In the realm of heavy machinery, understanding the layout of essential components is crucial for efficient operation and maintenance. A clear representation of the various elements allows operators and technicians to grasp how each piece interacts within the larger system. This knowledge not only aids in troubleshooting but also enhances the overall performance of the machine.

Accurate schematics provide valuable insights into the intricate design of construction equipment. By examining these visual aids, one can identify key sections and understand their functions. Such illustrations serve as a roadmap, guiding users through the complexities of mechanical systems and facilitating more informed decision-making during repairs and upgrades.

Furthermore, familiarity with the arrangement of components fosters a deeper appreciation of the machinery’s engineering. As operators become more adept at navigating these layouts, they can optimize maintenance routines, ensuring longevity and reliability. This foundational understanding is instrumental in maximizing productivity on job sites and minimizing downtime.

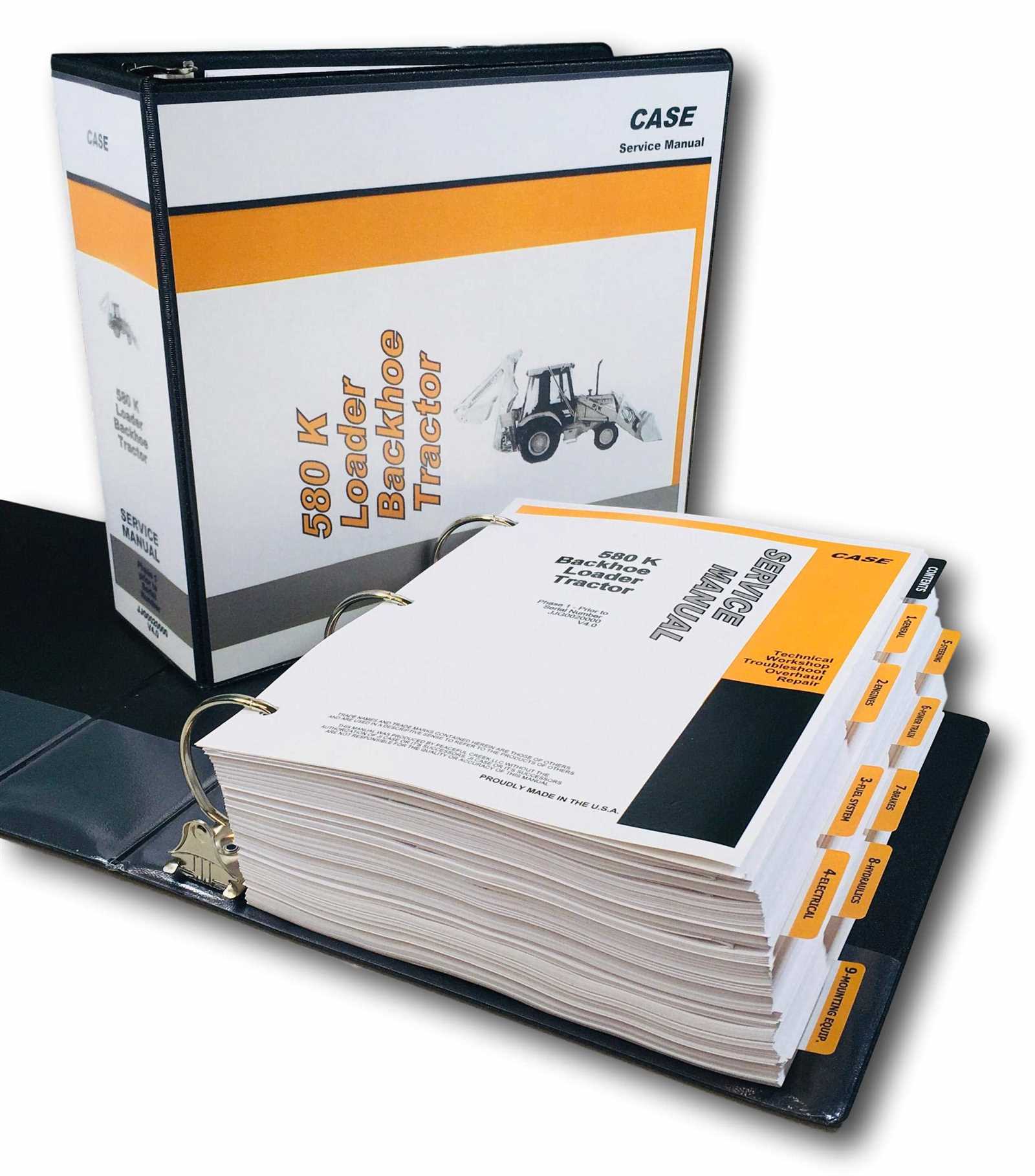

Overview of Case 580K Backhoe

This section provides a comprehensive look at a well-known machine used in construction and excavation. Renowned for its versatility and durability, this equipment plays a crucial role in various projects, showcasing its reliability and efficiency.

