In the world of construction and earthmoving, the intricacies of machinery components play a vital role in ensuring optimal performance and longevity. A clear comprehension of how these elements fit together is crucial for operators and maintenance teams alike.

Visual aids are essential tools that can greatly enhance this understanding, providing a roadmap for identifying and managing various components. Such illustrations serve as a reference point, allowing users to pinpoint specific parts and their respective functions within the machine.

By exploring the layout and relationships among these crucial elements, operators can improve maintenance routines and troubleshoot issues more effectively. Ultimately, having access to comprehensive resources can lead to enhanced efficiency and reduced downtime.

Understanding the Case 450 Dozer

This section provides an overview of a well-known piece of heavy machinery that plays a crucial role in construction and earthmoving tasks. Recognized for its durability and efficiency, this equipment is designed to handle a variety of tasks such as grading, digging, and pushing materials. Understanding its structure and functionality is essential for operators and technicians alike, as it enables them to maximize performance and ensure longevity.

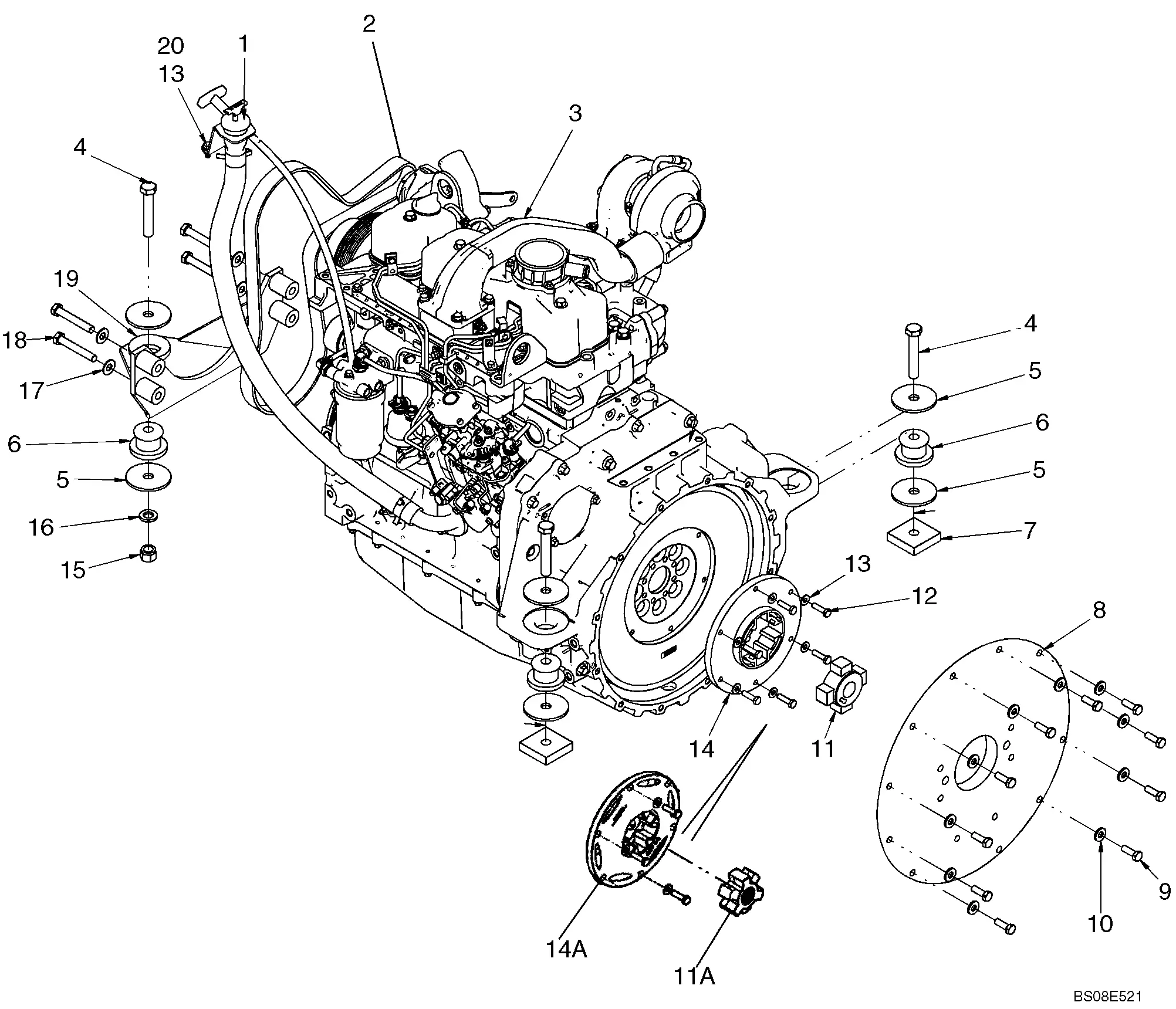

