When exploring the intricacies of mechanical devices designed for cutting, it’s essential to grasp the arrangement and functionality of their various elements. A comprehensive visual representation can greatly enhance one’s ability to maintain and repair such equipment, ensuring optimal performance and longevity.

Every tool consists of a multitude of components that work in harmony. Recognizing how these pieces fit together not only simplifies the process of troubleshooting but also empowers users to take control of their equipment’s maintenance.

In this section, we will delve into a detailed overview of the essential elements involved in these powerful machines. Understanding their layout will provide users with the ultimate insight into efficient operation and care.

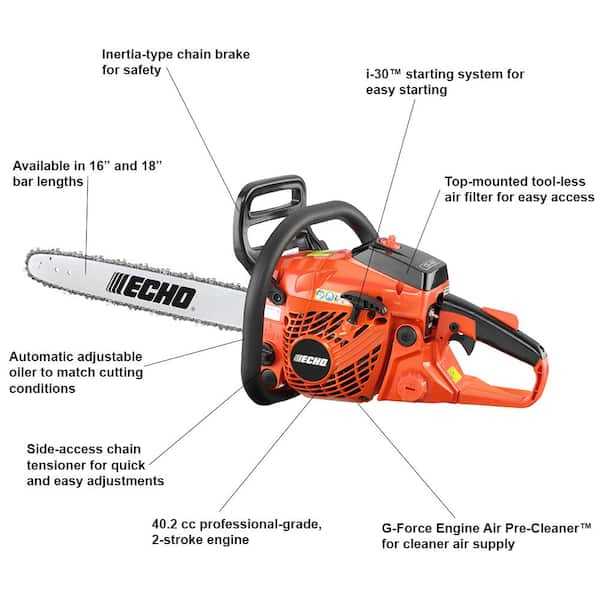

Understanding Echo Chainsaw Components

When exploring the intricate machinery of cutting tools, it is essential to familiarize oneself with the various elements that contribute to their functionality. Each component plays a pivotal role, ensuring that the tool operates efficiently and effectively. Recognizing how these pieces interact can enhance your ability to maintain and troubleshoot these devices.

The following sections highlight the fundamental components, providing insight into their purposes and interconnections:

- Power Unit: This is the heart of the tool, providing the necessary energy for operation.

- Bar: The long, flat piece where cutting occurs, often designed to withstand significant wear.

- Chain: This circular element is equipped with sharp teeth, essential for slicing through materials.

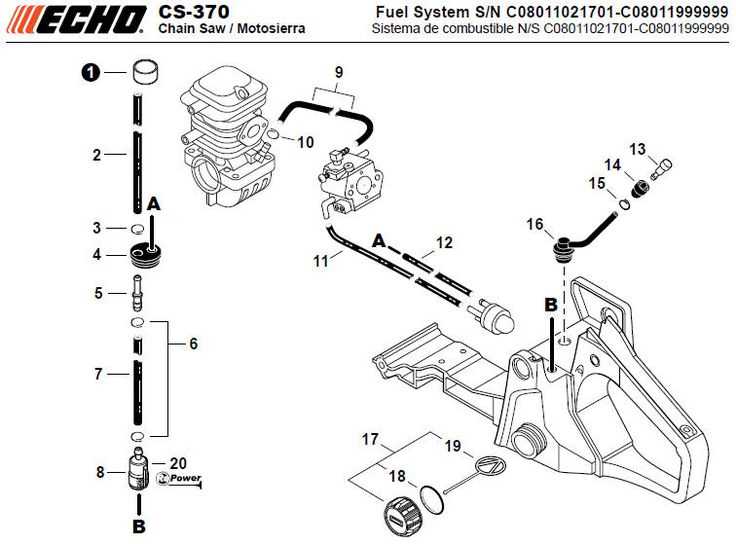

- Fuel System: Comprising the tank and lines, this system ensures a steady supply of energy to the engine.

- Lubrication Mechanism: It keeps the chain and bar functioning smoothly by reducing friction.

- Handle: Provides grip and control, allowing for precision during use.

