In the realm of heavy machinery, comprehending the various elements that contribute to operational efficiency is crucial. Each machine is a complex assembly of interconnected units, designed to perform specific tasks. By familiarizing oneself with these components, operators can enhance performance and ensure longevity in their equipment.

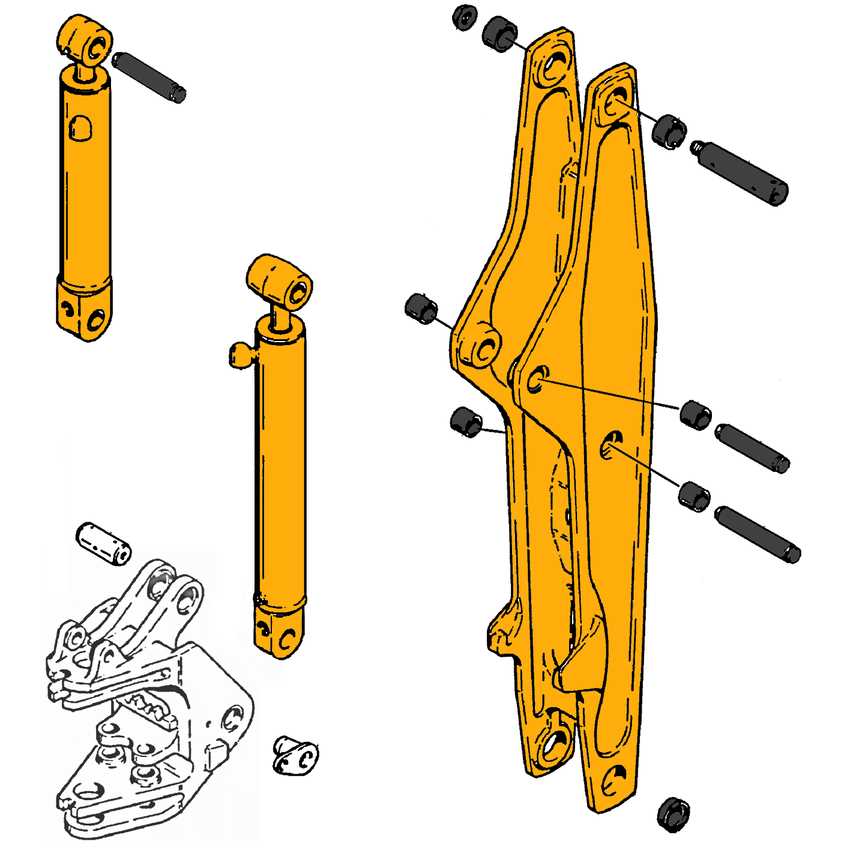

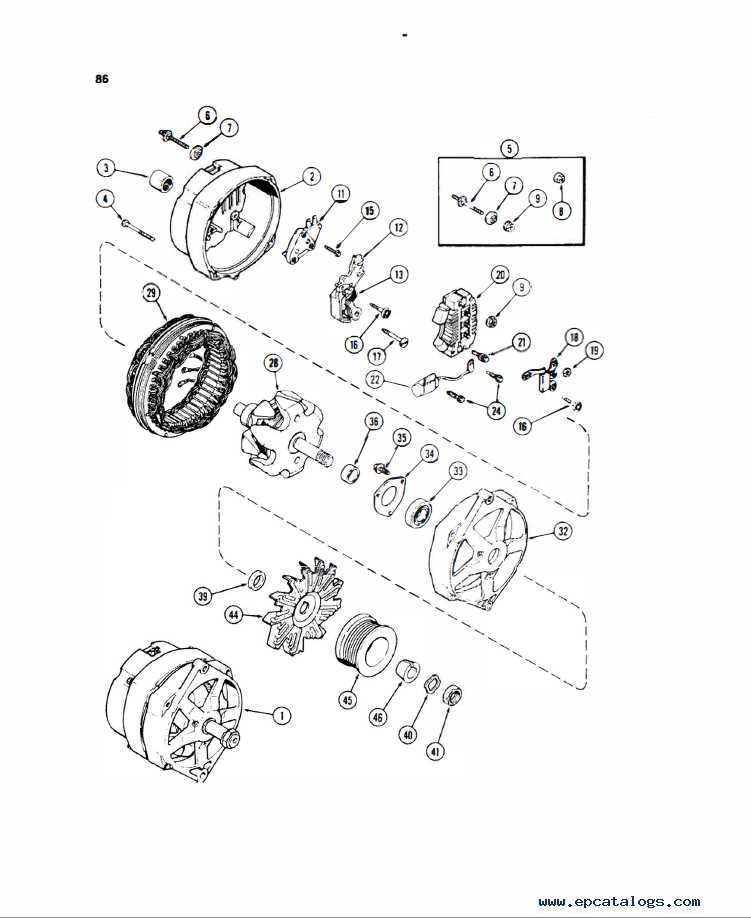

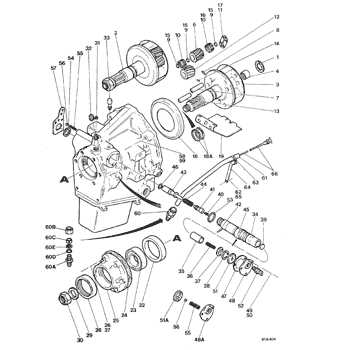

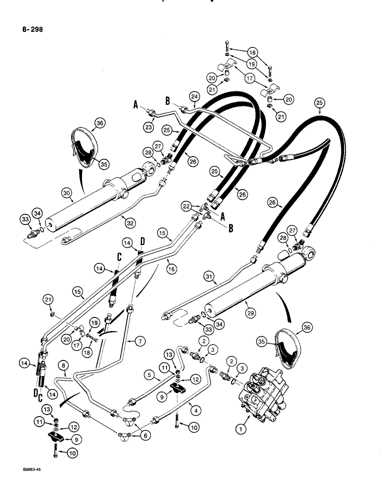

Visual aids play a significant role in illustrating the relationships between different components. These representations serve as valuable references, enabling technicians and operators to quickly identify and address issues. Understanding how each unit functions within the larger system is essential for effective maintenance and repair.

Moreover, an intricate knowledge of these mechanisms can lead to improved decision-making regarding upgrades and replacements. By staying informed about the latest advancements in technology and design, users can optimize their machinery for maximum productivity. This awareness not only fosters a safer working environment but also contributes to overall operational success.

