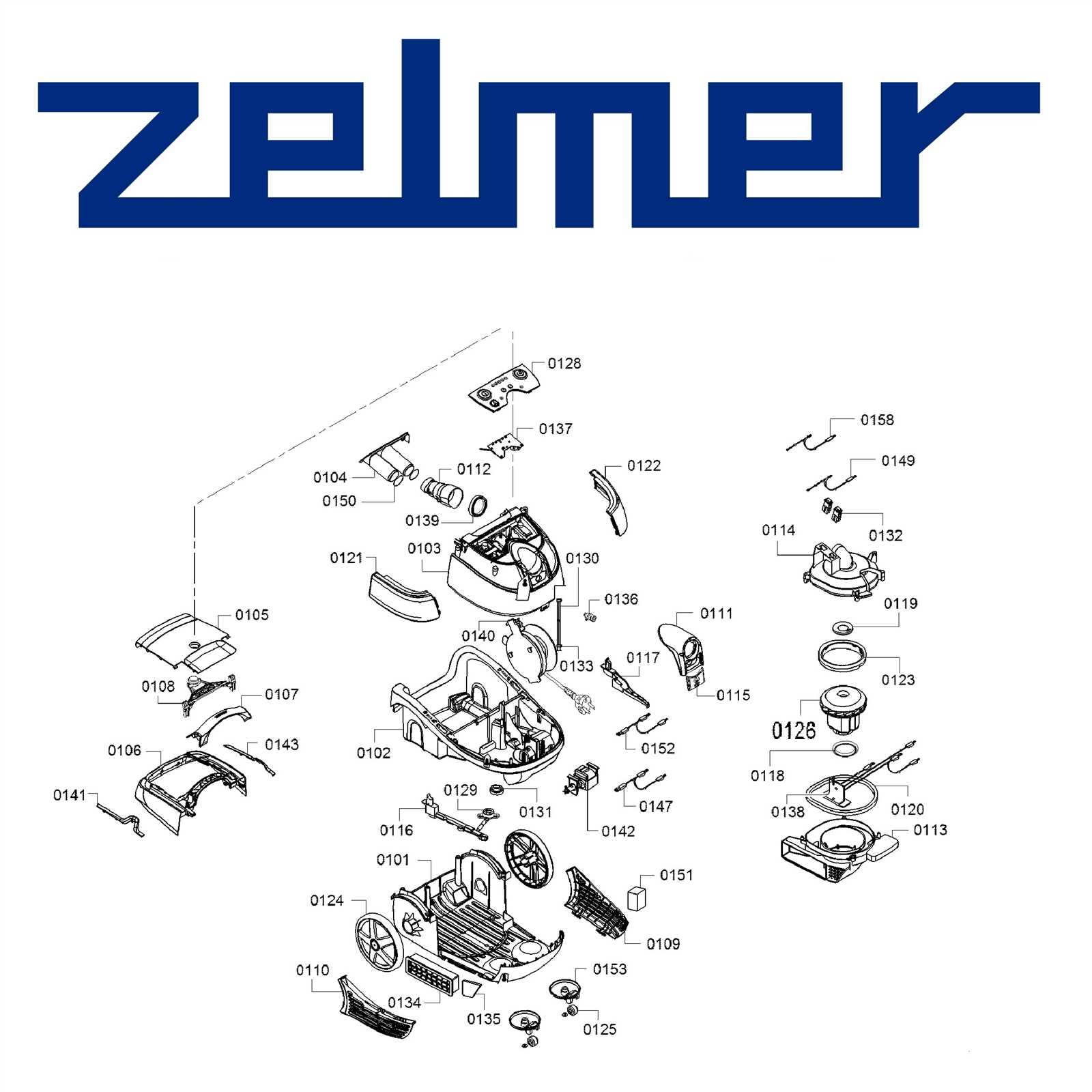

Exploring the intricate workings of a high-performance cutting device is essential for any user. Knowledge of its individual elements can enhance maintenance, troubleshooting, and overall efficiency.

Visual representations of these components offer invaluable insights into their arrangement and functionality. With a clear understanding of how each part interacts, you can ensure optimal performance and longevity.

