When it comes to operating a compact loader, having a clear understanding of its various elements is crucial for efficient maintenance and operation. Every piece of machinery comprises a complex interplay of components that work together to ensure optimal performance. Knowing how these elements fit together can save time and resources, preventing unnecessary downtime.

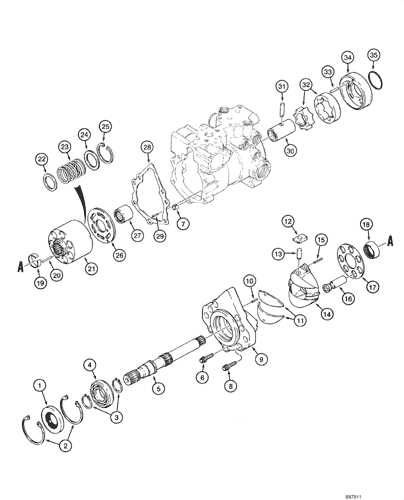

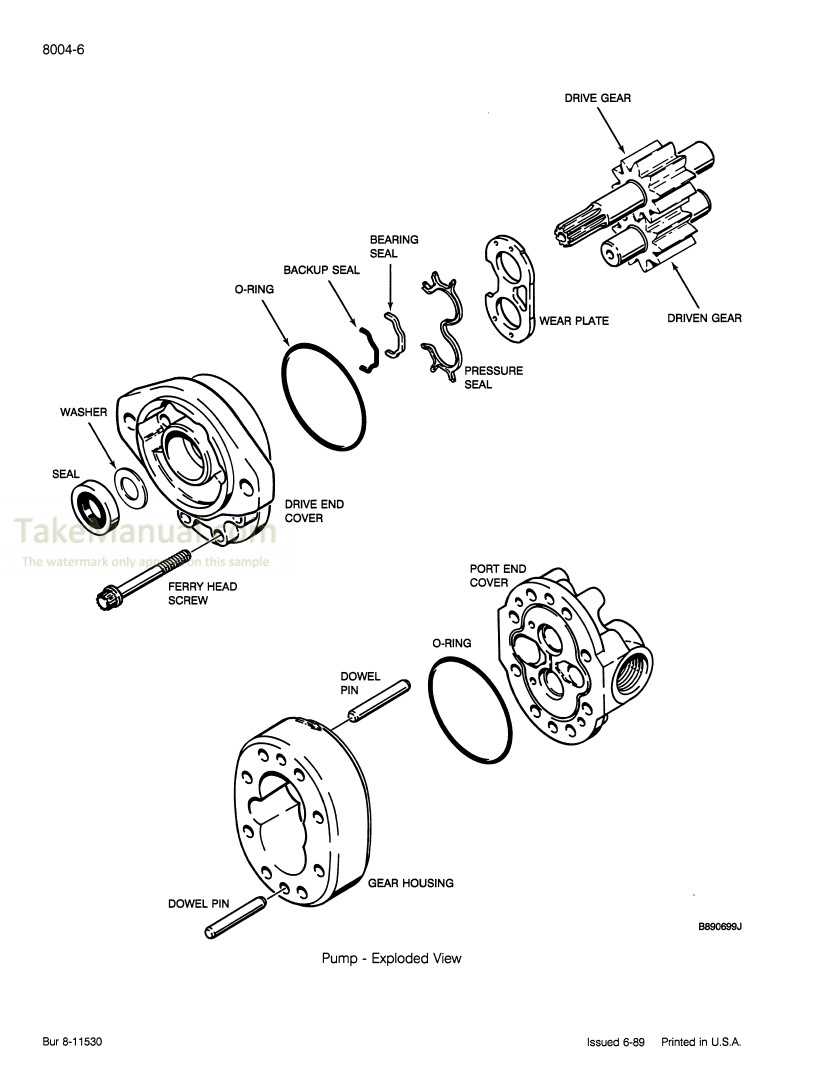

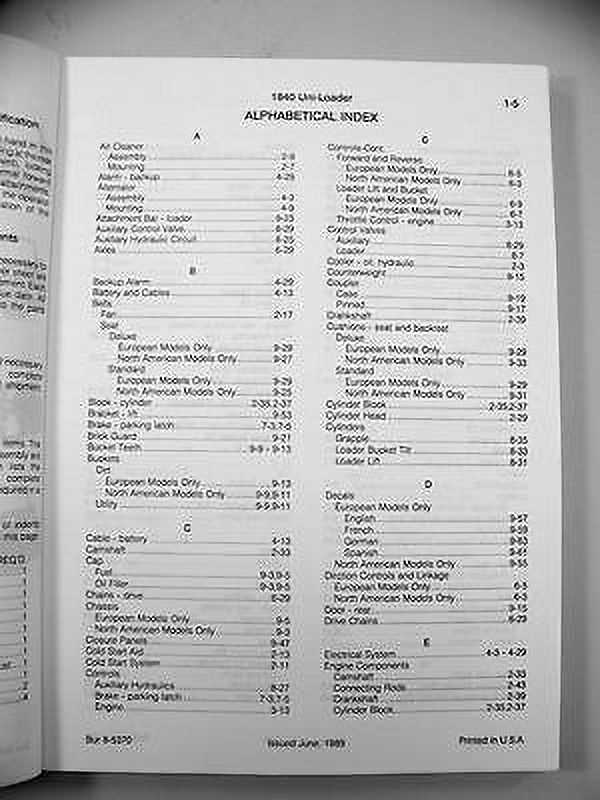

In this section, we will explore the intricate layout of a specific model, focusing on the essential components that contribute to its functionality. By breaking down the arrangement and identifying each part’s role, you will gain insights into how to troubleshoot issues and enhance the machine’s efficiency.

Whether you are a seasoned operator or a newcomer to the field, familiarizing yourself with the structure and function of these components will empower you to make informed decisions regarding maintenance and repairs. With this knowledge at your fingertips, you can ensure that your equipment remains in peak condition for all your projects.

Understanding the Case 1840 Skid Steer

This section delves into the features and functionality of a compact construction machine designed for versatility and efficiency. Known for its maneuverability and robust design, this equipment serves a multitude of tasks, making it an essential asset for various industries.

Key Features

Equipped with a powerful engine, this model showcases excellent performance in both heavy-duty applications and lighter tasks. The hydraulic system enhances its lifting capabilities, allowing for efficient handling of materials. Additionally, the intuitive controls enable operators to execute tasks with precision, improving overall productivity.

Maintenance and Care

Regular upkeep is crucial to prolong the lifespan of this machinery. Routine inspections of the hydraulic components, engine performance, and tire condition ensure optimal functionality. Utilizing the right tools and adhering to the manufacturer’s guidelines can significantly reduce downtime and repair costs.

In conclusion, understanding the intricacies of this equipment not only enhances operational effectiveness but also ensures safety and reliability on the job site. Whether used for construction, landscaping, or agriculture, mastering its capabilities leads to better project outcomes.

