In the world of gardening and landscaping, the efficient operation of trimming tools is essential for maintaining neat and tidy outdoor spaces. Knowing how each component functions and interacts with others can significantly enhance the user experience and tool longevity. This section explores the intricate relationships between various elements involved in the operation of these essential devices.

By familiarizing yourself with the different sections and features of a trimming machine, you can identify potential issues and address them promptly. This knowledge not only helps in effective maintenance but also allows for informed decisions when it comes to replacements or upgrades. Understanding the layout of these devices can ultimately lead to improved performance and satisfaction in their use.

Whether you are a seasoned professional or a novice gardener, having a comprehensive grasp of how each element works together empowers you to handle your equipment with confidence. Embracing this knowledge ensures that your gardening tasks are performed with efficiency and precision.

Understanding the essential components of outdoor power tools is crucial for maintaining their efficiency and longevity. This section provides an overview of frequently needed elements that ensure optimal functionality, focusing on typical replacements that users may encounter during routine upkeep.

| Component | Description | Function |

|---|---|---|

| String Trimmer Line | Flexible cord used for cutting grass and weeds. | Responsible for trimming and edging tasks. |

| Cutting Head | Attachment housing the line or blades. | Facilitates effective cutting by holding the line securely. |

| Air Filter | Device that cleans the air entering the engine. | Prevents dirt and debris from affecting performance. |

| Fuel Filter | Filter that removes impurities from fuel. | Ensures clean fuel reaches the engine, enhancing efficiency. |

| Starter Rope | Cord used to start the engine manually. | Engages the engine when pulled. |