The machine is equipped with several key components that work together seamlessly. Each element serves a specific purpose, contributing to the overall efficiency of the equipment. From the powerful engine that drives it to the hydraulic systems that facilitate movement, knowledge of these parts enhances operational proficiency and aids in troubleshooting common issues.

Maintenance is a vital aspect of ownership, as regular checks and replacements of components can prevent costly repairs and downtime. Familiarity with the internal layout and functionalities can empower users to conduct routine inspections, ensuring that the machinery remains in optimal working condition. This proactive approach not only extends the life of the machine but also boosts productivity on job sites.

In summary, gaining a thorough understanding of this machinery’s design and operation is fundamental for anyone involved in its usage or maintenance. Such knowledge not only fosters efficiency but also enhances safety, making it a valuable asset in any heavy equipment fleet.

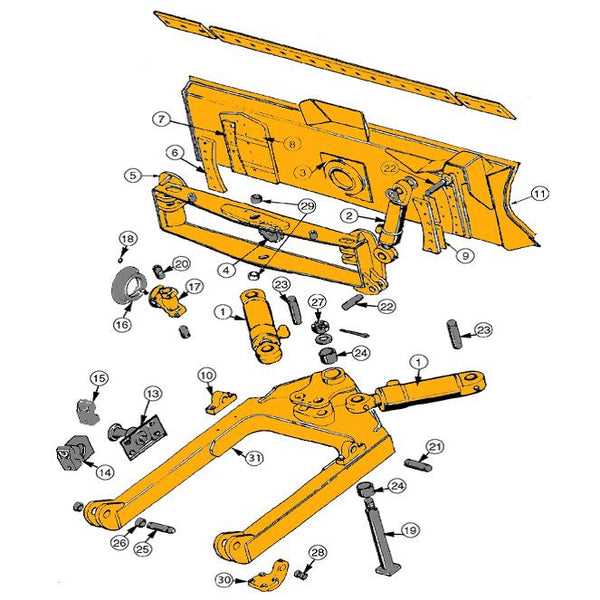

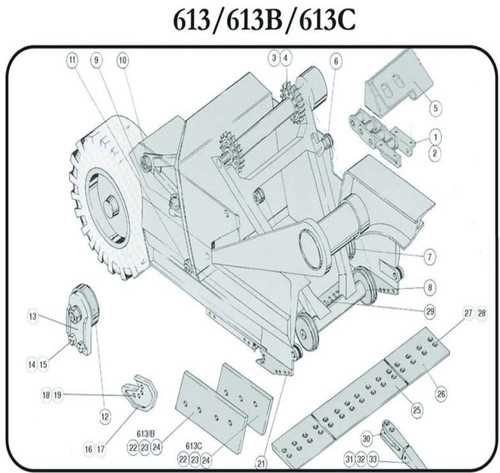

Key Components of the Dozer

The effectiveness of heavy machinery relies on a variety of essential elements that work in harmony to achieve optimal performance. Understanding these components is crucial for maintenance, repair, and efficient operation. Each part plays a vital role in ensuring that the machine can perform its tasks effectively, whether in construction, landscaping, or other applications.

