In the realm of heavy equipment, a comprehensive grasp of the various elements that contribute to optimal functionality is essential. Each machine is a complex assembly of parts, each serving a distinct purpose and playing a vital role in the overall performance. By exploring these individual components, one can gain insights into maintenance, repair, and efficient operation.

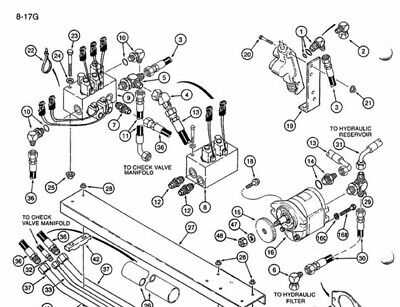

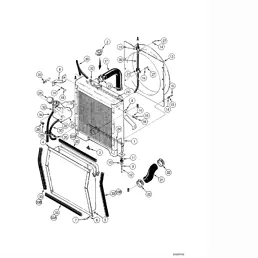

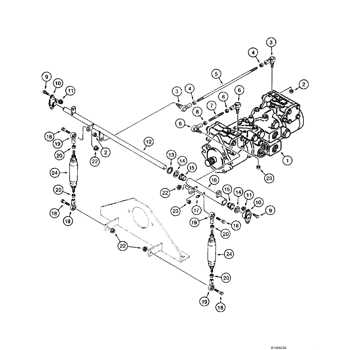