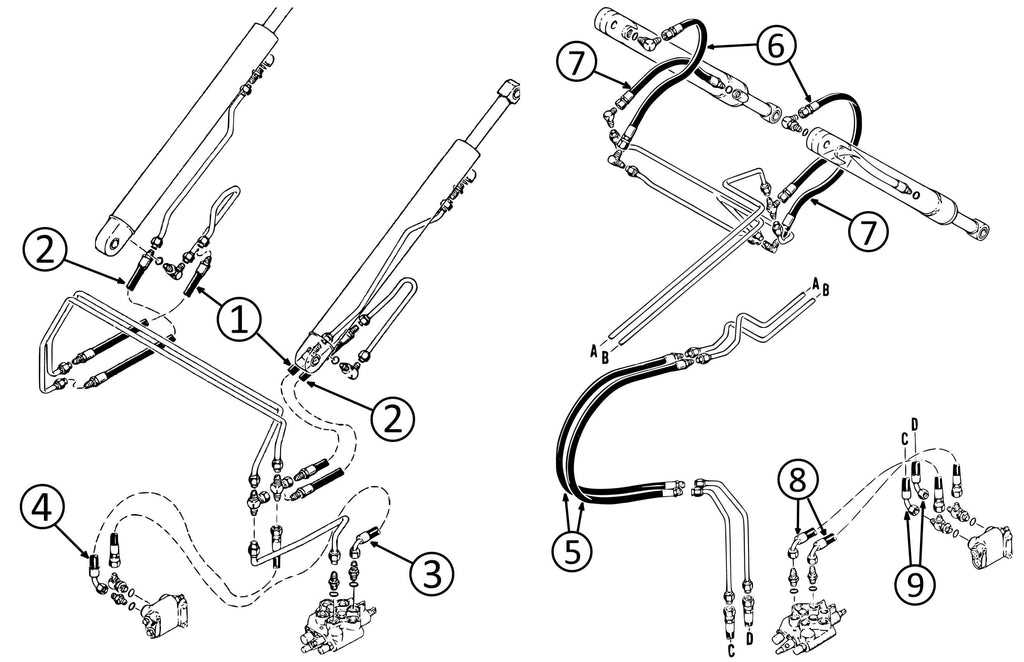

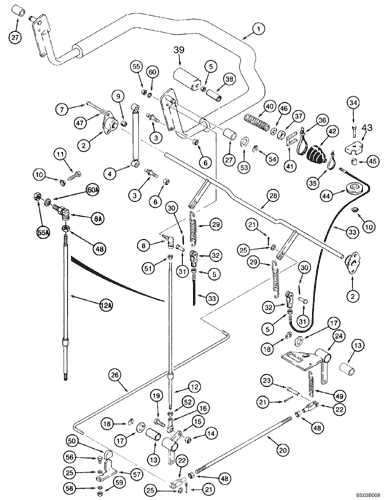

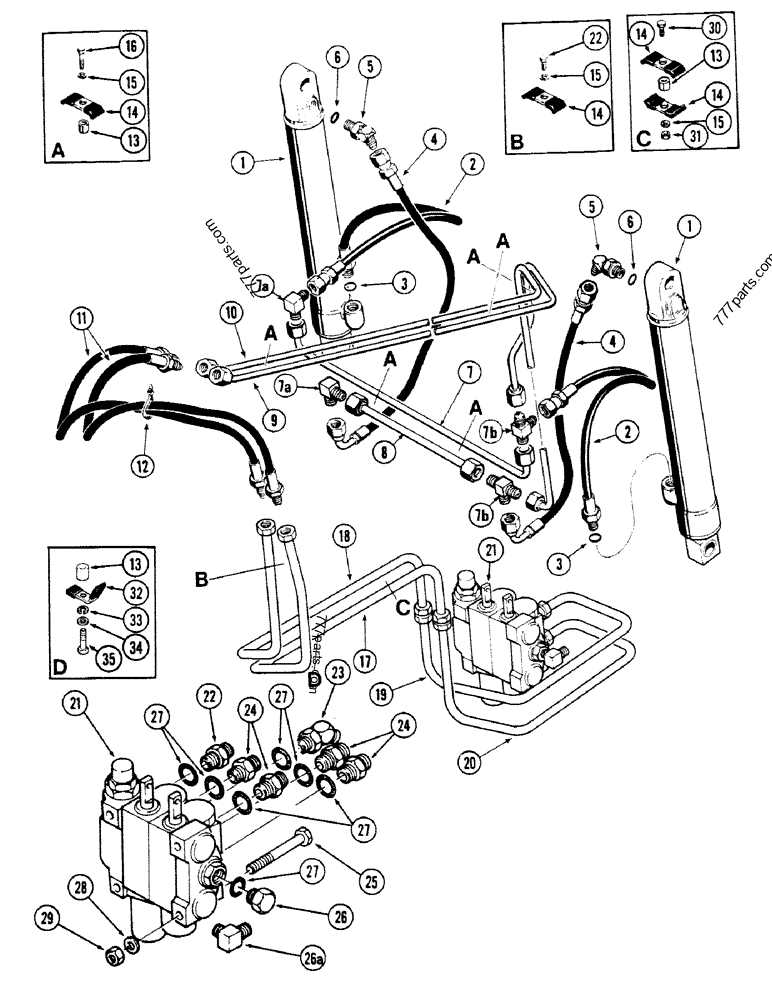

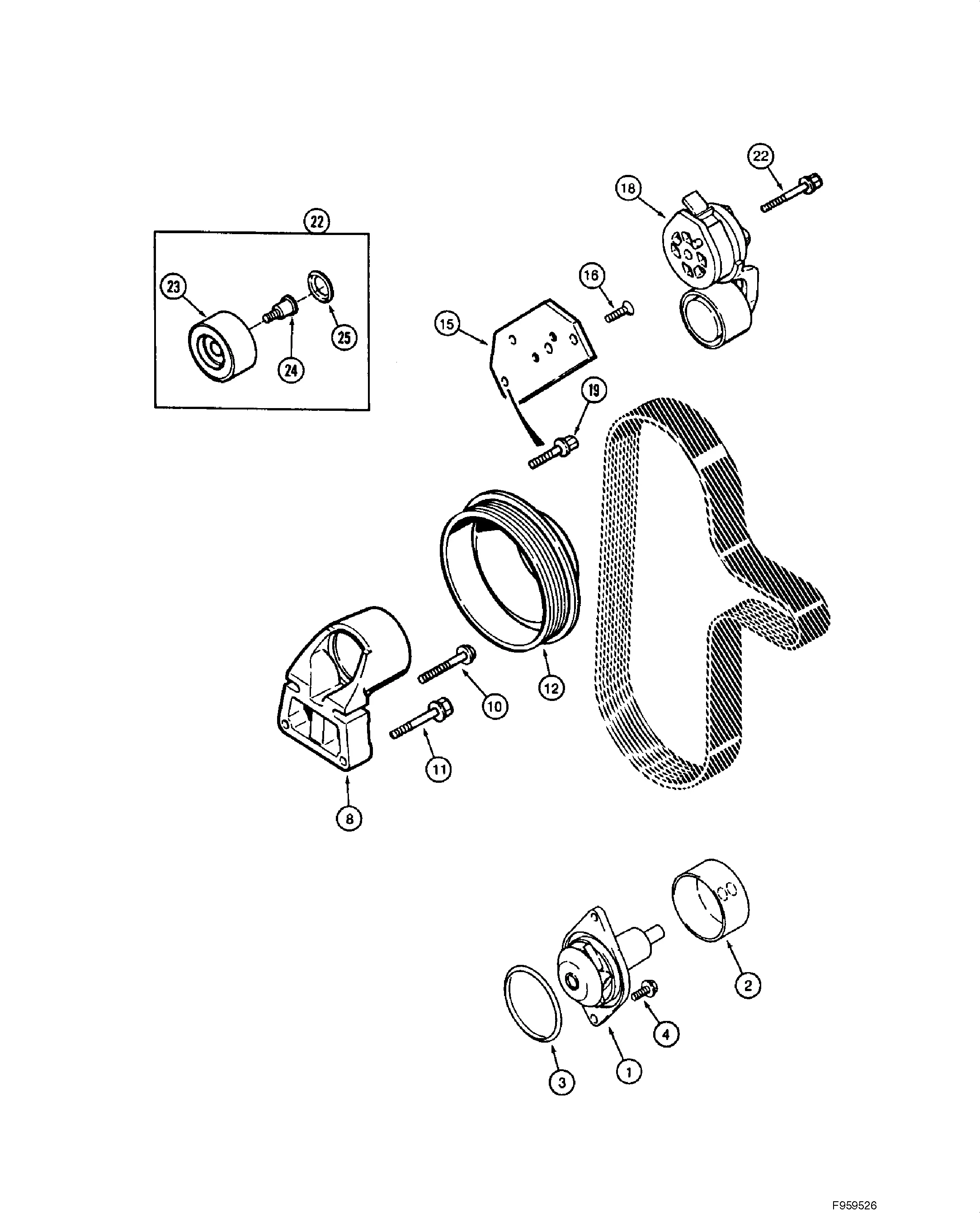

Importance of Parts Diagrams

Understanding the intricate details of machinery components is essential for efficient maintenance and repair. Visual representations serve as a critical resource, allowing operators and technicians to identify specific elements and their functions within the overall system. This clarity enhances troubleshooting, ensures accurate replacements, and minimizes downtime.

Benefits of Visual Representations

- Enhanced Clarity: Visual aids break down complex systems into manageable sections, making it easier to understand how each element interacts.

- Efficient Troubleshooting: Identifying faults becomes simpler when users can refer to a detailed visual layout, pinpointing the exact location of issues.

- Streamlined Repairs: Knowing the correct components to replace expedites the repair process, reducing unnecessary delays.

- Improved Safety: Understanding component placement helps prevent accidents during maintenance and operation.