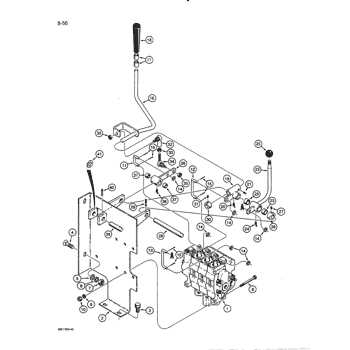

Hydraulic System

The hydraulic system is fundamental for controlling the movement of the blade and other attachments. It utilizes fluid power to transmit force, allowing for smooth and precise operations. Regular maintenance of this system is essential to prevent leaks and ensure reliable performance.

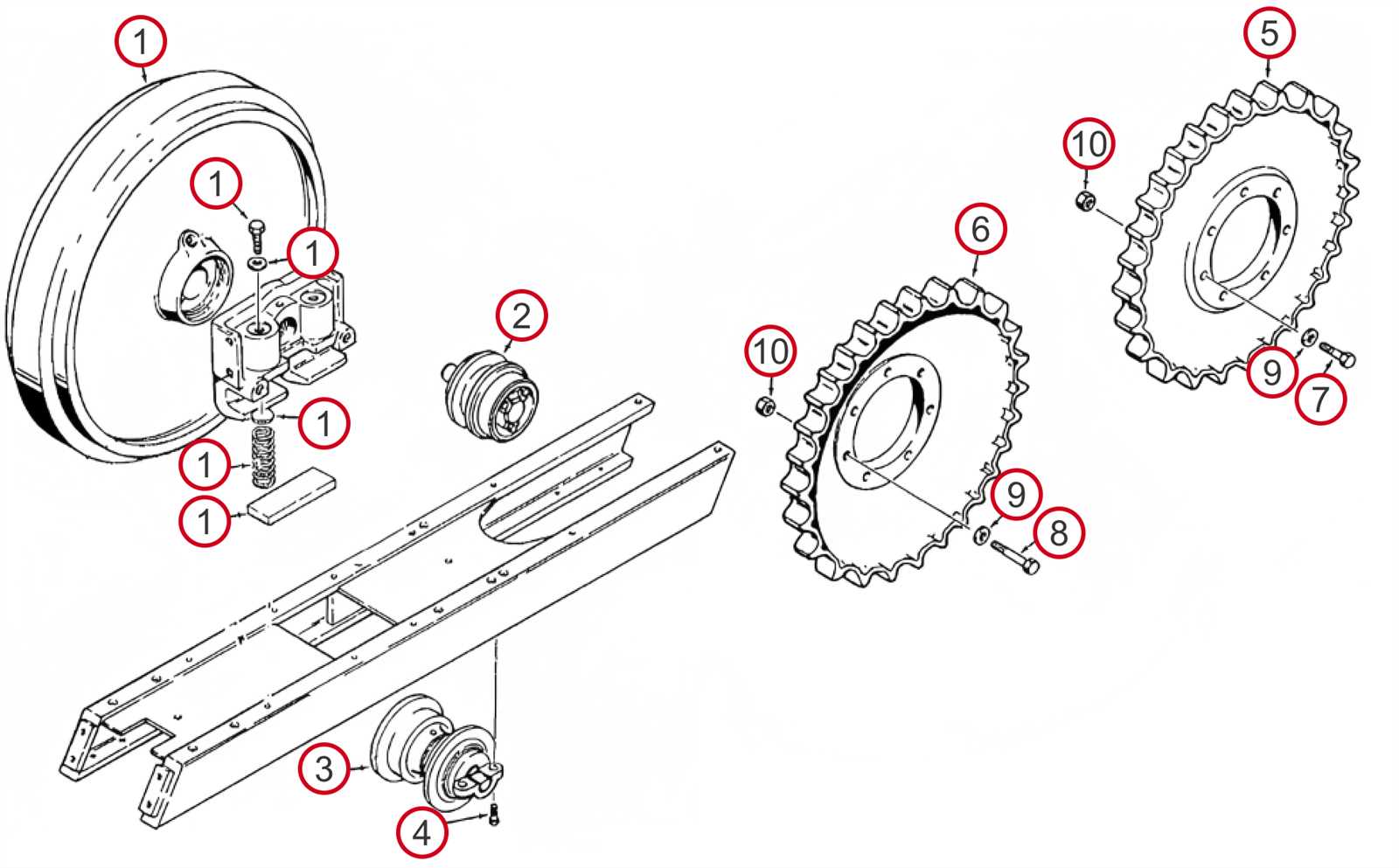

Undercarriage

The undercarriage supports the entire weight of the machine and is responsible for mobility. It consists of components such as tracks, rollers, and idlers, which work together to provide stability and traction. A well-maintained undercarriage enhances maneuverability and prolongs the lifespan of the equipment.

