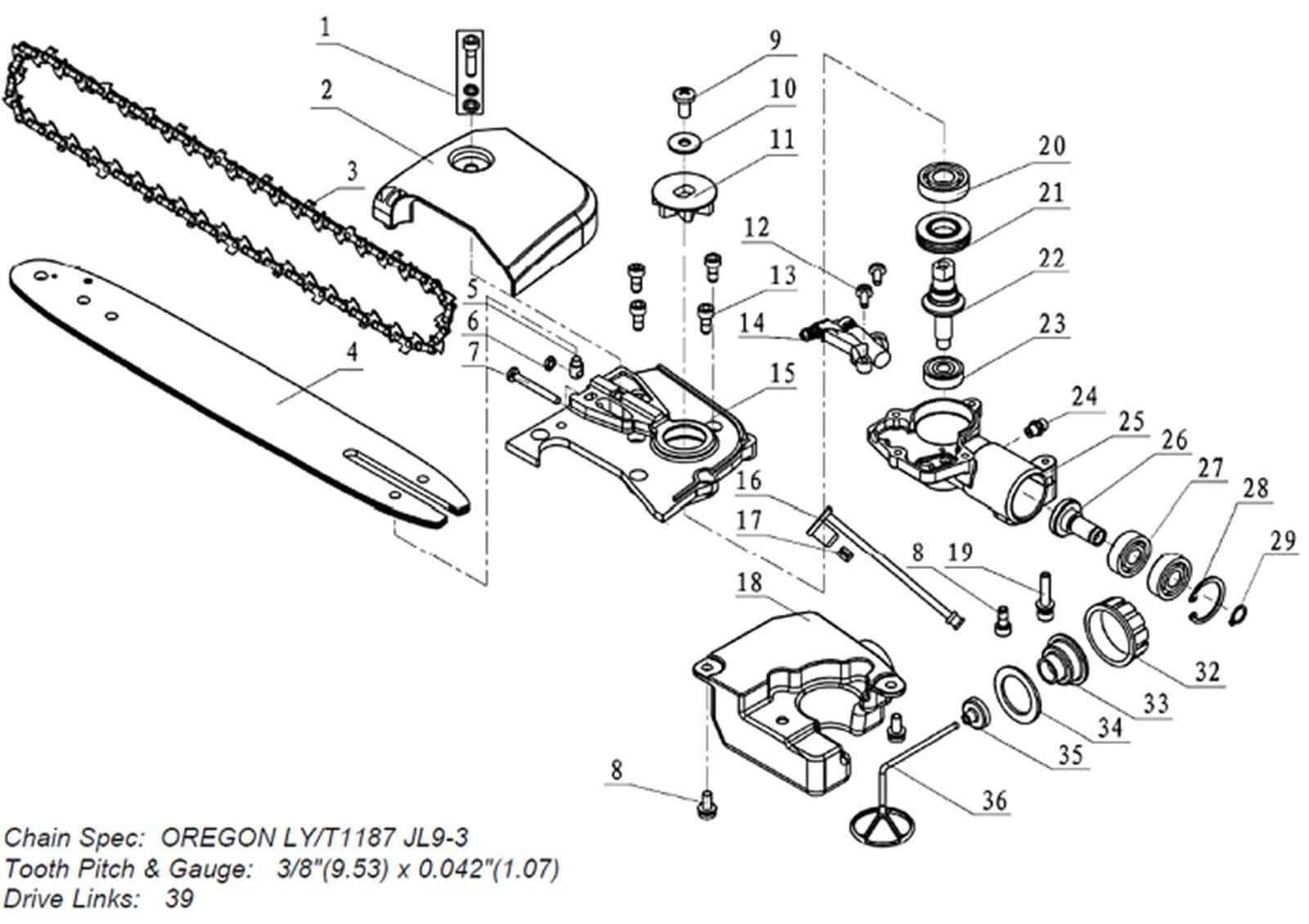

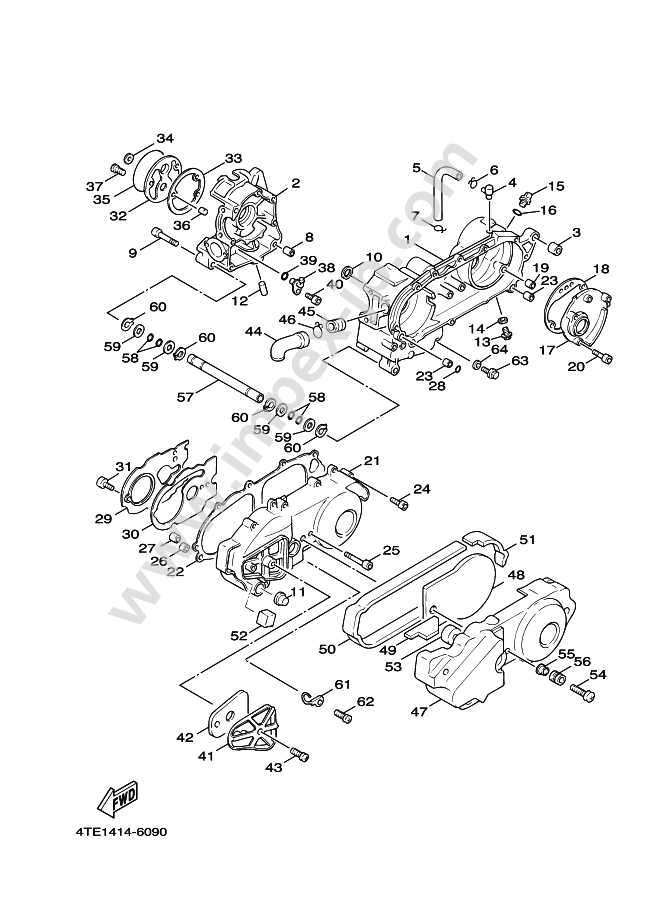

When it comes to maintaining and operating a reliable cutting instrument, a thorough comprehension of its individual elements is essential. Each segment plays a crucial role in ensuring optimal performance and longevity. By familiarizing oneself with the various components, users can enhance their experience and troubleshoot issues effectively.

Delving into the intricate assembly of such machinery reveals a complex network of parts, each contributing to the overall functionality. Recognizing how these elements interact can aid in identifying potential problems and facilitate smoother repairs. A clear representation of these components often serves as a valuable resource for both novices and seasoned operators alike.

Ultimately, having access to a detailed visual guide can transform the way users engage with their tools. It empowers them to take control of maintenance, ensuring that their equipment remains in peak condition. With the right knowledge at hand, the process of upkeep becomes not only manageable but also an opportunity to deepen one’s understanding of the craftsmanship involved.

Understanding Chainsaw Components

Every tool designed for cutting tasks is made up of various elements that work together to ensure efficiency and safety. Grasping how these components interact can enhance your experience and maintenance practices, leading to better performance and longevity of the equipment.

Main Elements of the Tool

The primary sections of this equipment include the motor, the cutting mechanism, and the control features. The motor generates power, while the cutting mechanism, typically a toothed blade, performs the actual cutting. Control features, such as the throttle and safety mechanisms, provide the user with command and protection during operation.

Support Structures