Furthermore, recognizing potential issues early can prevent costly repairs and enhance safety. Delving into the specifics of your equipment empowers you to tackle challenges with confidence and skill.

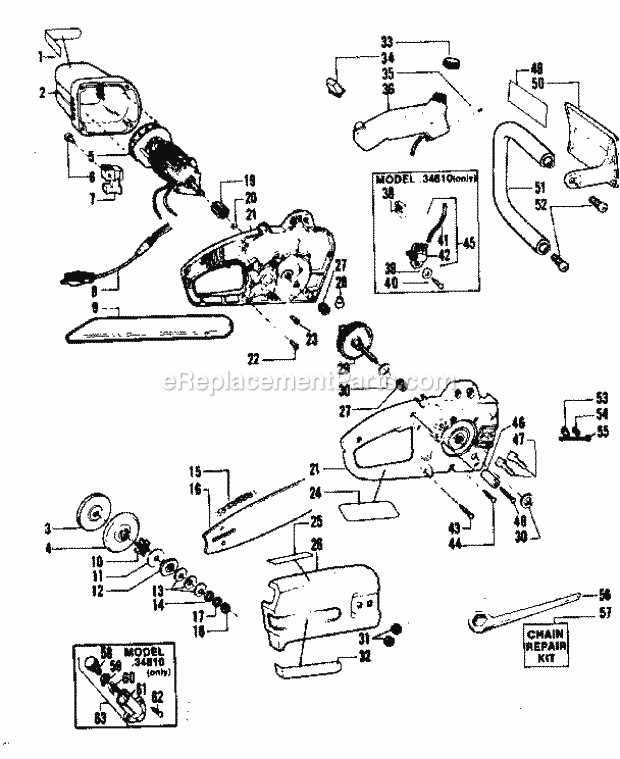

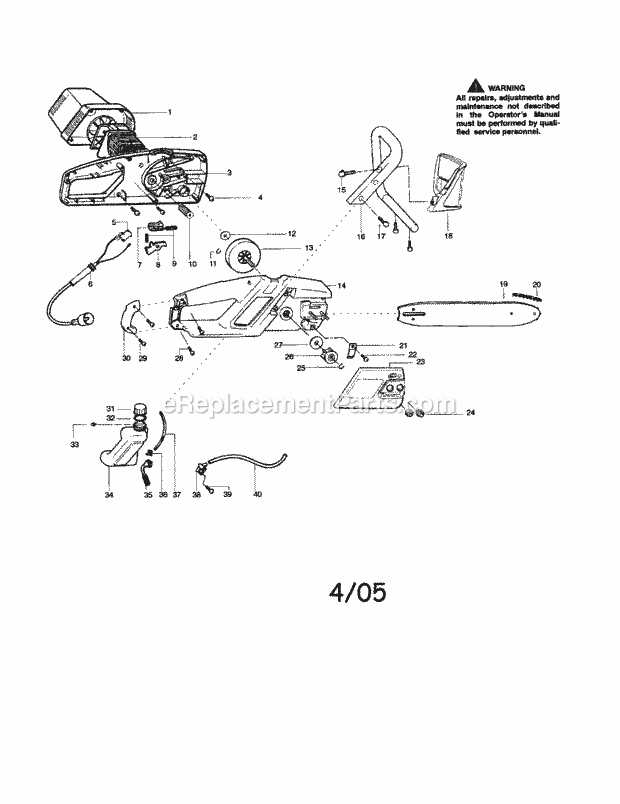

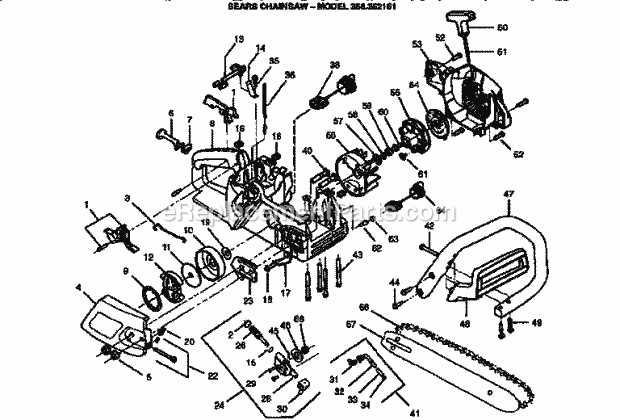

Understanding Chainsaw Parts Functionality

Every tool designed for cutting incorporates a variety of components, each serving a distinct purpose that contributes to the overall efficiency of the device. Understanding these elements is essential for proper maintenance and optimal performance.

