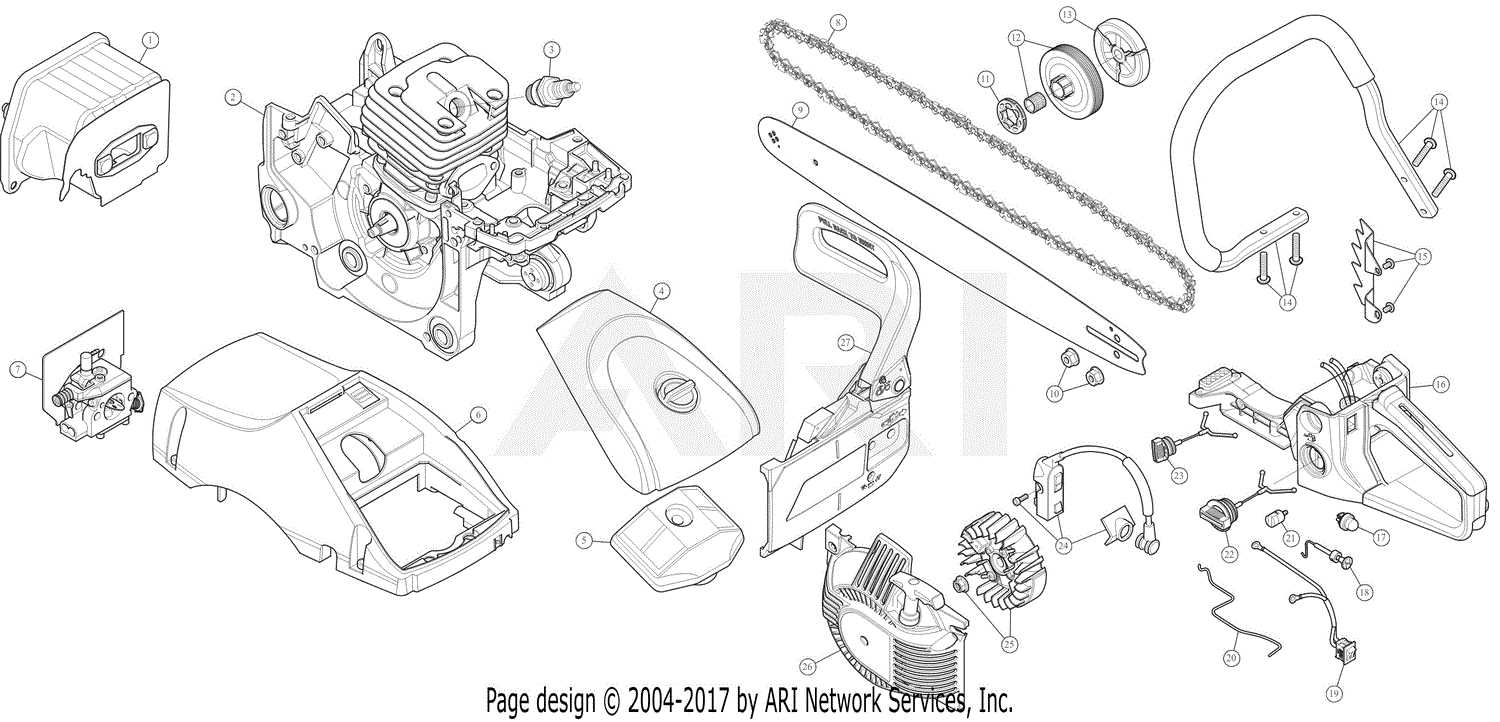

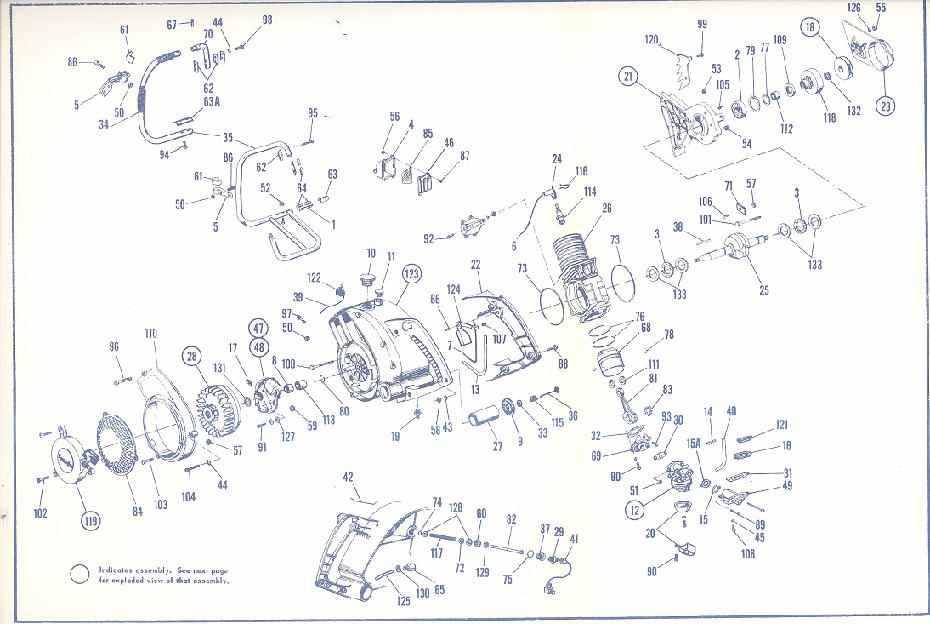

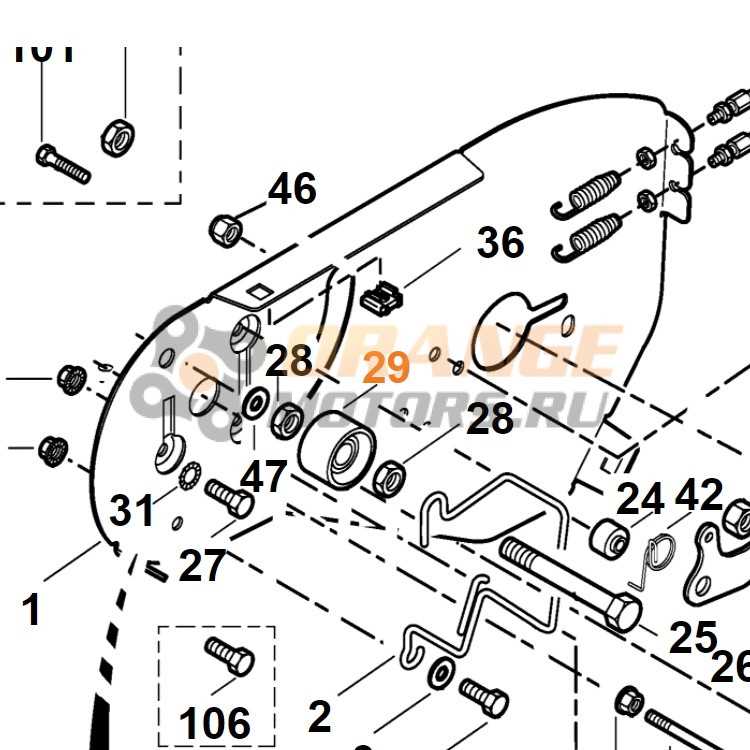

For anyone who operates a powerful cutting instrument, having a clear grasp of its components is essential for effective maintenance and operation. A comprehensive visual representation of the various elements can enhance your ability to troubleshoot issues and ensure longevity. By examining these elements closely, you can gain insights into how they interact and contribute to the overall functionality.

In this section, we will explore the intricate assembly that makes up this robust tool. Each section will highlight critical components, showcasing their roles and importance in the machine’s performance. This knowledge will empower users to make informed decisions regarding repairs and enhancements.

Whether you are a seasoned professional or a novice user, familiarizing yourself with the inner workings of your device is crucial. As you delve deeper into understanding these components, you’ll discover the ultimate way to optimize your equipment and enhance your cutting experience.

