In the realm of outdoor equipment, having a comprehensive grasp of the individual elements that contribute to functionality is essential. These instruments are composed of various sections that work in harmony, ensuring efficiency and reliability during operation. Gaining insight into how each segment operates not only aids in maintenance but also enhances overall performance.

Every machine consists of crucial units, from the engine assembly to the cutting mechanism, each serving a specific purpose. Identifying these components enables users to troubleshoot issues effectively and to make informed decisions regarding repairs or replacements. Whether you’re a novice or an experienced user, familiarizing yourself with the layout and function of these units can significantly improve your experience.

By exploring the intricate design and arrangement of these essential parts, one can unlock the potential of their equipment. A well-informed operator is better equipped to maximize the longevity and effectiveness of their tools. Thus, understanding the assembly’s configuration becomes not just beneficial, but indispensable for anyone seeking optimal performance from their machinery.

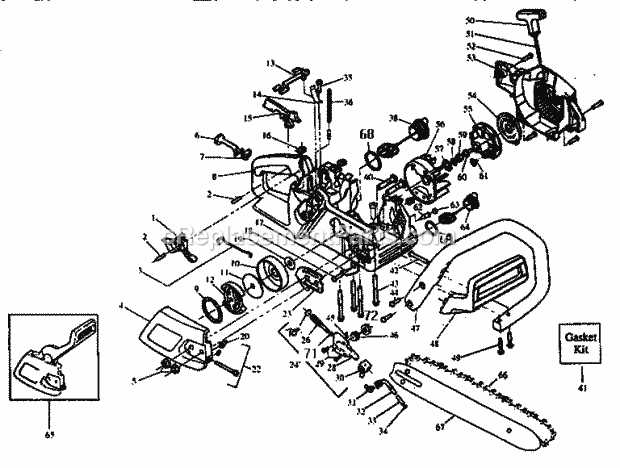

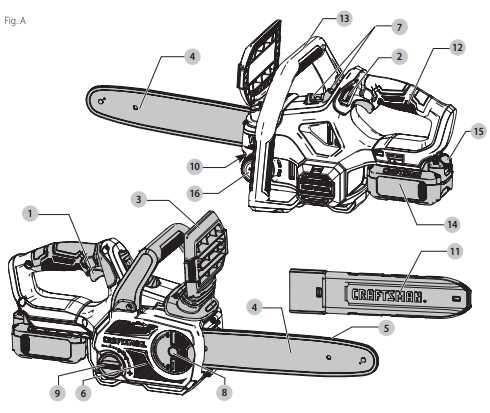

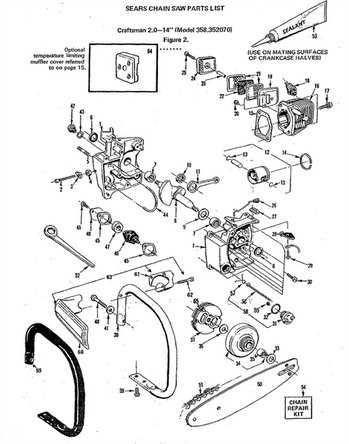

Understanding Craftsman Chainsaws

This section delves into the intricate workings and components of high-performance cutting tools designed for various tasks. Knowing how these devices function enhances user experience and maintenance, ensuring longevity and efficiency in every cut.

Proper comprehension of the elements that make up these powerful machines is essential for both novice and experienced users. Familiarity with the structure allows for effective troubleshooting and repairs, ultimately improving overall functionality.

| Component | Function |

|---|---|

| Engine | Powers the tool and provides necessary torque. |

| Guide Bar | Supports the cutting chain and guides its movement. |

| Cutting Chain | Engages in the cutting process by rotating around the guide bar. |

| Chain Brake | Stops the chain quickly for safety during operation. |

| Fuel System | Supplies the engine with necessary fuel and air mixture. |

By understanding these key components, users can make informed decisions regarding maintenance and repairs, ensuring their tools remain reliable for years to come.