- Power Unit: This is the heart of the machine, providing the necessary energy to operate.

- Cutting Bar: A vital component that dictates the length of the cutting path, allowing for different sizes of tasks.

- Chain: This element performs the actual cutting, featuring sharp teeth that slice through materials.

In addition to these main elements, other components enhance usability and safety:

- Throttle Control: Enables the operator to adjust the speed, ensuring precision during use.

- Safety Features: Various mechanisms designed to protect the user, such as chain brakes and guards.

- Fuel System: Supplies the necessary fuel to the power unit, impacting performance and efficiency.

Grasping the functionality of each component allows for better care and troubleshooting, ensuring the tool remains reliable for future tasks.

Importance of Maintenance in Performance

Regular upkeep is crucial for ensuring optimal functioning and longevity of any mechanical tool. Neglecting maintenance can lead to diminished efficiency and potential failures, ultimately impacting the overall performance and user experience.

Enhancing Efficiency

By routinely inspecting and servicing components, users can identify wear and tear before it escalates into significant issues. Proactive maintenance not only keeps machinery running smoothly but also enhances its overall effectiveness in accomplishing tasks.

Ensuring Safety

Well-maintained equipment significantly reduces the risk of accidents. Safety should always be a priority; ensuring all parts are in optimal condition can prevent unexpected malfunctions that could lead to dangerous situations.

Common Issues with Chainsaw Components

Understanding the frequent challenges associated with various tools can enhance their longevity and performance. Many users encounter specific malfunctions that stem from wear, misuse, or lack of maintenance, leading to decreased efficiency and safety hazards.

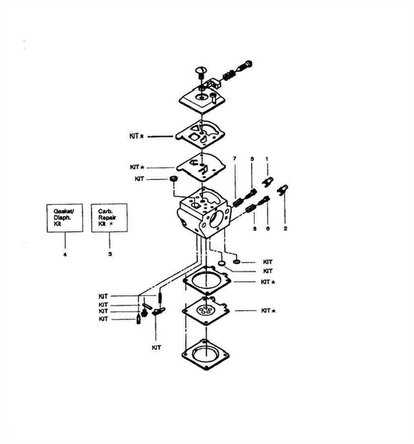

Fuel System Troubles

One prevalent issue involves the fuel delivery system. Clogs in the filter or carburetor can prevent proper fuel flow, causing erratic operation or starting difficulties. Regular inspection and cleaning can help mitigate these problems.

Bar and Chain Wear

The cutting mechanism is another area prone to issues. Dull or damaged teeth can hinder performance and increase the risk of kickback. Periodic sharpening and timely replacements are essential for optimal functionality.

How to Identify Worn-Out Parts

Recognizing components that have deteriorated is essential for maintaining optimal performance. This process involves careful inspection and attention to specific indicators of wear.

- Check for unusual noises during operation.

- Look for visible signs of damage, such as cracks or deformation.

- Monitor performance; decreased efficiency often indicates issues.

- Inspect for excessive vibrations, which can signal underlying problems.

Regular maintenance and early detection can prevent further complications and ensure longevity.