Understanding Remington Chainsaw Components

To effectively operate a cutting tool, it is essential to grasp the various elements that contribute to its functionality. Each component plays a pivotal role in ensuring optimal performance and safety during usage. A comprehensive understanding of these elements not only enhances user experience but also aids in maintenance and troubleshooting.

Key Elements of the Cutting Tool

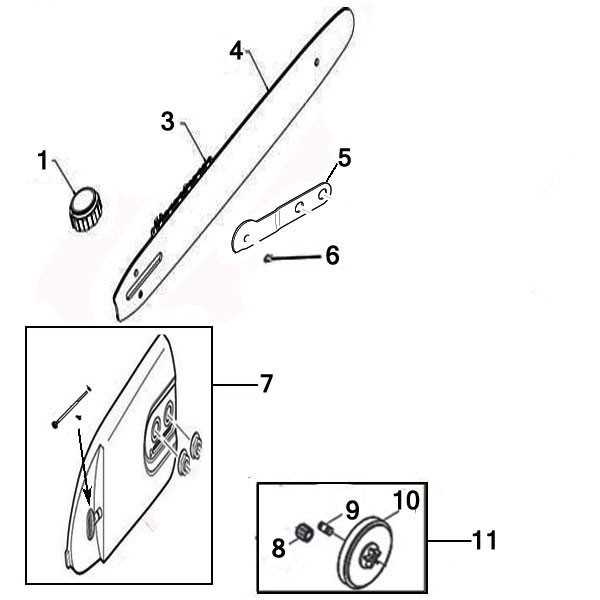

Every device is made up of several crucial components that work in harmony. The motor serves as the powerhouse, driving the mechanism that performs the cutting action. Additionally, the guide bar and chain interact closely, dictating the precision and efficiency of the cutting process. Regular inspection and familiarity with these elements can greatly improve longevity and reliability.

Maintenance and Care

Proper upkeep of the equipment is vital for ensuring its long-lasting performance. Regularly checking the sharpness of the cutting chain, ensuring the oil reservoir is filled, and inspecting the drive mechanisms can prevent potential failures. Understanding the significance of each element allows users to take proactive measures in maintaining their tools effectively.

Key Parts of Remington Chainsaws

Understanding the essential components of cutting equipment is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring smooth operation, safety, and durability. Familiarizing yourself with these key elements can enhance your overall experience and effectiveness during use.

One of the primary components is the power unit, which drives the entire mechanism. The bar, often regarded as the cutting surface, is vital for achieving precise cuts. Additionally, the chain is critical for delivering the cutting action, working in conjunction with the bar to perform its function. The safety features, including the chain brake, are designed to protect the user during operation.

Other notable components include the air filter, which ensures optimal engine performance by keeping contaminants at bay, and the fuel system, responsible for providing the necessary energy. Regular inspection and maintenance of these elements will lead to a longer lifespan and more reliable performance of your equipment.

