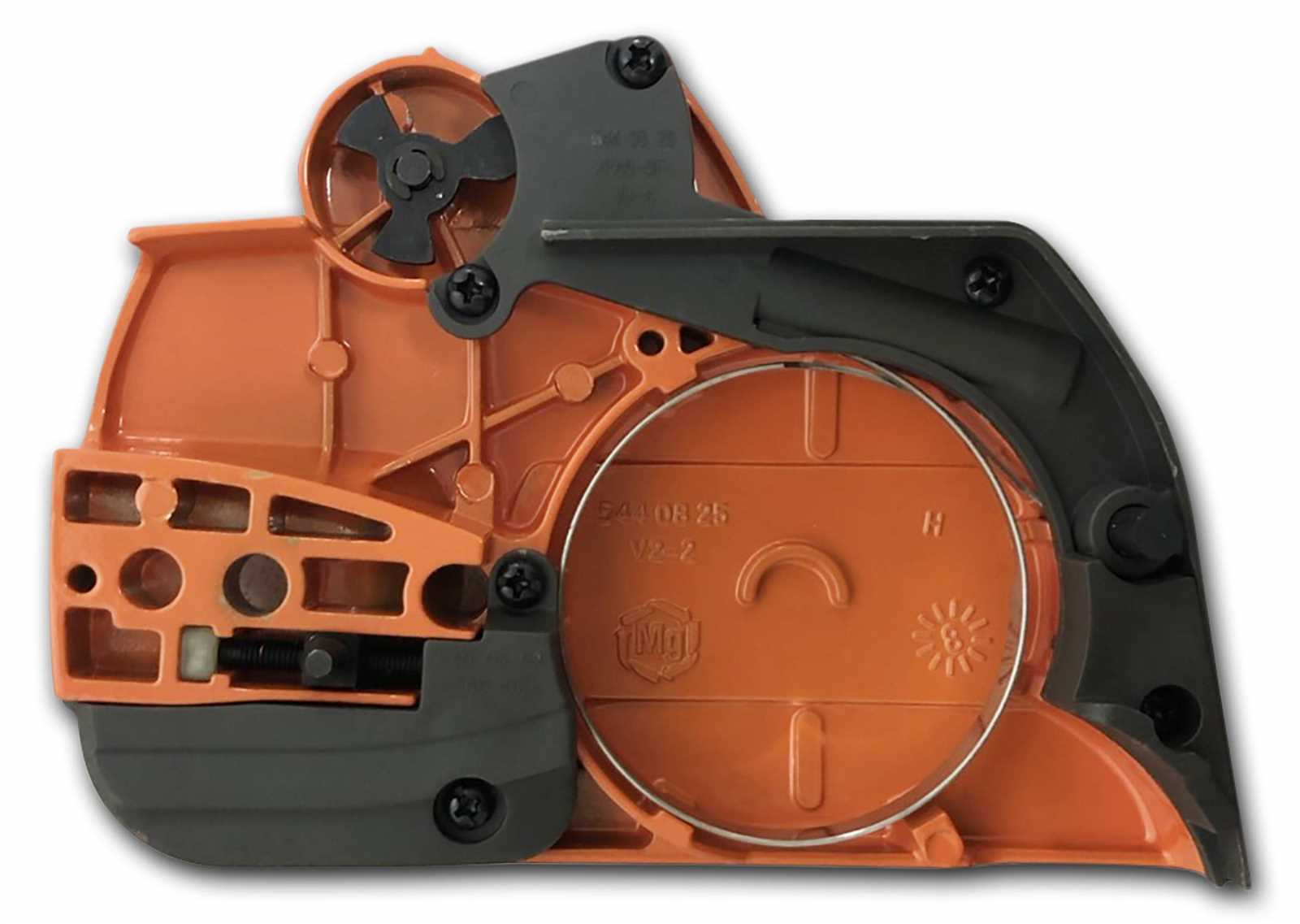

Key Components of the Chainsaw

The efficient operation of a cutting tool relies on various essential elements that work in harmony. Each component plays a crucial role in ensuring performance, safety, and reliability. Understanding these parts helps users maintain and troubleshoot their equipment effectively.

One of the most significant elements is the power unit, which drives the entire mechanism. This is typically a gasoline engine or an electric motor, providing the necessary energy for operation. Alongside this is the cutting system, which includes the blade and the guide bar, critical for achieving precise cuts in various materials.

