In the realm of pool maintenance, a comprehensive grasp of the various elements and their configurations is essential for optimal performance. Recognizing how these pieces interact ensures smooth operation and longevity of the system.

The intricate relationships between components can often be complex, yet deciphering these connections is crucial for effective troubleshooting. By examining the arrangement of individual elements, one can identify potential issues and enhance overall efficiency.

Moreover, having access to a detailed representation not only aids in repairs but also empowers users to make informed decisions regarding upgrades or replacements. This knowledge ultimately contributes to maintaining a pristine aquatic environment.

Understanding Hayward CL220 Components

Exploring the intricate elements of a specific water sanitization system reveals the critical roles each component plays in ensuring optimal performance. By grasping the functions and interrelationships of these parts, users can better maintain and troubleshoot their equipment, leading to a more efficient and effective operation.

Key Elements of the System

Each part of the unit serves a distinct purpose, contributing to the overall functionality. Familiarity with these components can enhance understanding and facilitate smoother maintenance practices.

| Component | Function |

|---|---|

| Filter | Removes debris and contaminants from the water. |

| Cell | Generates chlorine through electrolysis to sanitize the water. |

| Flow Switch | Monitors water flow to ensure safe operation of the system. |

| Power Supply | Delivers the necessary voltage for the electrolysis process. |

Maintenance Considerations

Regular inspection of these key components is essential for longevity and efficiency. Understanding how each part functions allows for timely interventions, ensuring the system operates smoothly and effectively over time.

Key Parts of the CL220 System

The effectiveness of a water treatment system relies heavily on its core components, each playing a vital role in ensuring optimal performance and longevity. Understanding these elements helps users maintain their equipment efficiently and troubleshoot issues as they arise.

Main Components

- Filter Unit: Essential for removing impurities and debris from the water, enhancing clarity and quality.

- Control Panel: Provides user interface for settings adjustment and monitoring system status, allowing for ease of operation.

- Flow Switch: Ensures proper water flow, activating the system only when needed, thus conserving energy.

- Power Supply: Converts electrical energy into usable power for the system, vital for its operation.

- Heating Element: Maintains the desired water temperature, contributing to a comfortable swimming experience.

Supportive Elements

- Hoses: Facilitate the movement of water through the system, connecting different components seamlessly.

- Valves: Control the flow of water, allowing for adjustments and system maintenance.

- Seals and Gaskets: Prevent leaks, ensuring that the system operates efficiently without loss of water.

- Diagnostic Sensors: Monitor system performance, providing alerts for any irregularities that may need attention.

Common Issues and Solutions

When maintaining and operating a swimming pool filtration system, users may encounter several frequent problems that can affect performance. Identifying these issues early and applying appropriate solutions can enhance efficiency and prolong the lifespan of the equipment.

-

Insufficient Filtration:

This can occur due to clogging or malfunctioning components. Ensure that filters are clean and replace them if necessary. Regular maintenance checks can prevent buildup.

-

Leaking Water:

Leaks may develop in seals or connections. Inspect all joints and gaskets for wear and tear. Tighten or replace any faulty components to stop leaks.

-

Noisy Operation:

Excessive noise can indicate a problem with the motor or impeller. Check for any obstructions and ensure all parts are properly lubricated and secured.

-

Inconsistent Flow Rate:

Variations in water flow can result from blockages or damaged hoses. Regularly inspect hoses for cracks and clear any debris in the system.

-

Power Issues:

If the system fails to start, check the power supply and connections. Ensure that circuit breakers are not tripped and that all wiring is intact.

Addressing these common challenges with timely and effective solutions can ensure optimal operation and maintain the quality of your swimming environment.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of your pool equipment, regular upkeep is essential. Following a systematic approach to maintenance can prevent issues and enhance performance, allowing for a clean and safe swimming environment.

Here are some key practices to consider:

- Regular Cleaning: Remove debris and sediment from the filtration system to maintain optimal flow and efficiency.

- Check Water Chemistry: Regularly test the water’s pH, chlorine, and alkalinity levels to ensure they remain within the recommended ranges.

- Inspect Components: Periodically examine all mechanical parts for wear and tear, replacing any damaged items promptly.

- Lubricate Moving Parts: Apply suitable lubricants to reduce friction on moving components, extending their lifespan.

By adhering to these maintenance guidelines, you can enhance the reliability and functionality of your equipment, making sure your pool remains an inviting oasis year-round.

Replacing CL220 Components Effectively

Maintaining and updating essential components is crucial for optimal performance. Proper replacement not only enhances functionality but also extends the lifespan of the equipment. Understanding the process and selecting the right parts can make a significant difference in the overall efficiency.

- Identify the Component: Recognize which part needs replacement based on performance issues.

- Gather Tools: Ensure you have the necessary tools at hand, including wrenches, screwdrivers, and seals.

- Follow Instructions: Refer to the manual for guidance on disassembly and reassembly.

- Use Quality Parts: Choose high-quality replacements to ensure reliability and durability.

- Test After Replacement: Run the system to confirm proper function post-replacement.

By following these steps, you can effectively manage the replacement of essential components, ensuring long-term functionality and efficiency.