Key Features

Designed for optimal performance, this model includes numerous features that enhance its functionality. The powerful engine, advanced hydraulic system, and user-friendly controls make it a favorite among operators.

Applications

This heavy machinery excels in multiple applications, including digging, lifting, and loading. Its adaptability allows it to handle diverse tasks, making it an essential tool on job sites.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine for efficient operation |

| Hydraulic System | Advanced hydraulics for enhanced lifting capabilities |

| Operator Comfort | Ergonomic controls and spacious cabin |

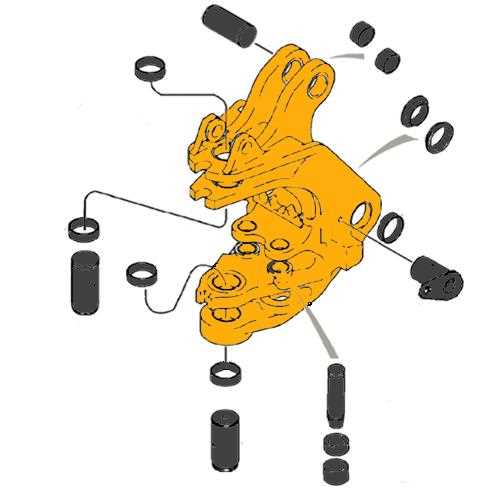

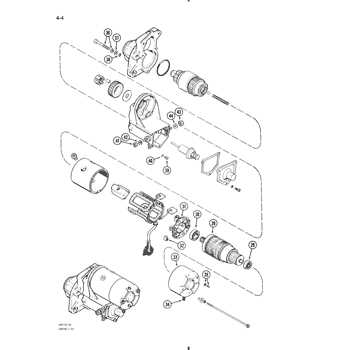

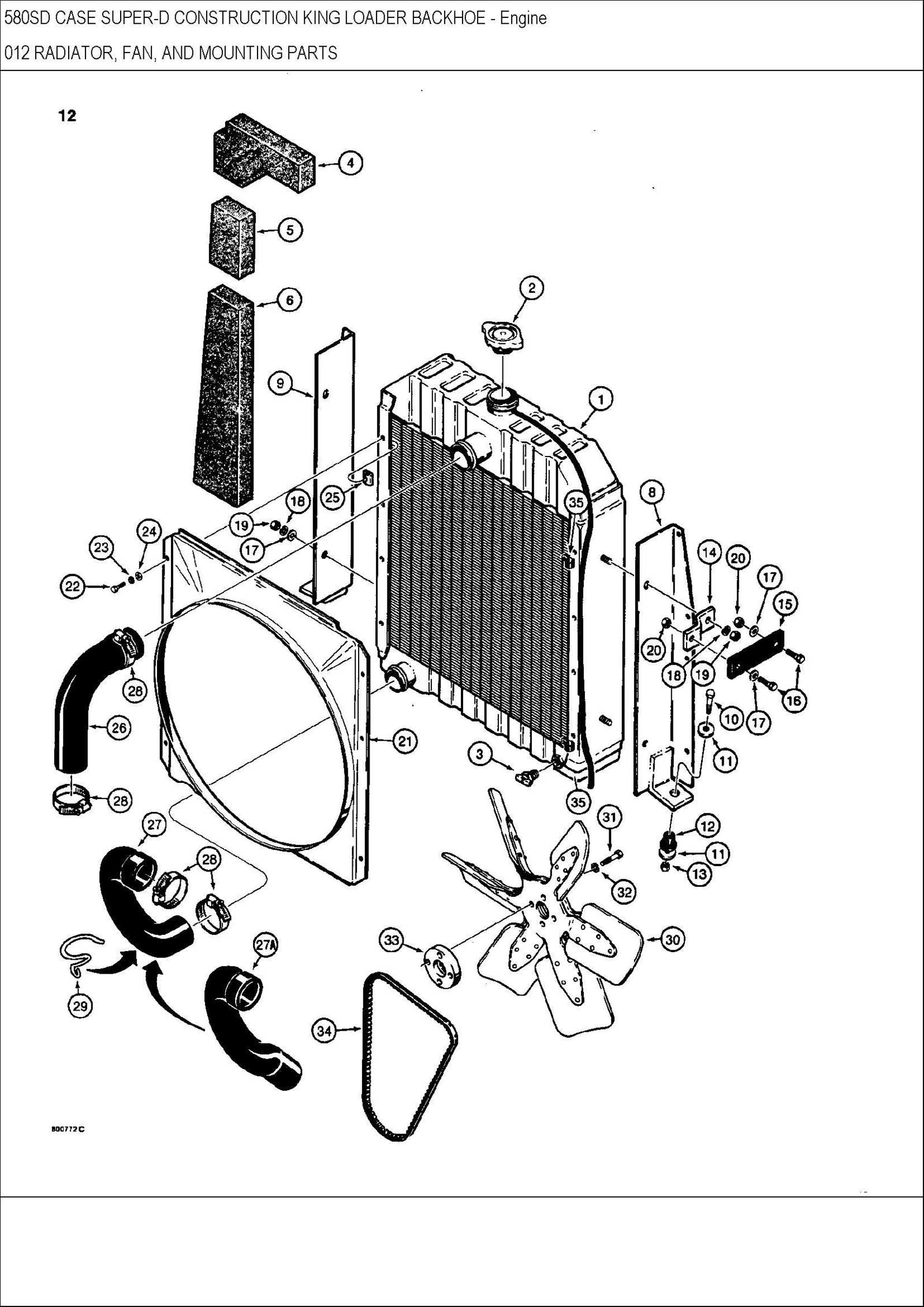

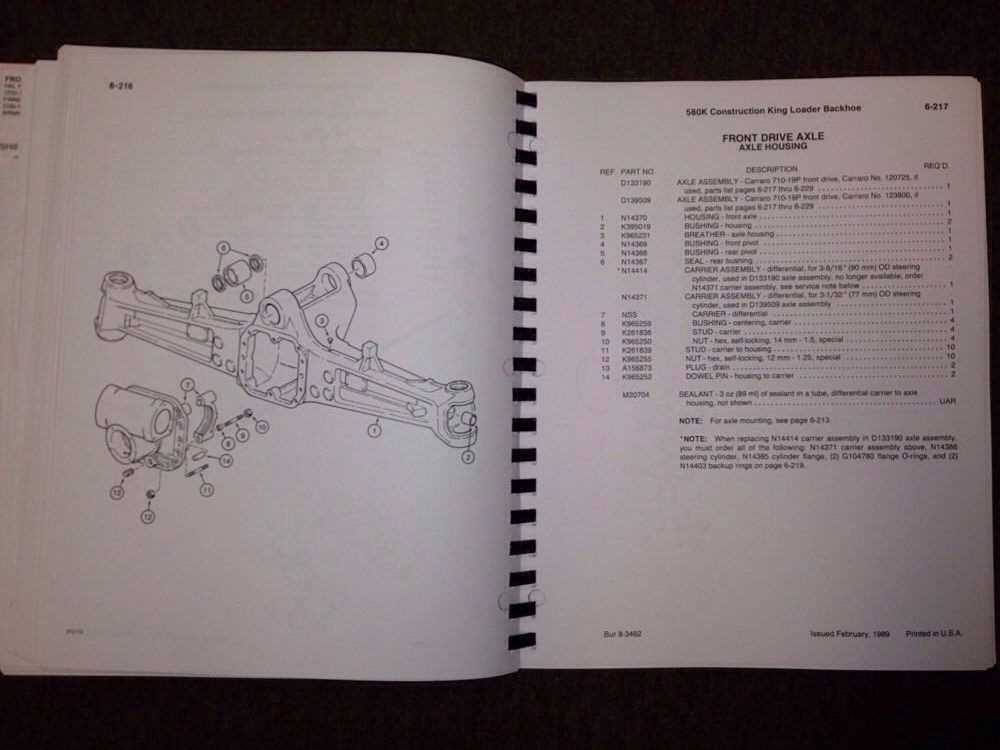

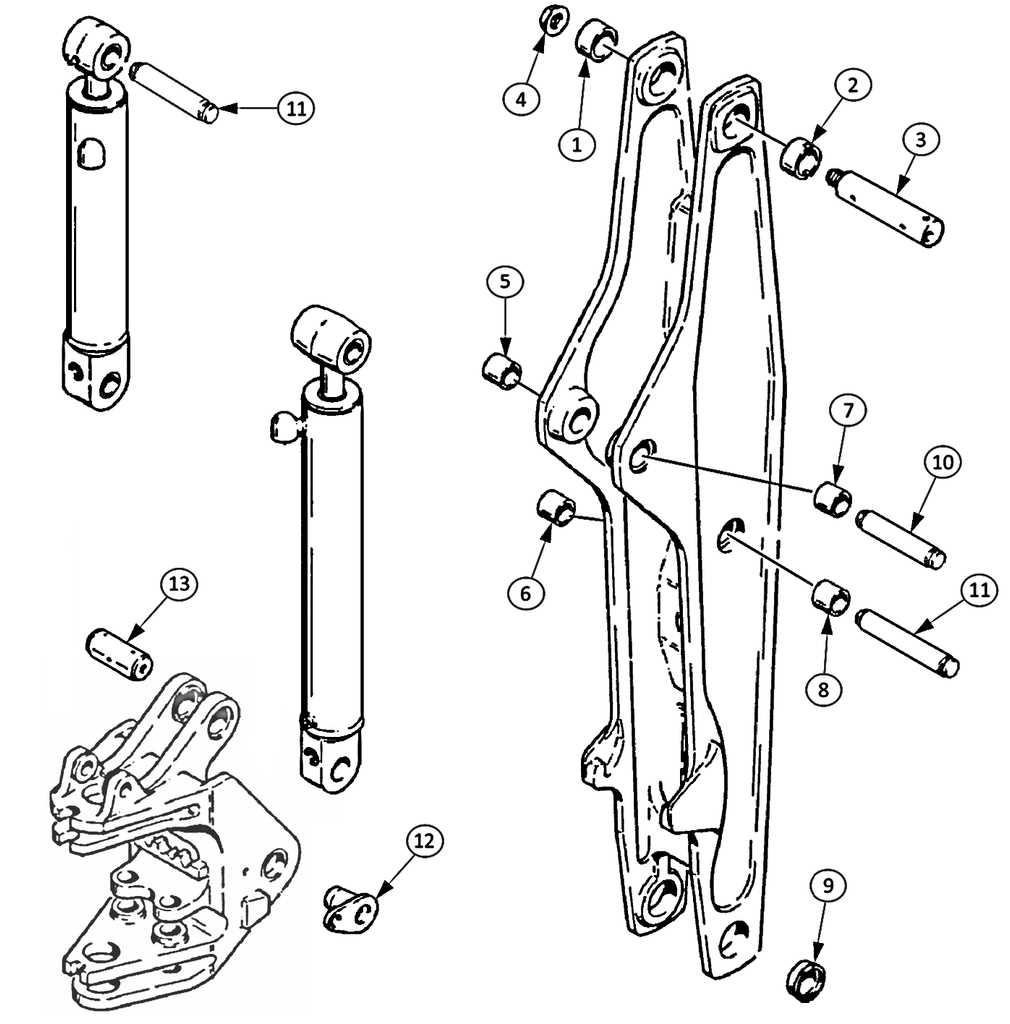

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as invaluable tools, allowing operators and technicians to identify individual elements and their relationships within the system. Such illustrations enhance clarity and reduce the likelihood of errors during servicing.

These visual aids not only facilitate the identification of specific components but also streamline the repair process. By providing a clear reference, they assist in locating parts quickly, thus saving time and minimizing downtime. Moreover, they can improve safety by ensuring that all necessary precautions are taken during disassembly and reassembly.

| Benefit | Description |

|---|---|

| Efficiency | Speeds up the identification and sourcing of components. |

| Accuracy | Reduces the risk of mistakes during repairs. |

| Safety | Promotes careful handling and awareness of parts during service. |

| Training | Serves as a helpful tool for educating new personnel. |

In summary, these visual tools play a vital role in ensuring the longevity and functionality of equipment, ultimately leading to improved operational effectiveness and reduced costs over time.