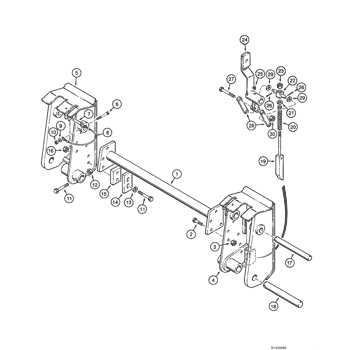

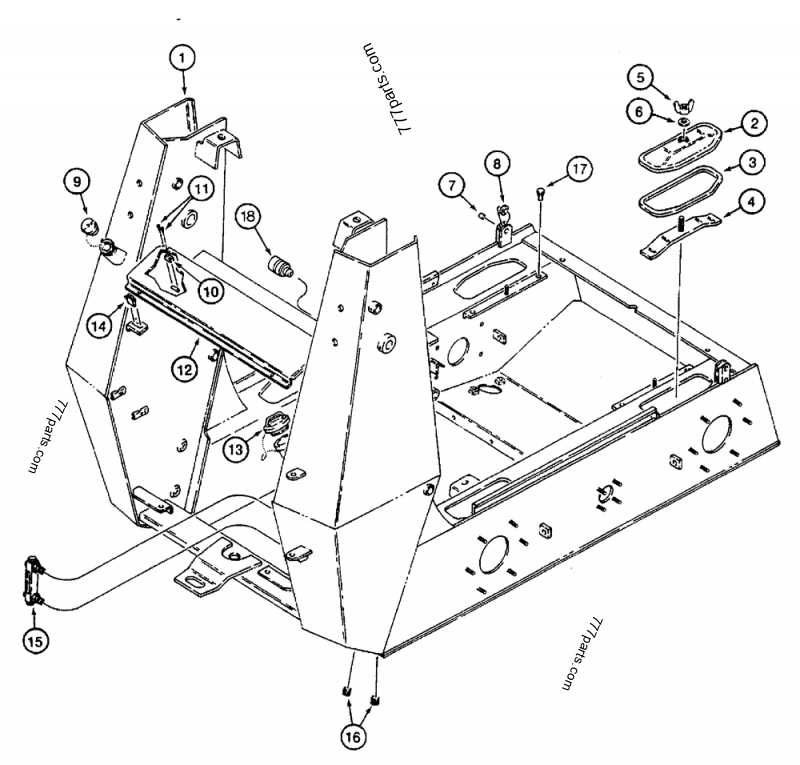

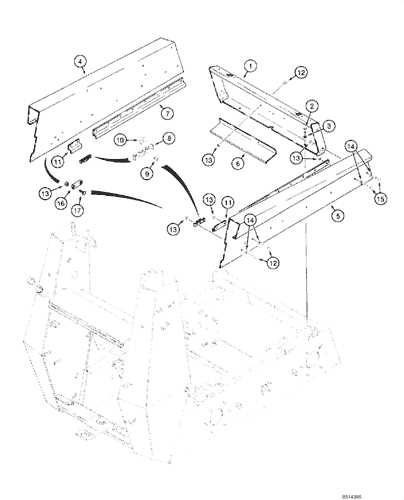

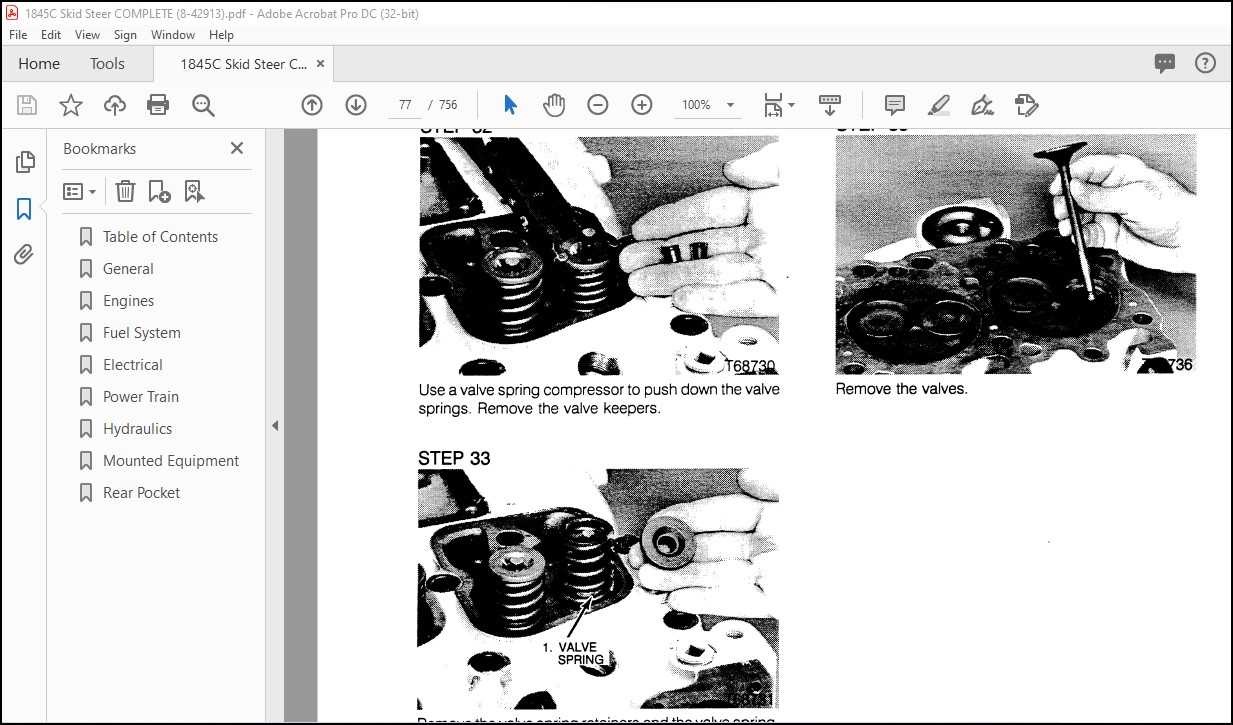

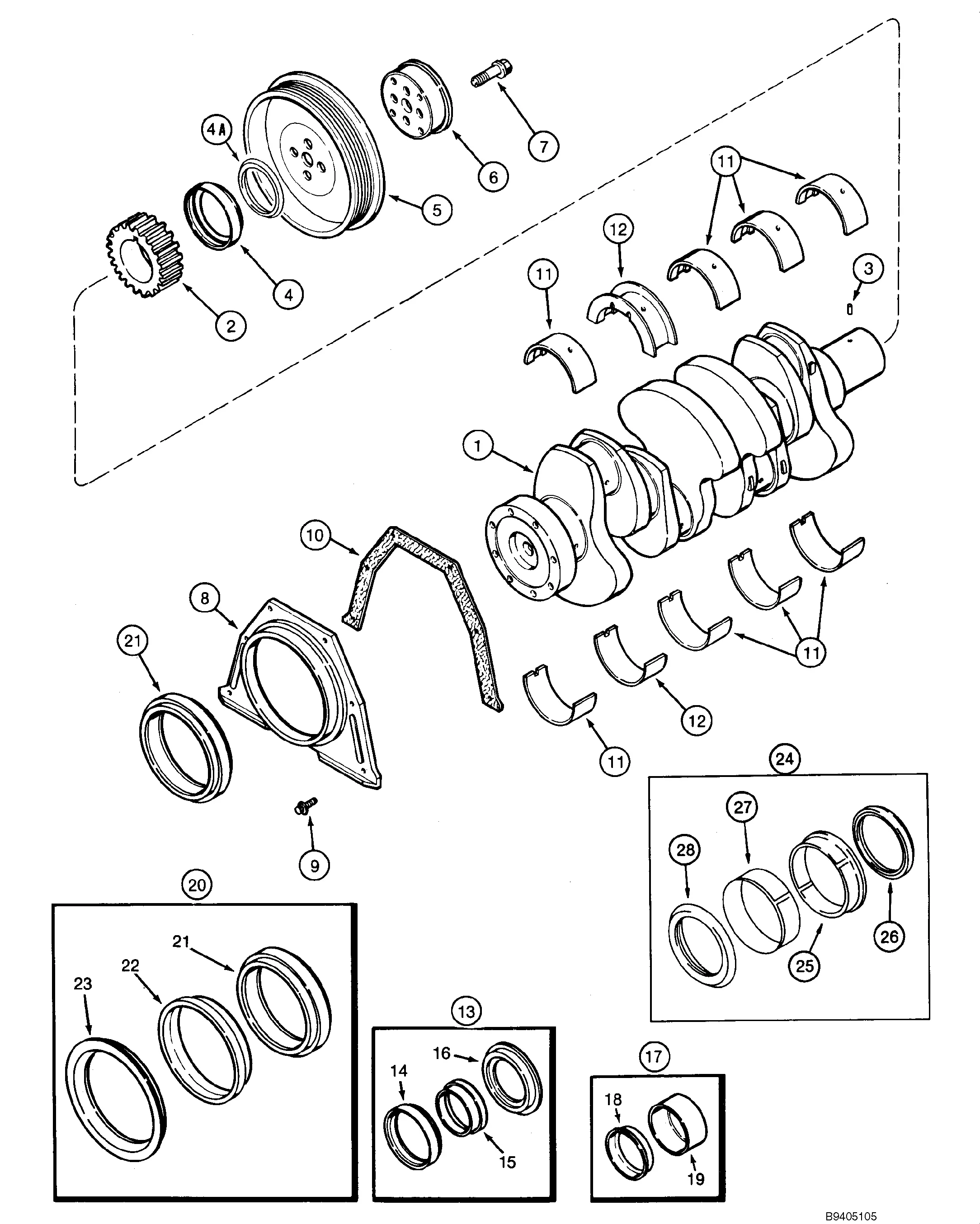

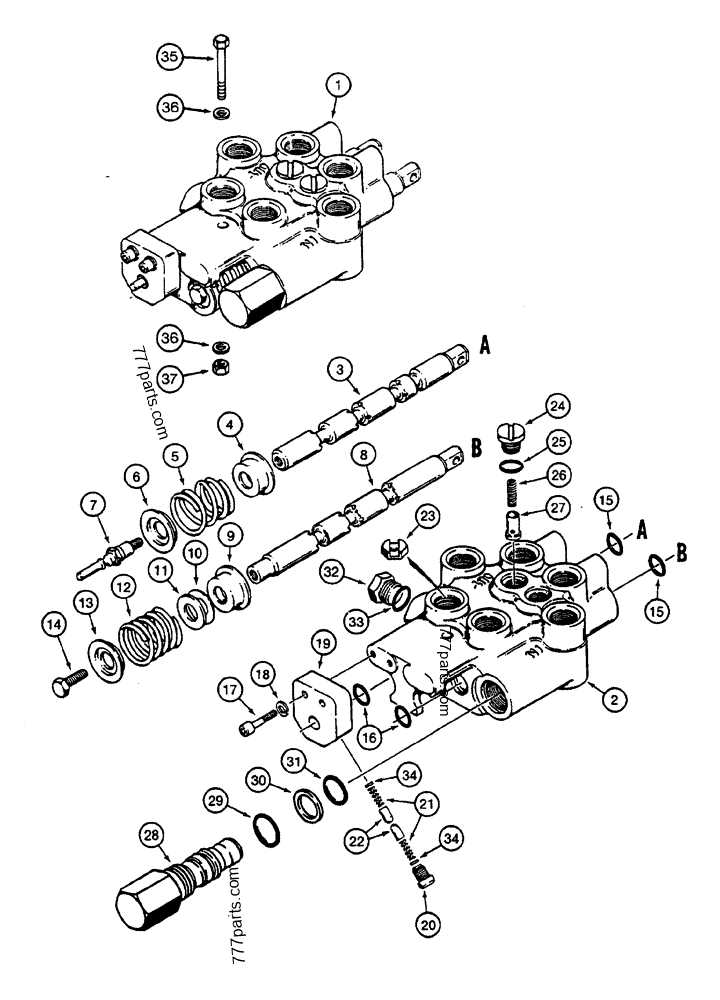

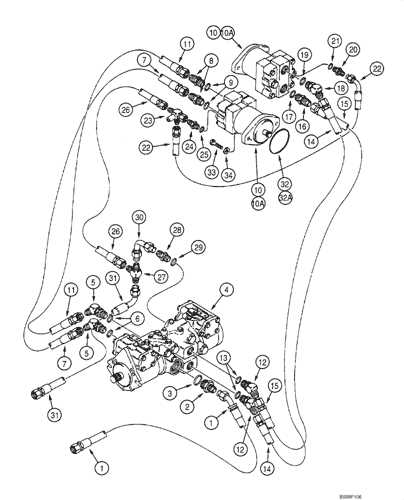

When addressing mechanical systems, visual representations become invaluable tools. They offer a clear perspective on how each segment interacts with others, facilitating