How to Read a Parts Diagram

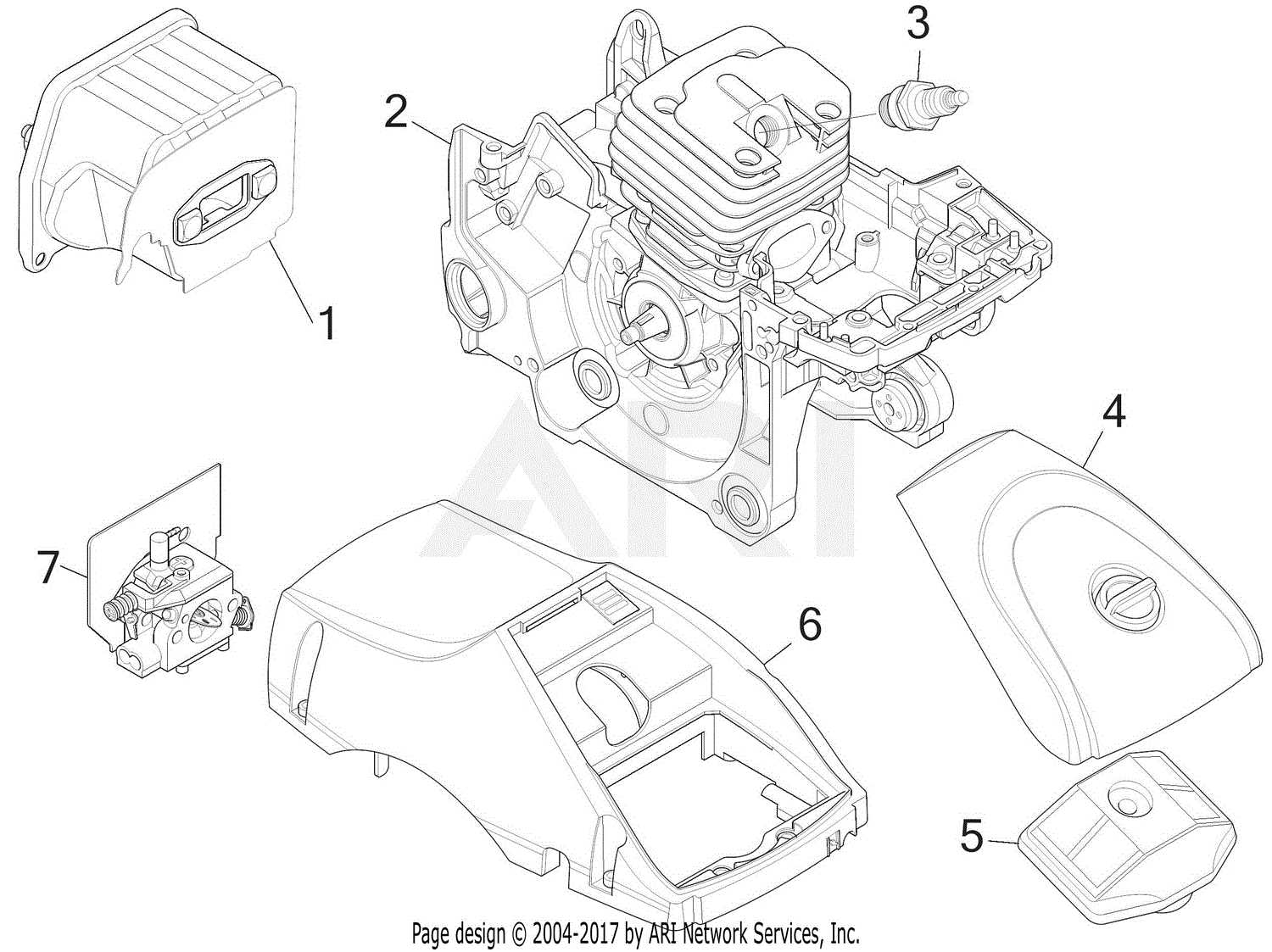

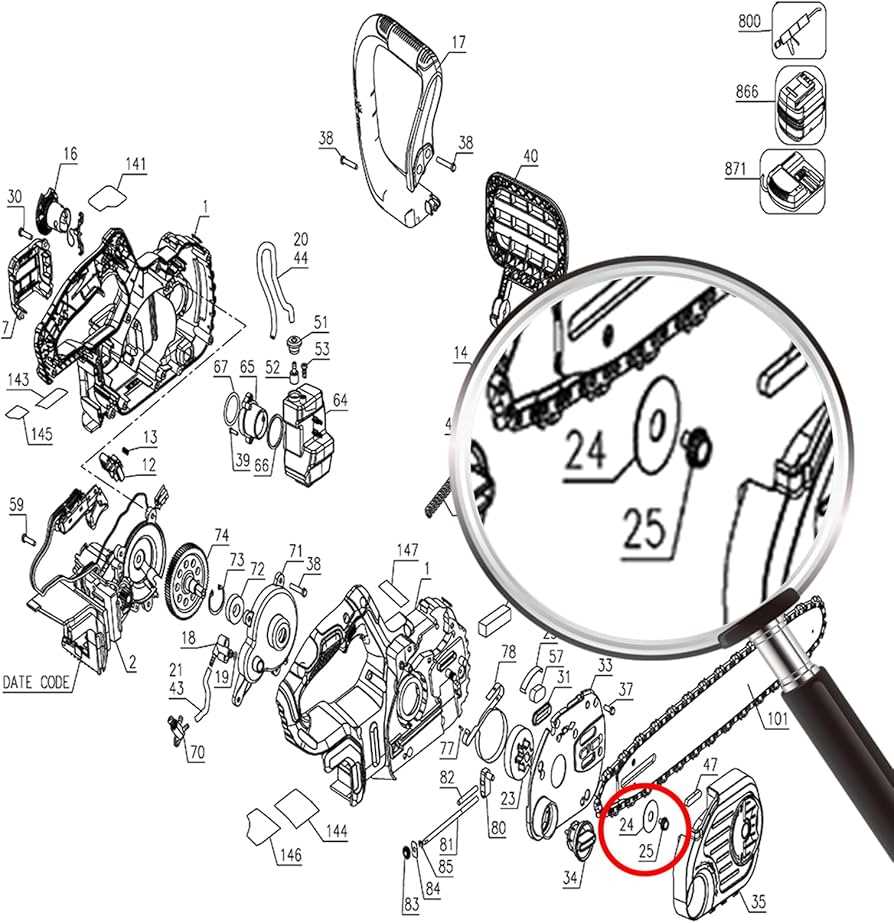

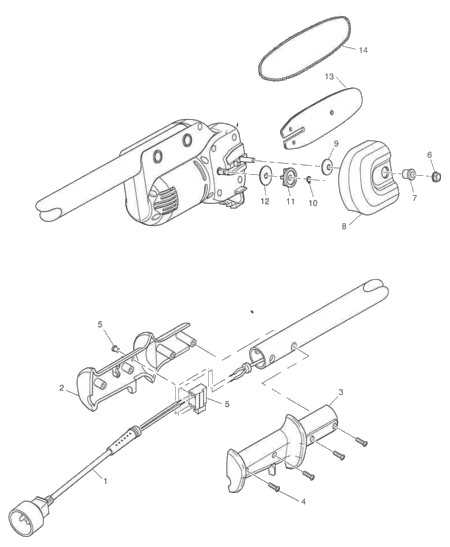

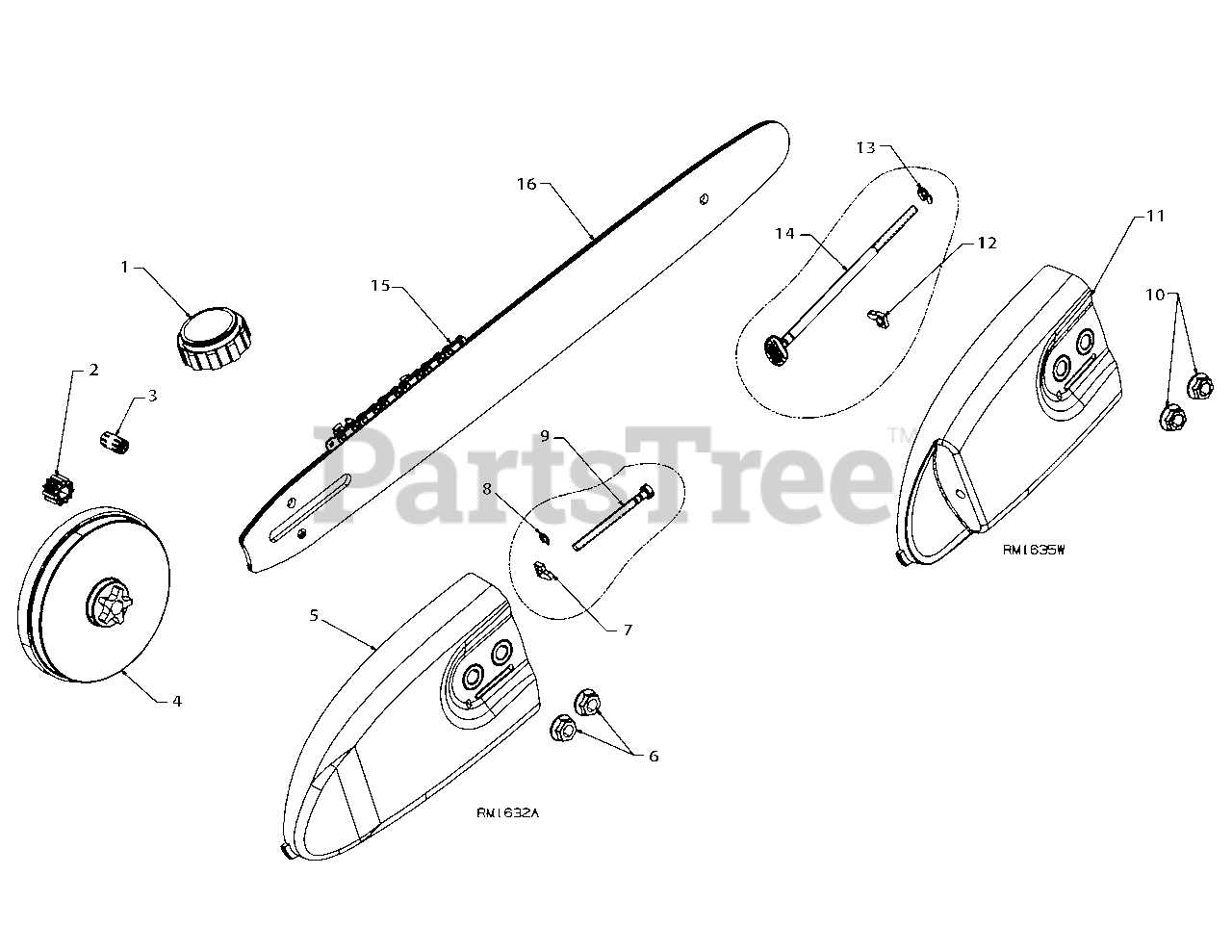

Understanding an illustration that displays the various components of a device can significantly enhance your ability to maintain and repair it. These visual guides typically provide a detailed representation of the elements involved, helping users identify each piece and its corresponding function. Grasping the structure and symbols used in such visuals is essential for effective troubleshooting and part replacement.

Key Elements of the Illustration

When examining a component layout, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Often, each part will be marked with a unique identifier, usually a number or letter, which corresponds to a list detailing specifications. |

| Legend | A legend is often included, explaining symbols used for various types of components and their materials. |