Support elements like the housing and the handle provide stability and comfort. The housing encases essential components, protecting them from debris and wear, while the handle ensures a secure grip for the user. Understanding these structures is crucial for effective handling and maintenance.

In summary, a comprehensive awareness of each element’s role not only facilitates better usage but also aids in identifying issues and performing necessary repairs, ensuring your tool remains reliable and efficient.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of equipment. They provide clarity and enhance understanding, making it easier to identify and address issues effectively.

- Facilitate accurate identification of individual elements

- Streamline the assembly and disassembly processes

- Enhance troubleshooting by highlighting potential failure points

- Support proper maintenance practices through clear instructions

- Empower users to order the correct replacements

Ultimately, these illustrations serve as an essential resource for both novices and experts, ensuring that tools remain in optimal condition for years to come.

Common Issues with Chainsaw Parts

Understanding the typical problems that can arise with these tools is essential for effective maintenance and troubleshooting. Identifying these issues can lead to enhanced performance and longevity of your equipment.

Frequent Problems

- Worn-out components that affect efficiency

- Fuel system blockages causing poor performance

- Chain tension irregularities leading to operational difficulties

- Electrical malfunctions disrupting ignition

Preventive Measures

- Regular inspection of key elements

- Ensuring proper lubrication to avoid wear

- Cleaning the air filter to maintain airflow

- Replacing damaged components promptly

Tools for Chainsaw Maintenance

Maintaining your cutting equipment is essential for optimal performance and longevity. Regular upkeep ensures that your machine operates efficiently and safely, preventing unexpected breakdowns and enhancing cutting capabilities. A well-maintained tool not only improves productivity but also contributes to user safety.