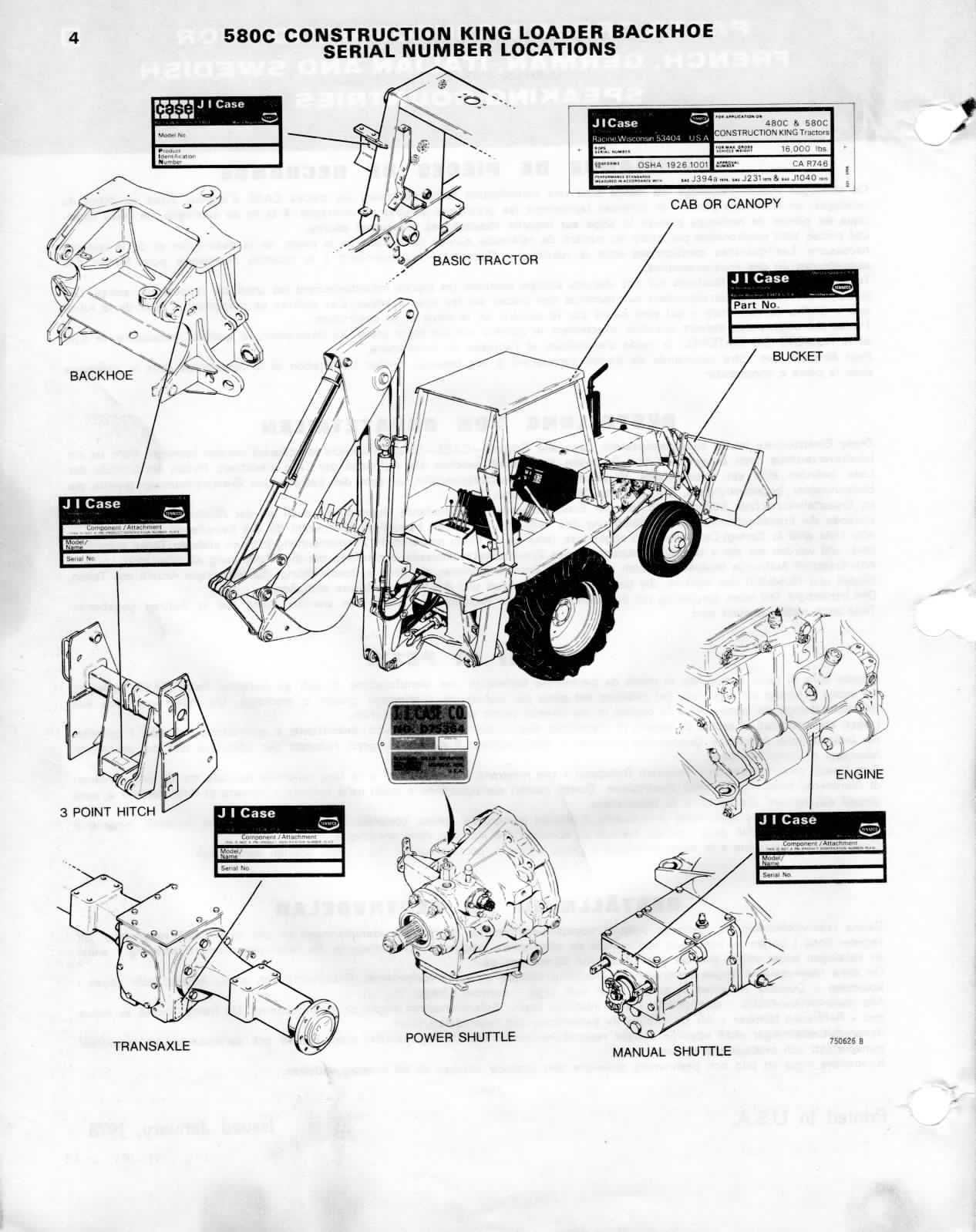

Understanding Backhoe Components

Exploring the various elements of heavy machinery reveals a complex interplay of components designed for efficiency and functionality. Each section plays a crucial role in the overall performance, enabling operators to execute tasks with precision. Gaining insight into these components enhances one’s ability to troubleshoot issues and maintain equipment effectively.

Key Elements of Machinery

The primary constituents of these machines include the lifting mechanism, hydraulic systems, and mobility features. The lifting mechanism facilitates the raising and lowering of loads, while hydraulic systems provide the necessary power for smooth operation. Mobility components, such as tracks or wheels, ensure that the equipment can navigate different terrains seamlessly.

Maintenance and Care

Proper upkeep of each element is vital for longevity and reliability. Regular inspections and timely replacements of worn-out components can prevent unexpected failures. Understanding the intricacies of each section allows for better planning and execution of maintenance tasks, ensuring that the machinery remains in optimal condition.

