Understanding the inner workings of complex machinery is crucial for both operators and technicians. When dealing with large equipment, familiarity with its structure and mechanisms can streamline maintenance, repairs, and overall operation. This section aims to offer a clear view of the intricate design, focusing on its essential components and their relationships.

Maintenance and troubleshooting require a thorough knowledge of the machine’s individual elements. By diving into the specific layout and understanding the function of each segment, users can efficiently diagnose issues, replace elements, and keep the machine running smoothly. Such knowledge enhances both performance and durability, minimizing downtime.

Operational efficiency greatly depends on the seamless interaction between various mechanical and hydraulic systems. Each part plays a role in the larger system, contributing to its overall functionality and precision. In the following sections, we will delve deeper into these essential systems and how they are integrated to optimize the machine’s performance.

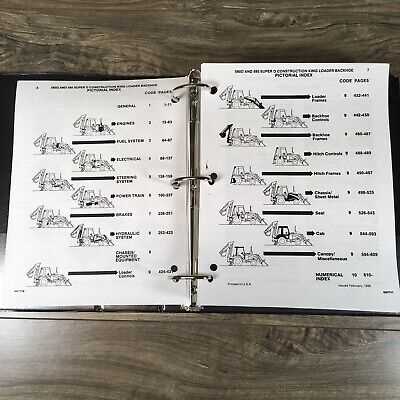

Overview of the Case 580D Parts Diagram

Understanding the key components of heavy machinery is essential for effective operation and maintenance. This section provides a comprehensive look at how the elements of this construction vehicle interact with one another. By visualizing the mechanical layout, it becomes easier to diagnose issues, optimize performance, and ensure proper upkeep.

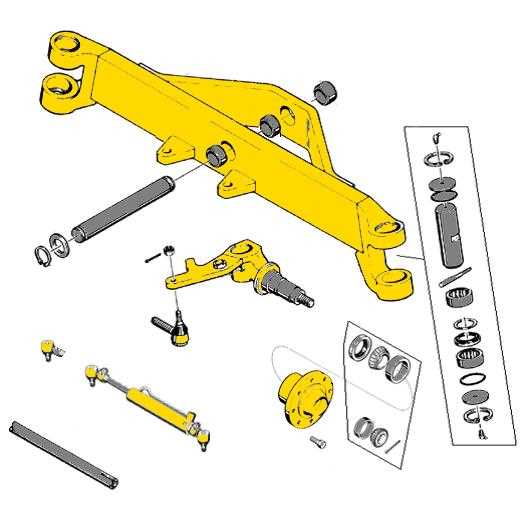

Main Components and Their Functions

The structure of this vehicle includes several crucial sections, each serving a unique role in its operation. From hydraulic systems to engine assemblies, each part works in tandem to support the overall functionality. Knowing these elements and their respective functions enables better handling and troubleshooting of potential issues.

Benefits of Familiarizing with the Layout

Having a clear understanding of the internal arrangement enhances your ability to carry out repairs and regular checks. It also improves your confidence when discussing repairs with technicians or sourcing specific replacement pieces. Mastery of this knowledge is key to maintaining long-term reliability and efficiency.

Understanding Key Components of the Case 580D

Efficient operation and long-term reliability of any heavy-duty machinery depend on the proper functioning of its critical systems. Identifying and understanding these essential elements can help maintain peak performance and reduce downtime.

- Engine Assembly: The heart of the machine, responsible for generating power to drive all mechanical systems. Regular maintenance of the engine is crucial for sustained performance.

- Hydraulic System: This system powers various attachments and ensures smooth operation of lifting, digging, and other hydraulic-based actions. Proper fluid levels and regular inspection are necessary to avoid leaks and ensure optimal performance.

- Transmission: Transfers power from the engine to the wheels or tracks. A well-maintained transmission ensures seamless gear shifting and efficient power distribution.