To achieve effective maintenance, several essential implements should be included in your toolkit. Wrenches and screwdrivers are crucial for tightening and loosening various components, while file sets are indispensable for keeping the cutting edges sharp. Regular sharpening is key to maintaining efficiency.

Moreover, cleaning brushes help remove debris from air filters and cooling fins, preventing overheating. Fuel stabilizers are also recommended to preserve fuel quality, especially during long periods of inactivity. Lastly, investing in protective gear ensures safety while performing maintenance tasks, providing necessary protection against accidents.

Replacing Chainsaw Components Safely

When it comes to maintaining your outdoor power tools, ensuring safety during component replacement is crucial. Proper precautions not only protect you but also enhance the longevity and performance of your equipment. Understanding the correct procedures and tools required for this task is essential.

First and foremost, always wear appropriate safety gear, including gloves and goggles, to shield yourself from potential hazards. Before starting any replacement, disconnect the power source to prevent accidental activation. Familiarize yourself with the tool’s manual to understand the specific components involved and their functions.

Additionally, organizing your workspace can significantly reduce the risk of accidents. Keep tools and replacement parts within reach and free from clutter. As you proceed with the replacement, take care to follow the manufacturer’s instructions meticulously, ensuring that each component is installed correctly to maintain optimal functionality.

Finally, once the new parts are installed, conduct a thorough inspection and test the equipment in a safe environment to confirm that everything operates as intended. By prioritizing safety and adherence to guidelines, you can effectively manage the replacement of components with confidence.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is essential for optimal performance and longevity. Fortunately, there are several avenues to explore when searching for the necessary replacements. Understanding where to look can save you time and ensure you find exactly what you need.

Online Retailers

One of the most convenient ways to find components is through online retailers. These platforms offer a wide variety of options and often provide detailed descriptions to help you make informed choices. Here are some popular online sources:

- Specialized hardware websites

- Large e-commerce platforms

- Manufacturer’s official sites

- Local and national parts suppliers

Local Stores and Repair Shops

Visiting local establishments can also be beneficial. These shops often carry inventory that may not be available online. Consider the following:

- Home improvement stores

- Independent repair shops

- Garden and outdoor equipment retailers

- Community marketplaces and swap meets

Exploring these options can help you find the right replacements to keep your tools in excellent condition.

Benefits of Regular Maintenance

Routine upkeep of your tools is essential for optimal performance and longevity. By engaging in consistent checks and care, you ensure that equipment operates smoothly, reducing the likelihood of unexpected failures and costly repairs.

Enhanced Performance: Regular maintenance boosts efficiency, allowing devices to function at their best. Well-maintained machinery often delivers superior results, improving overall productivity.

Increased Lifespan: Taking the time to care for your equipment can significantly extend its useful life. Addressing minor issues promptly prevents them from escalating into major problems that could necessitate replacement.

Safety Assurance: Well-maintained tools are safer to use. Regular inspections can identify wear and tear, minimizing the risk of accidents and ensuring a secure working environment.

Cost Savings: Investing time in routine care ultimately saves money. Preventative measures often outweigh the expenses of extensive repairs, keeping your budget intact while maximizing performance.

In summary, prioritizing regular maintenance not only enhances performance but also ensures safety and longevity, making it a wise investment for any operator.

Tips for Effective Troubleshooting

Troubleshooting equipment can be a daunting task, but a systematic approach can simplify the process significantly. By following a few key strategies, you can identify issues more efficiently and restore functionality with confidence.

- Understand the Basics: Familiarize yourself with the core components of the machine. Knowing how each part operates will aid in diagnosing problems more effectively.

- Gather Tools: Ensure you have the necessary tools on hand, such as screwdrivers, wrenches, and cleaning materials. Being prepared will save time during the troubleshooting process.

- Consult the Manual: Always refer to the user manual for specific troubleshooting steps. Manuals often contain valuable information on common issues and solutions.

Once you have a solid understanding, consider these steps:

- Identify Symptoms: Take note of any irregular behaviors, such as unusual sounds or performance issues. Documenting these symptoms can help pinpoint the problem.

- Check Fuel and Oil Levels: Low or contaminated fuel and oil can lead to performance issues. Always start by verifying that these are at appropriate levels and in good condition.

- Inspect Air Filters: A clogged air filter can restrict airflow, affecting performance. Regularly clean or replace filters as needed.

By employing these strategies, you can approach troubleshooting with clarity and purpose, increasing the likelihood of a successful resolution.