In the realm of heavy machinery, the intricacies of mechanical systems play a crucial role in their efficient operation. Each machine consists of numerous elements that work in harmony to perform a variety of tasks. This article delves into the specific components of a popular earth-moving vehicle, offering insights into its functional anatomy.

By exploring the arrangement and interaction of these crucial elements, operators can enhance their understanding of the machine’s performance and maintenance needs. A clear visual representation of these components aids not only in troubleshooting but also in optimizing the equipment’s use on job sites.

Furthermore, having a comprehensive grasp of these mechanisms is vital for ensuring the longevity and reliability of the machinery. Whether for professionals or enthusiasts, this exploration into the layout of these vital structures is essential for effective operation and care.

Understanding Hydraulic Case 580 Backhoe

This section delves into the essential components and functioning of a versatile earth-moving machine widely used in construction and excavation projects. A clear grasp of its mechanisms is crucial for effective operation and maintenance.

The equipment consists of various systems that work together to achieve optimal performance. Understanding these systems can enhance productivity and ensure longevity. Key elements include:

- Power system: Generates the necessary force for operation.

- Control mechanisms: Enable precise maneuvering and operation of attachments.

- Stabilization features: Provide balance during excavation tasks.

Familiarity with the core components facilitates better troubleshooting and repairs. The interplay between these elements allows for efficient handling of diverse tasks, making it an indispensable tool on job sites.

- Regular inspections: Ensure all systems are functioning correctly.

- Timely maintenance: Prevents unexpected breakdowns and extends the machine’s lifespan.

- Understanding safety features: Protects operators and workers in the vicinity.

In summary, a comprehensive understanding of this machinery’s structure and functions is vital for anyone involved in its operation or maintenance, ultimately leading to enhanced performance and safety on the job.