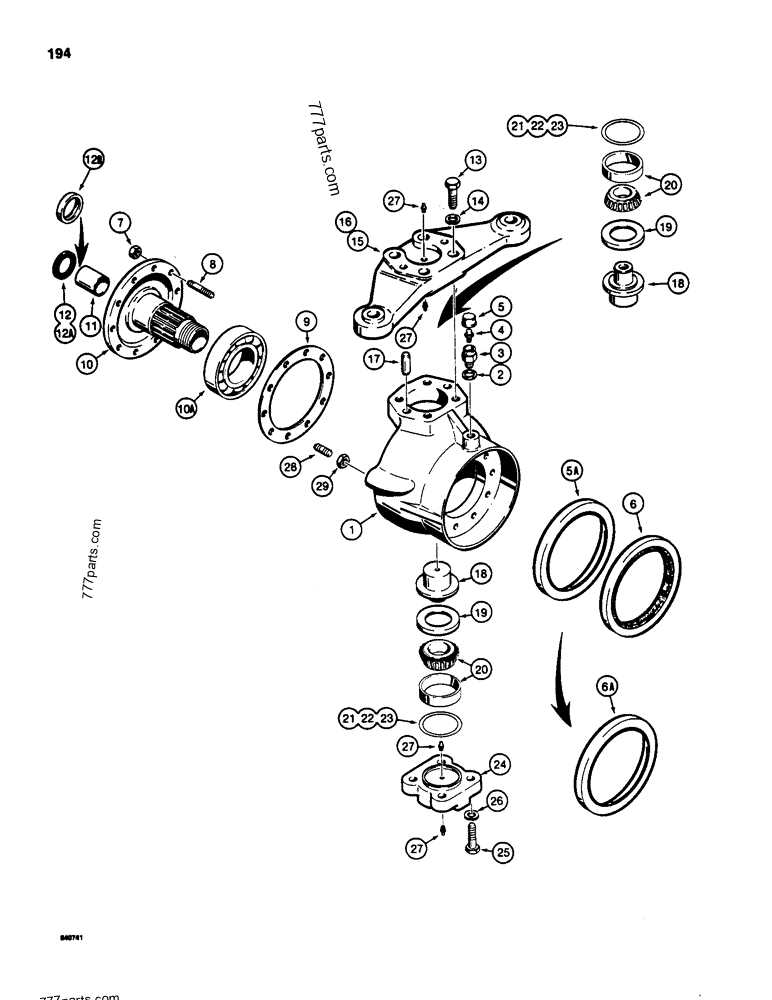

- Axles and

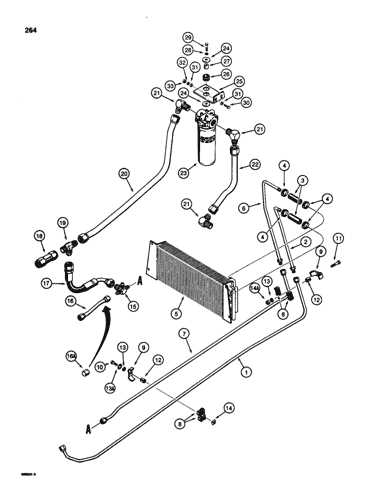

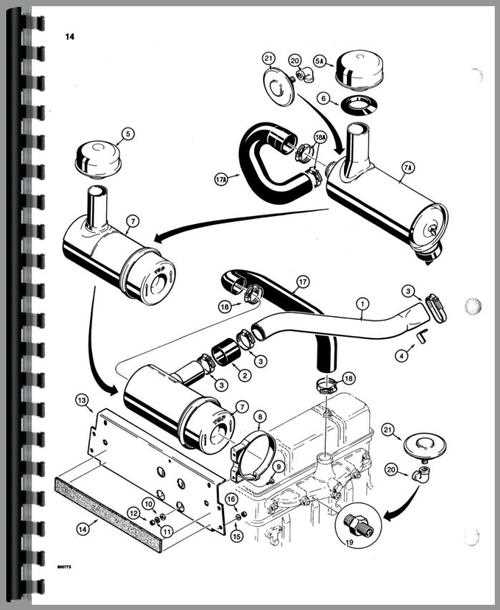

Exploring the Hydraulic System Layout

The hydraulic system is a crucial component of any heavy machinery, providing the power needed to operate various functions efficiently. This section delves into how hydraulic components are arranged to ensure optimal fluid movement, energy transfer, and performance across different operations. Understanding the flow of hydraulic fluid, key connections, and control mechanisms offers insight into maintaining and troubleshooting hydraulic systems.

Main Components and Flow

The core of the hydraulic layout includes a pump, valves, cylinders, and hoses. These elements work together to control fluid movement, which generates the necessary force for mechanical tasks. Each part plays a role in regulating pressure and directing fluid to the required areas of the machine.

