The intricate world of agricultural machinery involves numerous elements working in harmony to ensure efficiency and productivity. Navigating through this complex landscape requires a comprehensive understanding of each component’s role and function.

For operators and technicians alike, having access to detailed visual representations is essential. These resources not only enhance the comprehension of how various pieces fit together but also aid in troubleshooting and maintenance efforts.

Ultimately, by exploring these visual aids, users can delve deeper into the mechanics of their equipment, ensuring they are well-equipped to handle repairs and enhancements with confidence.

Understanding Case IH Parts Diagrams

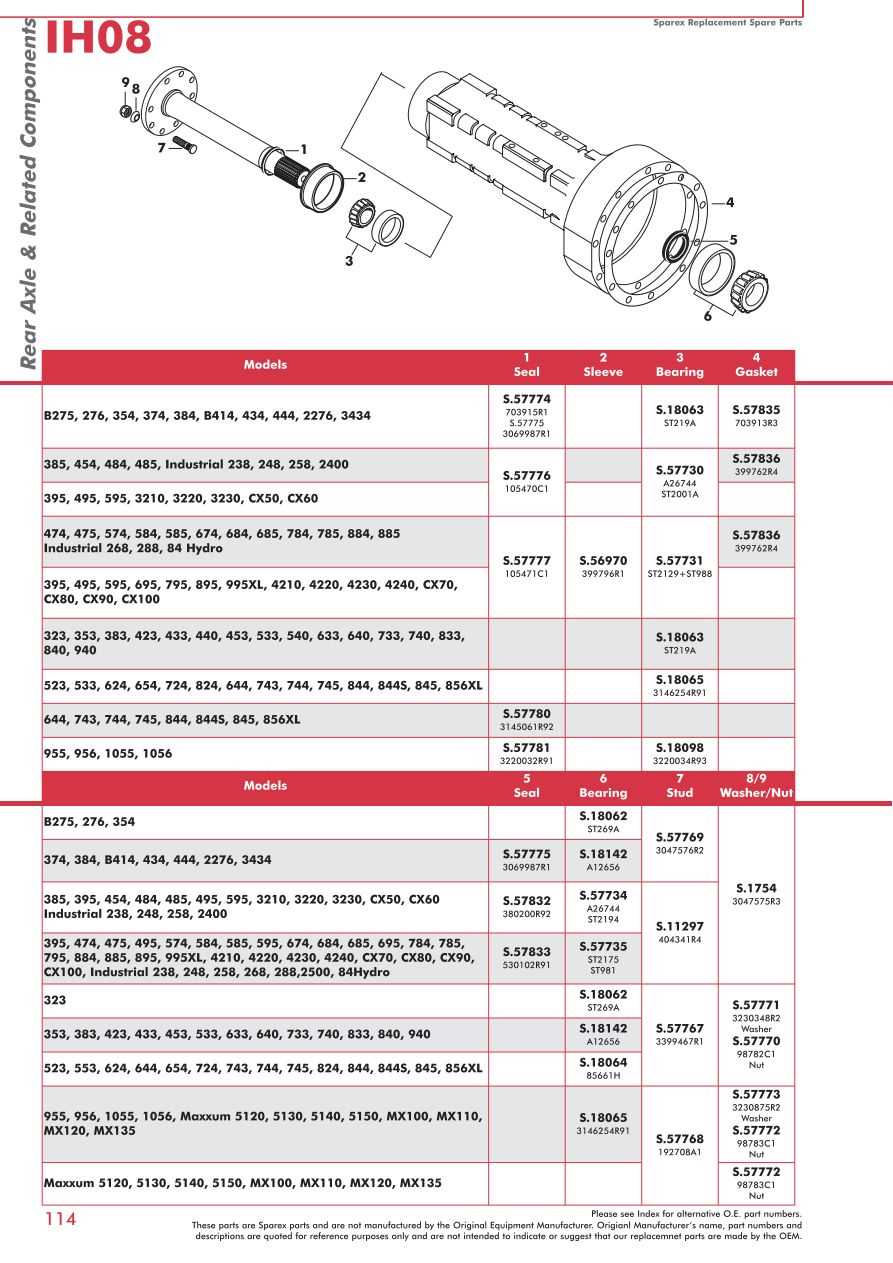

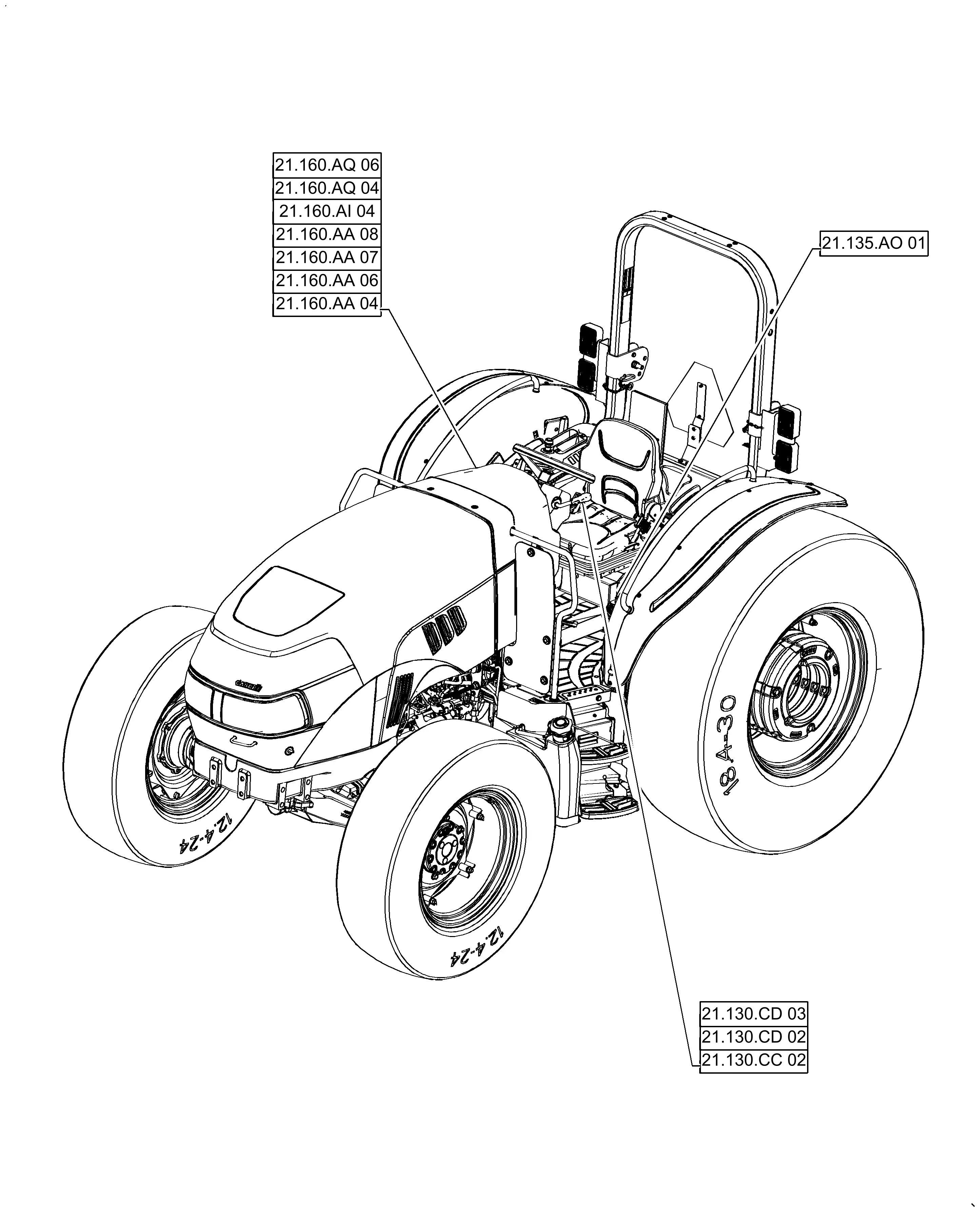

Grasping the intricacies of machinery components is essential for effective maintenance and repair. Visual representations serve as invaluable resources, allowing users to identify and locate individual elements within a system. This knowledge not only aids in troubleshooting but also enhances the overall efficiency of operations.