Best Practices for Utilizing Visual Aids

- Always reference the appropriate visual layout for your specific model.

- Cross-check parts against the representation before purchasing replacements.

- Keep a copy of the visual aid accessible during maintenance tasks.

- Share insights with team members to ensure collective understanding of the system.

Common Issues with Skid Steer Components

Understanding the frequent challenges faced by machinery components is crucial for maintaining efficiency and longevity. Various factors can lead to wear and malfunction, impacting overall performance. Identifying these issues early can save time and resources.

Hydraulic System Failures

Hydraulic systems are prone to leaks, pressure drops, and contamination. Regular inspections can help detect early signs of wear, ensuring optimal functionality and preventing costly repairs.

Electrical Malfunctions

Electrical issues can arise from faulty wiring, blown fuses, or corroded connections. Keeping electrical systems clean and well-maintained is essential for reliable operation and avoiding unexpected downtime.

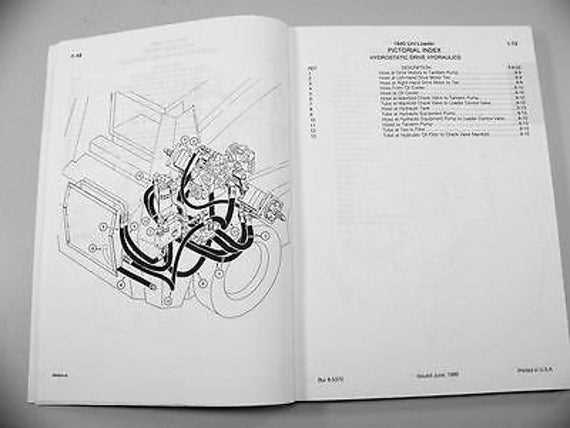

How to Interpret Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide crucial information about the components of machinery, helping users identify and locate specific elements.

Here are some key points to consider:

- Familiarize Yourself with Symbols: Different shapes and lines represent various parts and connections.

- Read the Legend: Most illustrations include a legend that explains the symbols and their meanings.

- Note the Numbers: Each component is usually numbered; cross-reference these with the accompanying list for clarity.

- Check the Orientation: Ensure you’re viewing the illustration from the correct angle for accurate identification.

By following these guidelines, you can navigate technical visuals with confidence and ensure proper repairs and replacements.

Where to Find Replacement Parts

Finding suitable components for machinery can be a daunting task, yet it’s essential for maintaining optimal performance. Numerous avenues exist for sourcing these critical items, ensuring that your equipment remains functional and efficient.

