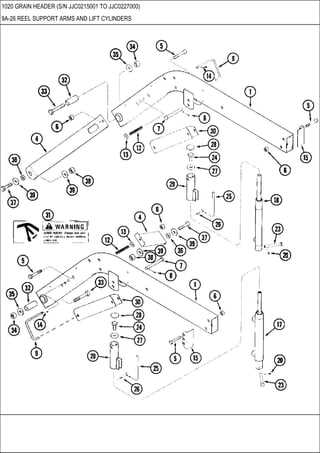

The efficient operation of a harvesting implement relies on the seamless integration of its various components. Each element plays a crucial role in ensuring optimal performance during the harvesting process. A clear understanding of these elements is essential for maintenance and troubleshooting, as well as for enhancing the overall functionality of the machinery.

In this section, we will explore the intricate assembly of a popular harvesting attachment, delving into its key components. By examining the relationship between each part, we can gain insight into how they work together to improve efficiency and effectiveness in the field. This knowledge not only aids in repairs but also empowers operators to maximize the capabilities of their equipment.

With a detailed overview of the various sections of the implement, including cutting mechanisms and support structures, we aim to provide a comprehensive resource for both experienced users and those new to this technology. Whether for routine maintenance or upgrading specific elements, understanding these components is vital for achieving the best results.

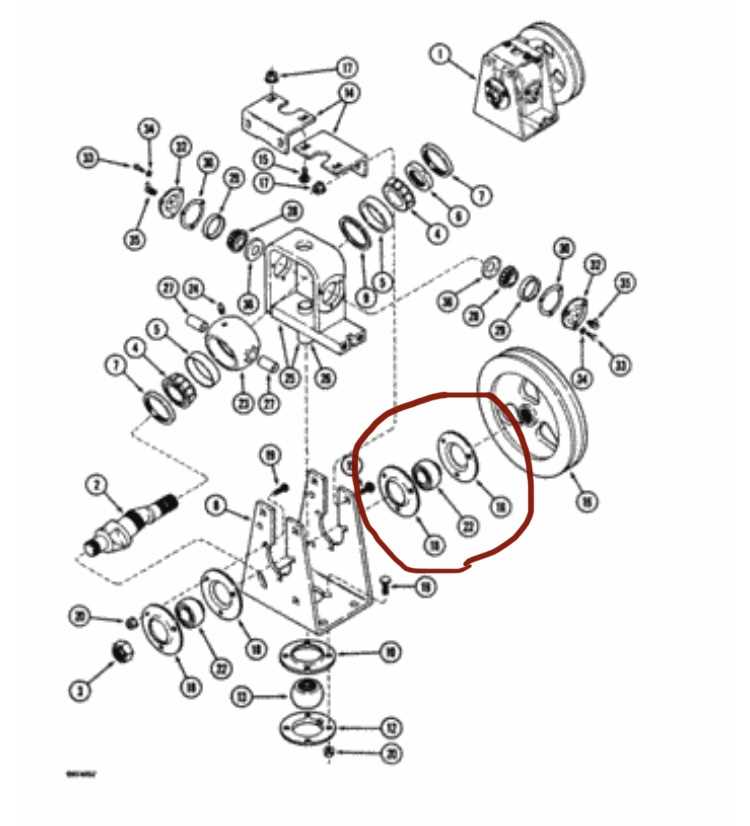

When operating agricultural equipment, various components may encounter issues that can affect overall performance. Understanding these common challenges can help in effective maintenance and troubleshooting.

- Wear and Tear: Over time, certain elements can experience significant wear, leading to decreased efficiency and functionality. Regular inspections are essential to identify such issues.

- Alignment Problems: Misalignment can occur due to improper installation or damage. This can result in uneven operation, affecting cutting performance and causing further complications.

- Obstruction: Debris buildup can block moving parts, leading to overheating and potential damage. Ensuring cleanliness in operating conditions is crucial for smooth functioning.

Addressing these issues promptly can enhance the reliability of your machinery and extend its operational life.

- Hydraulic Failures: Leaks or pressure drops in hydraulic systems can significantly impact performance. Regular maintenance and checking fluid levels are necessary to avoid such failures.

- Control Malfunctions: Problems with electronic controls can hinder operation, making it vital to regularly inspect and maintain these systems to ensure proper functionality.

By staying vigilant about these potential issues, operators can maintain optimal performance and reduce downtime.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of agricultural equipment requires a proactive approach to upkeep. Regular maintenance not only extends the lifespan of machinery but also enhances its performance, reducing the likelihood of unexpected breakdowns. Here are some essential practices to consider for optimal operation.

Routine Inspections

Conducting periodic evaluations of your equipment is crucial. Look for signs of wear, such as cracks or loose components, and address them promptly. Regular lubrication of moving parts minimizes friction and wear, contributing to smoother operation.

Proper Storage Practices

Storing equipment correctly can significantly impact its longevity. Always keep machines in a dry, sheltered environment to prevent rust and corrosion. Covering machinery when not in use helps protect it from dust and moisture, ensuring it remains in top condition for future use. Investing time in proper care now will pay off in the long run.

Replacement Parts Availability

Ensuring a steady supply of essential components is crucial for maintaining the efficiency of agricultural machinery. Access to high-quality replacement components can significantly reduce downtime, allowing operators to keep their equipment running smoothly throughout the farming season. Understanding the availability of these components helps in planning maintenance schedules and budget allocations effectively.

Sources for Replacement Components

- Authorized dealers: These suppliers often have a comprehensive inventory of components, ensuring that operators can find what they need quickly.

- Online retailers: Numerous e-commerce platforms offer a wide range of options, often at competitive prices. This convenience allows for easy comparison and selection of components.

- Aftermarket manufacturers: Many companies specialize in producing high-quality substitutes for original components, providing additional choices for operators.

Factors Affecting Availability

- Demand fluctuations: Seasonal variations can impact the availability of specific components, making it important to anticipate needs.

- Supply chain disruptions: Global events can affect the production and shipping of components, potentially leading to shortages.

- Compatibility requirements: Operators should verify that the components match the specifications of their machinery to avoid installation issues.

Comparative Analysis with Other Models

This section explores the distinctions and similarities between various harvesting equipment models. By examining their specifications, features, and performance, users can make informed decisions based on their operational needs.

When assessing different models, several factors come into play, including cutting width, durability, and technology integration. Each design caters to specific agricultural requirements, influencing efficiency and productivity. Below is a comparative overview highlighting key aspects of select models.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Cutting Width | 30 ft | 25 ft | 35 ft |

| Weight | 3,000 lbs | 2,800 lbs | 3,200 lbs |

| Max Yield | 4,500 bu/hr | 4,000 bu/hr | 5,000 bu/hr |

| Technology | GPS Enabled | Basic Control | Smart Sensors |

Ultimately, understanding these differences allows users to select the most suitable machinery for their specific agricultural tasks, maximizing productivity and efficiency in the field.