Every tool designed for precision cutting has a complex assembly of elements that work in harmony to achieve optimal performance. Understanding these components is crucial for maintenance and troubleshooting, ensuring your equipment remains reliable and efficient over time. A detailed exploration of these individual pieces can empower users to enhance their skills and prolong the life of their machinery.

In this section, we will delve into the various components of a popular cutting implement. From the powerful motor that drives the entire system to the smaller, often overlooked elements, each part plays a vital role in the functionality of the tool. By gaining insights into how these pieces fit together, users can make informed decisions regarding repairs, upgrades, or replacements.

Moreover, familiarity with the arrangement and purpose of each element fosters a deeper appreciation for the craftsmanship behind these tools. As we navigate through the intricate layout of the assembly, you’ll discover how to troubleshoot common issues and perform necessary upkeep. This knowledge not only enhances performance but also ensures safety during operation.

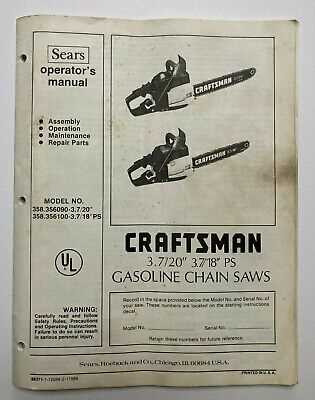

Understanding the Craftsman 358 Chainsaw

This section delves into the essential features and components of a popular power tool designed for cutting and trimming. Recognizing its various elements is crucial for effective operation and maintenance.

Key Features

- Lightweight design for easy maneuverability.

- Powerful engine for efficient cutting.

- Adjustable settings for different tasks.

Maintenance Tips

- Regularly check the fuel and oil levels.

- Clean the air filter to ensure optimal performance.

- Sharpen the blade frequently to maintain cutting efficiency.

Key Features of Craftsman 358 Model

This section highlights the distinctive characteristics of a well-regarded cutting tool known for its efficiency and durability. Users appreciate its design and functionality, making it a favored choice among both hobbyists and professionals.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine that provides high performance for various cutting tasks. |

| Lightweight Design | The lightweight construction enhances maneuverability, reducing user fatigue during extended use. |

| Easy Start System | Incorporates a reliable starting mechanism, ensuring quick and effortless ignition. |

| Adjustable Chain Tension | Features a tool-less chain tensioning system that allows for easy adjustments to maintain optimal performance. |

| Safety Features | Includes several safety mechanisms, such as a chain brake and low kickback chain, to enhance user protection. |