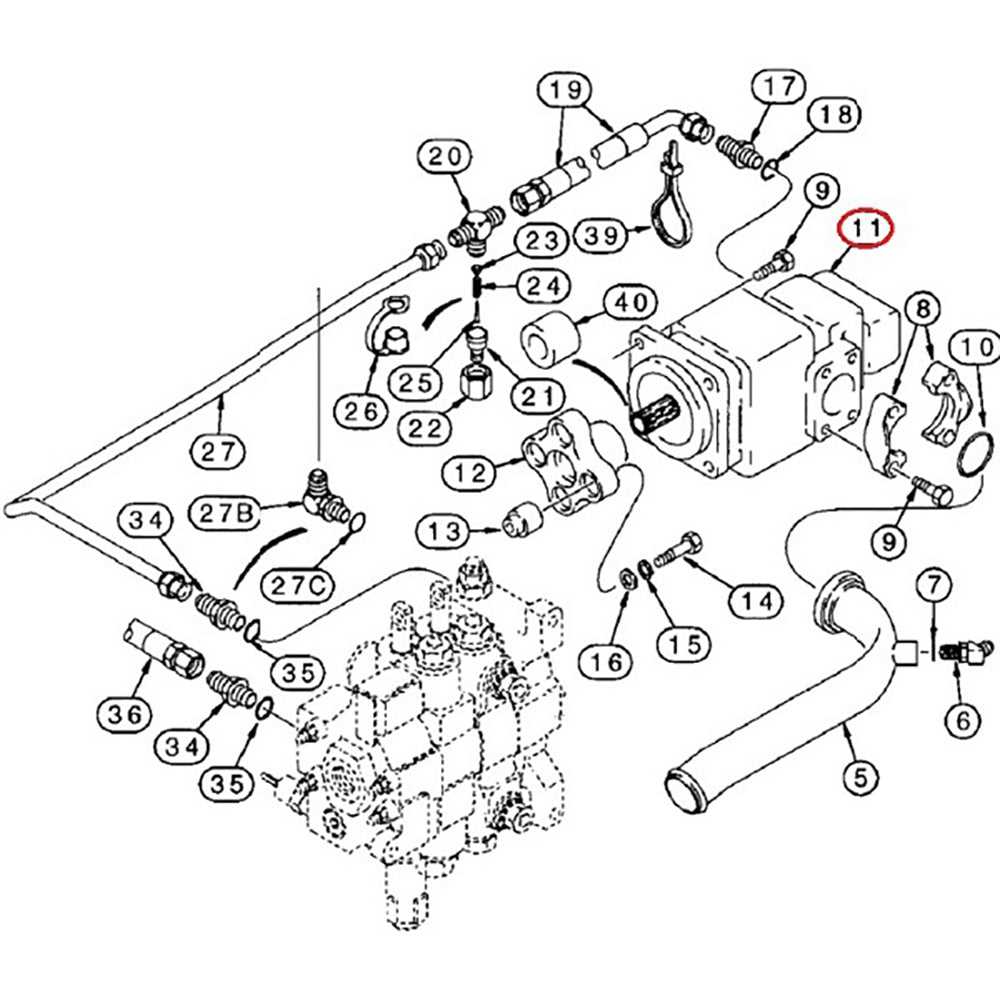

Importance of Accurate Diagrams

Precise representations are crucial for understanding complex machinery. They serve as a roadmap for assembly, maintenance, and troubleshooting, ensuring that each component is correctly identified and utilized. The significance of these visual aids cannot be overstated, as they facilitate efficient operations and reduce the likelihood of errors.

Benefits of Precision

- Enhances comprehension of mechanical systems

- Minimizes the risk of misinterpretation

- Streamlines maintenance procedures

- Improves safety during operations

Impact on Efficiency

- Reduces downtime caused by incorrect repairs

- Promotes faster training for new operators

- Ensures proper inventory management of components

Common Parts of Case Backhoes

Understanding the essential components of heavy machinery is crucial for effective maintenance and operation. This section delves into the frequently encountered elements that ensure optimal functionality and reliability in these versatile machines.

| Component | Description |

|---|---|

| Engine | The power source that drives the machine, providing the necessary torque and horsepower for various tasks. |

| Hydraulic System | A system that utilizes pressurized fluid to facilitate movement and control of the arm and bucket. |

| Transmission | The mechanism that transfers power from the engine to the wheels or tracks, allowing for movement. |

| Bucket | A digging attachment designed to scoop and move materials, available in various sizes for different applications. |

| Stabilizers | Supports that provide stability during operation, preventing tipping and enhancing safety. |

| Operator’s Cab | The enclosed area where the operator controls the machine, equipped with controls and visibility features. |

How to Interpret Diagrams Effectively

Understanding visual representations is crucial for anyone working with machinery. These illustrations provide a clear depiction of components and their relationships, making complex information more accessible. To maximize their utility, it’s important to develop skills for decoding these visuals accurately.