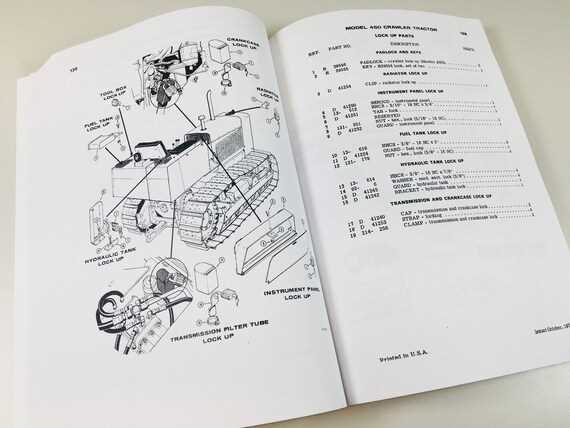

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial for effective machinery maintenance and repair. These visual representations provide a clear understanding of how different elements fit together, ensuring that technicians can efficiently diagnose issues and perform necessary replacements or adjustments. When clarity is prioritized, the likelihood of errors decreases significantly, leading to improved operational reliability.

Enhanced Efficiency in Repairs

Clear visual guides enable mechanics to quickly identify the required components, reducing downtime and streamlining the repair process. When technicians can easily locate and understand each element, they can focus on resolving problems rather than wasting time searching for information.

Reduction of Operational Errors

When maintenance personnel have access to detailed and accurate representations, the chance of misplacing or incorrectly installing components diminishes. This attention to detail not only enhances the lifespan of the machinery but also contributes to overall safety in the workplace. Comprehensive illustrations serve as a valuable reference point, fostering better communication among team members and enhancing collaborative efforts in maintaining equipment.

Common Issues with Case 450 Parts

When dealing with heavy machinery, several challenges can arise related to individual components. Understanding these common problems is crucial for maintaining optimal performance and longevity of the equipment. This section highlights frequent issues that operators may encounter, along with potential solutions to enhance efficiency.

Wear and Tear: Over time, certain elements may experience significant deterioration due to constant usage. Regular inspections can help identify these worn parts early, preventing further damage and costly repairs.

Hydraulic Leaks: Hydraulic systems are essential for the smooth operation of machinery. Leaks can occur in hoses or fittings, leading to reduced efficiency and operational failure. Regular checks and immediate repairs are necessary to mitigate this issue.

Electrical Failures: Electrical components can be prone to faults, which may result in malfunctioning systems. Ensuring proper connections and routine maintenance can prevent unexpected breakdowns and maintain functionality.

Improper Lubrication: Insufficient lubrication can cause friction and overheating in moving parts, leading to premature wear. Following a strict lubrication schedule is vital to ensure all necessary components are adequately serviced.

Compatibility Issues: When replacing components, using non-compatible parts can lead to performance problems. Always refer to manufacturer guidelines to ensure the correct fit and functionality.

Finding Replacement Parts Online

In today’s digital age, sourcing components for machinery has become significantly easier with the vast array of online platforms available. Whether you are looking for original equipment or aftermarket alternatives, the internet provides a convenient way to compare options and prices from various suppliers. This section will guide you through effective strategies for locating the necessary items to keep your equipment in optimal working condition.

Utilizing Specialized Websites

There are numerous dedicated websites that focus specifically on machinery components. These platforms often have extensive catalogs that allow you to filter results based on your specific model and requirements. By using these specialized resources, you can quickly identify the exact items you need, ensuring compatibility and quality.