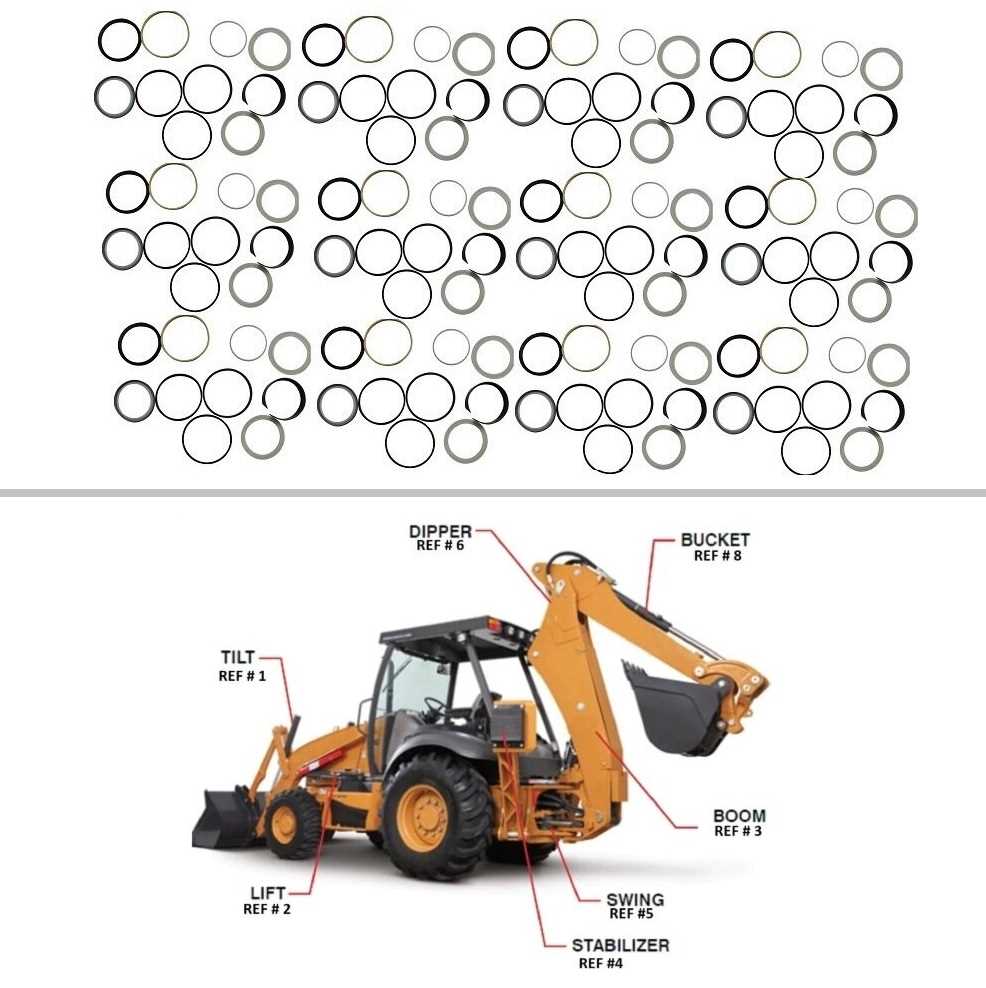

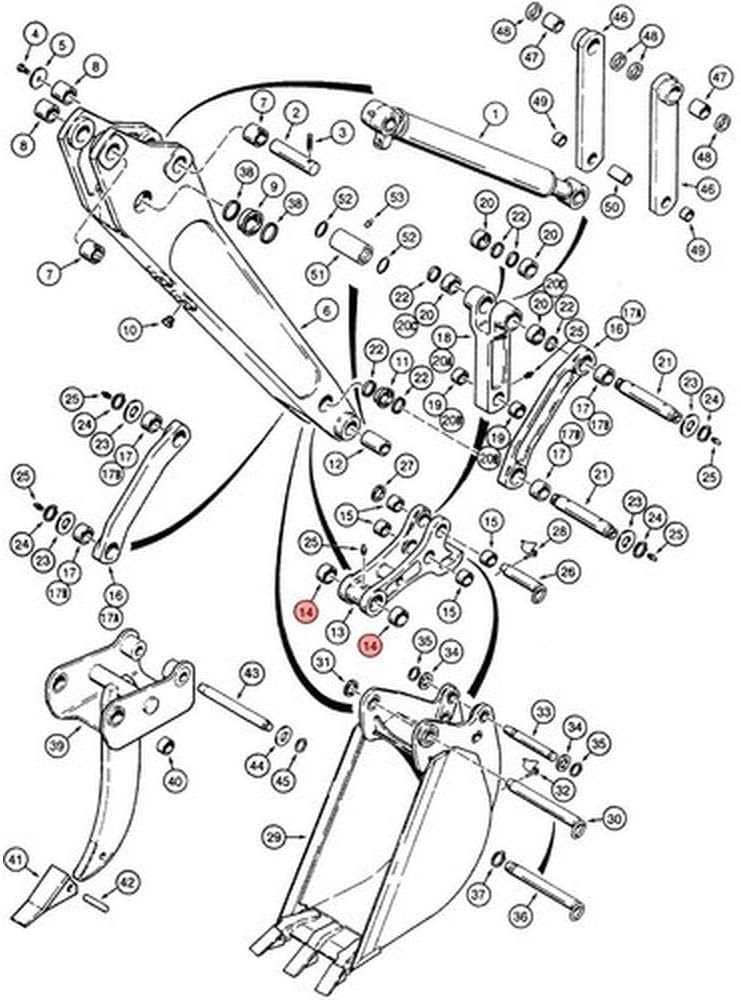

Key Components of Backhoe System

The efficiency and functionality of a digging machine rely on several essential elements that work together seamlessly. Understanding these components is crucial for optimal performance and maintenance.

- Operator’s Cabin: This enclosed space provides comfort and control, allowing the user to manage various functions with ease.

- Boom: A pivotal part that extends from the machine, it allows for reaching and lifting heavy loads.

- Stick: Attached to the end of the boom, it aids in precise digging and maneuvering in confined spaces.

- Bucket: The attachment at the end of the stick, designed for scooping and moving material.

- Frame: The structural foundation that supports all other components, ensuring stability and durability.

Each element plays a vital role in the overall operation, contributing to the machine’s ability to perform various tasks effectively.

- Stability: The frame provides a strong base.

- Reach: The boom enhances operational range.

- Precision: The stick allows for careful movements.

- Material Handling: The bucket is essential for loading and unloading tasks.

Regular inspection and maintenance of these critical components can significantly enhance the longevity and reliability of the equipment.

