The intricate design of machinery involves various essential elements working in harmony. This section aims to provide a comprehensive overview of these vital components, shedding light on their arrangement and functionality. By grasping the interplay of each section, users can enhance their knowledge and operational efficiency.

Exploring the visual representation of these integral parts offers a clearer perspective for both novices and seasoned professionals. Through an organized layout, one can easily identify and comprehend the roles of different sections, facilitating informed decision-making and effective troubleshooting.

In this exploration, we will delve into the ultimate configuration, examining how each element contributes to the overall performance. A thorough understanding of this arrangement not only empowers users but also fosters a greater appreciation for the engineering behind such machinery.

Understanding the Case 530 Parts Diagram

Comprehending the layout of machinery components is essential for effective maintenance and repair. A well-structured illustration serves as a valuable resource, enabling users to identify each element and its function within the system. This visual guide simplifies the troubleshooting process, ensuring that technicians can efficiently locate and address any issues that arise.

Each segment of the illustration plays a critical role in the overall operation of the equipment. Familiarity with the various sections can enhance one’s ability to perform tasks such as assembly, disassembly, and replacement of worn-out elements. By interpreting the visual cues presented in this schematic, operators can improve their understanding of how the machinery works as a cohesive unit.

Moreover, mastering this layout not only aids in immediate repairs but also contributes to long-term upkeep. Recognizing the interconnections among the components fosters a deeper appreciation of the mechanical relationships, which is crucial for anyone involved in the upkeep of such machinery. This foundational knowledge empowers users to make informed decisions, ultimately prolonging the lifespan of the equipment.

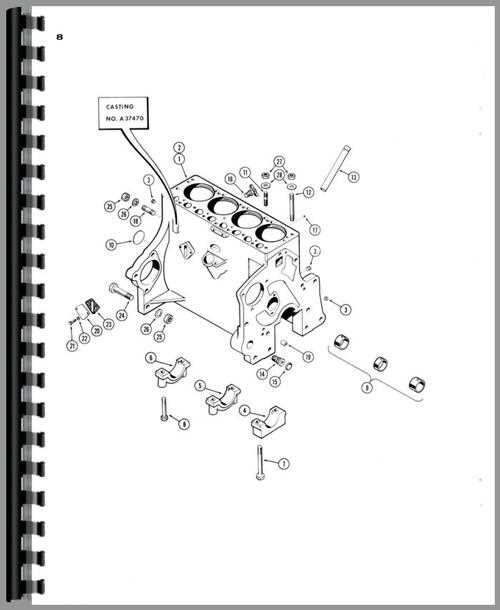

Components of the Case 530 Machine

The intricate machinery operates through a harmonious blend of essential elements, each contributing to its overall functionality. Understanding these individual components allows for better maintenance and improved performance.

Engine: The heart of the machine, providing the necessary power to perform various tasks efficiently.

Transmission: This vital system transmits power from the engine to the wheels, facilitating smooth movement and maneuverability.

Hydraulic System: A crucial feature that enables the operation of various implements, enhancing versatility and productivity.

Chassis: The framework that supports the entire structure, ensuring stability and durability during operation.

Control Panel: The user interface that allows operators to monitor and manage the machine’s functions seamlessly.

Wheels: Essential for mobility, they provide traction and stability on various terrains.

Each of these elements plays a significant role, working together to create a robust and efficient machine designed for demanding tasks.

How to Read the Diagram Effectively

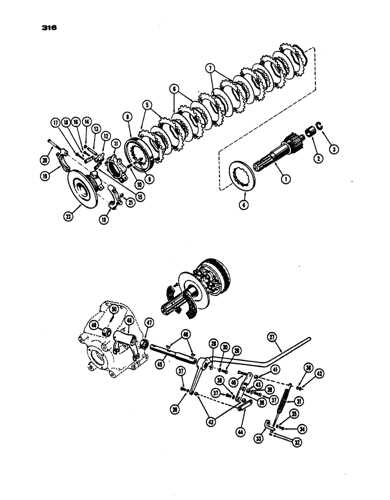

Understanding a visual representation of components can significantly enhance your ability to troubleshoot and maintain machinery. By grasping the layout and relationships illustrated, you can efficiently identify parts and their functions, leading to more informed decisions during repairs or upgrades.

Familiarize Yourself with Symbols

Every representation uses specific symbols to denote various elements. Take time to familiarize yourself with these icons, as they provide crucial information about the components’ roles and interactions. This knowledge is the foundation for successful interpretation.

Follow the Flow of the Diagram

Identify the sequence in which elements are arranged. Pay attention to directional arrows and connections, which indicate how each part operates within the larger system. Understanding this flow will help you see the ultimate purpose of each component.

Common Issues with Case 530 Parts

In any machinery, various components can encounter difficulties that affect overall performance. Understanding these challenges can lead to better maintenance practices and prolonged lifespan of the equipment. Below are some frequently observed problems related to components in this particular model.

