The intricate world of machinery used in agriculture requires a thorough comprehension of its various elements. Each component plays a crucial role in ensuring optimal functionality and efficiency. By breaking down these elements, operators can enhance performance and streamline maintenance processes.

Visual representations of equipment assembly can serve as invaluable resources. They provide clarity, allowing users to pinpoint specific items within the overall framework. With a well-organized visual guide, users can easily identify what is needed for repairs or replacements, ultimately prolonging the lifespan of their machinery.

Moreover, a detailed exploration of these resources can help both seasoned professionals and newcomers alike. Delving into the specifics can reveal insights that contribute to better operational practices, thus enhancing productivity on the field. This knowledge not only aids in efficient upkeep but also fosters a deeper understanding of how each component interacts within the larger system.

Understanding John Deere 4200 Parts

When working with complex machinery, understanding how each component functions is crucial for both maintenance and repair. A detailed grasp of the various elements that make up a tractor ensures smoother operations and reduces the risk of malfunctions. This knowledge allows operators and mechanics to identify the right replacement or repair processes more efficiently.

Key Components of the Tractor

The tractor in question consists of several critical components that work together to ensure optimal performance. From the engine and transmission to the hydraulic system, each part plays an essential role in the overall function of the machine. Knowing the specifications and interactions of these components can greatly aid in diagnosing issues and choosing appropriate solutions.

Identifying Common Issues

Regular wear and tear or improper handling can lead to breakdowns in different systems of the machine. Understanding the typical breakdowns and recognizing signs of damage can help in identifying which parts need attention. Comprehensive knowledge of the machine’s internal structure is indispensable for effective troubleshooting.

| Component | Function | Signs of Wear |

|---|---|---|

| Engine | Powers the entire machine | Reduced performance, strange noises |

| Hydraulic System | Operates lifting and steering mechanisms | Slow response, leaks |

| Transmission | Transfers power from the engine to wheels | Slipping gears, difficulty in shifting |

Importance of Parts Diagrams

Visual representations of components are essential for understanding the assembly and functionality of machinery. They serve as invaluable resources for technicians and enthusiasts alike, providing clarity and guidance in maintenance and repair tasks.

By utilizing these illustrations, users can efficiently identify specific elements, ensuring that replacements and repairs are conducted accurately. This not only enhances the longevity of equipment but also streamlines the troubleshooting process.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify complex systems, making them easier to comprehend. |

| Time Efficiency | Quick identification of components speeds up maintenance and repairs. |

| Accuracy | Reduces errors in part selection and assembly. |

| Improved Safety | Clear visuals help ensure safe handling and operation of equipment. |

Common Issues with John Deere 4200

When it comes to working with compact tractors, a few recurring issues can arise that may affect performance and reliability. These challenges are often tied to wear and tear on key components or improper maintenance. Identifying and addressing these concerns early can prevent costly repairs and downtime, ensuring smoother operation for extended periods.

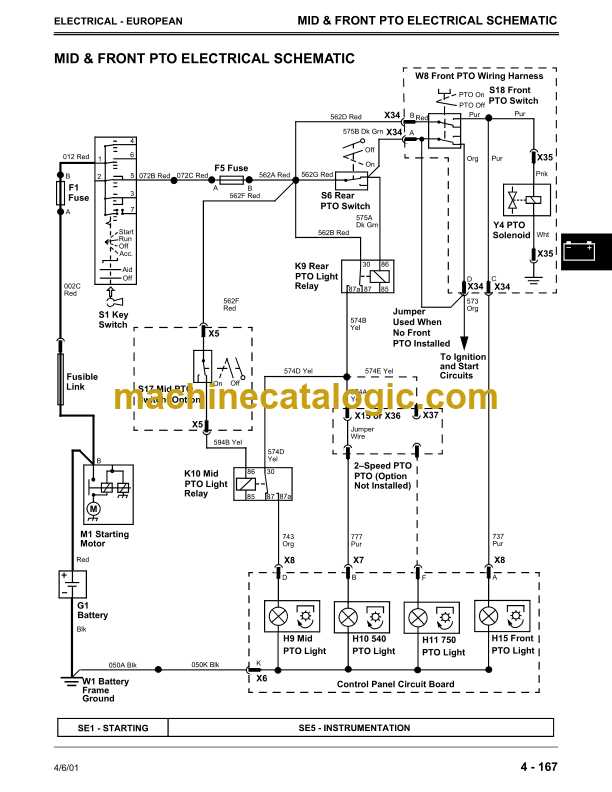

One of the most frequent problems reported by users of these machines involves the engine and transmission systems. These vital components are prone to issues such as overheating, oil leaks, or irregular performance due to clogged filters or lack of regular servicing. Additionally, mechanical parts connected to the power take-off (PTO) may also experience excessive wear, which can disrupt normal functioning.

Another common area of concern is the hydraulic system. Low fluid levels, leaks, or damaged seals can lead to inefficient operation of the loader and other attachments, making tasks more difficult and reducing overall productivity.

- Engine overheating or irregular operation

- Transmission issues such as slipping or rough shifting

- PTO system wear and tear

- Hydraulic system problems, including leaks and low pressure

- Electrical malfunctions, such as faulty wiring or dead batteries

Lastly, many operators have experienced electrical malfunctions, which might be linked to corroded terminals, worn-out switches, or failing relays. Regular checks and maintenance can mitigate these problems and keep the equipment running efficiently.

Where to Find Parts Diagrams

Locating detailed schematics for equipment can significantly enhance maintenance and repair efforts. Understanding where to seek these resources can save time and ensure accuracy in tasks.

- Manufacturer’s Website: Official sites often provide comprehensive resources, including digital manuals and technical drawings.

