In the realm of heavy machinery, comprehending the intricate assembly of various elements is crucial for optimal performance and maintenance. This section aims to provide insight into the specific configurations and functionalities that contribute to the effective operation of these powerful machines.

Identifying individual elements within the machinery allows operators and technicians to address issues promptly and enhance efficiency. By delving into the structural layout, users can better appreciate how each part interacts within the larger system.

Ultimately, a thorough grasp of these components not only facilitates repairs but also extends the lifespan of the equipment. This knowledge is essential for anyone involved in the operation or upkeep of heavy-duty vehicles.

Understanding Case 580 Super E Components

This section delves into the essential elements that contribute to the efficient functioning of heavy machinery. Understanding these components is crucial for maintenance and optimization, ensuring that the equipment operates at peak performance. A thorough grasp of each part allows for better troubleshooting and enhances overall operational longevity.

Key Elements of Heavy Machinery

Various sections of the machinery work in unison to facilitate its tasks. Familiarizing oneself with these critical components aids in recognizing their roles and potential issues that may arise during operation.

| Component | Description |

|---|---|

| Engine | The powerhouse that converts fuel into mechanical energy. |

| Hydraulic System | Responsible for the movement and operation of attachments through fluid power. |

| Transmission | Transfers power from the engine to the wheels or tracks, influencing speed and torque. |

| Frame | The structural base that supports all components and provides stability. |

| Electrical System | Powers various electronic controls and components, ensuring operational efficiency. |

Maintenance and Troubleshooting

Regular upkeep of these vital parts ensures the reliability and effectiveness of the equipment. Identifying common issues associated with each component helps operators take preventive measures, reducing downtime and repair costs.

Importance of Accurate Parts Diagrams

Precise visual representations of components play a critical role in maintenance and repair tasks. They serve as essential tools for technicians and operators, facilitating a better understanding of how individual elements interact within complex machinery. By providing clear guidance, these illustrations help to minimize errors and improve efficiency during repairs or replacements.

Enhancing Efficiency

Accurate visual guides contribute to quicker identification of required components, reducing downtime. When professionals can easily locate the necessary items, they can execute repairs or maintenance tasks more swiftly, ultimately leading to improved productivity.

Reducing Errors

Clear representations help in avoiding common mistakes that can occur during assembly or disassembly. When individuals have a reliable reference, they are less likely to misinterpret the arrangement or overlook crucial components, thus preventing costly errors and enhancing overall operational safety.

| Benefit | Description |

|---|---|

| Time Savings | Faster identification of components leads to reduced repair times. |

| Error Reduction | Minimizes the chances of incorrect assembly or part omission. |

| Improved Safety | Clear guidance reduces risks associated with faulty installations. |

Key Features of Case 580 Super E

This section highlights the essential attributes of a well-known heavy-duty construction machine. These characteristics contribute to its efficiency, versatility, and overall performance in various tasks, making it a reliable choice for operators in the field.

Performance and Power

- Robust engine delivering exceptional torque and horsepower.

- Hydraulic system designed for quick response and high productivity.

- Advanced transmission offering smooth gear shifting for enhanced control.

Operator Comfort and Safety

- Spacious cabin with ergonomic seating to reduce operator fatigue.

- Visibility features ensuring a clear view of the work area.

- Safety mechanisms designed to protect the operator and bystanders.

These features collectively make this equipment a top choice for professionals seeking reliability and efficiency in their projects.

Common Replacement Parts Overview

In any machinery, certain components experience wear over time and may require replacement to ensure optimal performance and longevity. Understanding these elements can help operators maintain their equipment effectively and avoid unexpected breakdowns. This overview highlights the frequently replaced components that are essential for keeping the machinery running smoothly.

Essential Components

Among the most commonly swapped elements are filters, which play a crucial role in maintaining fluid cleanliness and protecting the engine from contaminants. Additionally, seals and gaskets are vital for preventing leaks and ensuring proper functioning of hydraulic systems. Regular inspection and timely replacement of these items can significantly enhance the reliability of the equipment.

Performance-Enhancing Items

Another category includes items like belts and hoses, which are critical for power transmission and fluid conveyance. Over time, exposure to environmental factors can lead to deterioration, making routine checks necessary. By addressing these replacements promptly, operators can enhance efficiency and prolong the life of their machinery.