| Orientation | The orientation of the illustration is crucial; ensure you are viewing it from the correct angle to match the physical setup. |

Steps to Interpret the Visual

To effectively utilize the layout for your needs, follow these steps:

- Begin by identifying the main components and their labels.

- Cross-reference the labels with the accompanying list for specific details.

- Use the legend to understand any symbols that may not be immediately clear.

- Take note of any assembly instructions or sequences that may be indicated.

Common Chainsaw Issues Explained

Understanding the frequent problems that can arise with cutting tools is essential for maintaining their efficiency and longevity. Various factors can contribute to performance issues, ranging from mechanical failures to improper usage. By recognizing these common challenges, users can take proactive steps to ensure smooth operation.

Typical Problems and Their Causes

- Engine Difficulties: Often caused by fuel issues, such as old or contaminated gasoline.

- Starting Problems: Can result from a faulty spark plug or carburetor issues.

- Chain Slippage: Usually occurs due to improper tension or worn components.

- Overheating: Often linked to insufficient lubrication or air blockage.

Troubleshooting Tips

- Regularly inspect and replace fuel to ensure optimal combustion.

- Check and clean the spark plug periodically.

- Maintain the correct chain tension according to the manufacturer’s guidelines.

- Ensure proper lubrication and clean air filters to prevent overheating.

Maintaining Your Remington Chainsaw

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular attention to maintenance tasks ensures that your tool operates smoothly, reducing the likelihood of issues during use. A well-maintained unit not only enhances efficiency but also guarantees safety during operation.

Routine Inspections

Conducting regular inspections is crucial. Check for wear and tear on components, ensuring everything is functioning as intended. Pay close attention to blades and fuel systems, as these are vital for effective operation.