Checking Online Marketplaces

Popular online marketplaces can also be a treasure trove for finding essential components. Here, you can explore both new and used options, often at competitive prices. Make sure to read reviews and check seller ratings to ensure reliability before making a purchase. Leveraging user feedback can save you from potential pitfalls and help you make informed decisions.

Maintenance Tips for Dozer Owners

Proper upkeep is essential for ensuring the longevity and efficiency of heavy machinery. Regular attention not only enhances performance but also minimizes unexpected breakdowns. By following systematic maintenance practices, operators can safeguard their investment and optimize productivity.

1. Regular Inspections: Conduct routine checks on all critical components, including hydraulic systems, tracks, and engine parts. This helps in identifying wear and tear before they escalate.

2. Fluid Levels: Maintain appropriate levels of hydraulic fluid, engine oil, and coolant. Regularly change these fluids as per the manufacturer’s guidelines to ensure optimal functioning.

3. Cleaning: Keep the machinery clean by removing dirt and debris. This prevents corrosion and facilitates better visibility of potential issues.

4. Proper Storage: When not in use, store the equipment in a sheltered location to protect it from the elements, reducing the risk of rust and damage.

5. Follow Manufacturer’s Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. This is crucial for warranty compliance and overall machine health.

Implementing these practices will help maintain performance and extend the life of your equipment, ultimately leading to more efficient operations.

How to Read Parts Diagrams

Understanding schematic representations is essential for anyone involved in machinery maintenance and repair. These visual aids provide a comprehensive view of components and their relationships within a system, allowing for efficient identification and troubleshooting of issues. By familiarizing yourself with these illustrations, you can enhance your ability to source replacements and perform repairs accurately.

1. Familiarize Yourself with Symbols

Each illustration uses specific symbols to represent various elements. It’s crucial to learn what these symbols mean to accurately interpret the information. Look for a legend or key that explains the visual language used in the representation.

2. Identify Components

Focus on identifying individual elements within the illustration. Each component typically has a unique number or code associated with it, which can be cross-referenced with a catalog or manual. This step ensures you understand what each part does and how it fits into the overall assembly.

3. Understand Relationships

Pay attention to how components connect to one another. Lines or arrows often indicate relationships or flow of movement. Recognizing these connections is vital for understanding how to disassemble or reassemble parts during maintenance.

4. Use a Reference Guide

If available, consult a reference guide that corresponds to the schematic. These guides can provide additional context, including specifications and instructions for installation or replacement, further enhancing your comprehension.

5. Practice Makes Perfect

The more you engage with these representations, the more comfortable you will become. Regularly reviewing and interpreting different illustrations will improve your skills, making future repairs and maintenance tasks more manageable.

Upgrades for Enhanced Performance

Improving machinery efficiency can significantly boost productivity and extend the lifespan of equipment. Various enhancements can be implemented to optimize performance, ensuring that machines operate at their peak capabilities. These modifications often focus on key areas such as power, control, and durability.

One effective approach involves upgrading the engine components. Enhancing fuel injection systems or installing high-performance air filters can lead to better combustion, resulting in increased power output and reduced fuel consumption. Additionally, incorporating advanced cooling systems helps maintain optimal operating temperatures, preventing overheating during demanding tasks.

Another vital area for improvement is the hydraulic system. Upgrading hydraulic pumps and cylinders can enhance lifting capabilities and response times, allowing for smoother operations. Implementing advanced filtration systems can also prevent contaminants from damaging critical components, thereby increasing reliability.

Furthermore, enhancing the control systems with modern technology, such as GPS and automated controls, can lead to greater precision and efficiency in operation. These upgrades facilitate better tracking of work progress and allow for more strategic planning, ultimately resulting in cost savings and improved project outcomes.

Investing in high-quality tracks and undercarriage components can improve stability and traction, enabling better performance on various terrains. Durable materials and innovative designs can also contribute to reduced maintenance needs, further extending the life of the equipment.

Overall, strategically selected upgrades can transform machinery performance, leading to enhanced productivity, reduced operational costs, and increased overall satisfaction in the long run.