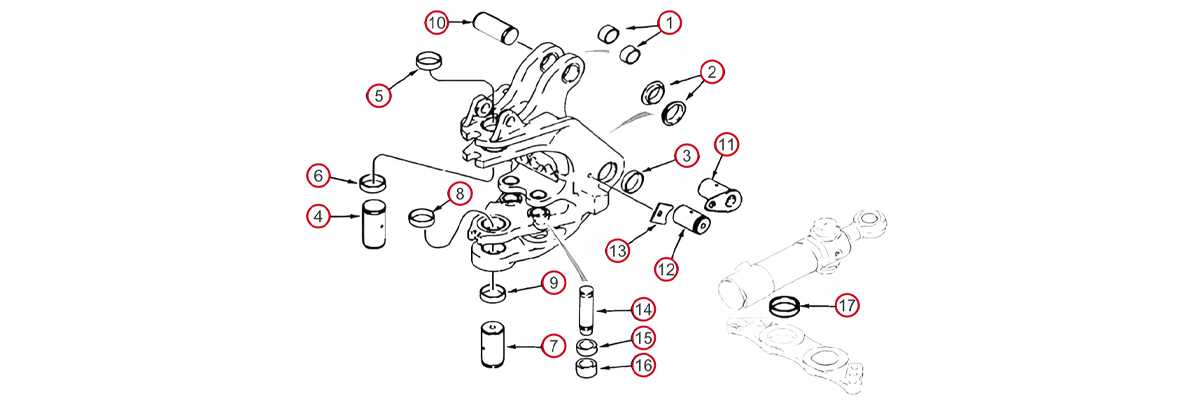

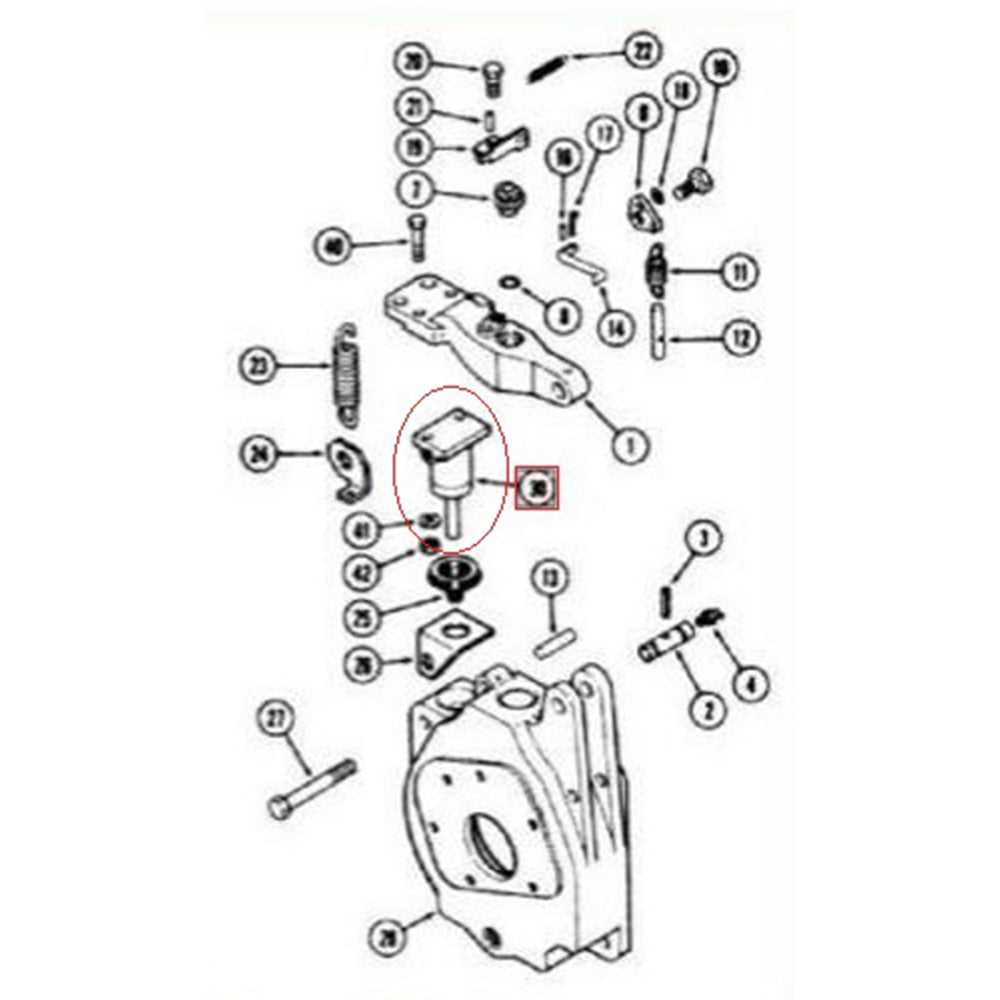

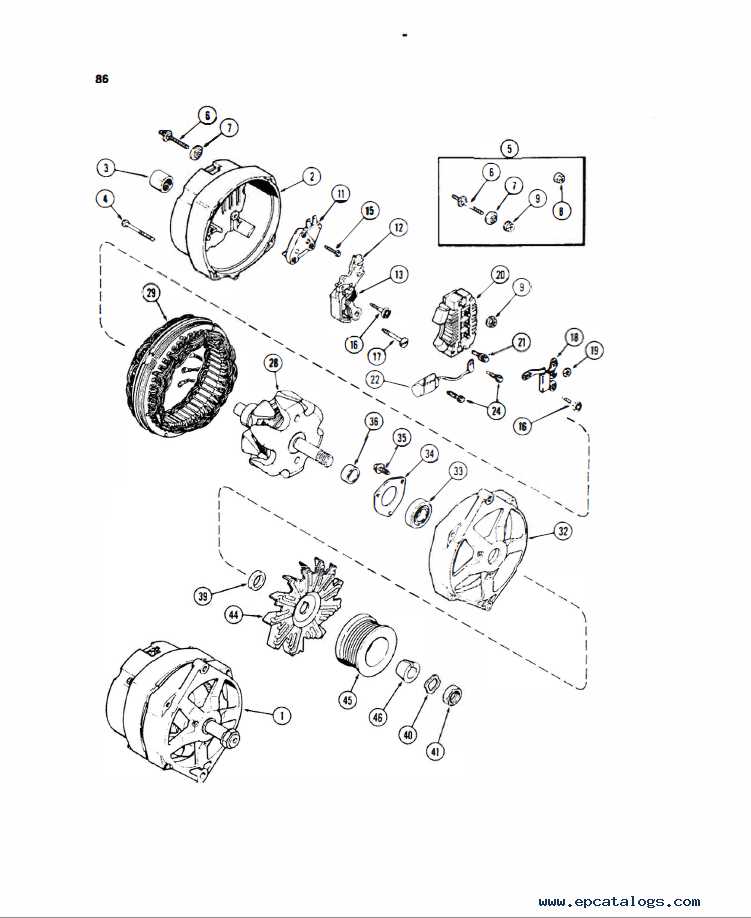

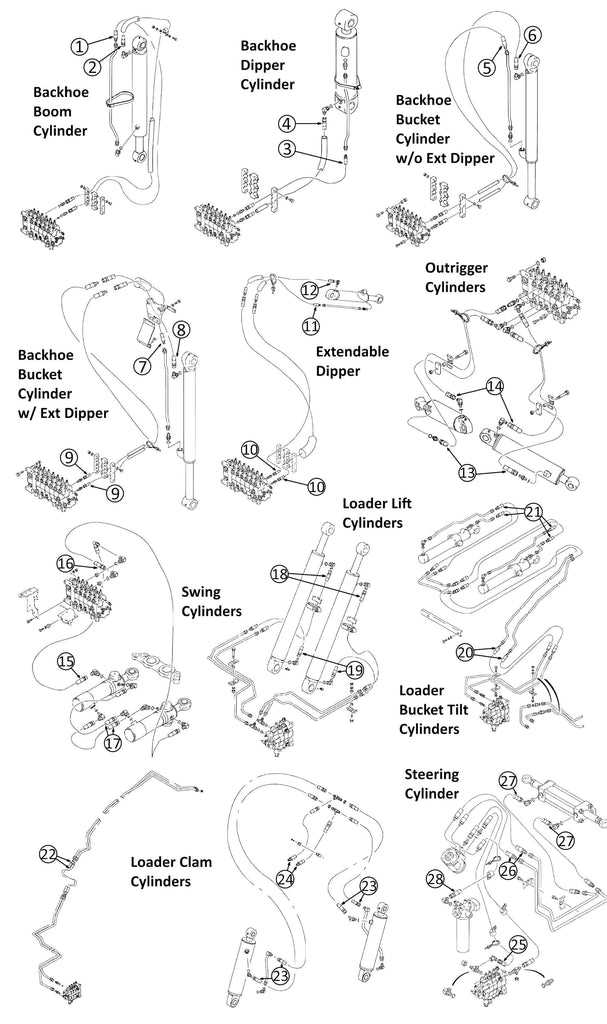

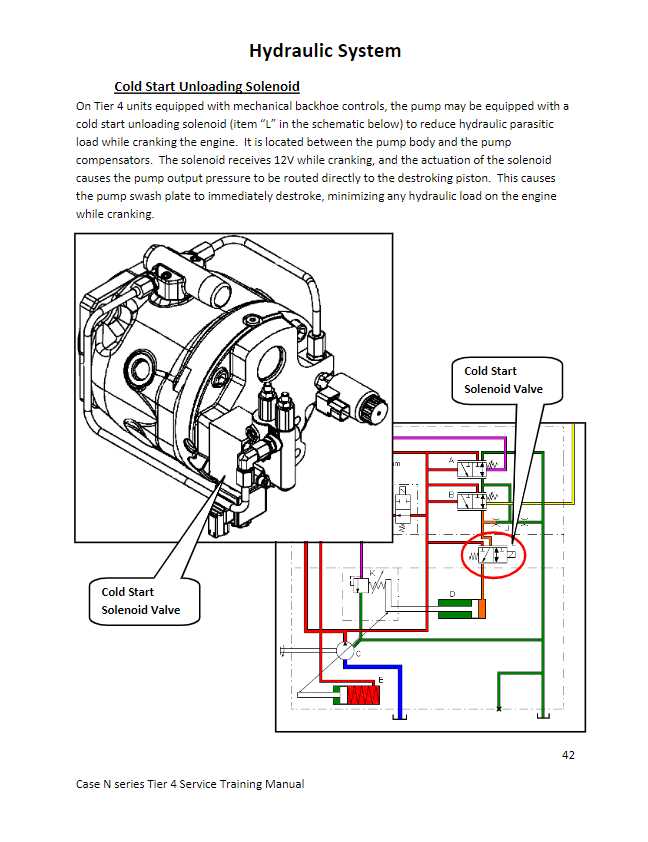

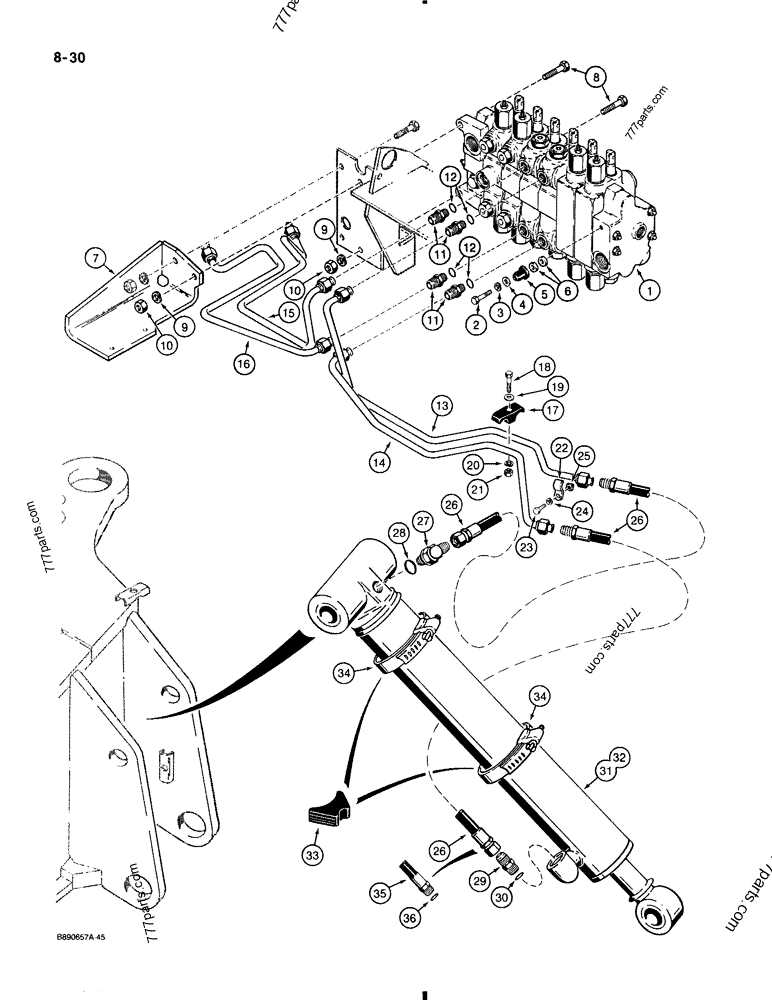

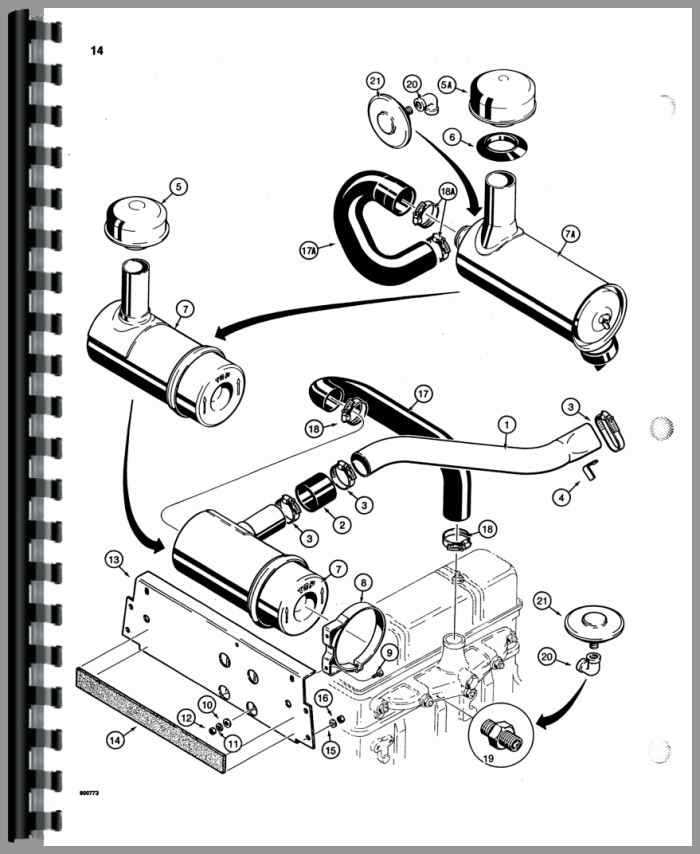

Importance of Hydraulic Diagrams

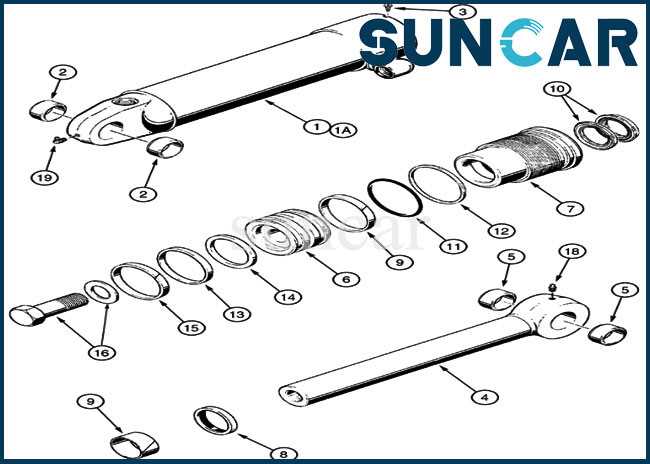

Understanding the intricacies of fluid systems is essential for maintenance and troubleshooting. Accurate visual representations serve as invaluable tools, helping technicians to grasp the relationships between components and the flow of liquids. This clarity ensures efficient repairs and minimizes downtime.

Benefits of Visual Representations

- Enhances comprehension of system functionality.

- Facilitates quick identification of issues.

- Improves communication among team members.

Applications in Maintenance

- Streamlines the diagnostic process.

- Guides assembly and disassembly tasks.

- Assists in training new technicians.

Common Issues with Backhoe Parts

When operating heavy machinery, various components can encounter challenges that affect overall performance and efficiency. Understanding these common complications is crucial for maintenance and operational longevity. Proper diagnosis and timely intervention can prevent minor issues from escalating into major repairs.

| Issue | Description | Symptoms | Solutions |

|---|---|---|---|

| Wear and Tear | Components may degrade over time due to prolonged use, leading to diminished functionality. | Unusual noises, reduced efficiency, leaks | Regular inspections, replace worn parts |

| Sealing Failures | Seals can become brittle or damaged, causing fluid leaks and pressure drops. | Fluid loss, visible leaks, erratic operation | Replace seals, check for proper installation |

| Clogged Filters | Filters can become blocked with debris, restricting flow and leading to overheating. | Overheating, engine strain, decreased power | Regularly clean or replace filters |