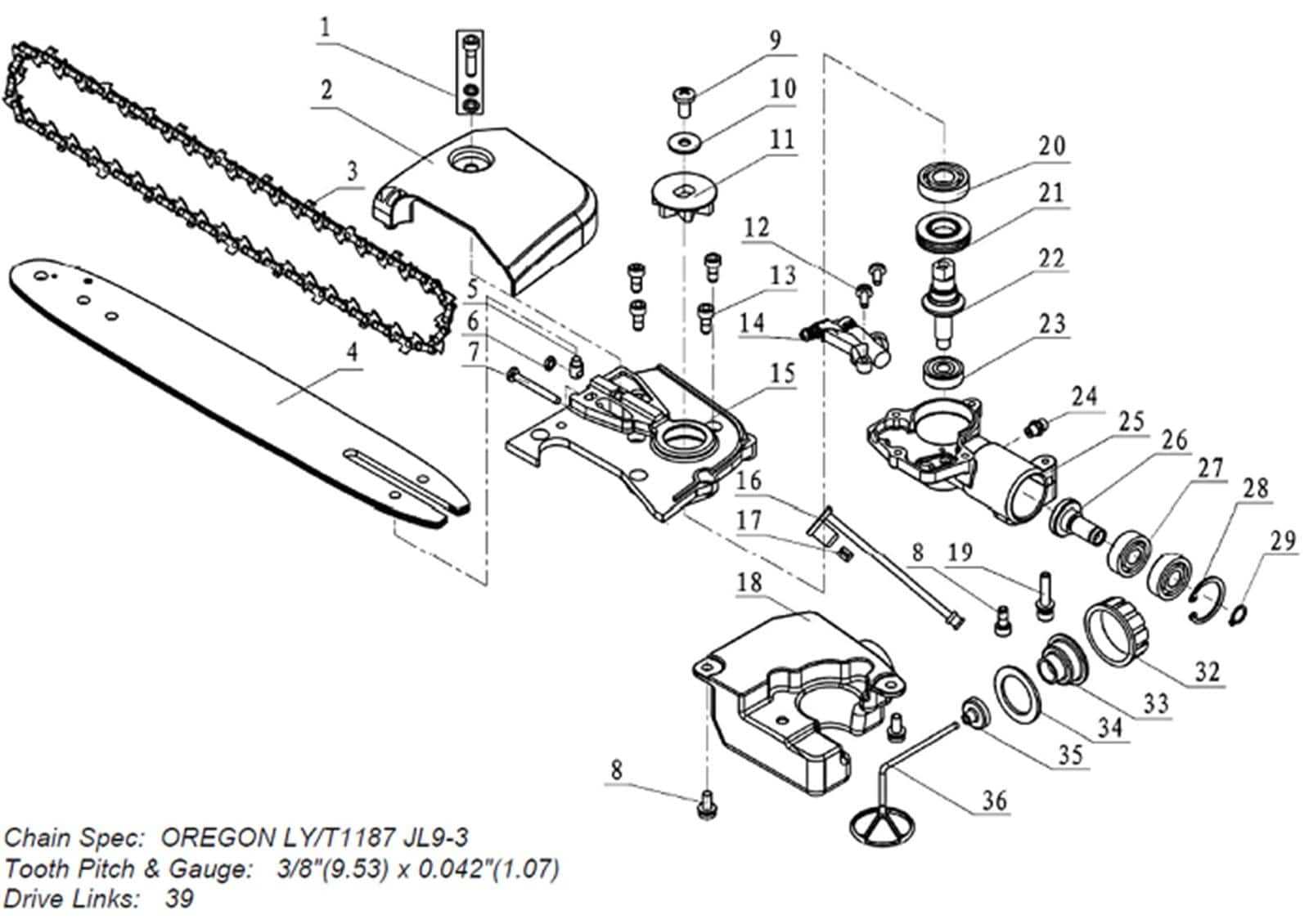

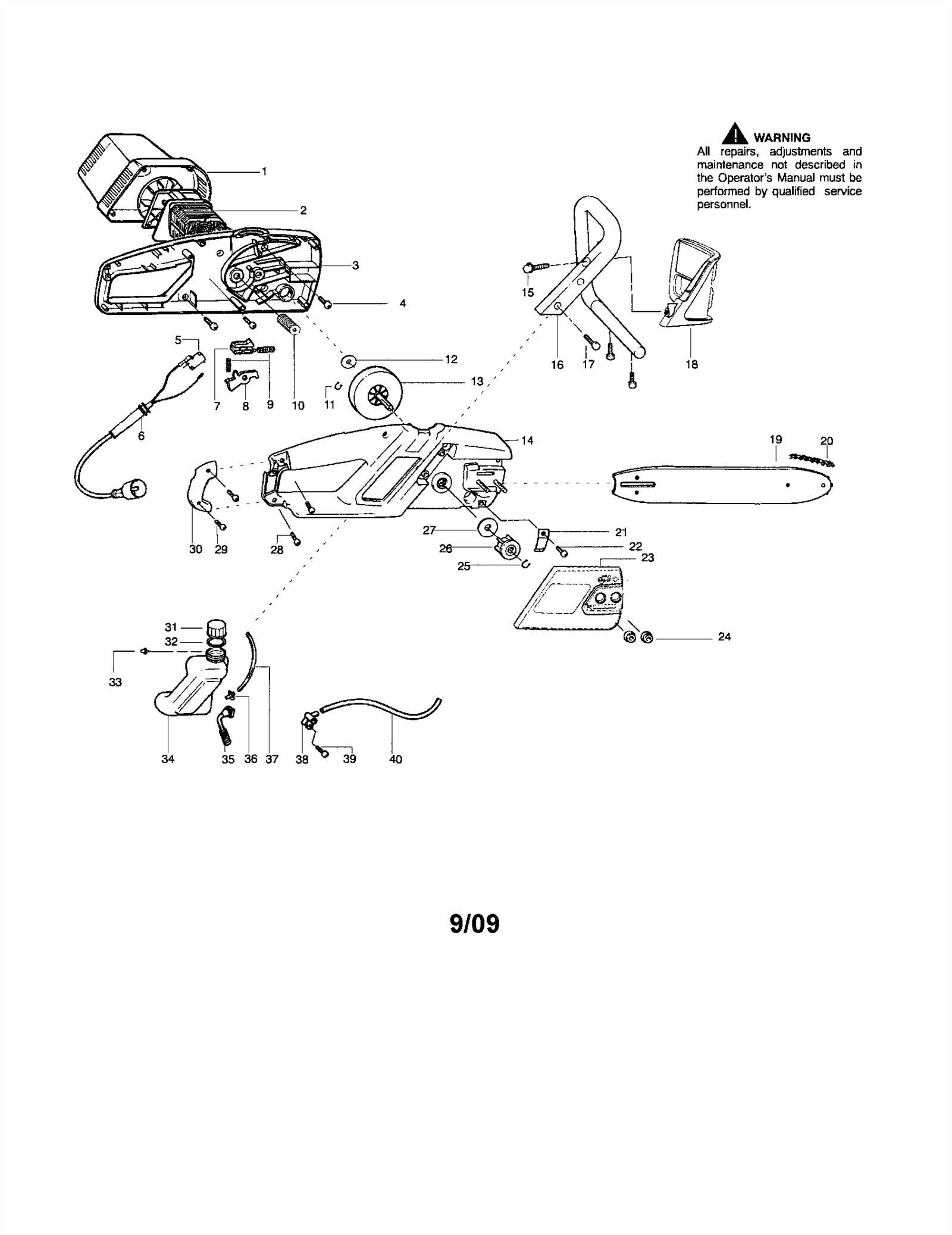

Key Components of Chainsaws

Understanding the essential elements of a cutting tool is crucial for both maintenance and effective usage. Each component plays a significant role in the overall functionality and performance, ensuring that the equipment operates efficiently and safely. Below are the primary parts that contribute to the tool’s operation.

Essential Elements

- Engine: The powerhouse that drives the entire mechanism, available in various types, including gas and electric.

- Guide Bar: The elongated piece that supports the cutting chain, available in different lengths for various tasks.

- Cutting Chain: A series of interlinked teeth that perform the actual cutting; its design varies for different applications.

- Chain Brake: A safety feature designed to stop the chain in case of kickback or sudden movement.

