In the world of outdoor equipment, maintaining the efficiency of a cutting device is essential for optimal performance. This section delves into the various elements that comprise a particular model, offering insights into their functions and interrelations. By grasping the roles of these components, users can enhance their understanding of the tool’s operation and longevity.

Every element of a cutting apparatus plays a vital role in its overall functionality. From the power source to the cutting mechanism, each part contributes to the seamless execution of tasks. This exploration aims to illuminate how these pieces work in concert, enabling users to troubleshoot issues effectively and ensure their equipment remains in prime condition.

Moreover, familiarizing oneself with the construction of the tool can empower individuals to make informed decisions regarding maintenance and repairs. Recognizing the significance of each segment fosters a proactive approach to care, allowing for a deeper appreciation of the craftsmanship involved in designing these machines. Understanding these relationships can lead to a more rewarding and efficient experience when utilizing outdoor tools.

Understanding the Poulan P3314 Chainsaw

This section delves into the intricacies of a specific model of cutting equipment, highlighting its essential features and functionality. Designed for efficient wood processing, this tool serves as a reliable companion for various tasks, from pruning to felling trees. Familiarity with its components and operation can enhance user experience and ensure optimal performance.

Key Features

The equipment boasts a powerful engine that provides the necessary strength for demanding tasks. Its lightweight design facilitates ease of use, making it accessible for both professionals and hobbyists. Additionally, the model incorporates safety mechanisms that protect users during operation, promoting a secure working environment.