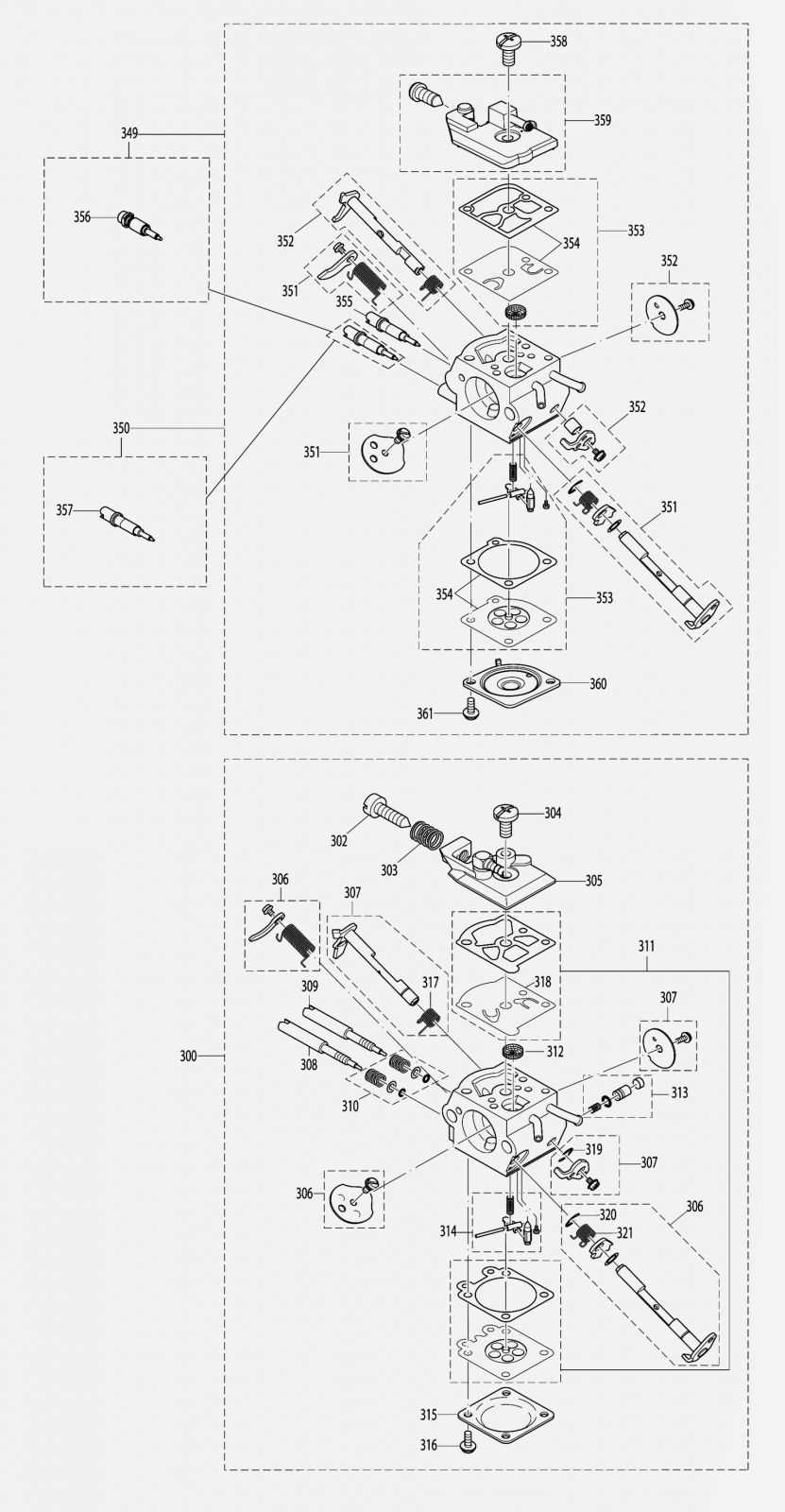

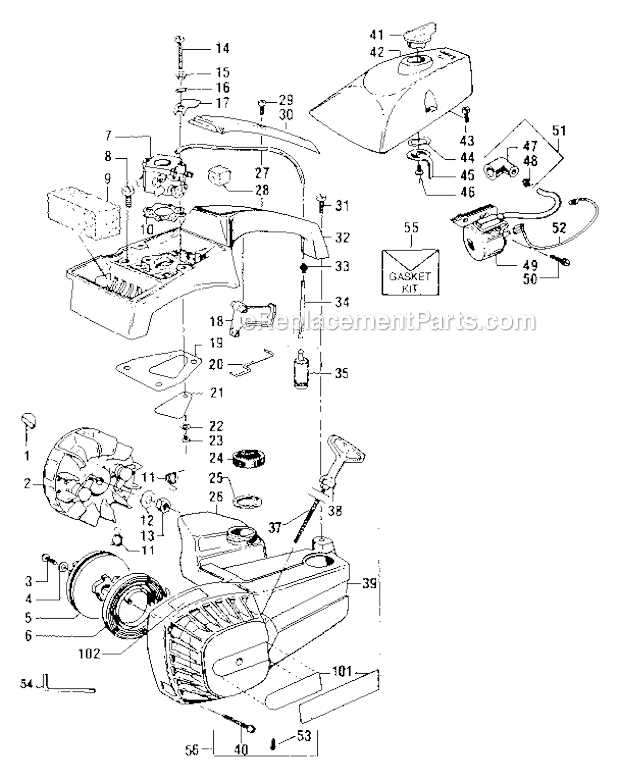

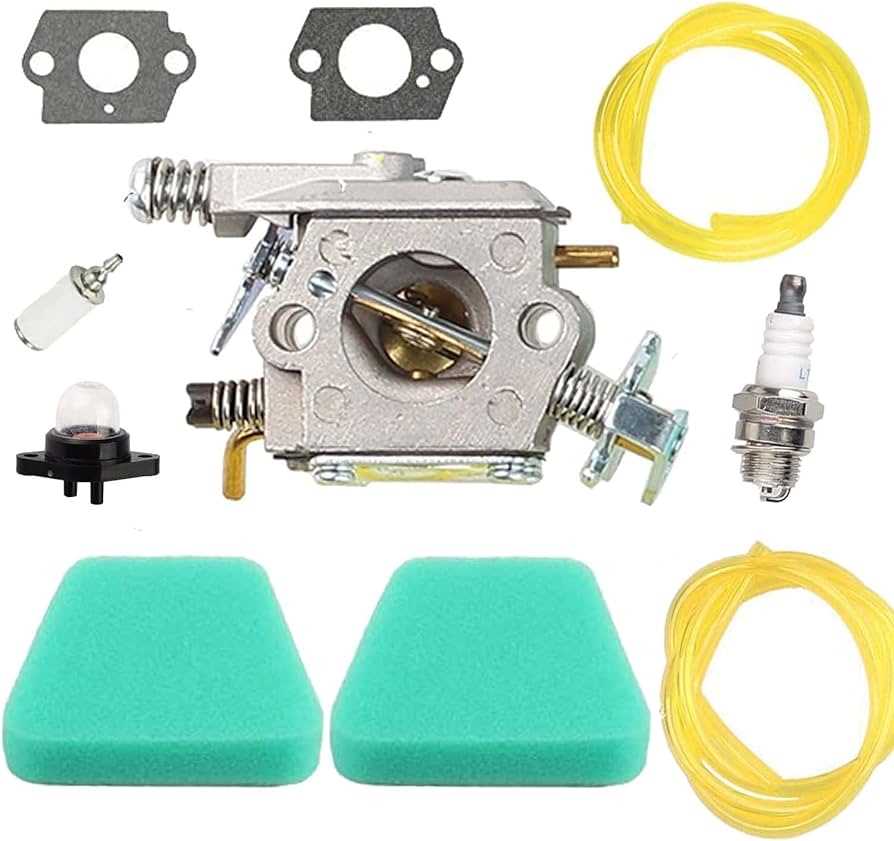

Common Parts and Their Functions

Understanding the key components of a power cutting tool is essential for efficient operation and maintenance. Each element plays a specific role in ensuring optimal performance, contributing to both safety and effectiveness during use. Here, we will explore several fundamental elements and their respective functions.

Engine: The heart of the device, this mechanism generates the necessary power to operate the tool. It converts fuel into kinetic energy, driving the cutting system.

Bar: This elongated piece serves as the support structure for the cutting chain, guiding it during operation. Its length can vary, affecting the depth and reach of cuts.

Cutting Chain: Comprised of sharp teeth, this flexible loop performs the actual cutting. Its design determines the speed and efficiency of the cutting process, making it crucial for various tasks.

Clutch: This component connects and disconnects the engine’s power to the cutting chain. It allows the user to maintain control, ensuring that the chain only operates when needed.

Fuel System: This assembly delivers the necessary mixture of fuel and air to the engine. Proper functioning is vital for efficient performance and to prevent engine issues.

Oiler: This system lubricates the cutting chain and bar, reducing friction and wear. Regular maintenance of this component extends the life of the tool and enhances cutting performance.

Safety Features: Various mechanisms, such as chain brakes and throttle locks, are integrated to protect the user. These features are essential for minimizing risks and ensuring safe operation.

Familiarity with these components not only aids in effective usage but also facilitates troubleshooting and maintenance, ultimately leading to a more enjoyable and productive experience.