Visual aids simplify the complex structure of equipment, presenting a clear layout of various elements and their interconnections. By familiarizing oneself with these illustrations, operators can gain deeper insights into how each component contributes to the overall functionality.

Additionally, familiarity with these visuals can streamline the process of ordering replacements or upgrades. Recognizing specific features and configurations ensures that the correct items are acquired, minimizing downtime and optimizing performance.

Ultimately, understanding these visual guides empowers users to take charge of their equipment, facilitating informed decisions that lead to improved productivity and longevity.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in understanding complex machinery. They serve as essential tools for technicians and operators, facilitating effective communication and maintenance. With accurate illustrations, users can swiftly identify components, reducing the risk of errors during repairs or upgrades.

Enhanced Understanding

Well-crafted visuals enable users to grasp intricate designs and functions, enhancing overall comprehension. This understanding ultimately leads to improved performance and longevity of the equipment.

Efficient Maintenance

Having reliable references minimizes downtime by streamlining the troubleshooting process. When professionals can quickly locate and address issues, operational efficiency significantly increases, ensuring optimal productivity.

How to Read Parts Diagrams

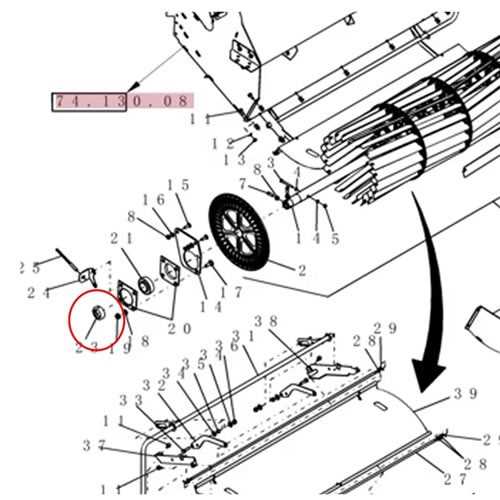

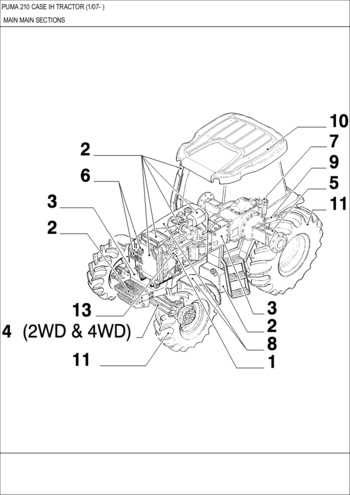

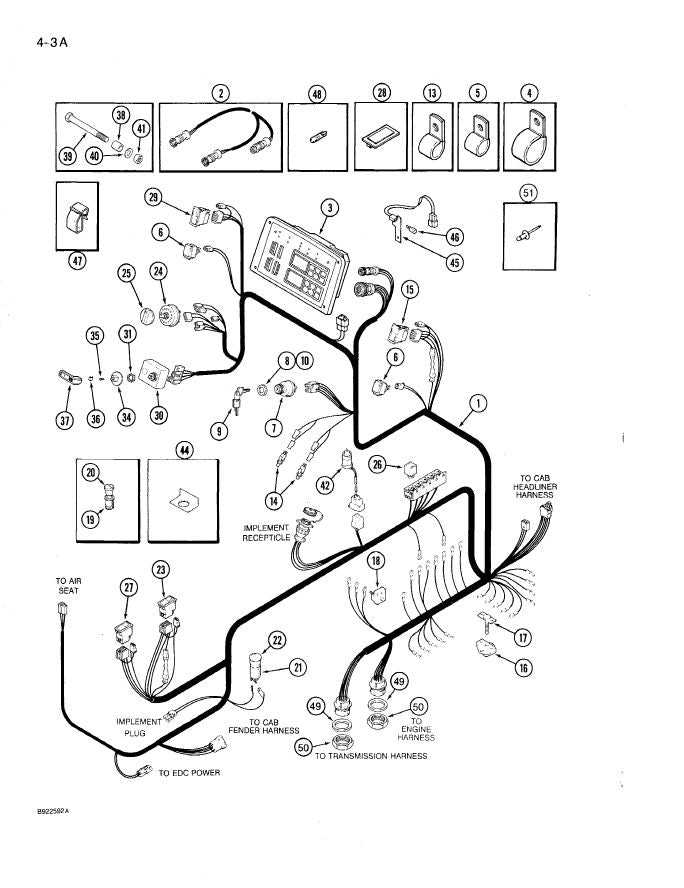

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual guides provide a clear representation of components, their arrangement, and how they interact within a system. Mastering this skill can significantly streamline the process of identifying necessary elements for servicing equipment.

Begin by familiarizing yourself with the overall layout of the illustration. Often, a key or legend accompanies the visual, explaining symbols and annotations used throughout the image. This foundational knowledge will help you navigate the drawing with confidence.

Next, focus on the labeled sections. Each element is usually accompanied by a reference number or letter that corresponds to a parts list. This list provides further details, such as dimensions and specifications, which are crucial when selecting replacements.

Additionally, pay attention to the grouping of components. Understanding how parts are assembled can aid in diagnosing issues or determining what needs to be replaced. Recognizing patterns in the layout can also assist in comprehending the operational flow of the machinery.