- Online Retailers: E-commerce platforms frequently feature listings with attached technical illustrations for various models.

- Forums and Community Groups: Enthusiast communities can be invaluable, sharing insights and resources that may not be widely available.

- Local Dealers: Authorized dealers usually have access to up-to-date resources and can assist with specific inquiries.

- Repair Manuals: Printed or digital manuals often include detailed schematics, proving useful for troubleshooting and repairs.

By exploring these avenues, one can ultimately enhance their understanding of equipment structure and functionality.

How to Read Parts Diagrams

Understanding schematic illustrations is essential for effectively identifying components and their arrangements in machinery. These visual representations can streamline maintenance and repair tasks, ensuring that you can quickly locate the necessary elements for your equipment.

Familiarize Yourself with the Key

Most illustrations will include a key or legend that explains the symbols used throughout the image. This section is crucial, as it provides insight into the meaning of various icons and notations. Take time to review this area carefully to enhance your comprehension of the schematic.

Follow the Flow

Begin at one end of the illustration and trace the layout systematically. Pay attention to how each component connects and interacts with others. This methodical approach allows for a better understanding of the overall structure and functionality of the system. Noticing the relationships between parts can also help in troubleshooting potential issues.

In summary, becoming proficient at interpreting these visual tools can significantly aid in the upkeep and operation of your equipment, making your tasks more efficient and effective.

Aftermarket vs. OEM Parts

When it comes to equipment maintenance, choosing the right components can significantly impact performance and longevity. Understanding the differences between alternative and original manufacturer options is essential for making informed decisions that align with both budget and quality standards.

Alternative components are often produced by third-party manufacturers, providing a more cost-effective solution. These can offer comparable functionality but may vary in quality and durability. On the other hand, original manufacturer components are designed specifically for the equipment, ensuring perfect compatibility and reliability. While they might come at a higher price, the assurance of meeting the original specifications is a key advantage.

Ultimately, the choice between these two types of components depends on the specific needs of the user, including budget constraints and performance expectations. It’s crucial to delve into the pros and cons of each option to determine the best fit for your equipment.

Maintenance Tips for John Deere 4200

Regular upkeep is essential to ensure the long-lasting performance of your tractor. Proper maintenance helps prevent costly repairs and ensures optimal efficiency, even under heavy use. By following simple guidelines, you can keep your machine in top condition, reducing downtime and extending its operational life.

Start by regularly checking fluid levels such as engine oil, transmission fluid, and coolant. Ensure that the filters for air, fuel, and hydraulics are replaced at the recommended intervals. Clean or replace them as needed to prevent blockages and maintain proper system function.

Inspect the belts and hoses for any signs of wear or cracks. Timely replacement of these components prevents sudden breakdowns and keeps all mechanical systems running smoothly. Lubricate moving parts, including linkages and pivot points, to minimize friction and wear.

Pay attention to tire condition and pressure. Properly inflated tires improve traction and overall stability, enhancing performance in various terrains. Also, check the battery regularly and clean the terminals to avoid corrosion.

Lastly, keep the machine clean by removing any dirt, debris, or buildup from the engine compartment and other key areas. A clean machine runs more efficiently and can help identify potential issues before they become major problems.

Frequently Replaced Components

Regular maintenance of agricultural machinery involves monitoring and replacing certain components that experience wear and tear due to frequent usage. Knowing which elements are most likely to need attention can help ensure optimal performance and extend the lifespan of the equipment. This section highlights some of the commonly replaced items, offering a quick overview of their roles and typical issues that lead to replacement.

| Component | Common Issues | Replacement Frequency |

|---|---|---|

| Fuel Filter | Clogging due to dirt and debris | Every 200-300 hours of use |

| Air Filter | Dust buildup, reduced engine efficiency | Every 100-200 hours of use |

| Belt | Wear and tear, fraying | Every 500-600 hours of use |

| Battery | Reduced charge holding capacity, aging | Every 2-3 years |

| Hydraulic Pump | Loss of pressure, leakage | Every 1000-1200 hours of use |

Repair Resources and Support

When it comes to maintaining and repairing agricultural machinery, having access to reliable resources and professional assistance is crucial for ensuring optimal performance. Whether you are troubleshooting an issue or conducting routine maintenance, finding accurate information and high-quality components is key to minimizing downtime and preventing costly repairs. Various resources are available to help you through the process, including manuals, online guides, and expert support services.

For those seeking detailed instructions on equipment assembly, disassembly, and maintenance procedures, online platforms and manufacturer-provided resources offer comprehensive technical documentation. These tools often include detailed step-by-step guides, which can be vital for both novice and experienced technicians. In addition to written instructions, video tutorials and interactive support forums provide valuable insights from fellow equipment owners and professionals in the industry.

Moreover, many manufacturers and dealers offer specialized customer support teams that can provide personalized assistance. Whether you’re looking for advice on selecting compatible components or need help troubleshooting a complex issue, direct contact with experts ensures that you’re receiving the best possible guidance tailored to your specific needs.

| Resource Type | Description | Access Method |

|---|---|---|

| Manuals | Comprehensive guides that offer step-by-step instructions for repairs and maintenance. | Available online or through authorized dealers. |

| Online Forums | Community-driven platforms where users share experiences, solutions, and tips. | Accessible via dedicated websites and social media groups. |

| Technical Support | Direct assistance from experienced technicians to solve specific issues. | Offered by manufacturers or through specialized service centers. |

| Video Tutorials | Visual guides that demonstrate common repair procedures and techniques. | Available on platforms like YouTube or manufacturer websites. |

Utilizing these resources will help ensure that you can complete necessary repairs efficiently and correctly, keeping your equipment in peak working condition for longer periods.