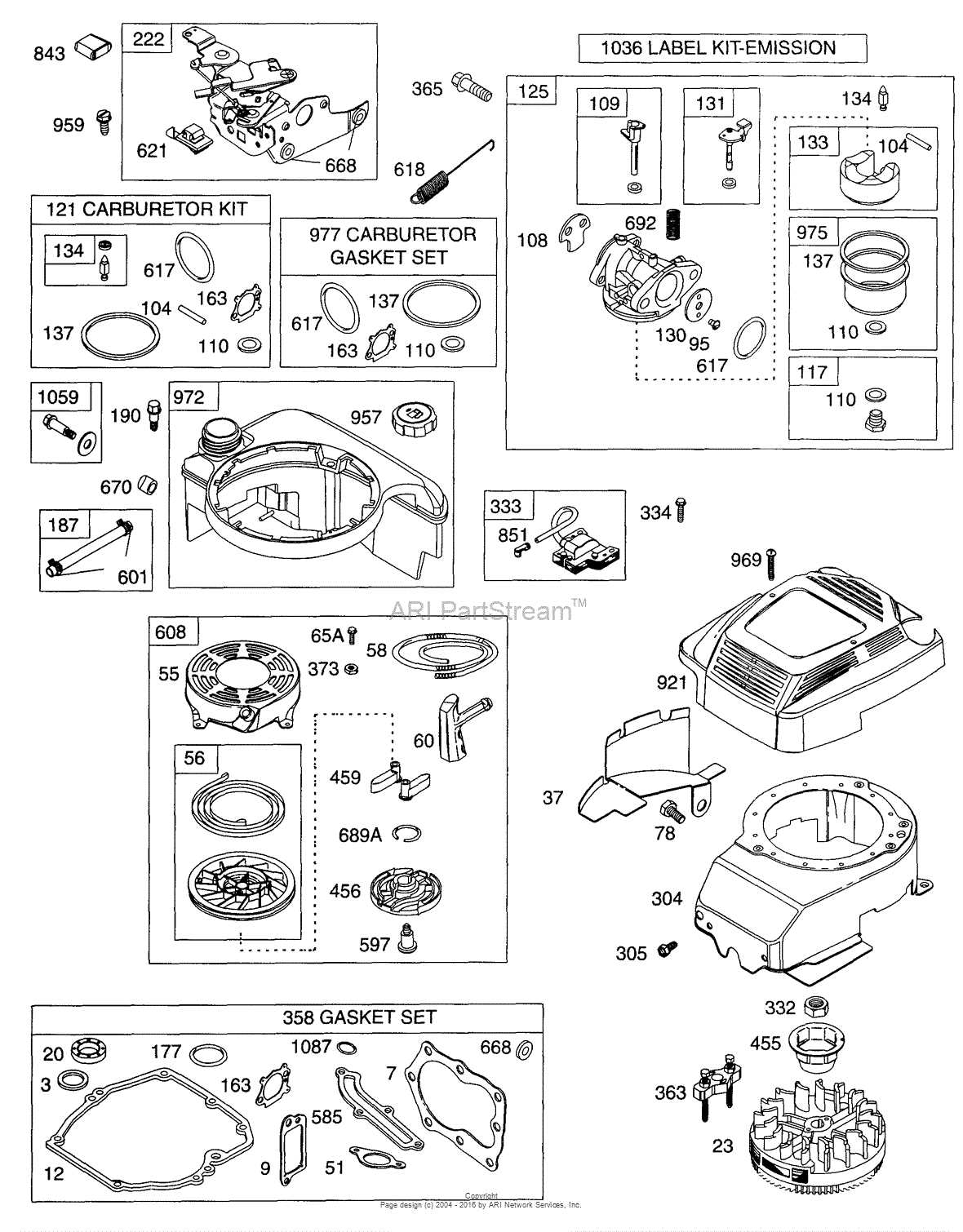

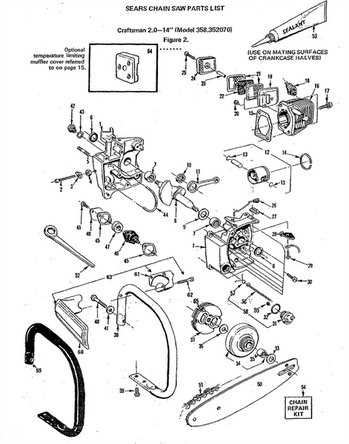

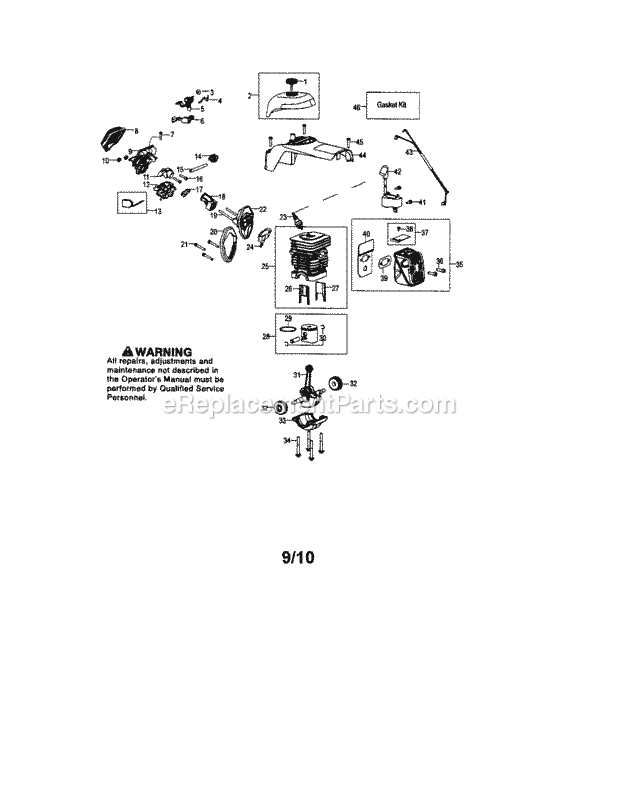

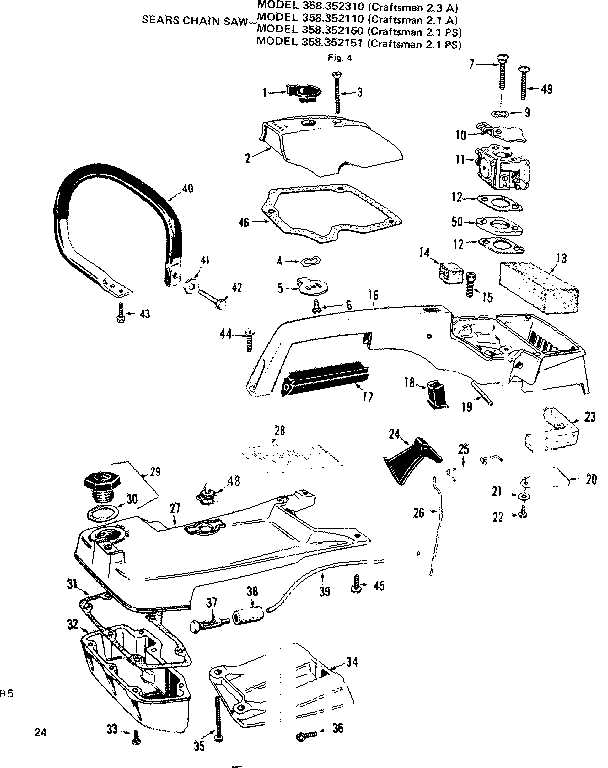

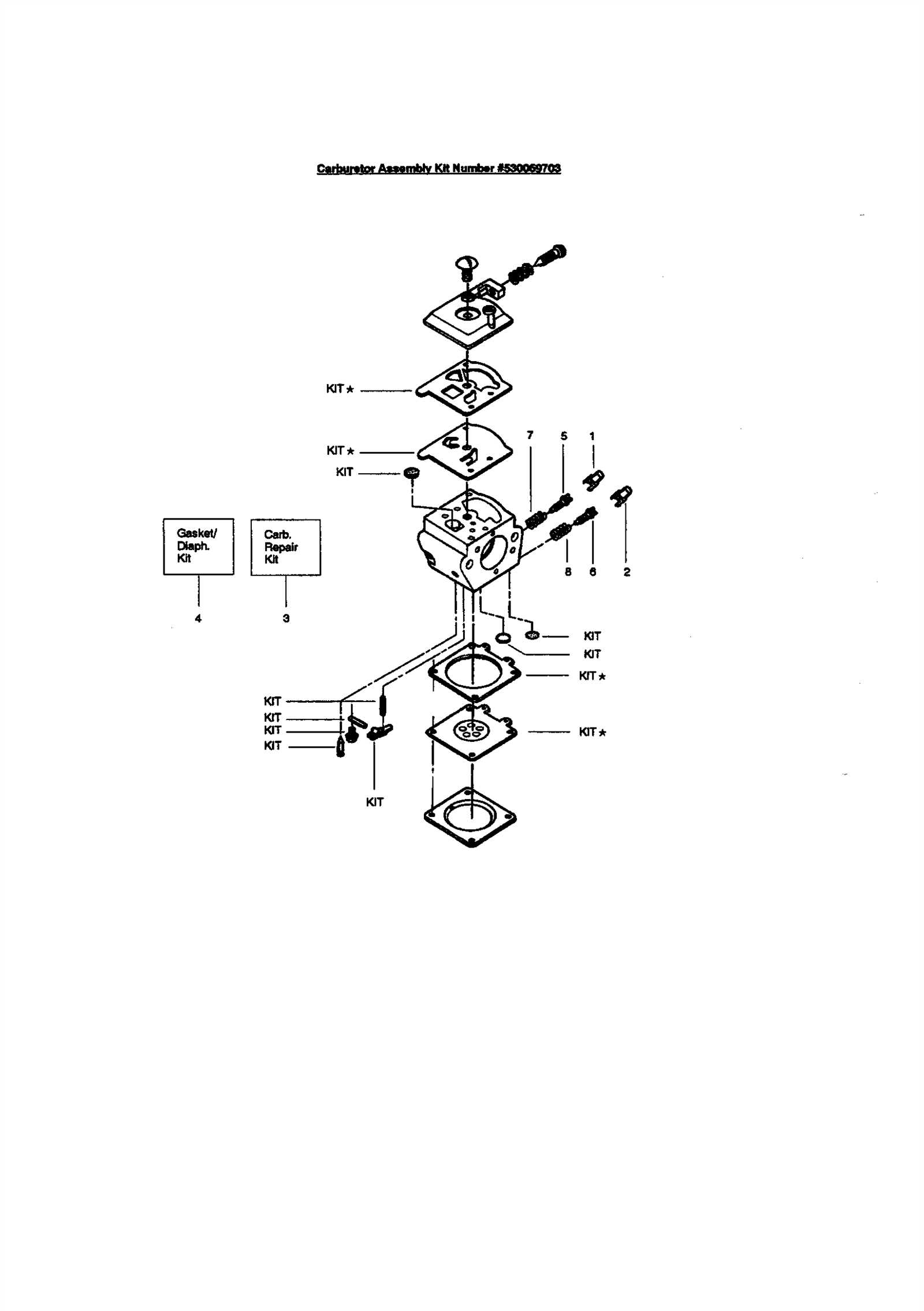

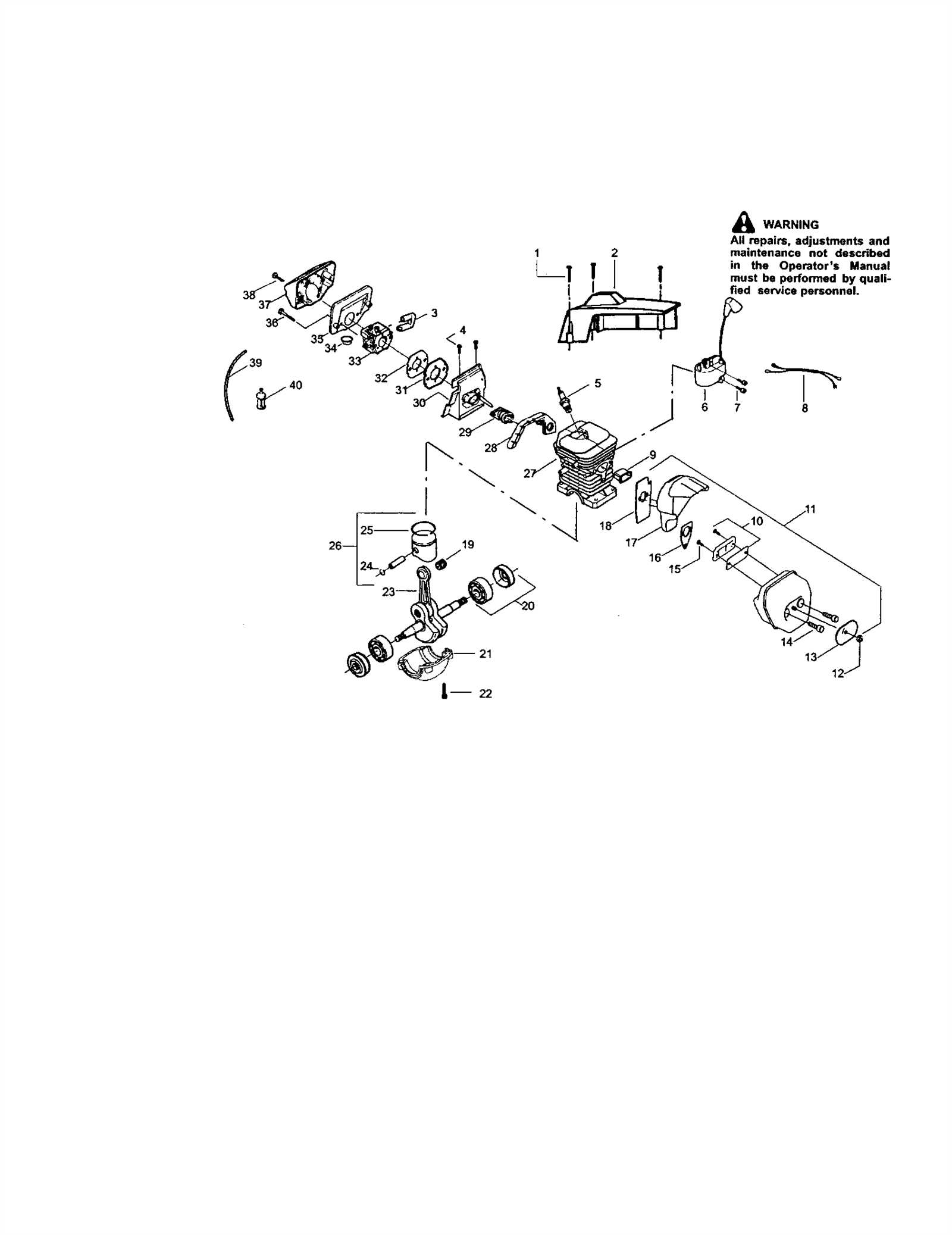

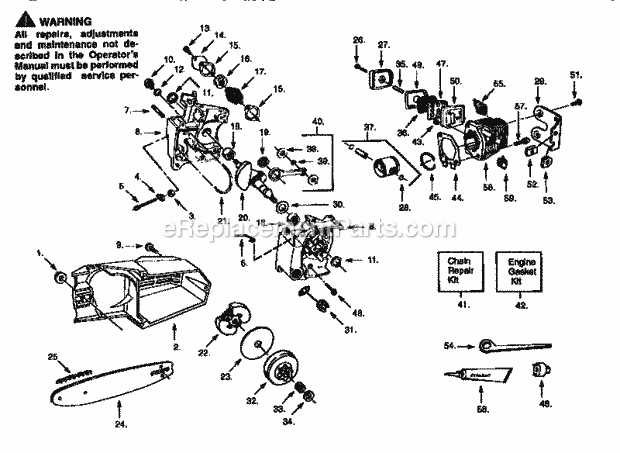

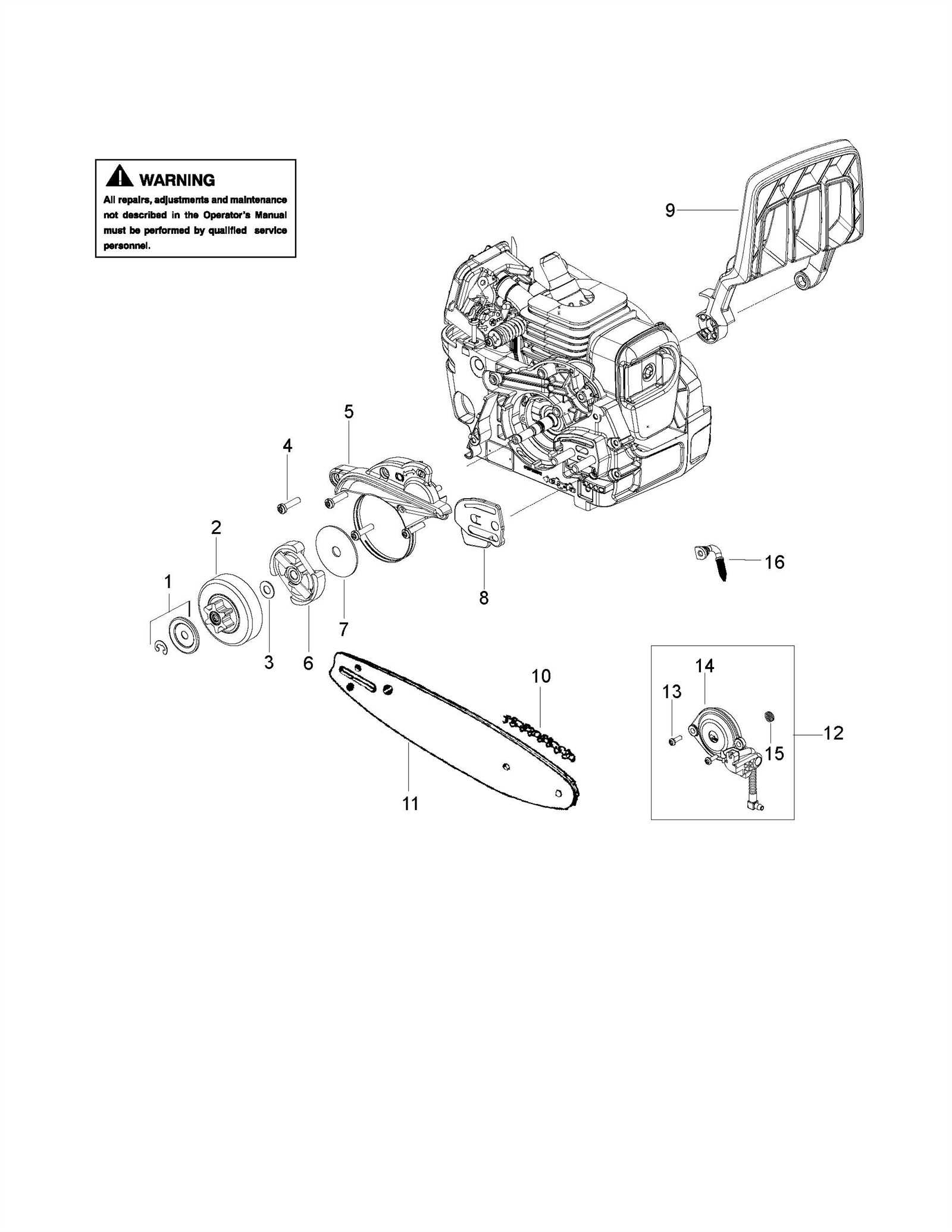