Cleaning and Lubrication

Keep your equipment clean to prevent debris buildup that could hinder performance. Regularly lubricate moving parts to reduce friction and wear. Using high-quality lubricants will ultimately extend the lifespan of your tool.

Ordering Replacement Parts Easily

Finding the right components for your equipment can be a straightforward process when you know where to look. By leveraging the right resources and following a few simple steps, you can ensure that you get the exact items you need without unnecessary hassle. This guide will help you navigate the ordering process effectively.

Steps to Simplify Your Order

Start by identifying the specific items required for your machinery. Once you have a clear understanding of what you need, follow these steps:

| Step | Action |

|---|---|

| 1 | Consult your user manual to find the correct specifications. |

| 2 | Visit authorized retailers or reputable online stores. |

| 3 | Use part numbers to ensure you are selecting the right items. |

| 4 | Add the components to your cart and review your order. |

| 5 | Complete your purchase and track shipping for updates. |

Tips for a Successful Purchase

When ordering, keep the following tips in mind to enhance your experience:

- Verify the return policy in case of incorrect items.

- Look for customer reviews to gauge the reliability of sellers.

- Consider bulk ordering if you anticipate needing several items.

Tools for Chainsaw Repairs

Maintaining your outdoor power equipment requires specific tools to ensure efficient repairs and optimal performance. Having the right instruments on hand can simplify tasks and enhance safety during maintenance. Understanding these tools can help extend the lifespan of your equipment.

Essential Tools

- Wrenches: Necessary for loosening and tightening various components.

- Screwdrivers: Crucial for adjusting or replacing screws in the machinery.

- File: Useful for sharpening blades and enhancing cutting efficiency.

Safety Gear

- Gloves: Protect your hands from sharp edges and debris.

- Goggles: Shield your eyes from flying particles during repairs.

- Ear Protection: Minimize noise exposure during operation.

Tips for Safe Chainsaw Operation

Operating a powerful cutting tool requires attention and respect for safety protocols to prevent accidents and injuries. Understanding the necessary precautions and best practices can significantly enhance your experience and ensure a secure working environment.

1. Wear Protective Gear: Always equip yourself with appropriate safety equipment such as goggles, gloves, ear protection, and sturdy boots. This gear minimizes the risk of injury.

2. Maintain a Clear Workspace: Ensure that your surroundings are free from obstacles and debris. A clutter-free area allows for better maneuverability and reduces hazards.

3. Inspect the Tool Before Use: Conduct a thorough inspection to check for any damage or wear. Ensure that all components are functioning correctly to prevent malfunctions during operation.

4. Follow Proper Techniques: Familiarize yourself with the correct handling techniques. Maintain a firm grip, stand securely, and always cut at waist height to maintain control.

5. Stay Focused: Avoid distractions while operating the equipment. Concentration is key to recognizing potential dangers and responding appropriately.

6. Keep Others at a Safe Distance: Establish a safety perimeter around your working area. Ensure that bystanders maintain a safe distance to avoid accidents.

7. Be Aware of Your Environment: Pay attention to your surroundings, including weather conditions and nearby obstacles, to anticipate and mitigate potential risks.

By implementing these guidelines, you can create a safer working environment and enhance your overall effectiveness while using powerful cutting equipment.

Upgrading Your Chainsaw Performance

Enhancing the efficiency of your cutting tool can significantly improve your overall experience and productivity. By focusing on key components and techniques, you can achieve a noticeable boost in power and precision. Whether you’re a weekend warrior or a professional, understanding how to optimize your equipment is essential for top-notch performance.

One of the most impactful upgrades involves the cutting mechanism. Consider investing in a high-quality blade that offers superior sharpness and durability. A well-maintained edge reduces friction, allowing for smoother cuts and less wear on the engine.

Another crucial area is the motor. Upgrading to a more robust engine can provide the ultimate strength needed for tougher tasks. Additionally, regular maintenance, such as cleaning air filters and spark plugs, can enhance performance and extend the lifespan of your tool.

Lastly, don’t overlook the importance of proper lubrication. Using the right oils and greases can minimize friction between moving parts, resulting in smoother operation and increased efficiency. Overall, these enhancements will lead to a more reliable and powerful experience.