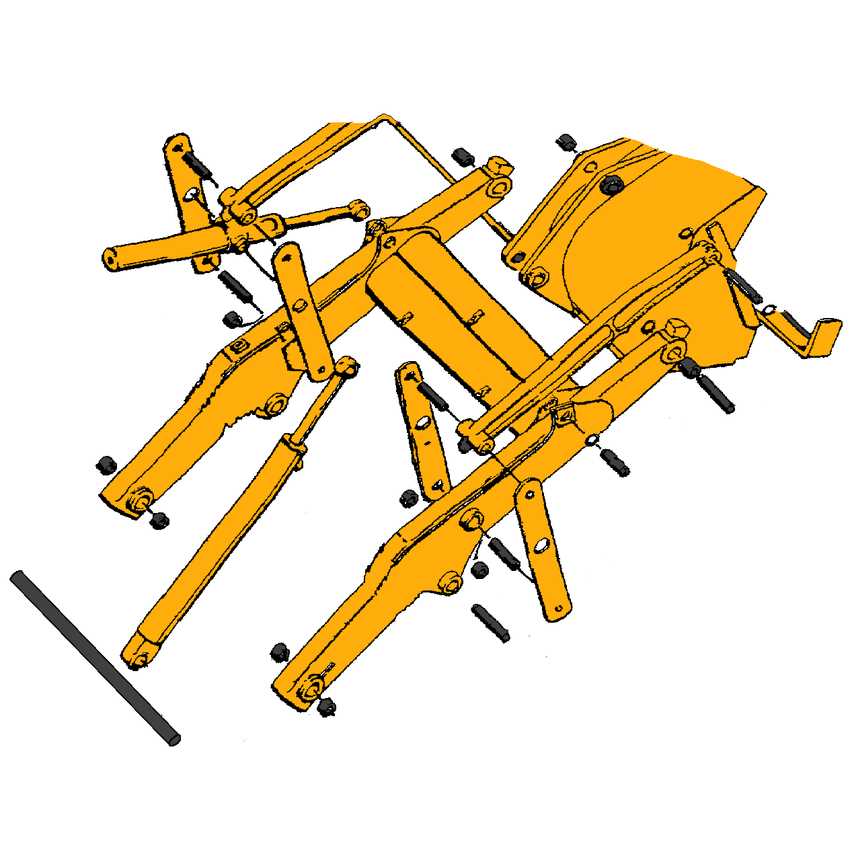

Key Components of the Backhoe

Understanding the essential elements of this versatile construction machinery is crucial for effective operation and maintenance. Each component plays a significant role in its overall functionality.

- Loader Bucket: Primarily used for lifting and moving materials.

- Excavator Arm: Enables digging and trenching activities.

- Stabilizers: Provide balance during operation, enhancing stability.

- Cab: The operator’s station, equipped with controls for maneuvering.

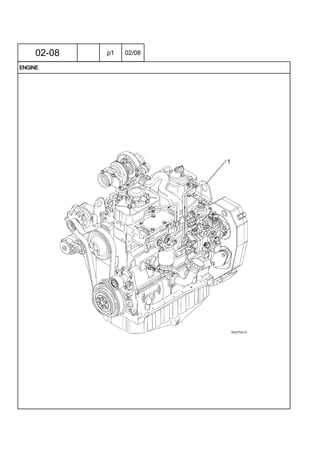

- Engine: Powers the entire machine, influencing performance and efficiency.

Each of these components contributes to the ultimate effectiveness and versatility of the equipment, making it an invaluable asset on job sites.

Understanding Hydraulic Systems

Hydraulic systems play a vital role in many machines, utilizing fluid power to facilitate various mechanical functions. By converting energy stored in hydraulic fluid into mechanical movement, these systems enable complex operations in construction, agriculture, and many other industries. Grasping the underlying principles of these systems is essential for effective maintenance and troubleshooting.

Key Components of Hydraulic Systems

- Hydraulic Fluid: The medium that transmits power, often oil-based, providing lubrication and heat dissipation.

- Pumps: Devices that generate flow, pushing hydraulic fluid through the system.

- Actuators: Components, such as cylinders or motors, that convert hydraulic energy into mechanical motion.

- Valves: Instruments that control the flow and direction of the fluid, regulating the system’s operation.

- Reservoirs: Storage tanks for hydraulic fluid, ensuring a consistent supply during operation.

How Hydraulic Systems Function

The operation of hydraulic systems is based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows for the amplification of force through the use of different sized cylinders. When a small force is applied to a small area, it can generate a much larger force over a larger area, making it possible to perform heavy lifting and precise movements.