- Pump: Converts mechanical energy into hydraulic energy, pushing fluid through the system.

- Valves: Control fluid flow, ensuring precise operation of different functions.

- Cylinders: Actuate the movement of parts by converting hydraulic energy into mechanical motion.

- Hoses and Lines: Direct the hydraulic fluid to the necessary components, ensuring a continuou

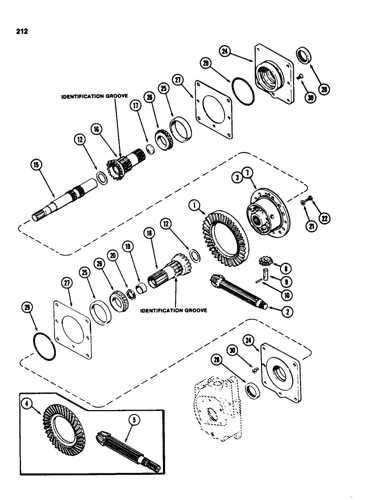

Detailed View of the Transmission Assembly

The transmission assembly is a crucial component in any mechanical system, ensuring the efficient transfer of power from the engine to the drivetrain. Understanding the internal structure and various elements of this assembly is essential for maintaining optimal performance and longevity of the machinery. Below, we examine the key components and their respective roles in the operation of the transmission.

Component Description Gearbox This central element manages speed and torque through the arrangement of gears, enabling the machinery to function under various loads and conditions. Clutch Mechanism Responsible for engaging and disengaging the engine from the transmission, allowing smooth shifts between gear ratios. Input Shaft The main shaft connecting the engine to the transmission, transferring rotational energy into the system for further distribution. Output Shaft This shaft transmits the mechanical force generated wi How to Identify Engine Parts in Diagrams

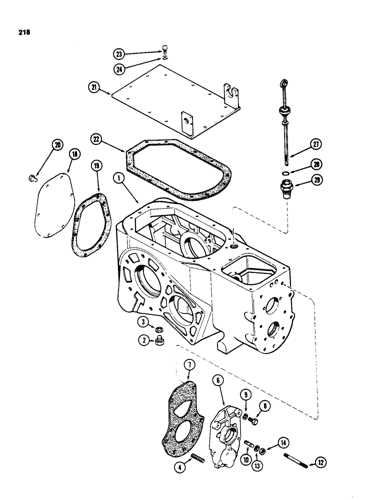

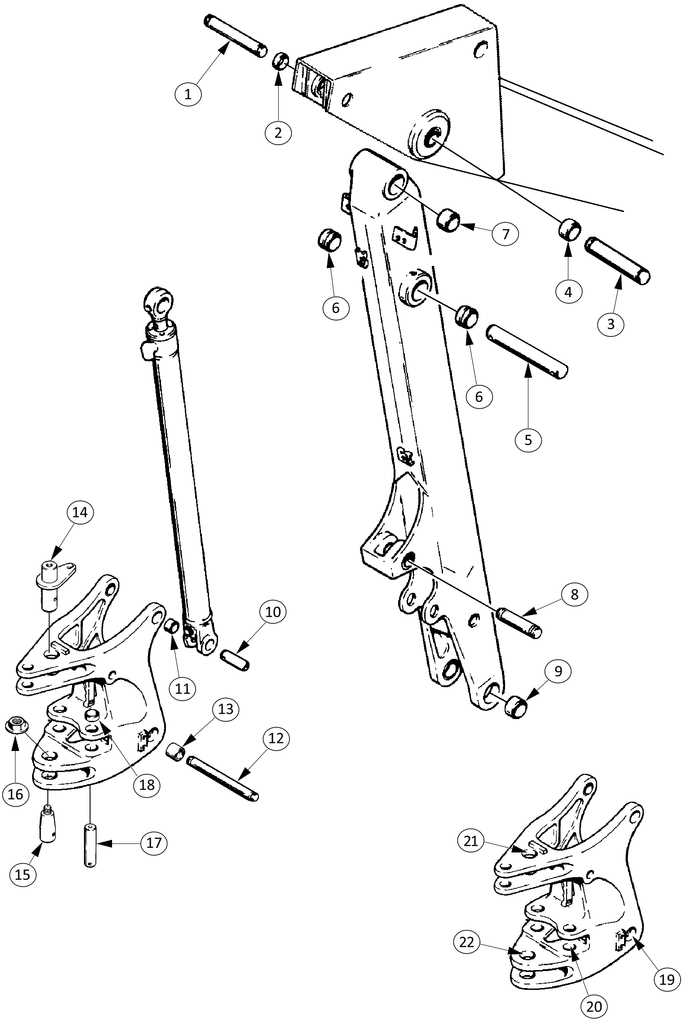

Understanding technical illustrations can be a key skill when working with mechanical systems. By examining the structure of these images, you can break down complex components into smaller, recognizable sections. The process involves familiarizing yourself with common shapes and arrangements typically found in engines, allowing for quicker identification and comprehension.

