In the world of heavy machinery, comprehending the intricate elements that contribute to the functionality of equipment is essential. Each segment plays a pivotal role in ensuring optimal performance, and recognizing these components enhances maintenance and operational efficiency.

Visual representation of these elements can significantly aid operators and technicians in troubleshooting and repairs. By dissecting the anatomy of machinery, users can easily identify issues and understand the interconnections among various units.

Furthermore, a detailed examination of these mechanisms equips users with the ultimate knowledge necessary for effective management and upkeep. This exploration not only fosters a deeper appreciation for the equipment but also empowers users to make informed decisions when it comes to service and replacement.

Understanding Case Skid Steer Functionality

This section explores the mechanics and operations of compact loaders, highlighting their design and the innovative technology that drives their performance. By examining how these machines interact with various attachments and handle diverse tasks, one can appreciate their versatility and efficiency in construction and landscaping.

Powerful Engine systems provide the necessary force, enabling these vehicles to lift heavy loads and navigate challenging terrains. The hydraulic components play a crucial role, allowing for precise control over movement and attachment engagement, ensuring operators can perform tasks smoothly and effectively.

Furthermore, the operator’s station is designed for comfort and usability, featuring controls that allow for intuitive handling. This ergonomic focus ensures that even during extended use, the operator can maintain productivity without fatigue.

By delving into these aspects, one gains insight into how compact loaders achieve their ultimate performance, making them essential tools in modern machinery fleets.

Importance of Parts Diagrams

Understanding the components and their interconnections is crucial for efficient maintenance and repair. Visual representations serve as essential tools for technicians, allowing them to identify specific elements quickly. This clarity reduces the likelihood of errors during service, ensuring that machinery operates smoothly and reliably.

Furthermore, these illustrations provide insight into the assembly process, making it easier for users to reassemble equipment correctly after maintenance. Knowledge of each element’s location and function fosters better troubleshooting practices, leading to faster resolutions of issues.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual guides help users understand complex systems and identify components easily. |

| Improved Efficiency | Quicker identification of parts leads to faster repairs and less downtime. |

| Accurate Assembly | Clear visuals assist in proper reassembly after maintenance tasks. |

| Effective Troubleshooting | Knowledge of each part’s role helps in diagnosing issues accurately. |

Common Components of Skid Steers

Understanding the essential elements of compact construction machinery is crucial for optimal performance and maintenance. These components work together to ensure efficient operation in various tasks, ranging from excavation to material handling.

Engine: The heart of any machine, it provides the necessary power to drive all functions.

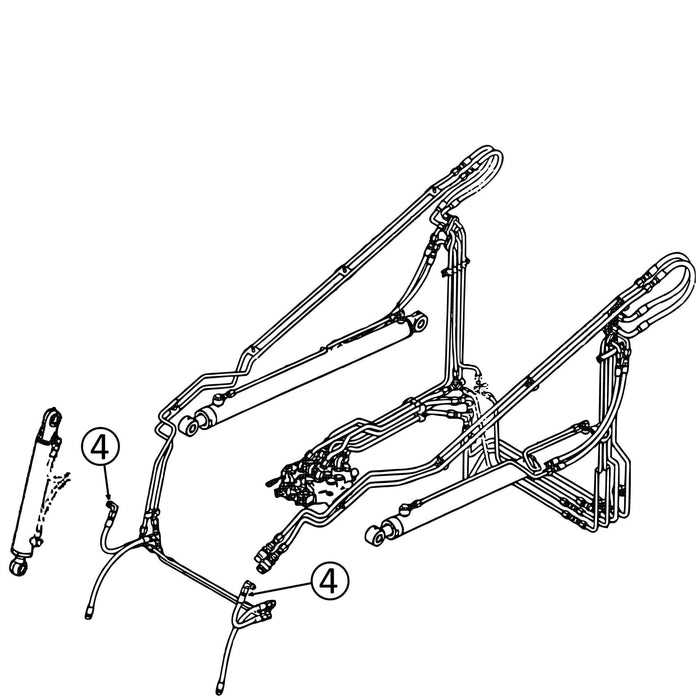

Hydraulic System: This system allows for smooth operation of attachments and controls, playing a vital role in the machinery’s versatility.

Chassis: The structural frame that supports all components, ensuring stability and durability during operation.