- Fluid is drawn from the reservoir into the pump.

- The pump pressurizes the fluid and sends it through the system.

- Valves direct the pressurized fluid to the appropriate actuator.

- The actuator converts hydraulic energy into mechanical work.

- Fluid returns to the reservoir, completing the cycle.

Understanding these components and their interactions is crucial for optimizing performance and ensuring longevity in hydraulic machinery.

Common Issues and Solutions

Heavy machinery often faces a variety of challenges that can impact its performance and efficiency. Understanding these common problems and their solutions is essential for maintaining optimal operation and minimizing downtime. Below are some frequently encountered issues along with practical approaches to resolve them.

Hydraulic System Failures: One of the most prevalent issues is related to the hydraulic system. Symptoms may include sluggish movements or complete loss of power. Regularly checking fluid levels and ensuring there are no leaks can prevent these issues. If problems persist, inspecting the hydraulic pump and cylinders for wear is crucial.

Electrical Malfunctions: Electrical components can be sensitive to wear and environmental factors. Problems may manifest as faulty lights or non-responsive controls. To address these issues, examine wiring connections for corrosion and ensure fuses are intact. In some cases, replacing damaged components may be necessary to restore functionality.

Engine Performance Problems: A lack of power or excessive smoke from the engine can indicate underlying issues. Regular maintenance, including oil changes and air filter replacements, is essential. If performance issues continue, conducting a thorough diagnostic to check fuel injectors and other key components is recommended.

Transmission Issues: Difficulty shifting gears or unusual noises from the transmission may signal a need for attention. Checking the transmission fluid level and condition is a good starting point. If the fluid appears contaminated, a complete fluid change and inspection of internal components might be required.

By proactively addressing these common challenges, operators can enhance the reliability and lifespan of their equipment, ensuring smooth operation for years to come.

Where to Find Replacement Parts

Finding components for heavy machinery can be a straightforward task with the right resources. Whether you are looking for original equipment or high-quality alternatives, various avenues are available to help you in your search.

| Source | Description |

|---|---|

| Authorized Dealers | Official representatives offer genuine components and expert advice. |

| Online Marketplaces | Platforms like eBay and Amazon provide a wide range of aftermarket options. |

| Local Distributors | Regional suppliers often have in-stock items and can assist with ordering specific needs. |

| Salvage Yards | Used components can be sourced at reduced prices, often in good condition. |

| Manufacturer Websites | Directly browse online catalogs for the latest offerings and specifications. |

Maintenance Tips for Longevity

Ensuring the durability and performance of heavy machinery requires diligent care and attention. Regular maintenance practices can significantly extend the lifespan of your equipment, minimizing downtime and costly repairs. By following some fundamental guidelines, operators can maintain optimal functionality and reliability.

Regular Inspections

Conducting frequent checks on essential components is crucial. Look for signs of wear, leaks, or damage. Addressing minor issues promptly can prevent major failures down the line.

Fluid Management

Maintaining proper fluid levels is essential for effective operation. Regularly check and change hydraulic fluids, oils, and filters to ensure smooth performance and prevent overheating or mechanical failures.

Comparative Analysis with Other Models

This section aims to explore the differences and similarities between various models of construction machinery, highlighting their design, performance, and functionality. Understanding these distinctions can aid users in selecting the most suitable equipment for their specific tasks.

When comparing different models, several key aspects should be considered:

- Power and Efficiency: Variations in engine capacity and hydraulic performance can significantly affect productivity.

- Operational Versatility: The adaptability of each model to various tasks, such as digging, lifting, and loading, is crucial.

- Comfort and Usability: Features like cab design and control layout impact operator comfort and ease of use.

- Maintenance Requirements: Some models may demand more frequent servicing, which can affect long-term operational costs.

- Durability and Build Quality: Material selection and construction techniques influence the longevity of the machinery.

Analyzing these elements provides valuable insights into the performance of different models, enabling informed decisions based on specific operational needs.

Here are some popular models for comparison:

- Model A: Known for its robust engine and superior lifting capacity.

- Model B: Offers exceptional fuel efficiency and lower operational costs.

- Model C: Features advanced technology for enhanced control and precision.

- Model D: Renowned for its ease of maintenance and user-friendly design.

By evaluating these factors, operators can identify the machinery that best aligns with their project requirements and preferences.