- Safety Features: Various systems that help prevent accidents and ensure user safety.

Understanding these components allows users to appreciate the design and engineering that goes into creating efficient cutting tools. By maintaining each part properly, one can ensure longevity and optimal performance.

Importance of Proper Maintenance

Regular upkeep of equipment is essential for ensuring optimal performance and longevity. Neglecting this crucial aspect can lead to diminished efficiency, increased wear and tear, and ultimately, costly repairs. By adhering to a systematic maintenance routine, users can safeguard their investment and enhance the reliability of their tools.

Enhancing Performance

Well-maintained machinery operates at its peak capability. Routine inspections and timely replacements of worn components prevent unexpected failures and maintain consistent output. This not only improves functionality but also increases safety during operation.

Cost Efficiency

Investing time in maintenance can significantly reduce overall expenses. Regular care minimizes the likelihood of severe breakdowns, which often require expensive repairs or replacements. Moreover, efficient operation leads to lower fuel consumption, ultimately saving money in the long run.

In summary, proper maintenance is vital for maximizing performance, extending the lifespan of equipment, and achieving cost savings. Emphasizing this practice ensures that tools remain reliable and efficient throughout their use.

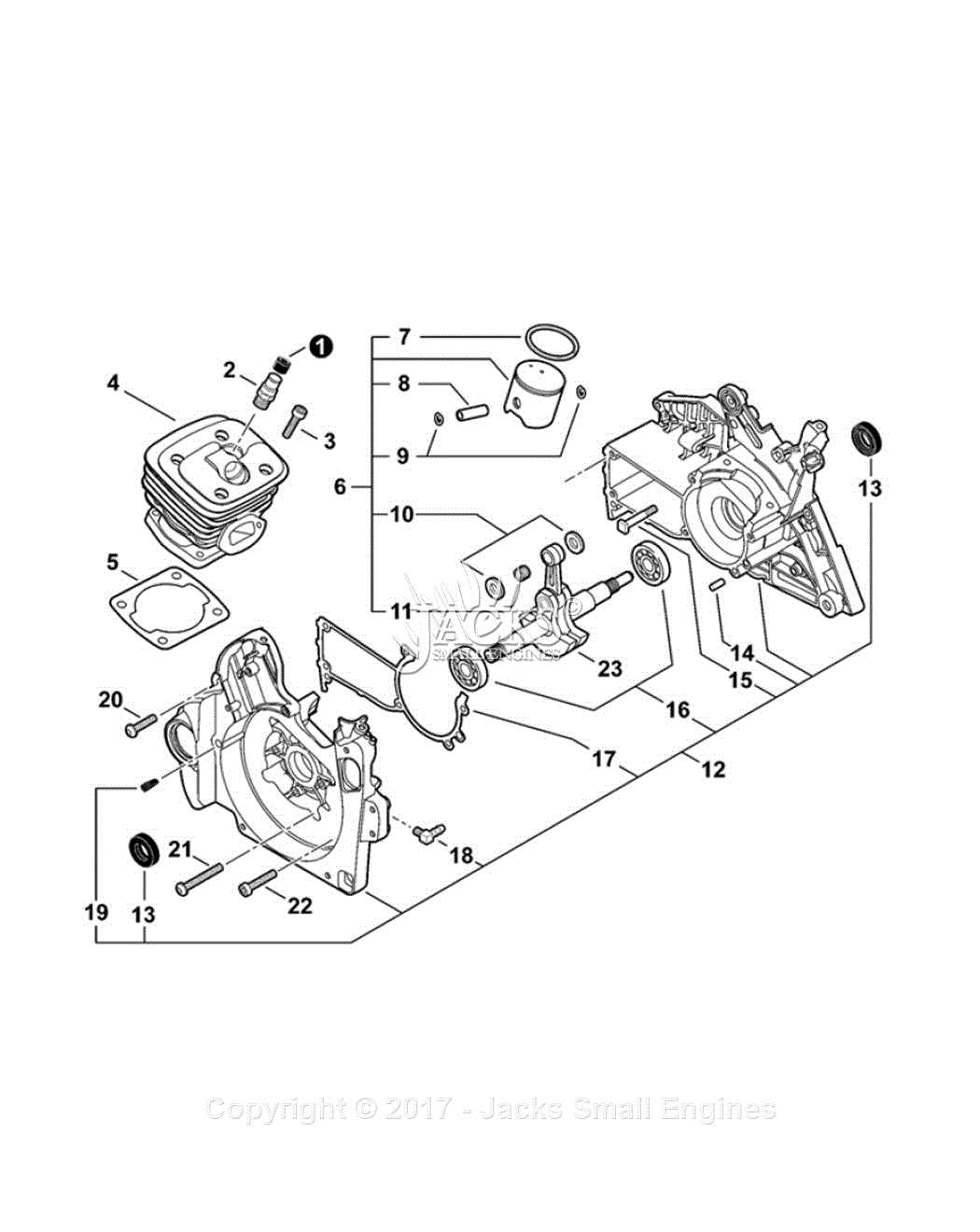

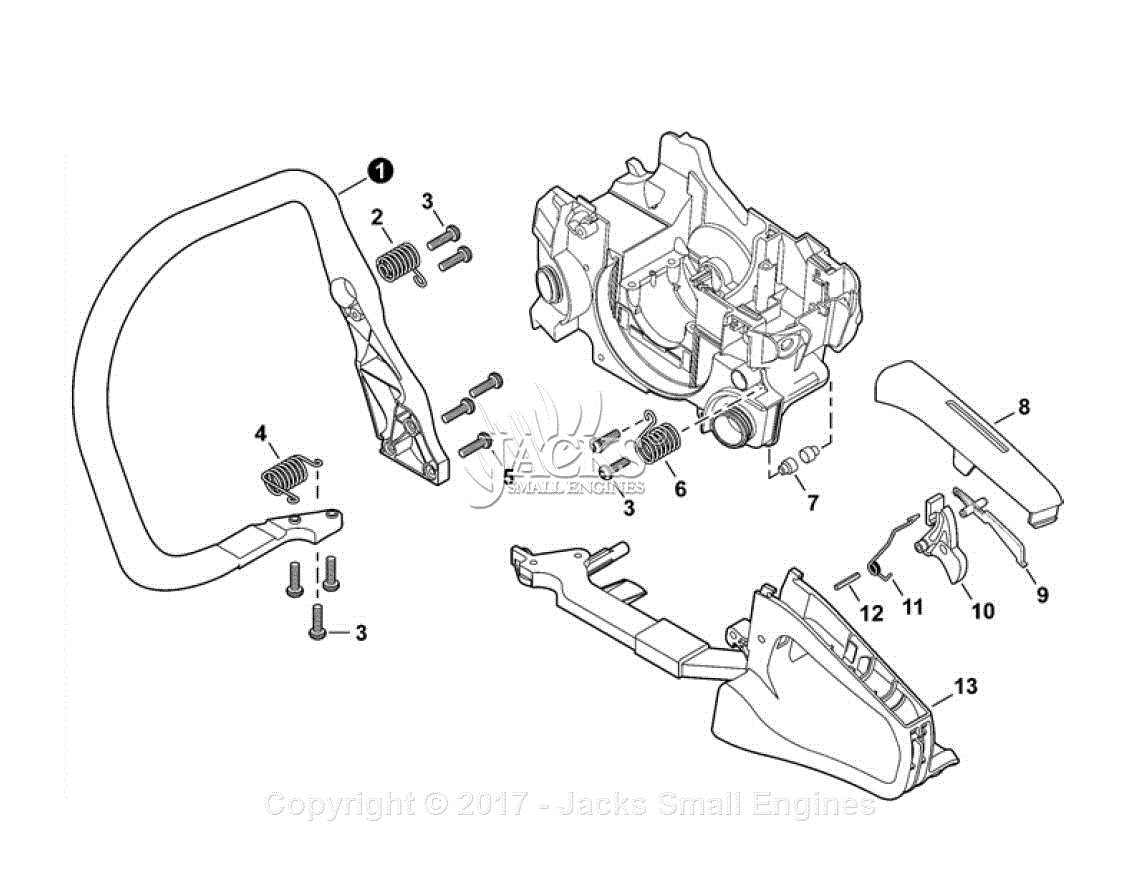

Identifying Common Parts in Diagrams

Understanding the various components illustrated in technical schematics is essential for effective maintenance and repair. Recognizing these elements enables users to identify specific functions and troubleshoot issues efficiently. By familiarizing oneself with common symbols and their corresponding roles, anyone can enhance their proficiency in interpreting these visual aids.

Key Components to Recognize

When examining a technical representation, certain components frequently appear. Motors and blades are often depicted prominently, indicating the primary functions of the equipment. Switches and guards also play critical roles, ensuring safety and control during operation. Being aware of these fundamental parts can greatly aid in understanding the overall system.

Tips for Effective Interpretation

To effectively decipher these illustrations, start by familiarizing yourself with the symbols commonly used in the field. Consulting a reference guide can be beneficial. Additionally, taking the time to study various schematics can build confidence and proficiency, allowing for quicker and more accurate assessments during repairs.