Recognizing Common Components

Most engine systems share standard elements that are consistently represented across technical drawings. By learning to spot key features like cylinders, crankshafts, and valves, you can begin to navigate the image with confidence. Pay attention to the placement of these elements, as their positions often give clues about the function of the surrounding parts.

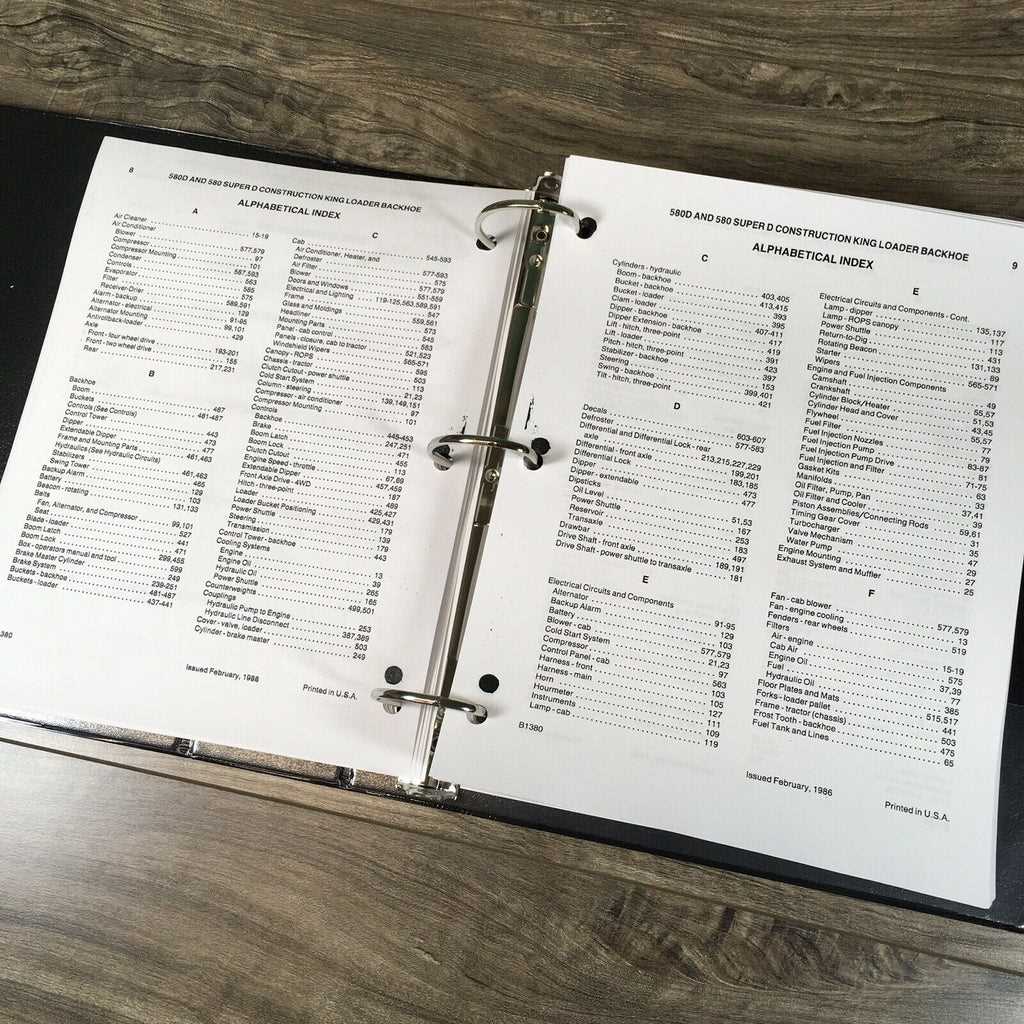

Using Labels and Numbering

Many illustrations include labels or numbered callouts that guide you through the layout. Carefully following these indicators can help you distinguish between similar elements and ensure you correctly identify each piece. Always cross-reference the labels with the accompanying legend or list for accurate interpretation.