Transmission: This element transmits power from the engine to the wheels, allowing for effective movement and maneuverability.

Attachments: Various tools and implements can be connected to enhance functionality, making the equipment adaptable to different jobs.

Familiarizing oneself with these key elements can significantly impact productivity and efficiency in the field.

How to Read a Parts Diagram

Understanding an illustration that depicts various components can be essential for efficient repairs and maintenance. These visuals provide a clear representation of how different elements fit together, allowing users to identify specific parts and their relationships within the overall structure.

Identifying Components

Begin by familiarizing yourself with the key labels and numbers that correspond to each piece. Often, these indicators are crucial for referencing parts in manuals or catalogs. Pay attention to groupings that show how certain elements connect, which will help in grasping the assembly process.

Utilizing Reference Numbers

Each component is typically assigned a unique identifier, making it easier to locate replacements. Use these reference numbers to search in parts inventories or online resources. This method not only saves time but ensures that you find the ultimate match for your needs.

Maintenance Tips for Skid Steer Parts

Ensuring the longevity and efficiency of machinery involves regular attention to its components. Proper upkeep not only enhances performance but also minimizes the risk of unexpected breakdowns. This guide offers practical strategies to help you maintain essential elements effectively.

Regular Inspections

Routine checks of machinery components can prevent minor issues from escalating into significant problems. Pay close attention to wear and tear, particularly on high-use items. Look for signs of damage and address them promptly to ensure optimal functionality.

Lubrication and Cleaning

Consistent lubrication of moving parts is vital for reducing friction and preventing wear. Clean surfaces regularly to remove debris and contaminants, which can compromise performance. Adopting a thorough cleaning routine will extend the lifespan of crucial elements.

Identifying Wear and Tear Issues

Recognizing signs of deterioration is crucial for maintaining optimal functionality of machinery. Regular inspections can help pinpoint problems before they escalate, ensuring safety and efficiency. By understanding common indicators of wear, operators can take proactive measures to extend the lifespan of their equipment.

Common signs of damage include unusual noises, decreased performance, and visible signs of wear on components. For instance, cracks, excessive play, or corrosion can indicate that a part is nearing the end of its usable life. Monitoring fluid leaks is also essential, as they can signal issues with seals or gaskets that require immediate attention.

Additionally, assessing the condition of tires and tracks can reveal important information about overall equipment health. Uneven wear patterns may suggest alignment issues, while reduced traction can affect operational efficiency. Regularly checking these elements contributes to a more comprehensive understanding of the machine’s condition.

By conducting thorough inspections and being vigilant for these signs, operators can address wear and tear issues early, ultimately reducing downtime and repair costs.

Where to Find Replacement Parts

Finding the right components for your machinery is essential for maintaining its efficiency and prolonging its lifespan. Various sources offer high-quality replacements, ensuring your equipment remains in optimal working condition. Here are some reliable avenues to explore when searching for the necessary items.

Authorized Dealers

One of the best places to start is with authorized dealers. These establishments provide genuine components that are specifically designed for your machine, ensuring compatibility and reliability. They often have a knowledgeable staff who can assist you in identifying the correct items based on your model and year.

Online Marketplaces

The internet offers a vast array of platforms where you can purchase components at competitive prices. Websites specializing in machinery supplies frequently have extensive catalogs, allowing you to compare options and read reviews from other users. However, it’s important to verify the credibility of sellers to avoid counterfeit products. Look for vendors with positive ratings and clear return policies to ensure a safe purchasing experience.

In summary, whether you choose to visit a local dealer or browse online, taking the time to find quality replacements will enhance the performance and longevity of your equipment.

Upgrading Components for Better Performance

Enhancing machinery efficiency often involves replacing or upgrading key elements. These modifications can significantly improve operation, reduce wear, and enhance productivity. This section explores various ways to achieve optimal performance through component enhancements.

Key Areas for Improvement

- Hydraulic System

- Engine Efficiency

- Transmission Upgrades

- Operator Controls

Benefits of Upgrading

- Increased Power Output

- Improved Fuel Efficiency

- Extended Lifespan of Equipment

- Enhanced Operator Comfort

Investing in these areas can lead to ultimate performance gains and ensure the machinery remains competitive in demanding environments.