Tools Required for Disassembly

When undertaking a detailed examination of machinery, having the right tools is essential for a successful process. Proper instruments not only facilitate the removal of components but also ensure that reassembly is smooth and efficient. Understanding which tools are necessary can greatly enhance your overall experience and outcome.

Essential Instruments

Begin with a set of screwdrivers in various sizes to tackle different types of fasteners. A wrench set is also crucial for loosening and tightening nuts and bolts. Additionally, a pair of pliers can aid in gripping and manipulating parts that are hard to reach.

Additional Gear

For those intricate tasks, consider using a torque wrench to ensure that fasteners are secured to the manufacturer’s specifications. A workbench or stable surface will provide the necessary support during disassembly, minimizing the risk of damage to components.

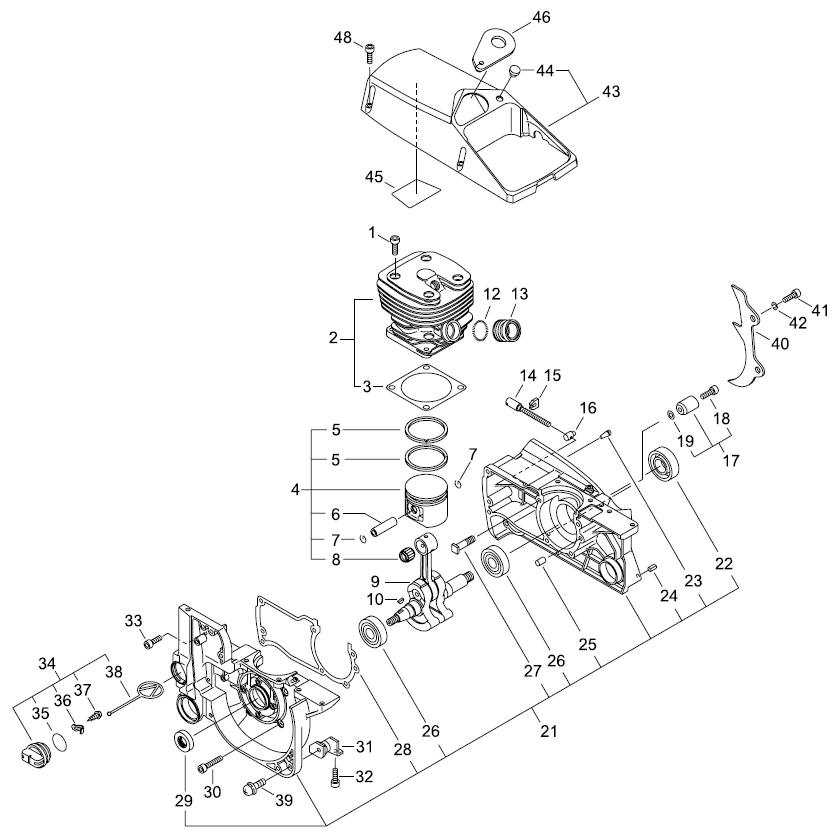

Step-by-Step Assembly Instructions

Assembling your tool correctly is crucial for optimal performance and safety. Following a systematic approach ensures that every component is properly fitted and functions seamlessly. The instructions outlined below provide a clear pathway to successful assembly.