Frequent Problems

- Wear and Tear: Over time, certain elements may degrade, leading to diminished efficiency.

- Fluid Leaks: Seals and gaskets can fail, causing hydraulic or oil leaks, which may result in operational failures.

- Electrical Failures: Wiring and connectors may corrode or break, impacting functionality.

- Alignment Issues: Improper alignment can lead to excessive strain on moving parts, causing premature damage.

Prevention Tips

- Regular Inspections: Routine checks can help identify wear before it leads to significant issues.

- Proper Lubrication: Ensuring adequate lubrication minimizes friction and prevents overheating.

- Timely Replacements: Replacing worn components promptly can avoid more costly repairs later.

- Training Operators: Educating users on proper handling techniques can reduce misuse-related damage.

Maintenance Tips for Optimal Performance

Ensuring the efficiency and longevity of your machinery requires regular upkeep and attention. Implementing a systematic maintenance routine not only enhances operational effectiveness but also minimizes unexpected breakdowns. Here are essential practices to keep your equipment running smoothly.

Regular Inspections

Conducting frequent assessments is crucial for identifying potential issues before they escalate. Focus on key components that influence overall performance, such as hydraulic systems, engine parts, and transmission mechanisms. Pay close attention to wear and tear, and replace any damaged items promptly to maintain optimal functionality.

Lubrication and Fluid Levels

Proper lubrication is vital for reducing friction and wear. Regularly check and replenish fluids, including oil, coolant, and hydraulic fluid, to ensure all systems operate efficiently. Adhering to the manufacturer’s recommendations regarding the types and frequencies of lubrication will significantly enhance durability and performance.

Comparing Case 530 with Other Models

This section explores the distinctions and similarities among various machinery models, highlighting performance, efficiency, and design aspects. Understanding these differences allows users to make informed decisions based on their specific needs and applications.

Performance Overview

When assessing different machinery, performance metrics such as horsepower, torque, and operational speed are critical. These factors determine the suitability of each model for various tasks, from agricultural to construction applications.

Design Features

The structural design and layout can significantly affect usability and maintenance. Comparing features like cab ergonomics, accessibility of controls, and overall build quality reveals how each model addresses user comfort and functionality.

| Model | Horsepower | Torque | Weight |

|---|---|---|---|

| Model A | 60 HP | 150 lb-ft | 4000 lbs |

| Model B | 70 HP | 180 lb-ft | 4500 lbs |

| Model C | 65 HP | 160 lb-ft | 4300 lbs |

Where to Find Replacement Parts

Locating components for machinery can be crucial for maintenance and repair. Understanding the best sources ensures you can keep your equipment functioning optimally without unnecessary downtime.

Online Retailers

Numerous online platforms specialize in providing an extensive range of machinery components. Websites such as eBay or Amazon often feature listings from both private sellers and established dealers. Searching for specific items can yield competitive pricing and availability.

Local Suppliers and Dealerships

Exploring nearby suppliers or authorized dealerships can also be advantageous. Many of these establishments maintain a stock of essential components and can offer valuable advice on compatibility and performance. Additionally, developing a relationship with local vendors can lead to personalized service and support.

DIY Repairs Using the Parts Diagram

Understanding the layout of components is crucial for efficient repairs. A clear visual representation can simplify the identification of each element, making the process more intuitive. This knowledge empowers individuals to tackle maintenance tasks with confidence, ensuring a smoother experience in handling mechanical issues.

For those eager to engage in self-repair projects, having a reference for the various elements can significantly streamline the process. Below is a helpful table outlining common components and their functions, providing guidance for effective troubleshooting and replacement.

| Component | Function | Common Issues |

|---|---|---|

| Engine | Power generation | Overheating, noise |

| Hydraulic System | Fluid movement | Leaks, slow operation |

| Transmission | Power transfer | Slipping, unusual sounds |

| Electrical System | Power distribution | Flickering lights, failure to start |

Utilizing a detailed reference not only aids in identifying parts but also enhances understanding of their roles, leading to more effective maintenance practices. Whether replacing a malfunctioning item or performing routine checks, this approach encourages a proactive stance on upkeep.

Expert Insights on Case 530 Maintenance

Proper upkeep of machinery is essential for optimal performance and longevity. Experts emphasize the importance of routine checks and timely replacements to prevent costly breakdowns. Understanding the components and their functions is key to ensuring smooth operations and enhancing efficiency.

Routine Maintenance Practices

Implementing a structured maintenance schedule can significantly reduce downtime. Regular inspections, fluid checks, and adjustments to critical systems are vital. Investing in quality tools and following manufacturer guidelines can lead to improved reliability.

Common Issues and Solutions

Many users encounter similar challenges, such as overheating or noise. Addressing these problems early can prevent further damage. Keeping a detailed log of maintenance activities helps in identifying patterns and optimizing repair strategies for future use.