Maintenance Tips

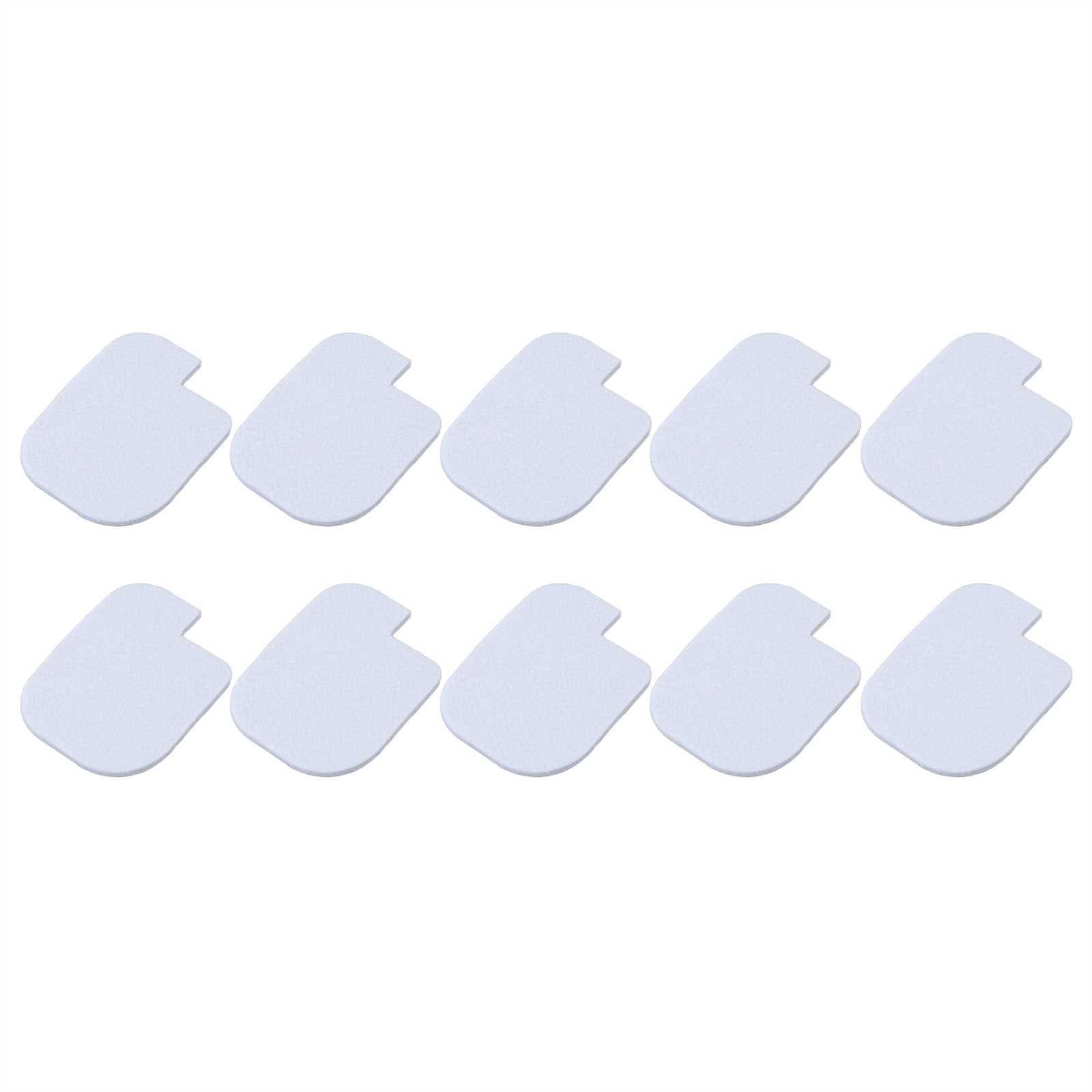

Regular upkeep is crucial for longevity and efficiency. Ensuring the cutting mechanism is sharp and well-lubricated enhances performance and reduces wear. It is advisable to check and clean air filters periodically, as a clean filter improves airflow and engine performance. Users should also inspect all components for signs of wear or damage, replacing any faulty parts to maintain reliability.