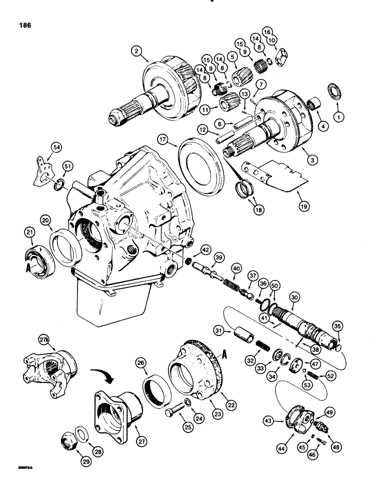

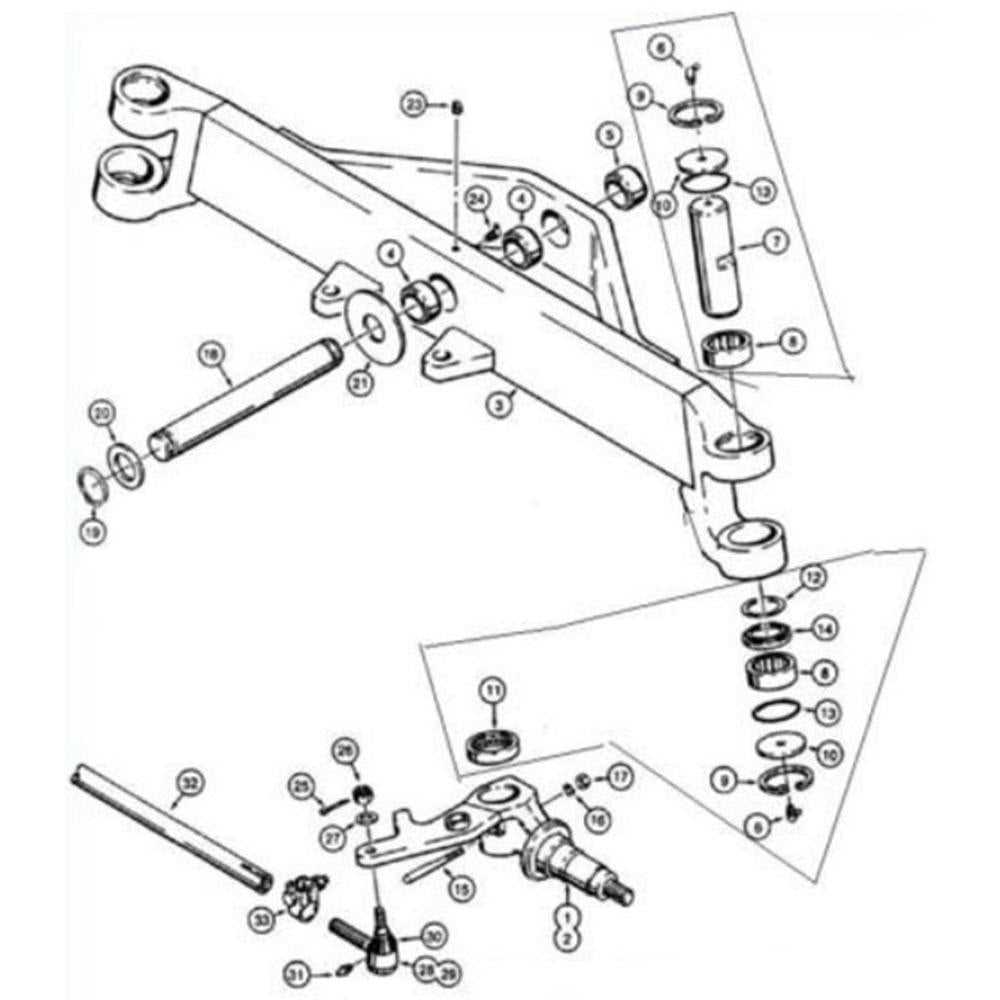

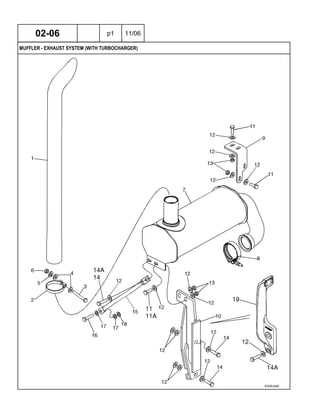

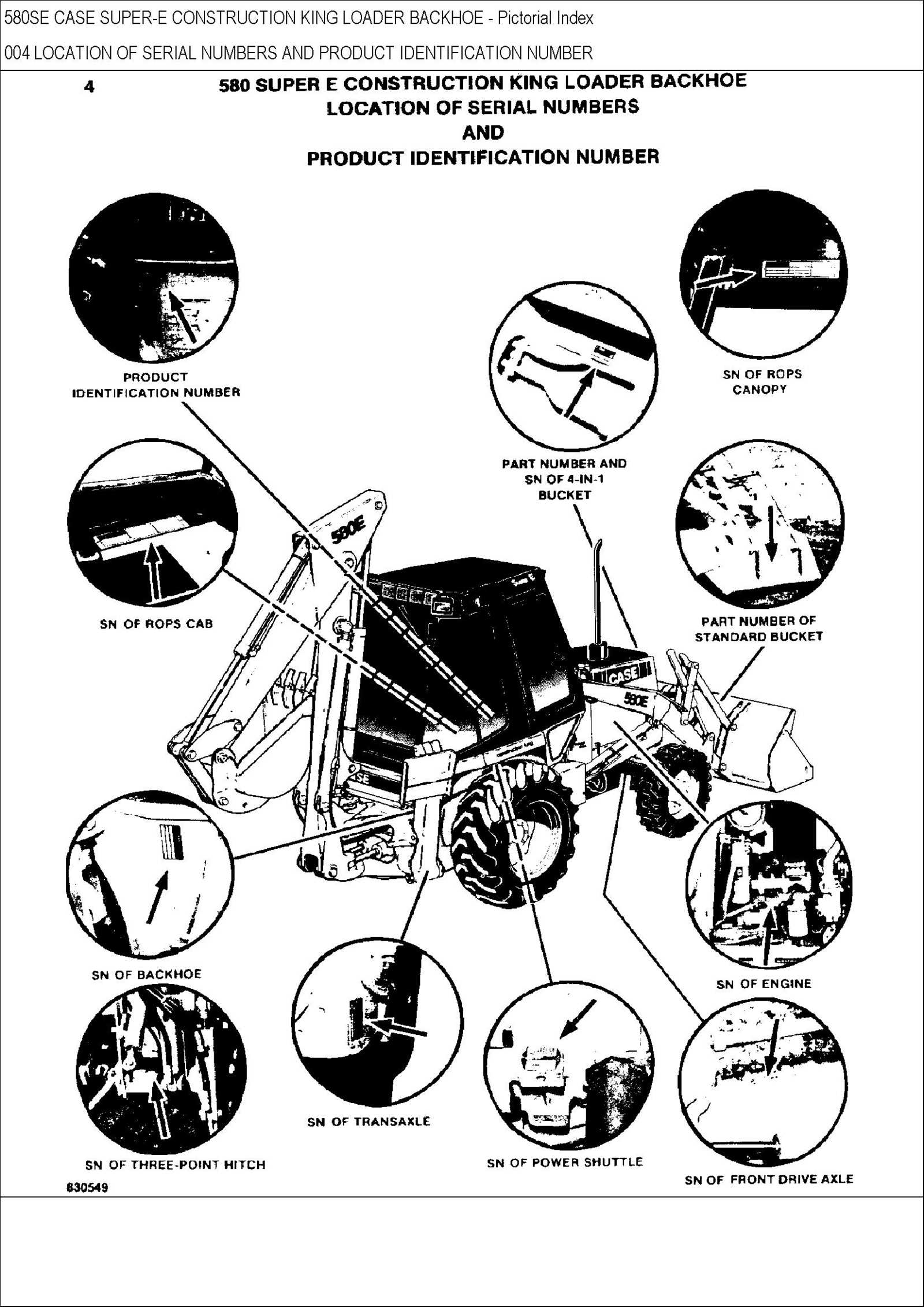

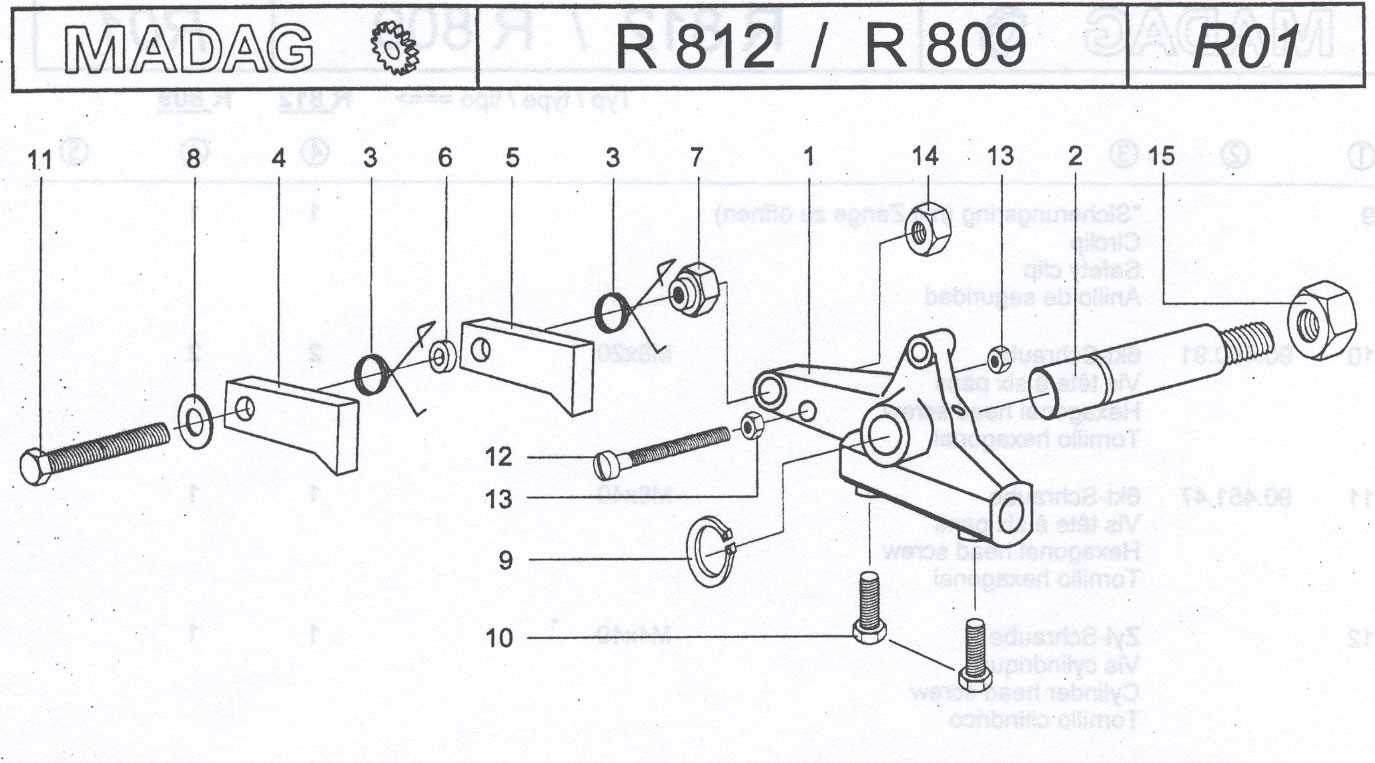

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone involved in machinery maintenance or repair. These visuals provide a detailed representation of components and their arrangement, allowing users to identify parts and comprehend their functions. Mastering the art of reading these schematics can significantly enhance troubleshooting efficiency and improve overall repair accuracy.

Key Elements of Technical Illustrations

To effectively interpret these visuals, it’s essential to familiarize yourself with common features. Look for labels, reference numbers, and symbols that indicate the nature of each element. Typically, the layout is organized in a way that shows the relationship between different parts, making it easier to locate specific items.