Familiarize Yourself with Symbols

Each illustration uses a specific set of symbols and notations. Take time to study the legend or key, as it provides essential insights into what each symbol represents. Familiarity with these symbols will enhance your ability to grasp the overall layout and function of the system.

Analyze the Layout and Connections

Pay attention to how elements are arranged and interconnected. Understanding the flow and relationships among components can help you identify how they work together. Look for arrows, lines, or other indicators that illustrate movement or interaction, as these details are often crucial for troubleshooting or assembly.

Maintenance Tips for Backhoe Parts

Regular upkeep of construction machinery components is essential for ensuring longevity and optimal performance. Understanding the importance of routine maintenance can help prevent costly repairs and downtime. Below are key strategies to maintain the efficiency and reliability of your equipment.

Regular Inspections

Frequent checks are crucial. Examine all critical elements for signs of wear or damage. Pay special attention to hydraulic systems, connections, and joints. Early detection of issues can save time and resources in the long run.

Proper Lubrication

Keeping moving parts well-lubricated is vital to reduce friction and wear. Use the recommended lubricants for each component. Consistent lubrication not only enhances functionality but also prolongs the life of the machinery.

Replacement Parts: When to Buy

Knowing the right time to acquire new components for your machinery is essential for maintaining efficiency and performance. Regular assessments of your equipment’s condition can help identify when a replacement is necessary, ensuring that your operations run smoothly without unexpected disruptions.

Signs of Wear: Pay attention to any unusual noises, vibrations, or decreased performance. If your equipment is showing these symptoms, it may indicate that certain elements are nearing the end of their lifespan.

Routine Maintenance: Incorporating regular inspections into your maintenance routine can help catch issues early. If you find that certain items are frequently needing attention, it might be wise to consider replacing them proactively.

Downtime Costs: Evaluate the potential costs associated with downtime versus the investment in new components. If prolonged inactivity could lead to significant financial loss, timely replacements become a crucial consideration.

Ultimately, being proactive rather than reactive can save you time and resources. Understanding when to invest in new elements not only enhances your machinery’s performance but also extends its overall lifespan.

Benefits of Using OEM Components

Utilizing original manufacturer components offers several advantages that can significantly enhance the performance and longevity of equipment. These components are designed specifically for compatibility and optimal functionality, ensuring seamless integration with existing systems. Choosing these high-quality parts can lead to improved efficiency and reduced maintenance costs over time.

Quality Assurance

One of the primary benefits of opting for original components is the assurance of quality. OEM items undergo rigorous testing and adhere to strict manufacturing standards. This guarantees that they meet the exact specifications necessary for reliable operation. Consequently, using these parts minimizes the risk of malfunctions and enhances overall equipment reliability.

Enhanced Performance

Incorporating original components can also lead to enhanced performance. These parts are engineered to work harmoniously with the machinery, ensuring optimal power delivery and efficiency. As a result, users can expect better fuel efficiency, improved productivity, and a smoother operational experience, making the investment in OEM components worthwhile.

Common Issues with Backhoe Parts

Understanding the frequent challenges faced by heavy machinery can enhance performance and longevity. Operators often encounter problems that can stem from wear and tear, improper maintenance, or manufacturing defects. Addressing these issues promptly is crucial to avoid costly repairs and ensure efficient operation.

One of the most prevalent concerns involves hydraulic systems, where leaks can lead to reduced efficiency and potential failure. Regular inspection and timely replacement of seals can mitigate this risk. Additionally, structural components may suffer from fatigue over time, resulting in cracks or breakages. Ensuring proper usage and adherence to load limits can help preserve these vital elements.

Another common issue arises with the articulation mechanism, which may experience excessive wear if not lubricated adequately. Implementing a consistent maintenance schedule that includes lubrication checks can prevent premature degradation. Lastly, electrical components can also present challenges, often due to corrosion or faulty connections, highlighting the importance of routine electrical system evaluations.