- Throttle Trigger: The control mechanism that allows the operator to adjust the speed of the engine.

Supporting Components

- Air Filter: Prevents dirt and debris from entering the engine, ensuring smooth operation.

- Fuel Tank: Holds the mixture of fuel and oil, necessary for engine performance.

- Handle: Provides grip and control, allowing for precision during operation.

- Oil Pump: Lubricates the chain for optimal performance and longevity.

- Starter Mechanism: Initiates the engine’s operation, critical for ignition.

Each of these components plays a vital role in the effective functioning of the tool, contributing to its performance, safety, and user-friendliness. Regular maintenance of these parts ensures longevity and reliability, making it essential for users to familiarize themselves with their functions.

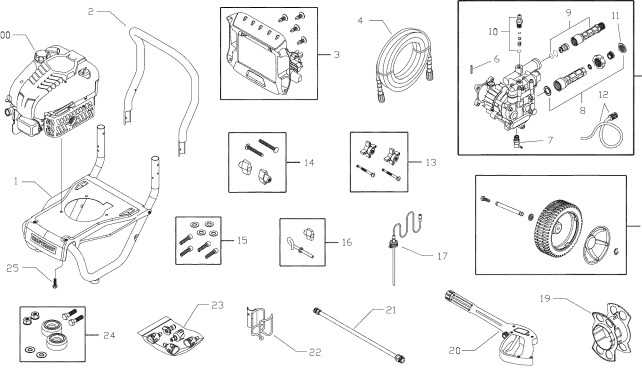

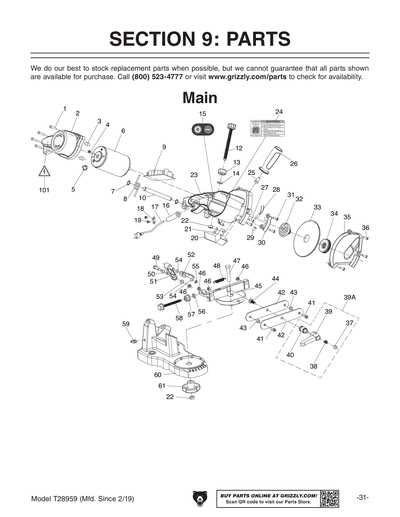

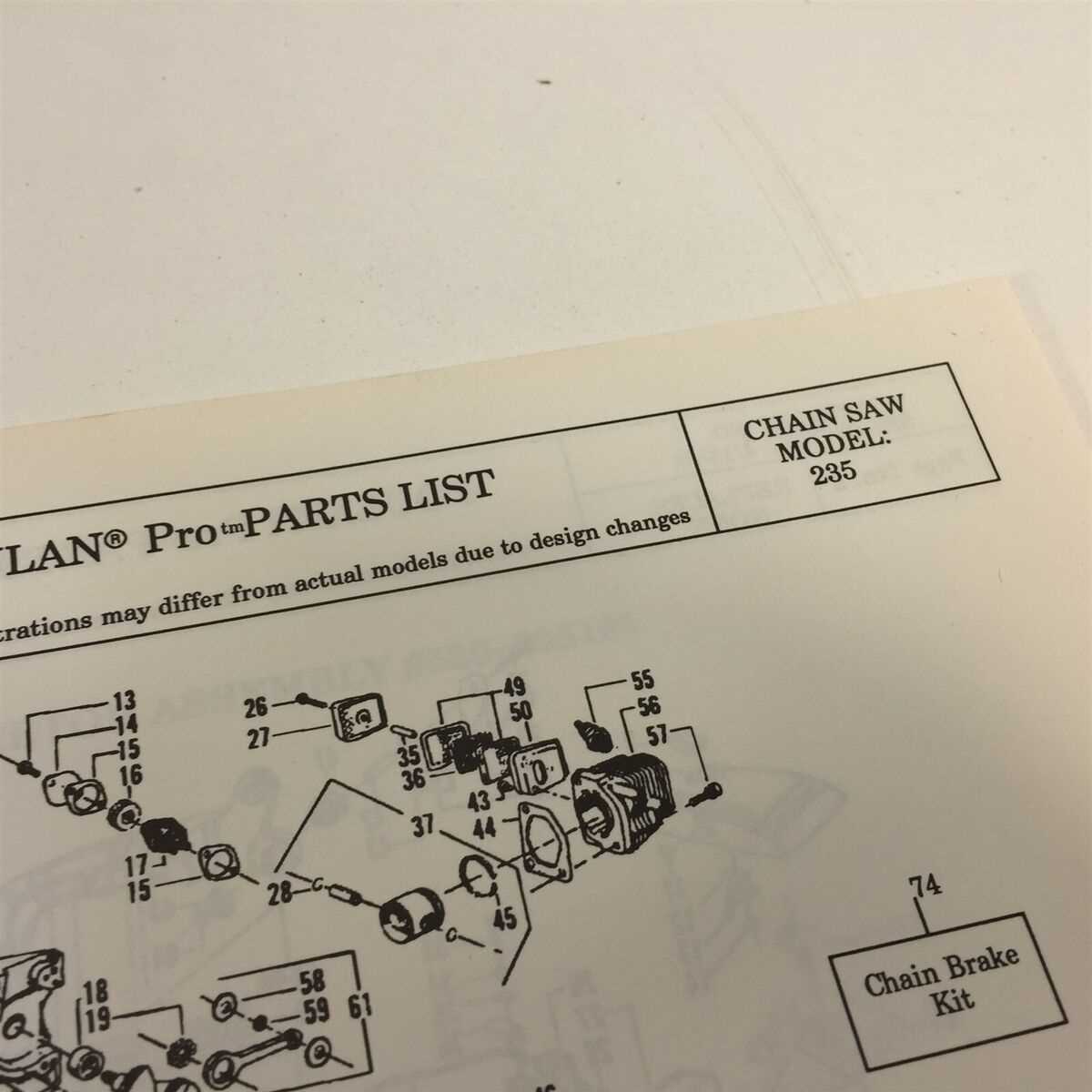

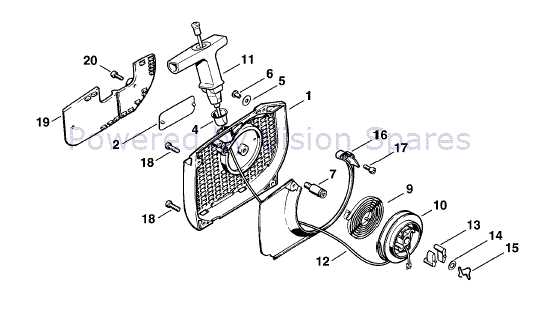

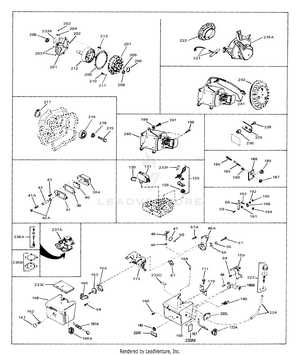

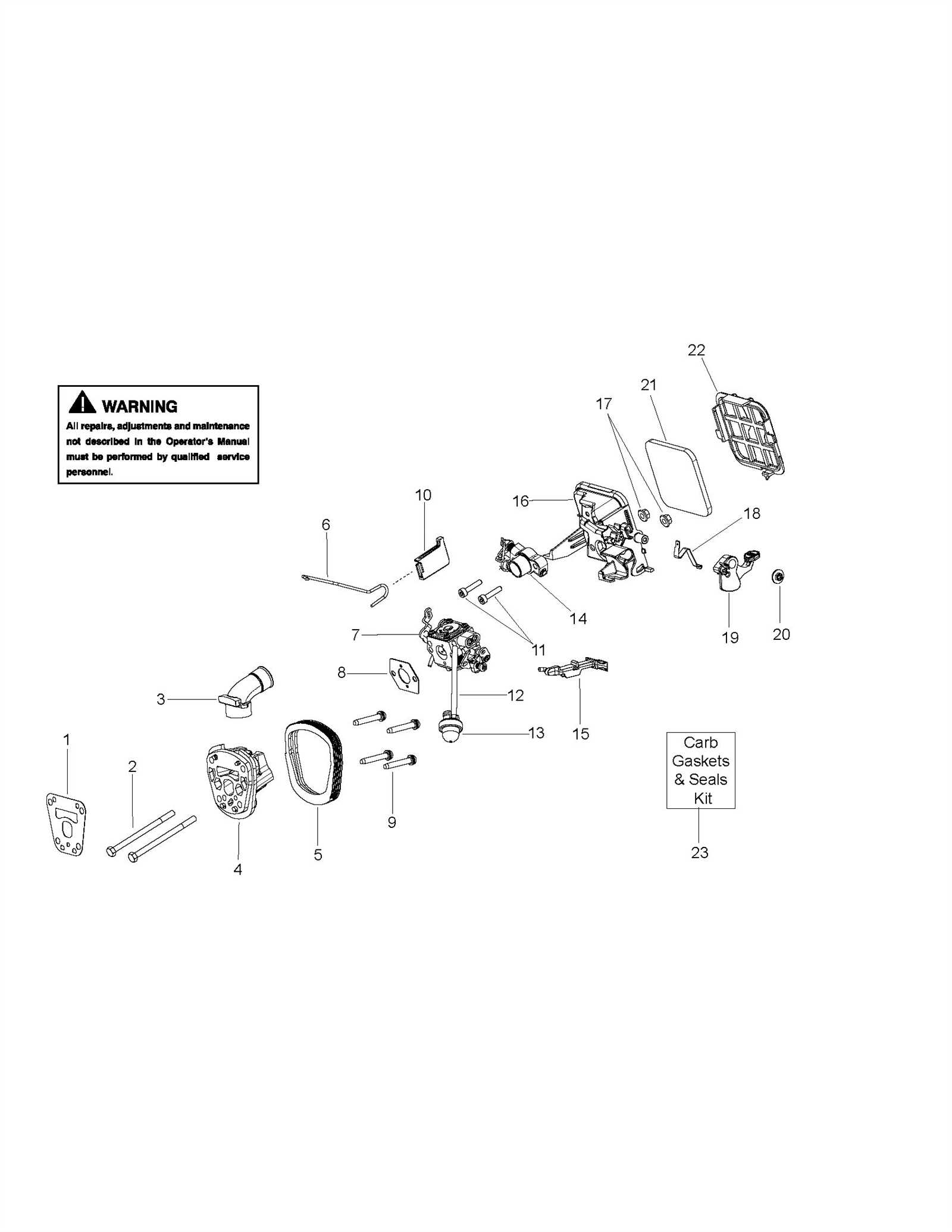