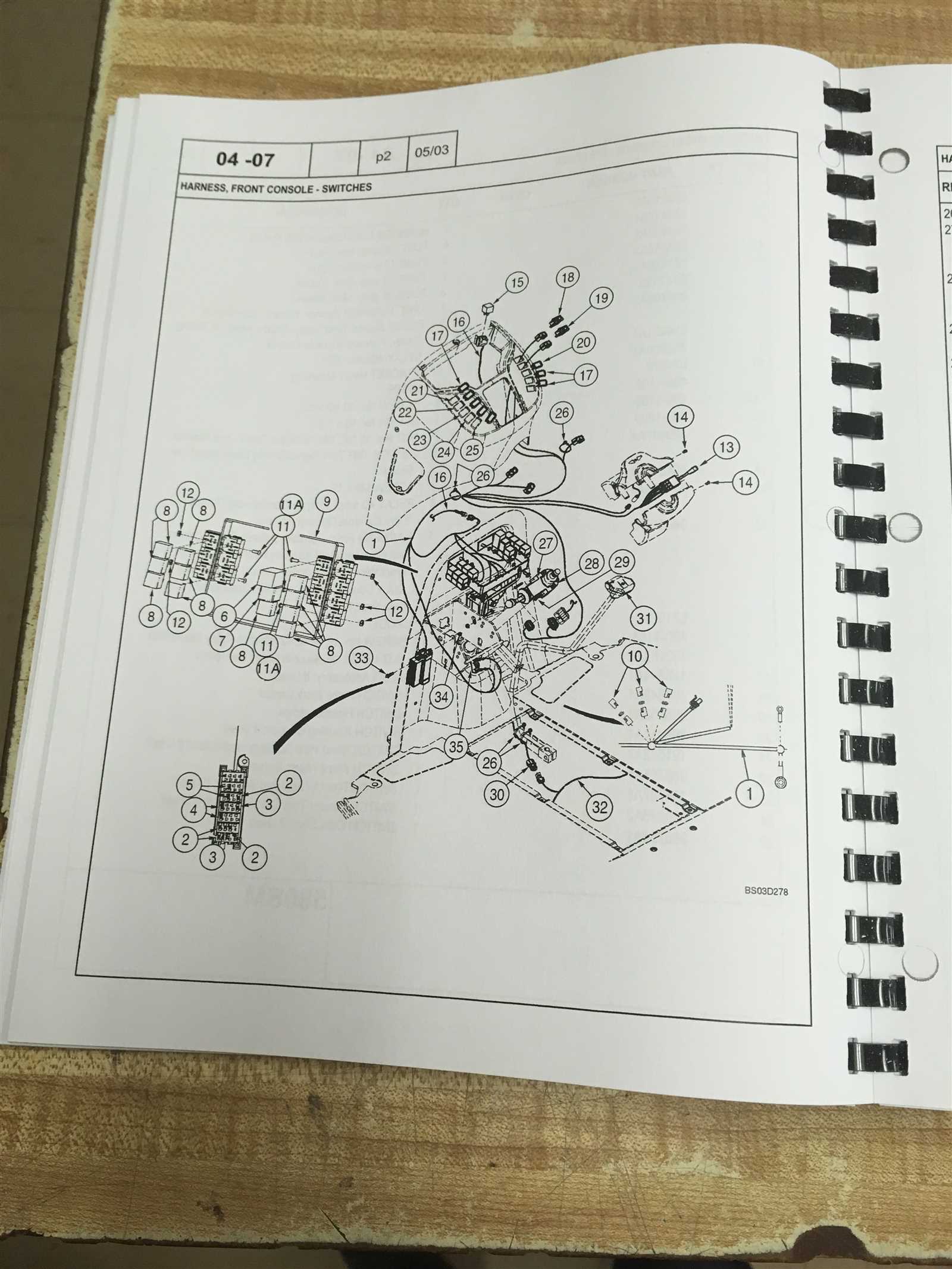

| Electrical Issues | Faulty wiring or connections can disrupt electrical systems, affecting performance. | Inconsistent operation, warning lights, failure to start | Inspect and repair wiring, ensure secure connections |

Maintenance Tips for Hydraulic Systems

Regular upkeep of fluid power systems is essential for ensuring optimal performance and longevity. By adhering to a few key practices, you can enhance the efficiency of these systems, reduce downtime, and prevent costly repairs.

Routine Inspections

Conducting frequent evaluations of the components is vital. Look for signs of wear, leaks, or contamination in the fluid. Pay close attention to seals and connections, as these areas are prone to issues. Establish a regular schedule for inspections to catch problems early and maintain smooth operation.

Fluid Quality Management

Maintaining the quality of the operational fluid is crucial. Regularly check the fluid levels and replace it according to the manufacturer’s recommendations. Ensure that the fluid is free from contaminants and is of the correct type for your system. Clean fluid not only extends the life of components but also improves overall system efficiency.

How to Read Hydraulic Diagrams

Understanding schematics is essential for effective maintenance and repair of machinery. These illustrations provide a visual representation of fluid flow and components, allowing operators to troubleshoot issues and ensure optimal performance. Familiarity with symbols and layout will enhance your ability to interpret these essential guides.

Key Components and Symbols

Familiarize yourself with common elements found in schematics:

- Pumps: Indicate the source of fluid movement.

- Valves: Control the direction and flow of the fluid.

- Actuators: Represent devices that convert fluid power into mechanical movement.

- Reservoirs: Store the hydraulic fluid for circulation.

Interpreting the Flow

To effectively read a schematic, follow these steps:

- Start from the pump and trace the flow path through the system.

- Note the connections between components, paying attention to how they are linked.

- Identify control points, such as valves, that alter the flow direction.

- Understand the feedback loops and how they affect system performance.

By mastering these aspects, you will enhance your understanding and capability in maintaining fluid systems efficiently.