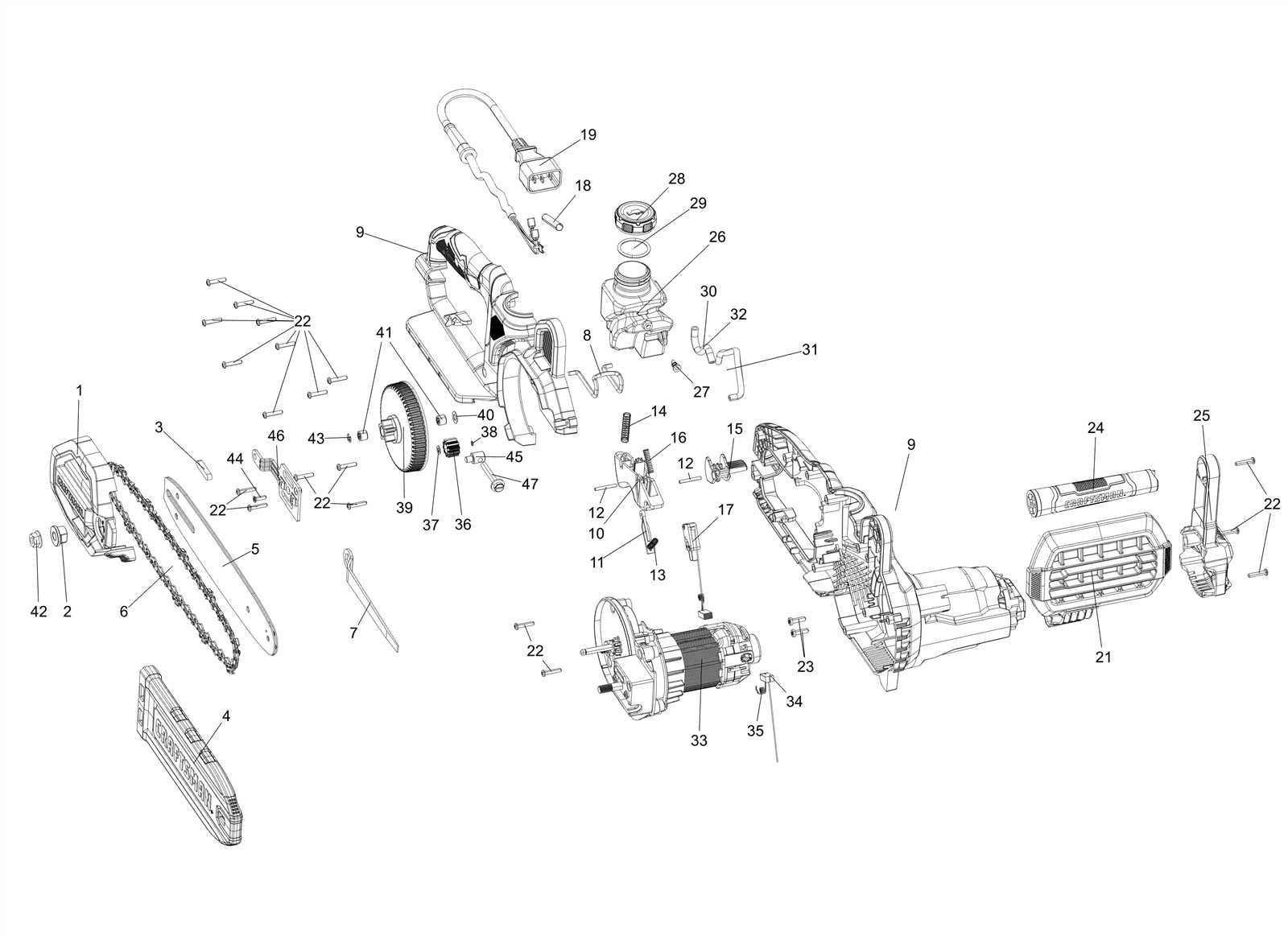

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring your equipment, ensuring optimal functionality and longevity. Following a structured method will help identify issues, replace necessary components, and enhance overall performance.

Preparation

- Gather essential tools: screwdrivers, wrenches, and safety gear.

- Ensure a clean workspace to avoid losing small parts.

- Consult the user manual for specific details related to your model.