Another vital part is the fuel system, responsible for supplying energy to the power unit. It comprises the fuel tank, lines, and filter, ensuring a steady flow of fuel. Additionally, the ignition system plays a key role in starting the engine, incorporating the spark plug and ignition coil to generate the necessary spark.

Safety features are also integral, with components like the chain brake and throttle lock, designed to protect users from potential hazards. Lastly, the housing and handle offer stability and control, allowing for better maneuverability during operation. Familiarity with these components enhances overall user experience and ensures effective maintenance practices.

Functionality of Each Part

The efficient operation of any cutting tool relies on the harmonious interaction of its components. Understanding how each segment contributes to overall functionality is crucial for optimal performance and maintenance. Each element plays a vital role in the tool’s ability to perform tasks effectively and safely.

Power Unit: This is the heart of the tool, converting fuel into mechanical energy. Its efficient design ensures that sufficient power is generated for rigorous cutting tasks.

Bar: The elongated structure serves as the guiding track for the cutting mechanism. Its length and design determine the reach and depth of the cuts made.

Cutting Mechanism: Often referred to as the blade, this sharp edge is essential for slicing through various materials. The geometry of this component influences cutting speed and efficiency.

Chain: This flexible loop carries the cutting mechanism and rotates around the bar. Its design and sharpness dictate the effectiveness and precision of the cuts.

Fuel System: Responsible for supplying energy to the power unit, this system ensures that the tool runs smoothly. Its components include a tank, filter, and lines that transport fuel without interruption.

Ignition System: This mechanism initiates the combustion process. A well-functioning ignition system is vital for reliable starting and consistent operation.

Air Filtration: This part protects the internal mechanisms by filtering out debris and particles from the air entering the system. A clean air supply is essential for maintaining engine performance and longevity.

Safety Features: Various mechanisms are integrated to enhance user safety. These include chain brakes and guards that prevent accidents during operation.

Each of these components is intricately designed to work in tandem, ensuring that the tool operates at peak efficiency while providing a safe user experience.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires regular care and attention. By implementing effective maintenance practices, you can extend the life of your tools and enhance their operational capabilities. This section provides essential tips to help you keep your equipment in optimal condition.

Regular Cleaning

Keeping your tools clean is vital for preventing dirt and debris from causing damage. Regularly remove any buildup from the exterior and internal components. This will not only improve performance but also reduce wear and tear.

Routine Inspections

Conducting routine inspections allows you to identify potential issues before they become significant problems. Check for signs of wear, loose components, or damage that may affect performance. Addressing these concerns promptly will help maintain functionality.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean external surfaces | After each use | Use a soft brush or cloth. |

| Inspect for wear | Monthly | Look for any signs of damage. |

| Check lubrication levels | Before each use | Ensure adequate lubrication for smooth operation. |

| Replace worn components | As needed | Use compatible parts for replacements. |

Common Issues and Solutions

Operating a power cutting tool can sometimes lead to challenges that affect its performance. Understanding these common issues and knowing the appropriate solutions can enhance efficiency and prolong the tool’s lifespan. This section outlines frequent problems encountered during use and offers effective remedies to ensure smooth operation.

Engine Difficulties

One prevalent issue is difficulty starting the engine. This can be caused by various factors, such as a clogged air filter, old fuel, or a malfunctioning spark plug. To address this, check the air filter for debris, replace any stale fuel with fresh gasoline, and inspect the spark plug for signs of wear or damage. Regular maintenance of these components can help prevent starting problems in the future.

Cutting Performance Issues

If the cutting tool is not performing efficiently, it may be due to a dull chain or improper tension. A dull chain can lead to increased effort during cutting and may damage the material. Regularly sharpening the chain and ensuring it is properly tensioned can significantly improve cutting performance. Additionally, lubricating the chain regularly helps to reduce friction and wear, enhancing overall efficiency.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right tools is essential for efficient and effective repairs. This section outlines the various implements and equipment you may need to ensure your device operates smoothly. Proper tools not only make the job easier but also enhance safety during the repair process.