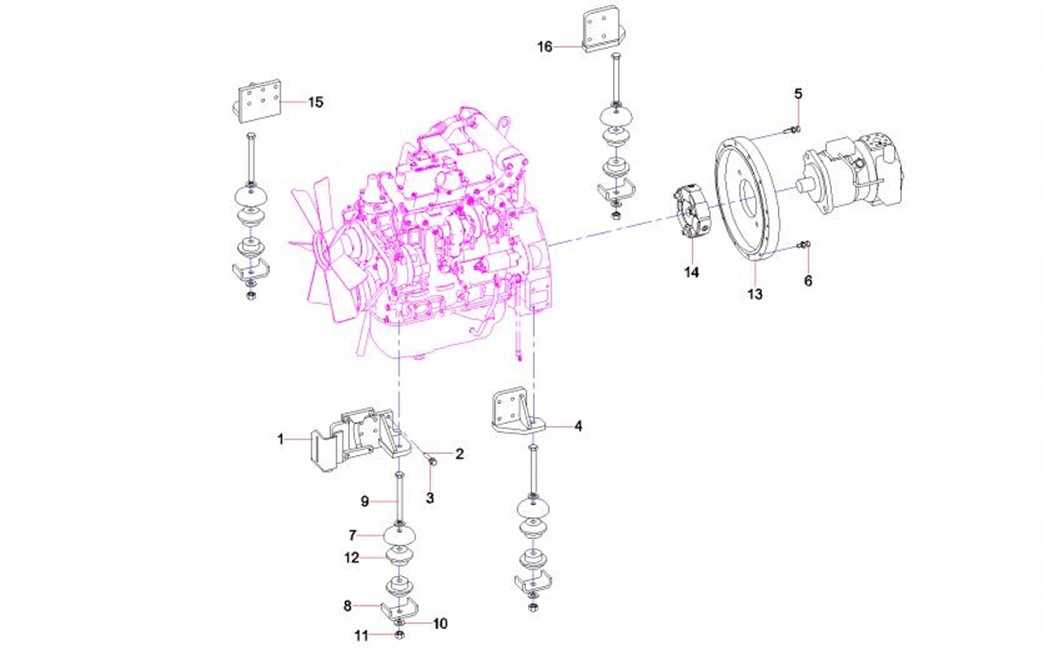

Replacement Parts for Case 580

Ensuring optimal performance of heavy machinery relies on the availability of quality components. When the time comes to restore functionality, understanding the variety of available options can enhance efficiency and extend the life of your equipment. From essential elements to specialized accessories, a thorough exploration of replacements is crucial.

Key Components

Vital elements include items such as filters, hoses, and bearings. Each plays a significant role in maintaining smooth operation and should be sourced from reputable suppliers. Regularly replacing these can prevent larger issues and costly downtime.

Aftermarket Options

Consider exploring aftermarket alternatives that may offer comparable quality at a reduced price. These options can be particularly beneficial for older models, providing flexibility without compromising performance. Always verify compatibility and durability before making a choice.

Upgrades for Enhanced Performance

Improving the efficiency and capability of your machinery can lead to significant operational benefits. By focusing on key enhancements, you can boost productivity and extend the lifespan of your equipment.

- Engine Modifications: Consider upgrades that enhance power and fuel efficiency.

- Transmission Enhancements: Explore options for smoother shifting and improved torque delivery.

- Attachment Options: Invest in specialized tools that increase versatility for various tasks.

- Control Systems: Upgrade to advanced controls for better precision and responsiveness.

- Suspension Improvements: Enhance stability and comfort, reducing wear on components.

Ultimately, these enhancements can lead to a more reliable and effective machine, maximizing your investment and minimizing downtime.

Resources for Further Learning

Exploring the intricacies of heavy machinery can greatly enhance your understanding and proficiency in maintenance and operation. This section provides valuable resources to deepen your knowledge and skills, enabling you to navigate complex systems with confidence. Whether you are a novice or an experienced technician, these tools and materials will aid you in your journey of discovery.

Online Courses and Tutorials

Numerous platforms offer specialized courses focused on machinery systems. Websites like Coursera, Udemy, and Khan Academy provide a variety of instructional videos and quizzes that cover topics from basic operations to advanced troubleshooting techniques. Engaging with these resources can help reinforce your theoretical knowledge and practical skills.

Technical Manuals and Reference Guides

Accessing detailed manuals and guides is essential for anyone looking to deepen their understanding of machinery components and functions. Manufacturers often publish comprehensive documentation that includes diagrams, specifications, and maintenance tips. Additionally, online forums and communities can serve as invaluable sources of peer advice and shared experiences, enhancing your learning process.