Online Retailers: A variety of e-commerce platforms specialize in selling machinery components. These websites often provide detailed specifications and customer reviews, making it easier to select the right items.

Local Dealers: Visiting nearby dealerships can yield significant benefits. These establishments typically have knowledgeable staff who can assist in identifying the appropriate components for your specific needs.

Salvage Yards: For those seeking more affordable options, salvage yards can be a treasure trove of usable parts. It’s a sustainable choice that also supports cost-effective repairs.

Manufacturer Resources: Consulting the manufacturer’s official website can provide access to valuable resources, including part catalogs and customer service contacts, ensuring you find exactly what you need.

Exploring these various sources can help you efficiently locate the necessary components to keep your machinery running smoothly.

Benefits of OEM vs. Aftermarket Parts

When it comes to equipment maintenance and repairs, the choice between original equipment manufacturer (OEM) components and aftermarket alternatives can significantly impact performance and longevity. Understanding the advantages of each option can help you make informed decisions that benefit your machinery and overall operations.

OEM components are produced by the original manufacturer and are designed specifically for your machinery. These components often come with a reputation for quality and reliability. In contrast, aftermarket options are made by third-party manufacturers and may vary in quality and compatibility.

- Quality Assurance: OEM components typically meet stringent quality standards, ensuring optimal performance.

- Compatibility: Original parts are engineered to fit perfectly, minimizing the risk of malfunctions or damage.

- Warranty Protection: Using OEM parts often helps maintain warranties, providing peace of mind in the event of repairs.

On the other hand, aftermarket components can offer some distinct advantages:

- Cost-Effectiveness: Aftermarket options are frequently less expensive, making them appealing for budget-conscious operators.

- Variety: The aftermarket offers a broader range of choices, allowing for potential customization to meet specific needs.

- Availability: Aftermarket parts are often easier to find, especially for older models where OEM components may be limited.

In conclusion, both OEM and aftermarket components have their own sets of advantages. Evaluating your specific needs, budget, and long-term goals will help you determine the best route for your equipment maintenance and repair strategies.

Maintenance Tips for Skid Steers

Proper upkeep of compact machinery is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also reduces the risk of unexpected breakdowns. Here are some key recommendations to keep your equipment in peak condition.

- Regular Inspections: Conduct routine checks on fluid levels, belts, and filters to ensure everything operates smoothly.

- Fluid Changes: Change engine oil and hydraulic fluid at recommended intervals to prevent wear and tear.

- Air Filter Maintenance: Clean or replace the air filter regularly to ensure proper airflow and engine performance.

- Battery Care: Inspect the battery terminals for corrosion and ensure connections are tight to avoid electrical issues.

Additionally, pay attention to the following:

- Tire Pressure: Maintain the correct tire pressure to enhance traction and fuel efficiency.

- Greasing: Apply grease to all moving parts according to the manufacturer’s schedule to minimize friction and wear.

- Cleaning: Keep the machine clean to prevent dirt buildup, which can lead to component damage.

- Operator Training: Ensure that operators are well-trained to use the machinery effectively and safely.

By adhering to these guidelines, you can ensure your compact equipment remains reliable and efficient throughout its operational life.

Upgrades to Enhance Performance

Improving machinery efficiency can significantly boost productivity and extend lifespan. By focusing on key enhancements, operators can ensure optimal functioning and achieve superior results in various applications.

Key Performance Enhancements

- Engine Modifications: Upgrading to a more powerful engine can provide better torque and speed.

- Hydraulic System Improvements: Installing a high-flow hydraulic pump increases lifting capacity and responsiveness.

- Track and Tire Upgrades: Choosing specialized tracks or tires enhances traction and stability on different terrains.

Maintenance Practices

- Regular Lubrication: Ensures all moving parts operate smoothly, reducing wear and tear.

- Filter Replacements: Keeping air and fuel filters clean maintains engine efficiency.

- Periodic Inspections: Routine checks help identify issues before they escalate into costly repairs.