easier identification and troubleshooting. Such illustrations not only enhance understanding but also assist in ensuring that every piece operates harmoniously within the larger system.

As operators and technicians delve into the intricacies of machinery, recognizing the significance of each part empowers them to make informed decisions. Knowledge of how components fit together and function can lead to improved performance, extended longevity, and ultimately, increased productivity.

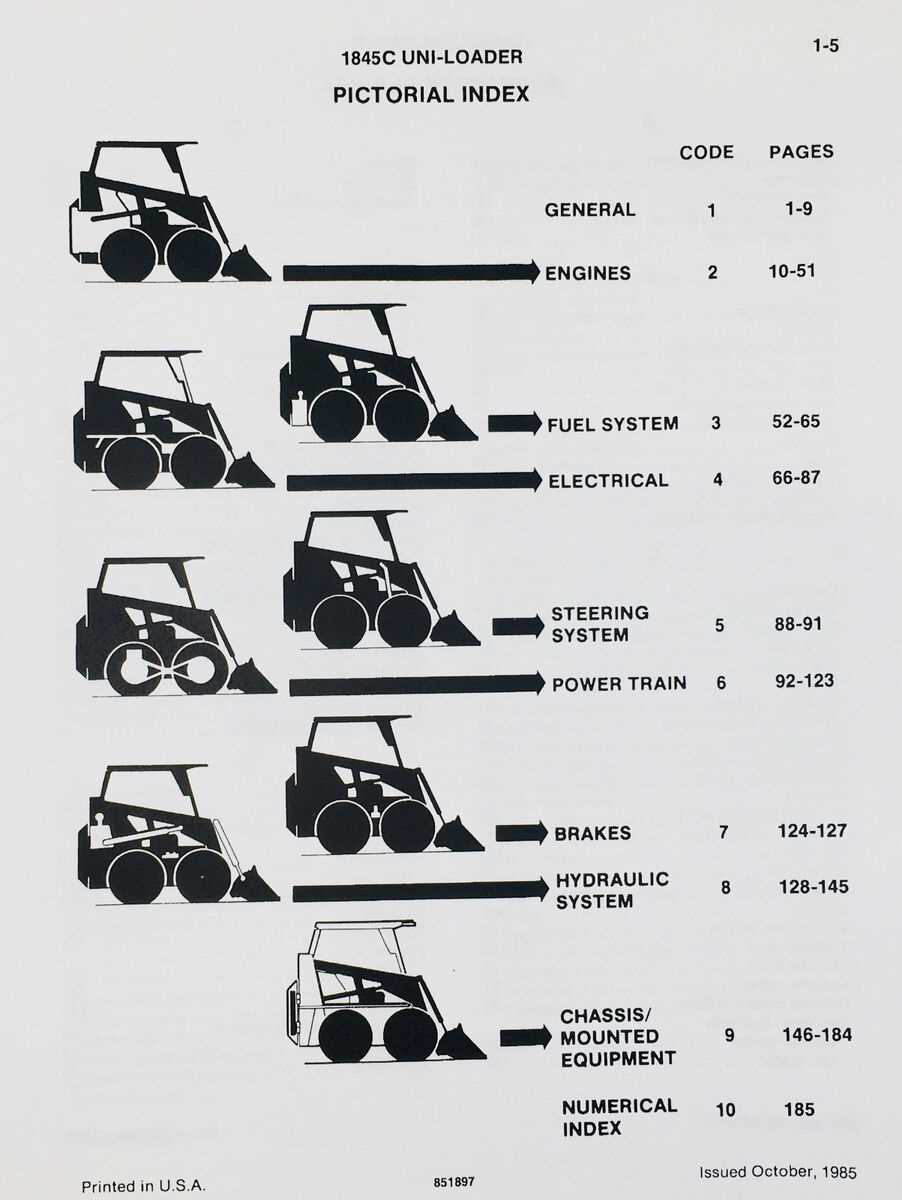

Understanding the Case 1845C Parts Diagram

Comprehending the intricacies of machinery components is essential for effective maintenance and repair. By visualizing the arrangement and function of each element, operators can enhance their understanding of how various pieces work together, ensuring optimal performance and longevity. This knowledge is crucial for troubleshooting and preventing potential issues that may arise during operation.