How to Read Parts Diagrams

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear view of each element’s placement and function, helping users identify the necessary items for a specific task. By grasping how to interpret these visuals, you can streamline your restoration efforts and ensure everything fits together correctly.

Familiarize Yourself with Symbols: Various symbols and notations are commonly used in these representations. Each symbol corresponds to a specific element, so taking the time to learn what each one means will enhance your comprehension.

Identify the Key: Most illustrations include a legend or key that explains the various components. This reference guide is invaluable for understanding how different parts interact with one another and assists in pinpointing the exact pieces you need.

Follow the Flow: Pay attention to how the elements are arranged. Often, the layout will show the sequence of assembly or the way components connect. Recognizing this flow can be critical when you’re reassembling a unit or troubleshooting an issue.

Take Notes: As you analyze the visual, jot down notes or highlight areas of particular interest. This can help reinforce your understanding and serve as a quick reference when you’re ready to start working on the project.

By mastering these techniques, you can effectively navigate any visual guide, making your repair and maintenance tasks much more manageable and efficient.

Common Issues with Chainsaw Parts

Understanding frequent challenges encountered with power equipment can enhance performance and longevity. Identifying these issues allows for timely interventions, preventing more severe damage and ensuring smooth operation.

- Fuel System Problems:

- Clogs in the fuel filter

- Improper fuel mixture

- Ignition Failures:

- Faulty spark plug

- Wiring issues

- Chain Malfunctions:

- Worn-out links

- Improper tension

- Bar Issues:

- Uneven wear

- Dirt buildup

Regular maintenance and inspection are key to mitigating these common pitfalls. Taking proactive steps ensures optimal functionality and extends the lifespan of the equipment.