Lastly, practice is key. Regularly consulting these visual aids will enhance your ability to interpret them quickly and accurately. With time, you’ll develop a keen eye for detail, making the repair process more efficient and effective.

Common Components Illustrated in Diagrams

Understanding the fundamental elements of agricultural machinery is crucial for effective maintenance and operation. Visual representations provide a clear insight into how each part interacts within the whole system. This section highlights the essential components typically featured in these visual guides, enhancing the user’s knowledge and enabling more informed decisions regarding their equipment.

Key Elements in Visual Representations

Visual aids often showcase a variety of critical elements that contribute to the functionality of machinery. Below are some of the most common components you might encounter:

| Component | Description |

|---|---|

| Engine | The powerhouse of the machine, responsible for generating the necessary energy for operation. |

| Transmission | A system that transmits power from the engine to the wheels or other components, allowing for controlled movement. |

| Hydraulic System | A mechanism that uses fluid pressure to perform work, crucial for lifting and controlling various attachments. |

| Chassis | The framework that supports the body and components of the machine, ensuring structural integrity. |

Importance of Understanding Components

Familiarity with these essential elements not only aids in routine checks and repairs but also fosters a deeper appreciation for the technology involved. By grasping the role of each component, operators can troubleshoot issues more effectively and ensure optimal performance of their machinery.

Benefits of Using Case IH Diagrams

Utilizing visual representations for machinery components offers numerous advantages that enhance maintenance and repair processes. These resources serve as essential tools for operators and technicians alike, streamlining workflows and improving efficiency.

- Enhanced Understanding: Visual aids clarify complex systems, making it easier to identify and locate elements.

- Time Efficiency: Quick reference reduces downtime during repairs, allowing for faster resolutions.

- Accurate Repairs: Detailed illustrations minimize the risk of errors, ensuring correct installation and adjustments.

- Cost-Effective: Reducing miscommunication and mistakes leads to lower repair costs in the long run.

In summary, these resources ultimately facilitate smoother operations and contribute to the longevity of equipment.