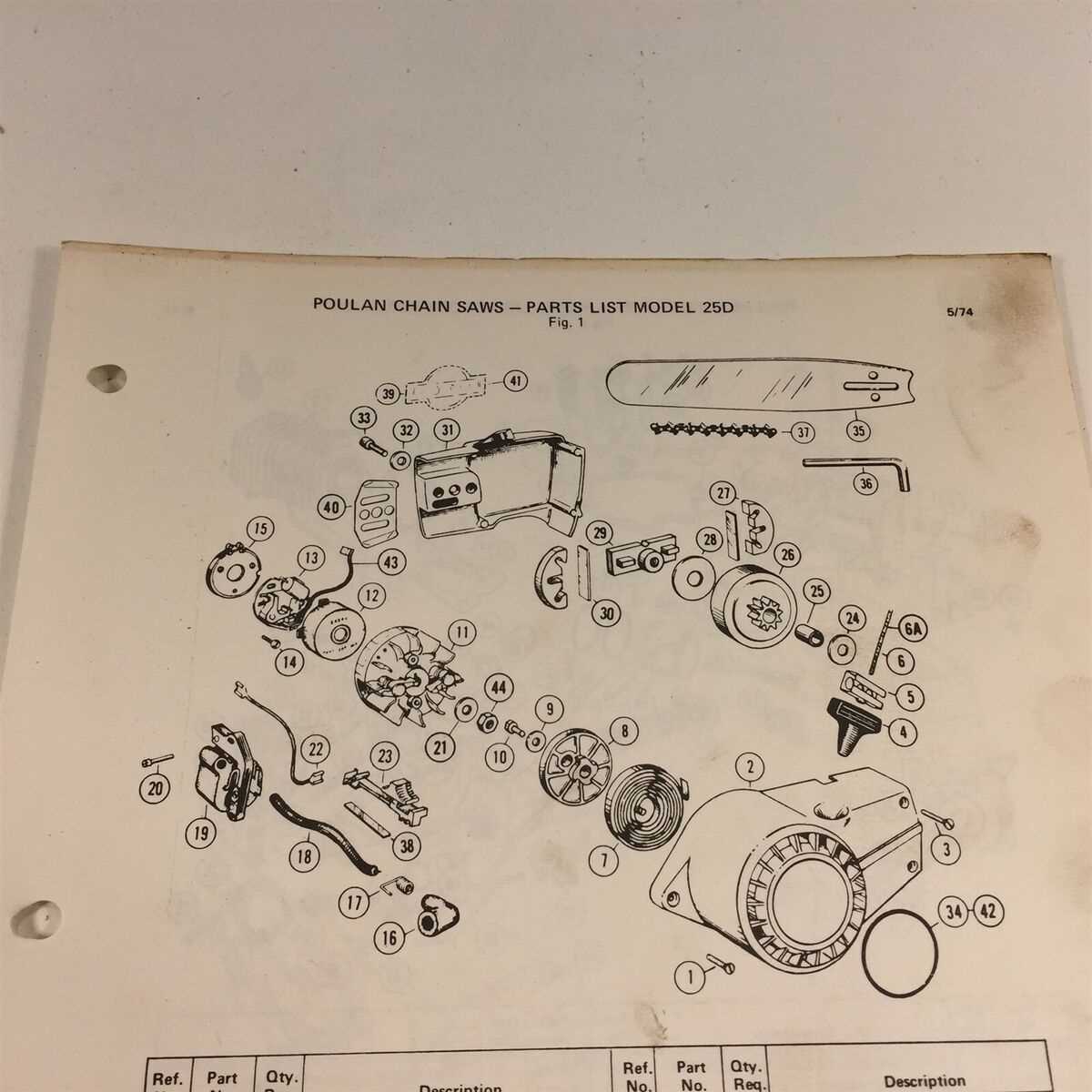

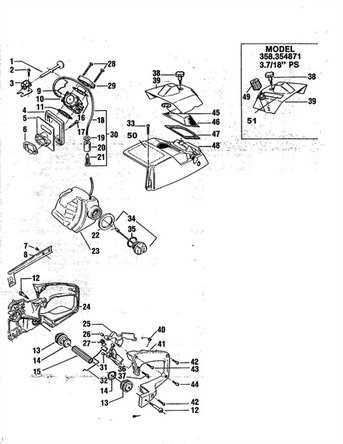

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool is crucial for effective operation and maintenance. Each part plays a vital role in the overall functionality, ensuring smooth performance and longevity.

Engine: The heart of the device, responsible for converting fuel into mechanical energy. Its efficiency directly impacts the tool’s power and performance.

Guide Bar: A crucial component that provides a stable surface for the cutting chain to run along. The length and design can influence the cutting capacity and maneuverability.

Cutting Chain: This component is equipped with sharp teeth that do the actual cutting. The configuration and material of the chain are significant factors in achieving optimal results.

Fuel System: Comprising the fuel tank and lines, this system ensures a steady supply of fuel to the engine, which is vital for uninterrupted operation.

Oiling Mechanism: This part ensures the chain is adequately lubricated, reducing friction and wear during use. Proper maintenance of this system is essential for the tool’s efficiency.

Handle and Safety Features: Designed for user comfort and safety, these components help maintain control during operation while minimizing the risk of accidents.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your cutting tool. Implementing a few simple practices can significantly enhance performance, minimize wear, and prevent costly repairs. This section outlines key maintenance strategies that can help you achieve the best results.

Routine Inspection and Cleaning

Inspecting your equipment frequently allows you to identify potential issues early. After each use, clean the exterior to remove debris and sap buildup, which can hinder functionality. Additionally, check the guide bar and chain for any signs of damage or excessive wear.

Proper Lubrication and Fueling

Using the correct type of lubricant is vital for keeping moving parts functioning smoothly. Ensure the oil reservoir is filled regularly to prevent overheating. When it comes to fueling, always use the recommended mixture to maintain engine efficiency and reduce emissions.

Common Issues and Troubleshooting

When operating a cutting tool, various challenges may arise that can hinder performance and efficiency. Identifying and resolving these issues is essential for maintaining optimal functionality and ensuring safety during use. This section explores some prevalent problems and offers practical solutions to enhance your experience.

-

Difficulty Starting:

If the equipment fails to start, check the following:

- Ensure the fuel tank is filled with fresh fuel.

- Inspect the spark plug for wear or damage.

- Verify that the on/off switch is in the correct position.

-

Engine Stalling:

Unexpected engine shutdowns can be frustrating. Consider these factors:

- Check for blockages in the air filter.

- Inspect fuel lines for leaks or obstructions.

- Ensure the choke is functioning properly.

-

Excessive Vibration:

High vibration levels can indicate underlying issues:

- Examine the blade for damage or dullness.

- Ensure that all components are securely fastened.

- Consider balancing the cutting tool to reduce vibrations.

-

Inconsistent Cutting:

Achieving a clean cut is vital. If the tool struggles, look into:

- Sharpening or replacing the cutting edge.

- Adjusting the tension of the chain.

- Inspecting the alignment of the blade.

By addressing these common challenges, users can significantly improve the performance and longevity of their cutting equipment, ensuring a smoother and more effective operation.