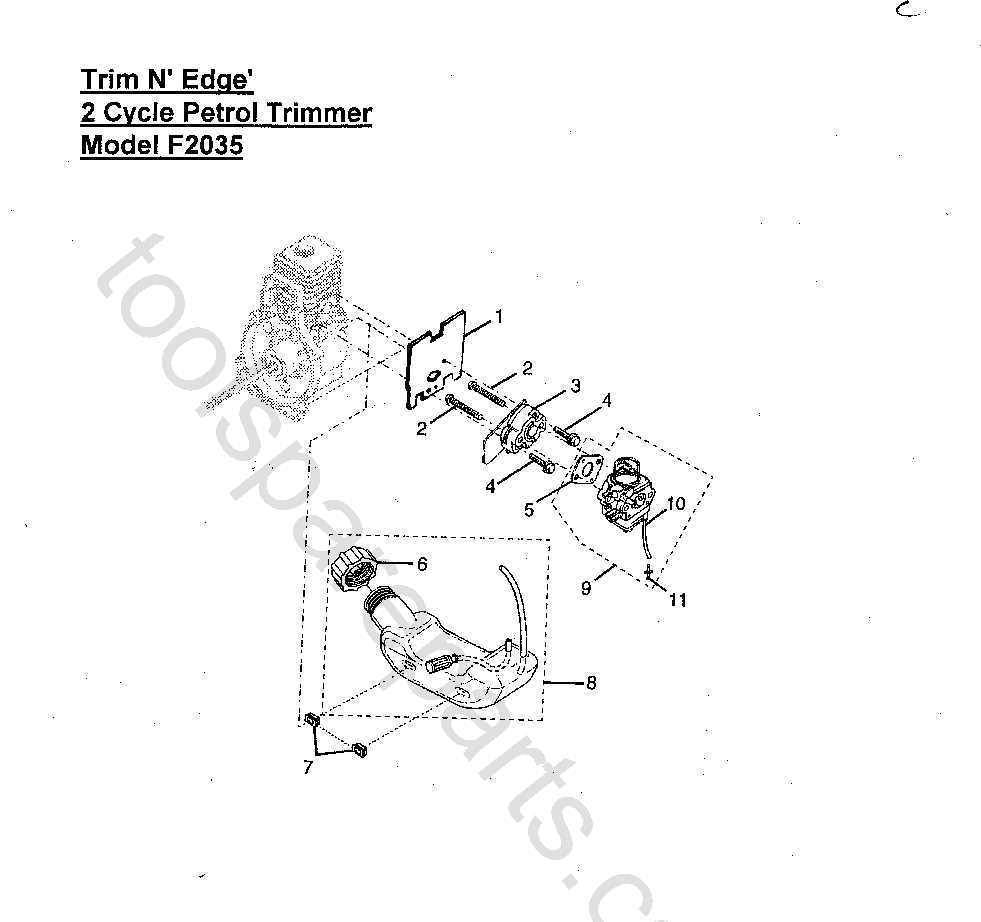

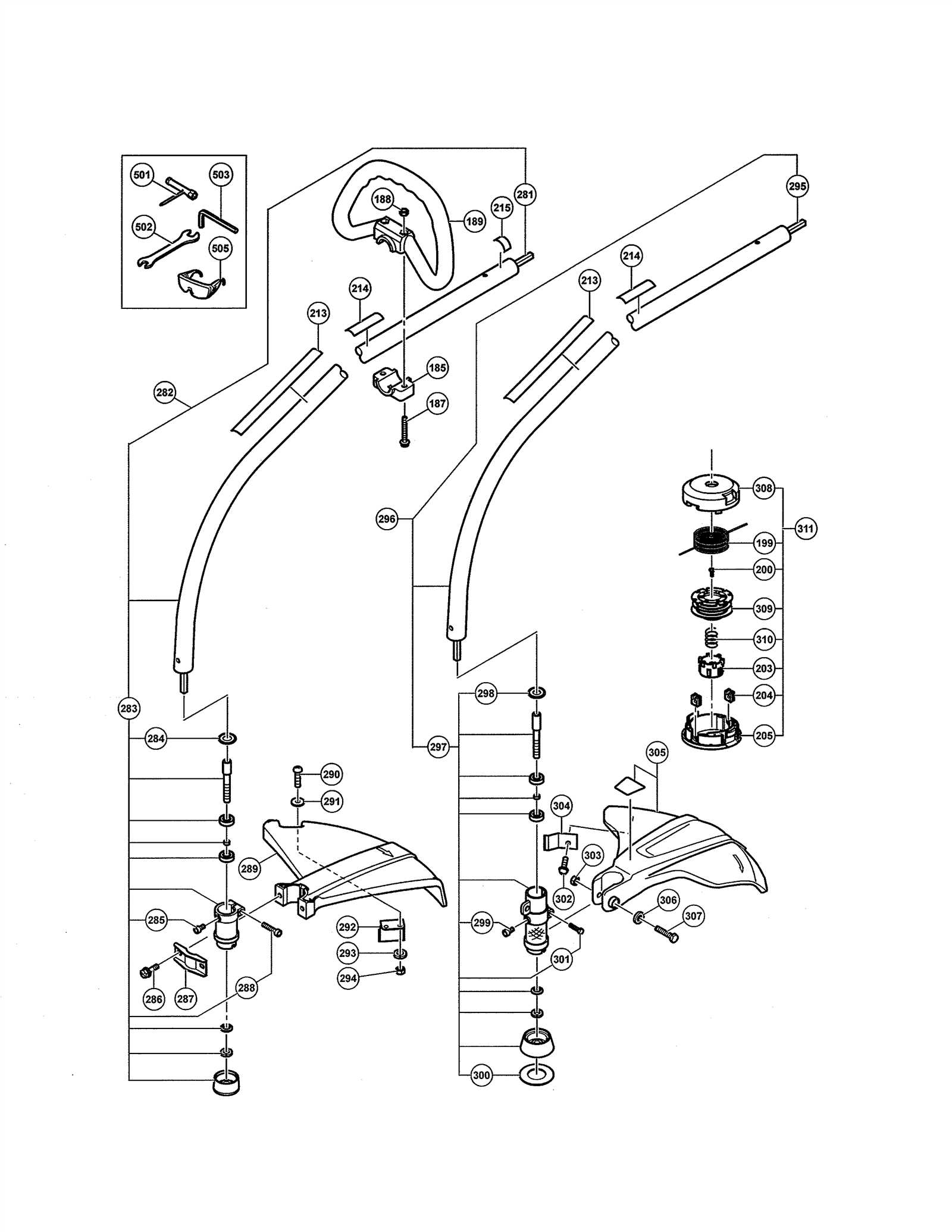

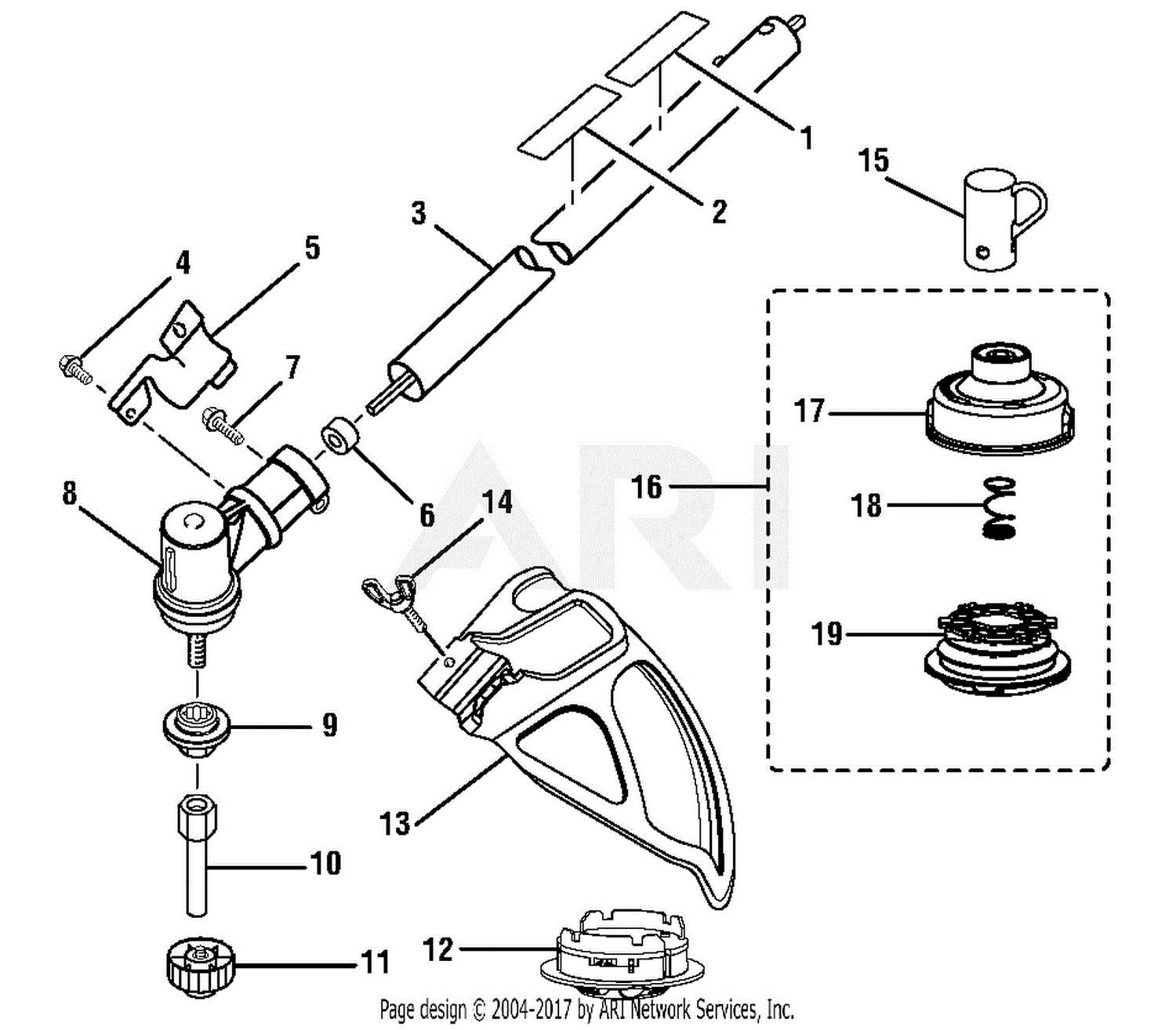

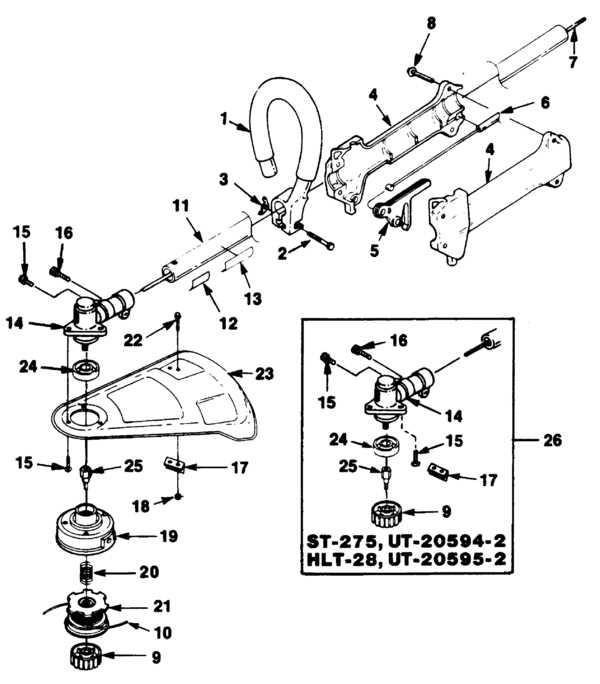