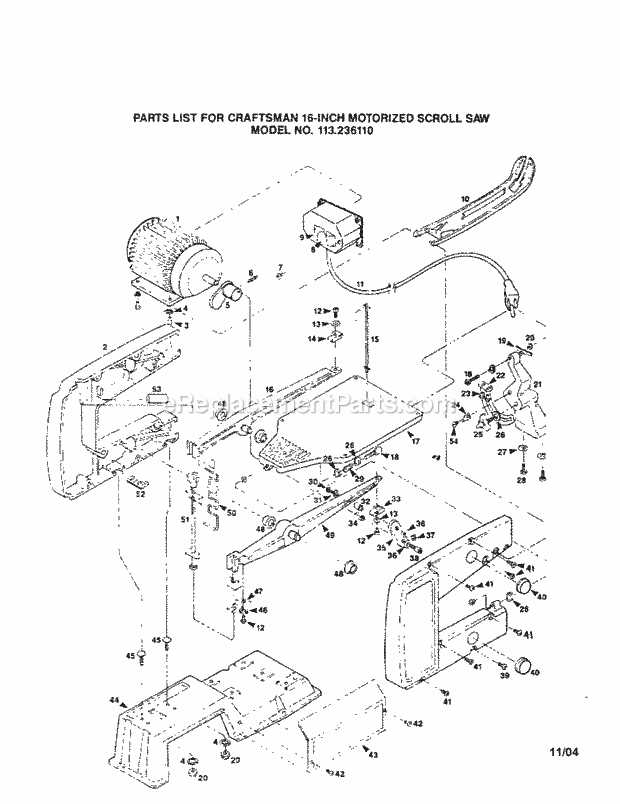

Disassembly

- Begin by removing the outer casing carefully.

- Take note of each component’s position for easier reassembly.

- Inspect for wear or damage as you disassemble.

By following these steps diligently, you can ensure a smooth repair process, leading to reliable equipment performance.

Tools Required for Chainsaw Repair

Proper maintenance and repair of cutting tools require a specific set of instruments to ensure effectiveness and safety. Having the right equipment can significantly simplify the process, allowing for efficient troubleshooting and fixing of any issues.

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types for various screws.

- Replacement blades: Vital for ensuring optimal cutting performance.

- Fuel mixture container: Necessary for preparing the correct fuel blend.

- Cleaning brushes: Useful for removing debris from components.

In addition to these basic tools, certain specialized instruments can enhance the repair experience.

- Torque wrench: Ensures proper tension on bolts and screws.

- Chain breaker: Facilitates chain adjustment and replacement.

- Gauge tool: Helps in measuring bar and chain wear.

Equipping yourself with these tools will provide the ultimate advantage in maintaining your equipment’s performance.

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating the right components is essential for optimal performance. Many resources are available for enthusiasts looking to replace worn or broken elements. Knowing where to search can save time and ensure you find high-quality alternatives.

Online Retailers: Numerous websites specialize in outdoor tools and equipment. These platforms often provide a wide selection of components, along with detailed specifications to assist in your search.

Local Hardware Stores: Visiting nearby home improvement centers can be beneficial. Staff members may offer insights and help you find what you need without the wait associated with online orders.

Manufacturer Websites: Checking the official site can lead you to specific offerings tailored for your equipment. This ensures compatibility and reliability, making it a preferred choice for many.

Forums and Community Groups: Engaging with online forums can connect you with fellow users who may have leads on hard-to-find components or even offer used items at reasonable prices.

Exploring these avenues will enable you to keep your gear in top shape, ready for any challenge ahead.

Tips for Proper Assembly and Disassembly

Ensuring the correct assembly and disassembly of tools is crucial for optimal performance and longevity. Following precise guidelines can prevent damage and enhance safety during maintenance procedures.

Here are some essential tips to consider:

- Read the Manual: Always refer to the user manual for specific instructions related to your device.

- Organize Your Workspace: Keep your area tidy and arrange all components in an easily accessible manner to avoid confusion.

- Use the Right Tools: Utilize appropriate tools to prevent stripping screws or damaging parts.

During the disassembly process:

- Work Methodically: Take your time to remove each component in the correct order to prevent losing any small pieces.

- Document the Process: Consider taking photos or notes to help remember how parts fit together when reassembling.

- Inspect Components: Check each part for wear or damage before reassembly to ensure everything is in good condition.

For reassembly:

- Follow the Reverse Order: Reassemble by retracing your steps from disassembly to avoid missing any components.

- Ensure Proper Alignment: Make sure that all parts are aligned correctly before tightening screws or fasteners.

- Double-Check Connections: Confirm that all connections are secure and functioning properly before use.

By adhering to these guidelines, you can ensure a smooth experience while maintaining your equipment, prolonging its life and efficiency.