Finding Diagrams for Older Models

Locating illustrations for vintage machinery can be challenging, yet it is essential for effective maintenance and repairs. Whether you’re restoring a classic model or simply trying to keep an older unit operational, understanding where to find these resources can save time and effort.

Online Resources

- Manufacturer Websites: Many companies maintain archives of their older models.

- Online Forums: Communities of enthusiasts often share valuable resources.

- Third-party Websites: Specialized sites may offer manuals and visuals for various machinery.

Local Resources

- Dealerships: Authorized dealers might have access to old archives.

- Libraries: Some local libraries hold technical manuals and historical documents.

- Machinery Shows: Attending these events can connect you with knowledgeable individuals.

Integrating Diagrams into Repair Processes

Incorporating visual representations into maintenance routines significantly enhances the efficiency and accuracy of repairs. These illustrations serve as essential tools, guiding technicians through intricate procedures and ensuring that every component is properly addressed. By utilizing these resources, the likelihood of errors diminishes, and the overall repair process becomes more streamlined.

Benefits of Visual Aids

- Improved Understanding: Visual guides break down complex systems into manageable parts, making it easier for technicians to grasp their functions.

- Time Efficiency: Quick reference materials allow for faster identification of components, reducing the time spent searching for information.

- Reduced Errors: Clear visuals help minimize mistakes during assembly and disassembly, leading to higher-quality repairs.

- Enhanced Training: New technicians can learn more effectively with visual support, accelerating their learning curve.

Implementing Visual Resources in Repairs

- Identify Key Areas: Determine which systems or components benefit most from visual assistance.

- Source Reliable Illustrations: Utilize trusted references that provide accurate representations of the equipment.

- Integrate into Workflow: Make visuals easily accessible during repairs, ensuring that technicians can consult them as needed.

- Encourage Feedback: Gather insights from users to improve the effectiveness of the visual resources continuously.

By thoughtfully integrating visual materials into the repair process, organizations can foster a more knowledgeable and efficient workforce, ultimately leading to better service and customer satisfaction.

Resources for Accessing Diagrams Online

Finding detailed illustrations and schematics for machinery can greatly enhance maintenance and repair tasks. Numerous platforms offer these resources, making it easier for users to locate the necessary visual aids. This section highlights some effective online tools and websites where users can access comprehensive visual references to aid in their projects.

Online Platforms

There are several websites specifically designed to provide users with easy access to a variety of schematics and illustrations. Here are a few notable options:

| Website | Description |

|---|---|

| OEM Parts Websites | Official manufacturer sites often have extensive libraries of illustrations and schematics available for download. |

| Third-Party Parts Retailers | Many retailers provide access to visuals alongside product listings, aiding in identification and installation. |

| Online Forums | Community-driven platforms frequently share resources and may have user-uploaded illustrations for various machinery. |

Digital Libraries and Resources

In addition to dedicated websites, several digital libraries offer access to a wealth of technical illustrations. These resources can be invaluable for in-depth understanding and troubleshooting:

| Resource | Description |

|---|---|

| Technical Manuals Archives | Many archives host manuals that include detailed illustrations relevant to specific machinery models. |

| YouTube Tutorials | Video tutorials often showcase the machinery in action, complemented by visual references to support users in repairs. |

| Library of Congress | This resource provides access to historical manuals and documents that may contain useful visuals. |

Tips for Maintaining Your Equipment

Proper care of your machinery ensures optimal performance and longevity. Regular maintenance not only prevents breakdowns but also enhances efficiency, saving time and resources in the long run.

Regular Inspections

Conduct frequent checks to identify wear and tear early. Look for signs of corrosion, leaks, or any unusual noises. Documenting these observations can help track performance over time.

Routine Cleaning

Keep your machines clean to avoid buildup of dirt and debris. Utilize appropriate cleaning methods for each component to maintain functionality and appearance, ensuring that all parts operate smoothly.