Using the Legend and Reference Numbers

Most illustrations include a legend or key that explains the symbols used. This guide is invaluable for decoding the information presented. Additionally, reference numbers often correspond to parts lists, enabling you to cross-check details quickly and accurately.

| Element | Description |

|---|---|

| Labels | Text indicating the name or function of a component. |

| Reference Numbers | Unique identifiers that link to a list of components. |

| Symbols | Graphic representations that convey specific information about parts. |

Identifying OEM vs. Aftermarket Parts

When it comes to maintaining and repairing machinery, understanding the difference between original equipment manufacturer components and those made by third-party suppliers is crucial. Each type has its own advantages and disadvantages that can significantly impact performance, longevity, and cost-effectiveness. This knowledge helps users make informed choices tailored to their specific needs.

Original components are produced by the same company that manufactured the equipment, ensuring compatibility and adherence to the original design specifications. In contrast, alternative components are created by independent manufacturers, often aiming to provide a more affordable option. However, the quality and fit can vary greatly.

| Aspect | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Generally high, consistent with original standards | Varies widely; some may exceed OEM, others may underperform |

| Cost | Typically more expensive | Often more affordable, but with potential trade-offs |

| Availability | May be limited to specific suppliers | Widely available through various outlets |

| Warranty | Usually comes with a manufacturer’s warranty | Warranties vary; some may not be offered |

| Compatibility | Guaranteed to fit and function as intended | May require additional verification for fit |

Choosing between these options requires careful consideration of factors like budget, performance needs, and long-term maintenance plans. Understanding these differences can ultimately lead to better decisions and improved outcomes for your equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of heavy machinery. By adopting effective maintenance strategies, operators can minimize wear and tear, enhance performance, and avoid costly repairs.

- Regularly inspect all components for signs of wear.

- Keep the machine clean to prevent dirt accumulation.

- Change fluids and filters as recommended by the manufacturer.

- Lubricate moving parts to reduce friction.

- Monitor tire pressure and tread for optimal traction.

Implementing these practices will ultimately lead to improved reliability and performance.

Where to Find Parts Diagrams

Locating visual references for machinery components is essential for maintenance and repairs. These illustrations can simplify the process of identifying and acquiring necessary elements, ensuring efficient operation. Understanding where to access these resources can save time and enhance the accuracy of repairs.

Online Resources

The internet hosts a wealth of platforms that provide comprehensive illustrations for various machinery. Websites dedicated to machinery repair often feature searchable databases where users can input model numbers to find the appropriate references. Additionally, manufacturer websites frequently offer downloadable resources that include detailed views and specifications.

Manuals and Repair Guides

Printed manuals and repair guides are another reliable source for visual references. These documents typically include exploded views and descriptions of each component. They can often be found through local dealers, libraries, or online marketplaces, making them accessible for those who prefer physical copies.

| Source Type | Description |

|---|---|

| Manufacturer Websites | Official resources with downloadable visuals and specs. |

| Online Forums | Community-driven platforms where users share diagrams and tips. |

| Printed Manuals | Physical books or brochures containing comprehensive illustrations. |

| Local Dealers | Businesses that may provide access to hard copies of diagrams. |

Resources for Repair and Support

Accessing reliable resources for maintenance and troubleshooting is essential for ensuring the longevity and efficiency of heavy machinery. Whether you’re a seasoned technician or a novice operator, having the right information at your fingertips can make all the difference in resolving issues promptly and effectively.

Online Forums and Communities: Engaging with online platforms where enthusiasts and professionals share their experiences can be invaluable. These forums often contain a wealth of knowledge, including troubleshooting tips, modification ideas, and even firsthand accounts of repairs.

Manufacturer’s Manuals: Official documentation is a vital resource. These manuals typically provide detailed instructions, specifications, and safety guidelines tailored to specific models. Having access to the right manual ensures you have the correct information for any repair task.

Local Distributors and Parts Suppliers: Building a relationship with local dealers can simplify the process of sourcing necessary components. Many distributors also offer expert advice and support, helping you make informed decisions about repairs and upgrades.

Workshops and Training Sessions: Participating in hands-on training and workshops can enhance your skills and knowledge. These sessions often cover the latest techniques and technologies, equipping you to handle various repair scenarios more effectively.

Utilizing these resources will empower you to tackle challenges with confidence, ensuring your machinery operates at its best for years to come.