Importance of Regular Inspections

Conducting routine evaluations of equipment is crucial for ensuring optimal performance and longevity. These assessments help identify potential issues before they escalate, reducing downtime and costly repairs. Consistent monitoring promotes efficiency and safety, ultimately enhancing the overall functionality of the system.

Regular inspections provide several key benefits:

| Benefit | Description |

|---|---|

| Early Detection | Identifying problems at an early stage prevents further damage and costly repairs. |

| Increased Efficiency | Well-maintained systems operate more efficiently, leading to lower energy costs. |

| Enhanced Safety | Routine checks minimize the risk of accidents and ensure safe operation. |

| Extended Lifespan | Regular maintenance prolongs the life of equipment, providing better return on investment. |

By prioritizing these assessments, individuals can ensure their systems remain in peak condition, ultimately fostering reliability and peace of mind.

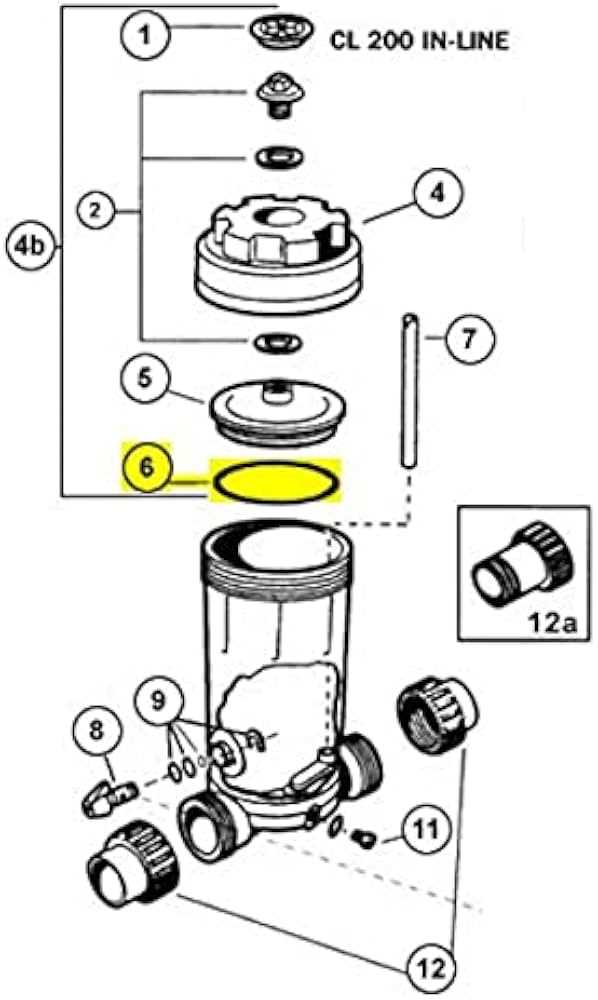

Diagram Analysis for Troubleshooting

Analyzing a schematic can significantly enhance the troubleshooting process by providing a visual representation of components and their relationships. This clarity aids in identifying potential issues and facilitates effective repairs. Understanding how different parts interact is crucial for pinpointing the source of problems.

Key Elements to Consider

When examining a schematic, focus on the following aspects:

| Element | Description |

|---|---|

| Connections | Reviewing how components are linked can reveal shorts or disconnections. |

| Symbols | Familiarity with the symbols used helps in understanding function and troubleshooting. |

| Flow Paths | Identifying the flow of current or water is essential for diagnosing blockages or failures. |

Troubleshooting Steps

Utilize the following steps for effective analysis:

- Examine the overall layout for any visible irregularities.

- Trace connections to ensure integrity.

- Compare findings with operational behavior to identify discrepancies.

Finding Replacement Parts Easily

Locating components for maintenance can often feel daunting, yet it doesn’t have to be. A streamlined approach involves utilizing both online resources and local retailers to simplify the search process. By leveraging various tools and platforms, users can efficiently identify what they need without unnecessary hassle.

Start by exploring manufacturer websites, where detailed catalogs and specifications are readily available. Online marketplaces also offer a wide selection, often accompanied by customer reviews that provide insight into the quality of the items. Additionally, connecting with local distributors can yield immediate assistance and recommendations, ensuring that you find the right fit swiftly.

Don’t forget to consult community forums and discussion groups. Engaging with fellow enthusiasts can reveal tips and tricks for sourcing materials effectively. By combining these resources, you can ultimately save time and ensure that you have everything required for successful repairs.

Enhancing Efficiency with Upgrades

Improving performance in any system can significantly enhance functionality and reduce operational costs. By focusing on key components, users can optimize their setups, ensuring they operate at peak efficiency. This not only prolongs the lifespan of the equipment but also contributes to overall effectiveness.

Key Benefits of Upgrading

- Increased energy savings

- Improved performance and reliability

- Reduced maintenance costs

- Enhanced user experience

Considerations for Optimal Upgrades

- Assess current components for compatibility.

- Research modern alternatives that provide better performance.

- Consult with experts to identify the ultimate upgrades.

- Plan for installation and potential downtime.