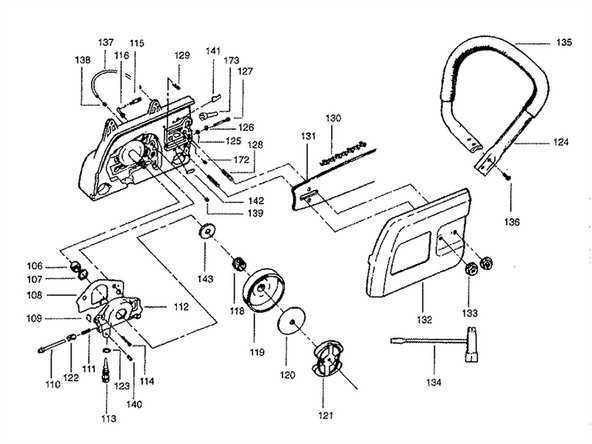

How to Read a Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed overview of each element, helping you identify and locate the necessary pieces for your projects. By grasping how to interpret these visuals, you can streamline your work and ensure proper assembly.

Key Elements of the Illustration

To effectively navigate the illustration, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Each component is typically labeled with a unique identifier, making it easier to reference parts. |

| Connections | Lines or arrows indicate how parts interact or connect with one another. |

| Legend | A legend may explain symbols or color codes used in the illustration for clarity. |

Steps for Interpretation

Follow these steps to effectively interpret the visual:

- Start by locating the legend, if available, to understand any symbols.

- Identify key components by their labels, focusing on those relevant to your task.