| Tool | Description |

|---|---|

| Socket Set | A versatile collection of sockets for loosening and tightening bolts and nuts. |

| Torque Wrench | Used to apply a specific torque to fasteners, ensuring they are secured to the manufacturer’s specifications. |

| Screwdrivers | Essential for removing and securing screws; having various sizes and types is beneficial. |

| Hex Keys | Also known as Allen wrenches, used for hexagonal screws typically found in assembly areas. |

| Pliers | Useful for gripping, twisting, and cutting wire or other materials. |

| Cleaning Brush | Helps remove debris and buildup from various components for optimal performance. |

| Safety Gear | Includes gloves, goggles, and ear protection to ensure safety during repairs. |

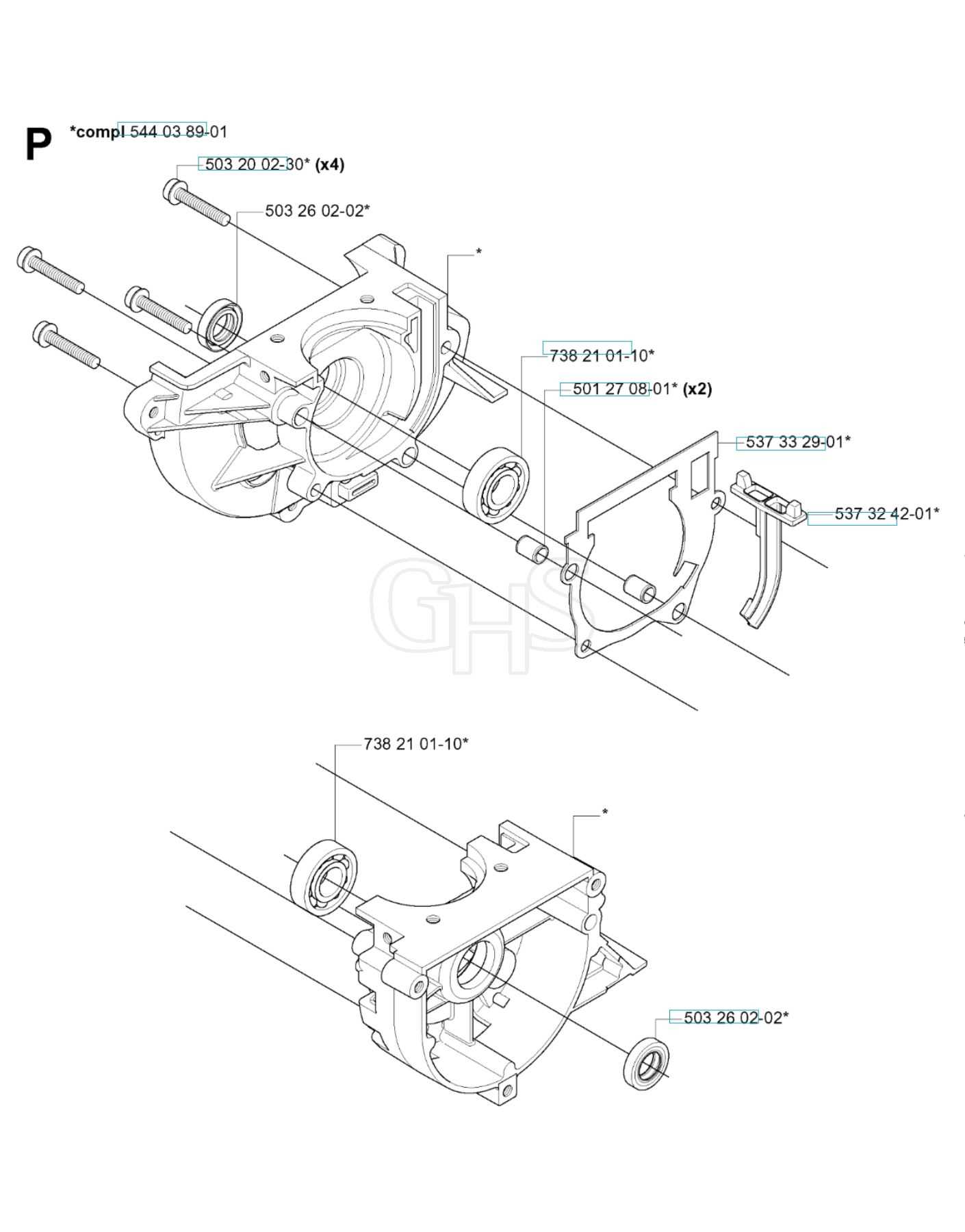

Replacement Parts Availability

Finding the right components for your equipment is essential for maintaining its performance and longevity. Whether you are conducting routine maintenance or making necessary repairs, having access to quality replacements is crucial. This section outlines the options available for sourcing these essential elements, ensuring that you can keep your machinery running smoothly.