Replacing Worn-Out Parts

Over time, components of your tool may become less effective due to wear and tear. Identifying and substituting these deteriorating elements is crucial for maintaining optimal functionality. Regularly assessing the condition of these pieces can help ensure your equipment operates smoothly and efficiently.

Signs of Deterioration

Keep an eye out for common indicators that suggest components may need replacement. Unusual noises, decreased performance, and visible damage are all signs that something might be amiss. Regular inspections can help you catch these issues early, preventing further complications down the line.

Choosing the Right Replacements

When selecting new elements, it’s essential to ensure compatibility with your specific model. Consider purchasing high-quality replacements that meet the manufacturer’s standards. Doing so will not only enhance performance but also extend the lifespan of your equipment. Don’t hesitate to consult the user manual for guidance on appropriate specifications and installation procedures.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right instruments at hand is crucial for ensuring efficient and effective repairs. A well-equipped workspace not only streamlines the process but also enhances safety while working on various components.

Essential tools include screwdrivers of varying sizes, wrenches, and pliers, which are fundamental for loosening and tightening bolts. Additionally, a set of replacement blades and sharpening tools is important for maintaining optimal performance. For more intricate tasks, a torque wrench may be necessary to apply the correct amount of force without damaging parts.

Lastly, protective gear such as gloves and safety goggles should not be overlooked, as they play a vital role in keeping you safe during maintenance activities. With the right tools and precautions, you can tackle repairs confidently and ensure your equipment operates smoothly.

Assembly Instructions for Users

This section provides essential guidance for users to effectively assemble their equipment. Following these instructions will ensure a smooth process and optimal performance, allowing for a better experience in utilizing the tool for various tasks.

Preparation Steps

Before beginning the assembly, gather all necessary components and tools in a well-lit area. Review the manual to familiarize yourself with each element’s function. Ensuring that you have a clean workspace will facilitate the organization of parts and reduce the risk of misplacing any items during the assembly process.

Assembly Process

Start by aligning the main sections according to the provided guidelines. Carefully insert any fasteners to secure the components, ensuring they are tightened adequately but not excessively. As you progress, regularly check the stability of the assembly. Once completed, inspect the entire setup for any loose connections or misalignments to guarantee safe and efficient operation.

Finding Quality Replacement Parts

When it comes to maintaining equipment, securing high-quality components is essential for optimal performance. Whether you’re repairing or upgrading, sourcing reliable items can significantly enhance functionality and longevity. The following guidelines will help you navigate the selection process effectively.

Key Considerations for Quality Components

- Compatibility: Ensure that the new components fit seamlessly with your existing machinery to avoid any issues during operation.

- Material Quality: Look for items made from durable materials that can withstand wear and tear.

- Brand Reputation: Opt for components from reputable manufacturers known for their reliability and performance.

Where to Find Reliable Components

- Authorized Dealers: Visit certified dealers who offer genuine components that meet manufacturer specifications.

- Online Marketplaces: Explore reputable online platforms that provide user reviews and detailed product descriptions.

- Local Repair Shops: Consult local repair professionals who can recommend trusted suppliers or provide components directly.

By following these steps, you can ensure that you obtain top-notch items, which will contribute to the efficiency and effectiveness of your equipment.

Safety Guidelines for Operation

Ensuring safe usage of power tools is paramount for both the operator and those nearby. Adhering to proper safety practices helps minimize risks and promotes a secure working environment. This section outlines essential precautions that should be taken when handling cutting equipment.

- Personal Protective Equipment (PPE): Always wear appropriate gear, including protective goggles, gloves, and sturdy footwear to shield against debris and potential injuries.

- Inspection Before Use: Conduct a thorough check of the equipment before operation. Ensure all components are in good condition, and replace any damaged parts immediately.

- Work Environment: Maintain a clean and organized workspace. Remove any obstacles or hazards that may interfere with safe operation.

- Awareness of Surroundings: Be aware of your surroundings and the presence of others. Keep bystanders at a safe distance while working.

- Proper Technique: Use correct handling techniques to maintain control of the equipment. Follow the manufacturer’s instructions for safe operation.

Following these guidelines will not only enhance safety but also improve efficiency during use. Always prioritize safety to ensure a successful and incident-free experience.