Recognizing Common Wear Parts on a 580D

Understanding the essential components that experience frequent deterioration is crucial for effective maintenance and longevity of your machinery. These elements often require regular inspection and timely replacement to ensure optimal performance and prevent unexpected breakdowns. Familiarity with these key items can help operators and technicians maintain a reliable and efficient work environment.

1. Tires: The wheels are among the most visible components that endure significant wear. Inspect them regularly for signs of damage, such as cracks or uneven tread wear. Maintaining proper inflation levels can extend their lifespan and enhance stability during operation.

2. Filters: Air and oil filtration systems are vital for the engine’s health. Over time, these units can become clogged with dirt and debris, leading to reduced efficiency and potential engine damage. Regular replacement is essential to maintain proper airflow and lubrication.

3. Hydraulic Hoses: These flexible tubes are critical for the operation of various hydraulic functions. They are susceptible to abrasion and pressure fatigue. Look for signs of leaks, cracks, or bulges, as any deterioration can lead to system failures and costly repairs.

4. Brake Pads: Effective stopping power is essential for safety. Brake pads wear down with use and should be inspected regularly. Replacing them promptly can prevent further damage to the braking system and ensure safe operation.

5. Cutting Edges: On attachments like buckets and blades, these edges can become dull or chipped over time. Keeping them sharp is necessary for efficient material handling and can significantly reduce strain on the machine’s hydraulic system.

By regularly monitoring these components, operators can avoid costly repairs and ensure that their machinery operates smoothly. Developing a keen eye for wear indicators will not only save time and money but also enhance safety on the job site.

Troubleshooting with a Case 580D Diagram

When encountering issues with heavy machinery, visual references are invaluable for efficient diagnostics. Utilizing schematics enables operators and technicians to identify and resolve problems systematically, enhancing the overall maintenance process. A well-structured layout provides clarity on various components and their interactions, allowing for quicker troubleshooting and effective repairs.

Understanding the Components

Each element within the machinery plays a critical role in its operation. Familiarity with these elements and their functions helps in pinpointing the source of malfunctions. For instance, understanding how hydraulic systems work can assist in diagnosing fluid leaks or pressure drops, which may lead to operational failures.

Identifying Common Issues

Many challenges can arise during the operation of equipment. Regular symptoms include unusual noises, decreased performance, and warning indicators. By consulting the visual reference, one can trace these symptoms back to their origins, whether they stem from electrical faults, mechanical wear, or fluid imbalances.

Step-by-Step Diagnosis

A systematic approach is essential for effective troubleshooting. Begin by observing the symptoms and cross-referencing them with the visual guide to locate the relevant components. Next, check for loose connections, leaks, or signs of wear. This organized method ensures that no detail is overlooked, ultimately leading to a more efficient repair process.

Documentation and Maintenance

Keeping accurate records of issues encountered and resolutions implemented is crucial. This documentation not only assists in future diagnostics but also aids in identifying patterns that may indicate the need for preventative maintenance. Regularly referring to the visual schematic during routine checks can help maintain the machinery’s optimal performance.

Maintenance Planning Based on Part Layouts

Effective upkeep of machinery is crucial for ensuring optimal performance and longevity. A systematic approach that utilizes layout representations of components can significantly enhance maintenance strategies. By understanding the arrangement and interrelationship of various elements, operators can better anticipate service needs, minimize downtime, and streamline repair processes.

Identifying Key Components

Incorporating a visual representation of the machinery’s structure allows for the identification of critical components that require regular attention. This clarity enables maintenance personnel to prioritize tasks based on the significance of each element’s role in the overall functionality. Consequently, addressing the needs of vital parts can lead to improved operational efficiency and reduced risk of unexpected failures.

Streamlining the Maintenance Process

A well-organized depiction of components facilitates a more efficient maintenance routine. Technicians can quickly locate specific elements and determine the necessary procedures for service. Additionally, this approach aids in creating comprehensive checklists and schedules tailored to the specific requirements of each part. Such planning not only ensures timely interventions but also promotes a proactive maintenance culture.