- Trace connections to visualize how parts fit together, noting any dependencies.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your outdoor power equipment requires regular care and attention. Proper maintenance not only enhances performance but also extends the lifespan of your tools, allowing for more efficient work and reduced replacement costs.

1. Regular Cleaning: After each use, take the time to clean your equipment. Remove debris, dust, and any residues that may accumulate. This helps prevent corrosion and keeps all moving parts functioning smoothly.

2. Lubrication: Regularly check and apply appropriate lubricants to moving components. This minimizes friction and wear, ensuring that everything operates seamlessly. Follow manufacturer guidelines for the best results.

3. Inspection: Frequently inspect your equipment for signs of wear or damage. Look for loose screws, cracks, or frayed cables. Addressing these issues early can prevent more significant problems down the line.

4. Fuel Quality: Always use high-quality fuel and store it properly. Contaminated or old fuel can lead to performance issues and damage the engine. Consider using fuel stabilizers for longer storage periods.

5. Storage Conditions: When not in use, store your equipment in a dry, cool place. Protect it from extreme temperatures and humidity to prevent rust and deterioration of materials.

6. Professional Servicing: Schedule periodic professional maintenance to ensure all systems are functioning optimally. Experts can identify potential issues that may go unnoticed during regular inspections.

By following these simple yet effective maintenance tips, you can enhance the durability of your tools and ensure they remain reliable companions for all your outdoor tasks.

Identifying Worn Components

Recognizing signs of wear in various machinery is crucial for maintaining optimal performance and safety. Over time, certain elements may degrade due to usage, leading to decreased efficiency or potential failures. Understanding how to identify these worn parts can save time and resources, ensuring the equipment remains reliable and effective.

Common indicators of wear include unusual noises, vibrations, or difficulty in operation. Inspecting components for cracks, rust, or other physical damages is essential. Pay attention to areas that experience friction or heat, as these are often the first to show signs of deterioration. Regular maintenance checks should focus on these aspects, allowing for timely replacements and preventing further issues.

Additionally, comparing the condition of specific elements against manufacturer specifications can provide a clearer picture of their operational integrity. Keeping an eye on performance metrics will help in assessing when parts require replacement, ultimately extending the life of the entire system.

Where to Find Replacement Parts

Finding components for your power tool can often feel like a daunting task, but there are several reliable sources that can help you locate the necessary items for maintenance and repair. Understanding where to look is essential to ensure you get high-quality replacements that fit perfectly and function effectively.

Authorized Dealers

One of the best places to start your search is with authorized retailers. These dealers typically offer genuine components that are specifically designed for your model. They often provide additional support, including installation advice and warranty information, making them a trusted option for obtaining high-quality replacements.

Online Marketplaces

The internet has transformed the way we shop for tools and accessories. Numerous online platforms feature extensive catalogs of items, often including user reviews and detailed descriptions. Be sure to check the credibility of the seller and the return policy to ensure a smooth purchasing experience. Some websites even specialize in aftermarket options, giving you a variety of choices at different price points.

DIY Repairs for Craftsman Chainsaws

Maintaining your cutting tool can significantly extend its lifespan and improve performance. Simple repairs can often be accomplished with basic tools and a little know-how, making it possible to tackle issues without professional assistance. This guide will explore common repairs and provide helpful tips for enthusiasts looking to keep their equipment in top shape.

Common Issues and Fixes

- Fuel Leaks: Check for cracks in the fuel lines and replace them as necessary.

- Chain Tension: Adjust the tension according to the manufacturer’s specifications for optimal cutting.

- Starting Problems: Inspect the spark plug; clean or replace it if it appears worn or dirty.

- Bar Damage: Look for wear on the guide bar and file or replace it if necessary.

Tools Needed

- Wrench set

- Screwdrivers

- Chain file

- Replacement parts as required

By taking the time to delve into these repairs, you can enhance your equipment’s efficiency and enjoy a more satisfying experience during use.

Safety Precautions During Repairs

When undertaking maintenance on power equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also ensure that the equipment functions correctly once reassembled. Below are essential safety measures to follow during the repair process.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety goggles, gloves, and ear protection to safeguard against debris and noise. |

| Disconnect Power Source | Ensure that the equipment is unplugged or the battery is removed before starting any repair work. |

| Work in a Well-Ventilated Area | Ensure proper airflow to avoid inhaling fumes from any chemicals or lubricants used during repairs. |

| Use Proper Tools | Utilize the correct tools for the job to avoid damage and ensure effective repairs. |

| Follow Manufacturer Guidelines | Refer to the instruction manual for specific repair procedures and safety recommendations. |

| Keep Workspace Organized | A tidy area minimizes the risk of accidents and makes it easier to locate tools and parts. |

By adhering to these safety guidelines, individuals can conduct repairs more effectively while minimizing risks associated with mechanical work. Taking the time to prepare properly ensures a smoother and safer repair experience.