Sources for Components

There are several reliable sources to consider when looking for replacement elements. Online retailers, local hardware stores, and authorized dealers offer a variety of options that cater to different needs and preferences. When selecting a source, it is important to verify the authenticity of the components to ensure compatibility and reliability.

Component Compatibility

When searching for replacements, always check the specifications to confirm that the selected items are compatible with your machinery. This helps prevent issues that may arise from using incorrect components, which can lead to decreased efficiency or potential damage.

| Source | Description | Website/Contact |

|---|---|---|

| Online Retailers | Wide selection of components available for various models, often at competitive prices. | www.onlineretailers.com |

| Local Hardware Stores | Convenient access to essential components, with knowledgeable staff to assist. | Contact your local store |

| Authorized Dealers | Guaranteed genuine components that ensure optimal performance and compatibility. | www.authorizeddealers.com |

Safety Features and Their Importance

When working with powerful equipment, the integration of safety mechanisms is crucial. These features are designed to minimize the risk of accidents and enhance user protection. Understanding their significance helps users maintain a secure operating environment while effectively utilizing the tool.

Key Safety Mechanisms

Modern devices often include several essential safety elements. These may consist of automatic shut-off systems, chain brakes, and anti-vibration technology. Each component plays a vital role in preventing injuries by halting operation in critical situations or reducing user fatigue.

The Importance of Regular Maintenance

Ensuring that safety features remain functional requires regular upkeep. Users should periodically inspect and maintain these systems to ensure optimal performance. Neglecting maintenance can lead to malfunctions, increasing the likelihood of accidents. Thus, proactive care is necessary for safe and effective operation.

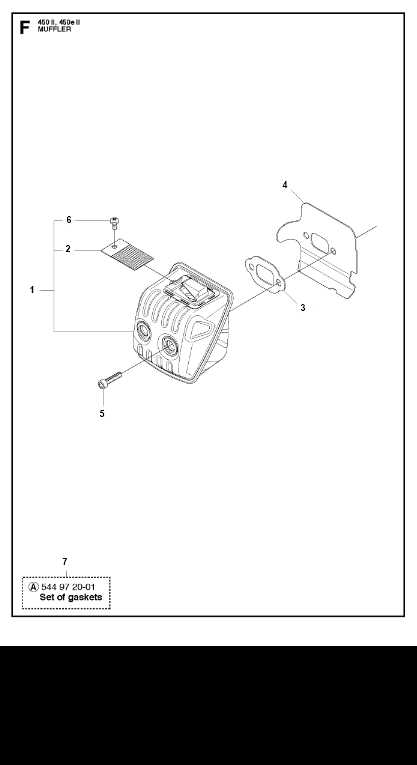

Upgrades for Enhanced Performance

Improving the efficiency and effectiveness of your cutting tool can significantly enhance your overall experience. Upgrades not only boost power but also improve handling and reduce wear over time. By investing in the right enhancements, you can achieve superior performance that meets your cutting needs.

1. High-Performance Bar and Chain: Upgrading to a high-performance bar and chain can greatly increase cutting speed and efficiency. Look for options that offer better durability and reduced friction, allowing for smoother cuts.

2. Advanced Air Filter: An upgraded air filter can improve airflow, ensuring that your engine receives optimal combustion levels. This can lead to better fuel efficiency and enhanced power output, resulting in improved cutting performance.

3. Fuel System Enhancements: Consider modifying the fuel system with a high-flow fuel filter and a performance carburetor. These improvements can provide a more consistent fuel supply, resulting in smoother operation and increased power during use.

4. Vibration Dampening Technology: Installing vibration dampening components can significantly enhance user comfort and control. This is particularly beneficial during extended use, reducing fatigue and improving precision in cutting tasks.

5. Custom Muffler: A custom muffler not only improves exhaust flow but also reduces noise levels. This upgrade can enhance the overall experience by providing a quieter work environment while maintaining optimal performance.

Investing in these upgrades will not only enhance the efficiency of your equipment but also extend its lifespan. With the right modifications, you can enjoy a cutting tool that performs at its best, making your tasks easier and more enjoyable.