Preparation Steps

Before you begin, gather all necessary components and tools. Ensure you are working in a well-lit area to enhance visibility. It’s also advisable to wear protective gear to safeguard against potential hazards during the assembly process.

Assembly Process

Follow the steps below to ensure a smooth assembly:

| Step | Action | Notes |

|---|---|---|

| 1 | Align the base with the frame. | Ensure secure positioning before proceeding. |

| 2 | Attach the handle to the main body. | Verify tightness to avoid movement during operation. |

| 3 | Install the power unit. | Follow manufacturer guidelines for connections. |

| 4 | Secure all fasteners and screws. | Double-check for any loose components. |

| 5 | Conduct a visual inspection. | Ensure everything is in place and aligned correctly. |

By following these instructions carefully, you can ensure that your tool is assembled correctly and ready for use. Regular maintenance and inspections are also recommended to prolong its lifespan and maintain efficiency.

Common Issues and Troubleshooting Tips

Every mechanical device can encounter challenges over time, and knowing how to address these problems can greatly enhance performance and longevity. Here are some frequent complications users may face and effective strategies to resolve them.

- Starting Difficulties:

- Check fuel quality and ensure it’s fresh.

- Inspect the ignition system for faults.

- Examine the air filter for clogs.

- Inconsistent Power:

- Ensure the spark plug is clean and functioning properly.

- Look for fuel line blockages.

- Adjust the carburetor settings as needed.

- Excessive Vibration:

- Inspect the blade for damage or misalignment.

- Check for loose components and tighten them.

- Examine the mounting system for wear and tear.

- Overheating:

- Ensure adequate lubrication levels.

- Clean any debris from cooling fins.

- Verify proper air circulation around the engine.

By understanding these common challenges and applying the suggested solutions, users can significantly improve their equipment’s functionality and extend its lifespan.

Where to Find Replacement Parts

When it comes to maintaining outdoor power tools, locating the right components is essential for ensuring optimal performance. Whether you are looking to repair a malfunctioning unit or simply wish to replace worn-out elements, understanding where to source these items can save you time and effort.

Online Retailers: Numerous websites specialize in offering a wide range of replacement items. Major e-commerce platforms often have extensive catalogs, making it easy to search for specific components by model number or description.

Authorized Dealers: Visiting an authorized dealer can provide peace of mind, as they typically stock genuine components. These establishments often have knowledgeable staff who can assist in identifying the right parts for your equipment.

Local Repair Shops: Local service centers or repair shops can be invaluable resources. They often carry essential components and may also provide installation services, ensuring that your equipment is serviced correctly.

Manufacturer’s Website: The official website of the manufacturer may offer a section dedicated to replacement items. This can include detailed listings and, in some cases, direct purchasing options.

Forums and Community Groups: Online forums and community groups dedicated to outdoor equipment often feature discussions about sourcing specific components. Members frequently share recommendations and experiences that can guide you to reliable suppliers.

By exploring these options, you can efficiently find the necessary items to keep your equipment in peak condition.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also ensure that the equipment functions optimally after the work is completed.

Before starting any repair, it is essential to disconnect the power source to eliminate the risk of accidental activation. Wearing appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, can greatly reduce the chances of harm. Additionally, working in a well-lit and clutter-free environment minimizes the potential for mishaps.

Understanding the specific tools required for the job is vital. Using the right tools not only makes the task easier but also decreases the likelihood of injury. Furthermore, always follow the manufacturer’s guidelines and recommendations to ensure proper handling and assembly of components.

It is advisable to have a first aid kit nearby in case of emergencies. Regularly reviewing safety protocols and being aware of the surroundings can significantly contribute to a safer repair experience.