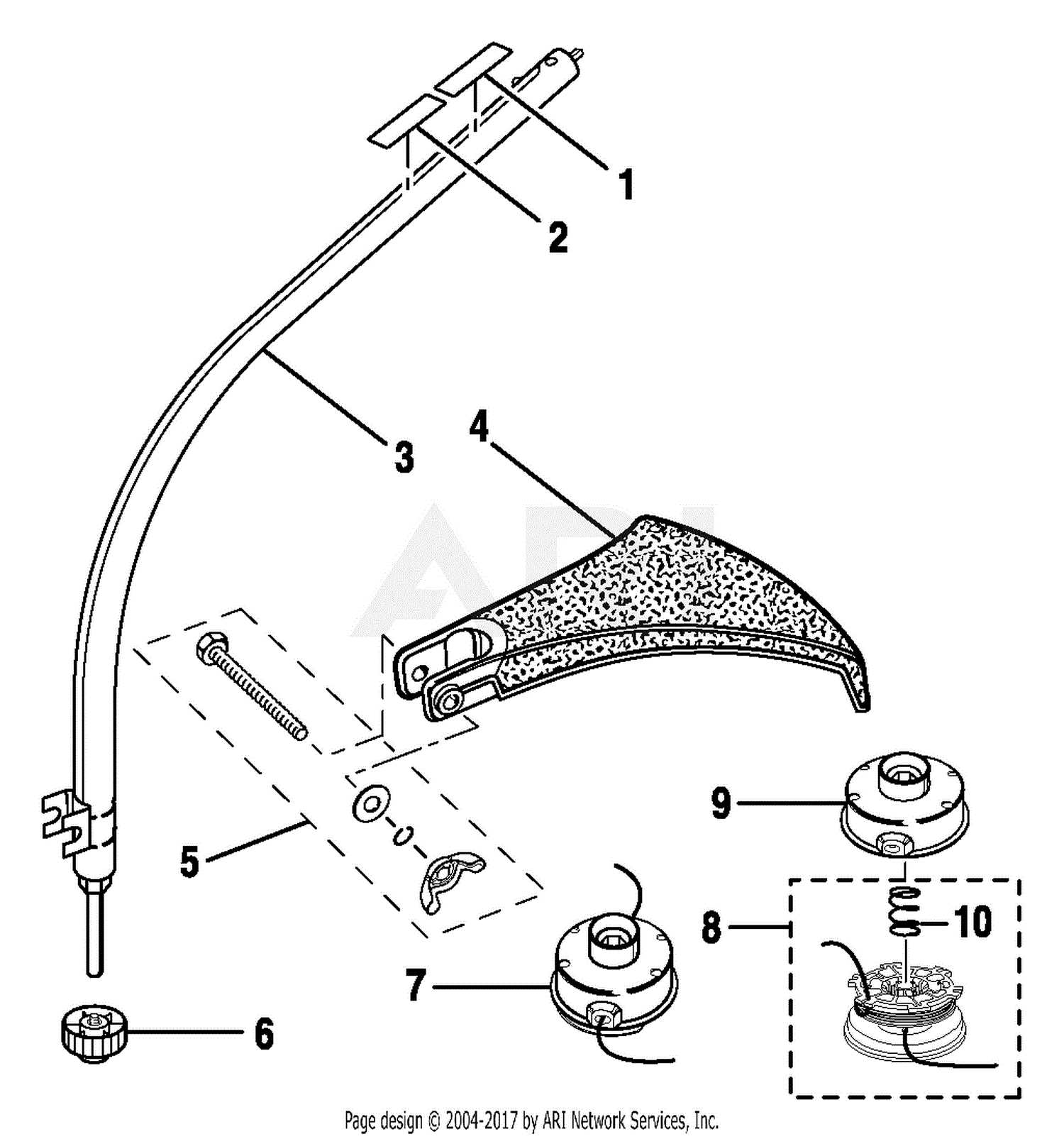

Exploring the Parts Diagram

Understanding the assembly of a cutting tool is essential for its effective maintenance and operation. Analyzing the schematic representation provides insights into each component’s role, ensuring that users can identify and troubleshoot issues efficiently.