Maintenance Tips for Longevity

Proper upkeep is essential to extend the lifespan of your equipment. Regular attention not only enhances performance but also minimizes the risk of malfunctions.

- Regularly clean all components to prevent debris accumulation.

- Inspect and tighten fasteners to ensure stability during use.

- Lubricate moving parts to reduce friction and wear.

- Replace worn or damaged components promptly to avoid further issues.

- Store the equipment in a dry, safe place to prevent rust and corrosion.

Implementing these practices will help you maintain peak performance over time, ensuring reliability when needed most.

Identifying Replacement Parts

Understanding how to recognize components in your equipment is essential for maintenance and repair. When a tool shows signs of wear or malfunction, knowing which elements need replacement can save both time and resources. This section will guide you through the process of identifying the necessary items to restore your device to optimal working condition.

Common Indicators of Wear

Before diving into specifics, it’s crucial to be aware of the typical signs that suggest a component may need to be changed. Unusual noises, decreased performance, or visible damage are often the first clues. Regularly inspecting your equipment can help you catch these issues early, ensuring you can address them before they escalate.

Utilizing Reference Guides

Once you’ve identified a potential problem, consulting reference materials is key. Exploded views and component lists can provide clarity on the specific items in your tool. Familiarizing yourself with these resources will enable you to pinpoint the exact replacements required and streamline the repair process.

Tools Needed for Repairing Chainsaws

Effective maintenance and repair of power tools require a specific set of instruments. Having the right tools not only simplifies the process but also ensures safety and precision during work. Below is a comprehensive list of essential equipment for tackling various repairs and upkeep.

Essential Tools

- Wrenches: Useful for loosening and tightening bolts and nuts.

- Screwdrivers: Flathead and Phillips for various screw types.

- Pliers: Handy for gripping, twisting, and cutting wires or small parts.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Chain Breaker: Facilitates the removal and installation of the cutting link.

- File: Essential for sharpening the cutting edges for optimal performance.

Safety Equipment

- Safety Glasses: Protects eyes from debris during repairs.

- Gloves: Offers grip and protection from sharp components.

- Hearing Protection: Reduces noise exposure when testing the tool.

By ensuring you have these tools at hand, you will be well-prepared to perform effective maintenance and repairs, enhancing the longevity and performance of your equipment.

Safety Precautions During Repairs

When performing maintenance or repairs on power tools, it is essential to prioritize safety to prevent accidents and ensure a secure working environment. Understanding and following specific precautions can significantly reduce the risk of injury and promote effective repair processes.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure that the tool is turned off and unplugged before beginning any work to prevent accidental activation.

- Work in a well-lit and organized area to avoid tripping hazards and to clearly see your tasks.

- Keep a first aid kit nearby in case of minor injuries.

In addition to basic precautions, following specific guidelines will further enhance safety:

- Read the manufacturer’s manual to understand the tool’s components and repair procedures.

- Use the right tools for the job, ensuring they are in good condition to avoid malfunctions.

- Never rush through repairs; take your time to focus on each step.

- Be cautious of sharp edges and moving parts during the disassembly and reassembly process.

- Keep children and pets away from the work area to minimize distractions and risks.

By adhering to these safety measures, you can create a safer working environment and ensure that maintenance tasks are performed effectively and efficiently.

Resources for Further Learning

Expanding your knowledge on equipment maintenance and repair can greatly enhance your skills and confidence. There are numerous materials available, including online tutorials, manuals, and instructional videos, that provide in-depth insights into the mechanisms and functionality of various tools.

Consider exploring specialized forums and communities where enthusiasts share their experiences and tips. Books focused on repair techniques and safety measures can also serve as invaluable resources. Additionally, hands-on workshops or local classes can offer practical experience and expert guidance.

Lastly, reputable websites and manufacturers often provide detailed guides and troubleshooting advice, allowing you to delve deeper into specific challenges and solutions. By leveraging these resources, you can ultimately improve your proficiency and understanding in the field.