Key Components and Their Functions play a vital role in the overall performance of the equipment. Each segment, from the engine to the handle, contributes uniquely to the functionality, affecting how the machine operates and handles various tasks.

By familiarizing oneself with the schematic layout, users can enhance their repair skills and extend the lifespan of their equipment. Recognizing the interplay between different elements not only aids in repairs but also empowers users to make informed decisions regarding replacements and upgrades.

Troubleshooting Part-Related Issues

When operating outdoor equipment, encountering problems related to components is common. Identifying and resolving these issues promptly can enhance the performance and longevity of your device. Below are some common concerns and their solutions.

Common Symptoms and Solutions

- Device Fails to Start:

- Check the fuel level and ensure it is fresh and appropriate for the engine.

- Inspect the spark plug for damage or wear and replace if necessary.

- Examine the ignition system to ensure it is functioning correctly.

- Reduced Power Output:

- Clean or replace the air filter to ensure proper airflow.

- Inspect the fuel lines for blockages or leaks that may hinder performance.

- Check for any obstructions in the cutting mechanism that may affect operation.

Maintenance Tips

- Regularly clean the equipment after use to prevent dirt buildup.

- Perform routine checks on all essential components to catch issues early.

- Keep the manufacturer’s manual on hand for specific troubleshooting guidance.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the long-lasting performance of your outdoor equipment. By following a few straightforward guidelines, you can enhance its durability and efficiency, preventing premature wear and tear.

Routine Checks

- Inspect components frequently for signs of damage or wear.

- Clean the exterior and internal parts to remove dirt and debris.

- Examine the fuel system for leaks or blockages.

Proper Storage

- Store in a dry and sheltered area to protect from the elements.

- Ensure the device is not exposed to extreme temperatures.

- Disconnect the power source when not in use for extended periods.

By implementing these maintenance practices, you can significantly extend the life of your equipment, ensuring it remains reliable and effective for many seasons to come.

Where to Find Genuine Parts

Finding authentic components for your gardening tools is essential for maintaining their performance and longevity. Quality replacements ensure your equipment operates efficiently and reliably, preventing potential issues in the future.

Here are some reliable sources for obtaining original components:

- Authorized Dealers: Visiting authorized retailers is one of the best ways to find genuine replacements. They offer a wide selection of original products and can provide expert advice.

- Manufacturer’s Website: Many manufacturers have online stores where you can browse and purchase official items directly. This option often provides the latest offerings and guarantees authenticity.

- Specialty Stores: Look for local stores that specialize in garden tools and equipment. These establishments often carry a variety of original components and can assist in identifying the correct items for your needs.

- Online Marketplaces: Websites like Amazon or eBay can be great resources, but it’s crucial to verify the seller’s credibility to ensure you receive genuine products. Check reviews and ratings before making a purchase.

- Repair Shops: Many repair shops for garden equipment have access to authentic components. They can also assist in installation if needed.

Choosing the right source is vital to ensuring the reliability of your tools. Always opt for established retailers or verified online platforms to guarantee quality and performance.

Step-by-Step Assembly Guide

This section provides a detailed guide to help you efficiently assemble your equipment. Following these instructions will ensure that all components fit together properly and function effectively. Each step is crucial for achieving optimal performance and longevity.

Preparing the Components

Before starting the assembly process, gather all necessary components and tools. Ensure that you have a clean workspace to facilitate an organized assembly experience. Reviewing the assembly instructions in advance can help you understand the sequence of the steps involved.

Assembly Process

Begin by connecting the main body of the equipment to the handle. Ensure that all fasteners are tightened securely. Next, attach the cutting mechanism, making certain that it is aligned correctly. Finally, check all connections and perform a quick test to ensure everything operates smoothly. If adjustments are needed, refer to the guidance provided in the manual.