Components Overview

The illustration of the assembly provides a detailed look at individual elements, showcasing their specific roles within the system. Familiarity with each section allows for informed decision-making regarding repairs and upgrades, ultimately leading to more efficient operations.

Table of Key Elements

| Element Name | Function | Common Issues |

|---|---|---|

| Hydraulic Pump | Generates hydraulic pressure for movement | Leaks, loss of pressure |

| Drive Chain | Transfers power from the engine to the wheels | Wear and tear, misalignment |

| Control Panel | Interface for operator to manage settings | Electrical failures, unresponsive controls |

| Frame | Supports and houses various components | Corrosion, structural damage |

By recognizing the significance of each component and its relationship within the entire system, operators can proactively address maintenance needs and enhance overall functionality.

Key Components of the Case 1845C

This section explores the essential elements that contribute to the functionality and efficiency of this robust machinery. Understanding these vital components allows operators to enhance performance and maintain longevity.

Hydraulic System

The hydraulic system is critical for the operation of the machine, providing power for various tasks. Efficiency and responsiveness are achieved through well-designed pumps and valves that regulate fluid movement.

Drive Mechanism

The drive mechanism ensures smooth movement and maneuverability. Key aspects include the engine, transmission, and axle configuration, which work together to deliver the ultimate driving experience on diverse terrains.

Importance of Accurate Diagrams

In the realm of machinery and equipment maintenance, precision is paramount. Visual representations serve as essential tools that facilitate understanding and enhance operational efficiency. When these illustrations are detailed and accurate, they significantly contribute to the effective assembly, disassembly, and troubleshooting of complex systems.

Clarity is one of the primary benefits of well-crafted visual aids. They provide users with a clear roadmap, illustrating where each component fits within the larger framework. This clarity helps prevent errors during repairs and upgrades, ultimately saving time and resources.

Moreover, accurate visual guides promote safety. By clearly depicting the necessary parts and their interactions, users are less likely to make mistakes that could lead to accidents or equipment failures. This is especially crucial in high-stakes environments where safety is a top priority.

Lastly, having reliable visual references aids in training new personnel. Clear illustrations allow for a more intuitive learning process, enabling individuals to grasp complex concepts more quickly. As a result, teams can become proficient faster, ensuring smooth operations and minimizing downtime.

How to Read the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. By becoming familiar with this visual guide, you can easily identify each segment and its function, ensuring a smoother troubleshooting process.

Familiarize Yourself with the Layout

The initial step involves recognizing the overall structure. Typically, components are arranged logically, often grouped by functionality. This arrangement aids in quickly locating specific elements and comprehending their relationships within the system.

Deciphering Symbols and Notations

Each element in the visual representation is depicted with distinct symbols and labels. Learning these conventions is crucial, as they convey important information about sizes, shapes, and connections. By mastering these notations, you will enhance your ability to navigate the schematic efficiently.

Common Issues with Parts Identification

Identifying components within machinery can often be a challenging task, particularly when multiple models share similar attributes. The complexity of variations in design and manufacturing can lead to confusion, causing delays in repairs and maintenance. Understanding these obstacles is essential for efficient operation and upkeep.

Ambiguity in Model Numbers

One of the primary hurdles arises from ambiguous model numbers. When numbers are not clearly defined or are similar across different series, it becomes increasingly difficult to pinpoint the exact component needed. This can result in ordering incorrect items, which wastes both time and resources.

Lack of Visual References

Without adequate visual aids, such as comprehensive images or charts, identifying specific items can be daunting. The absence of clear visual references makes it hard to distinguish between components that may appear nearly identical. Therefore, having reliable visual resources is crucial for accurate identification and efficient problem-solving.

Maintenance Tips for Case 1845C

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following some key practices, you can enhance reliability and reduce the risk of unexpected failures.

- Regular Inspections: Check all components for wear and tear regularly.

- Fluid Levels: Maintain proper fluid levels and change them as recommended.

- Cleaning: Keep the machine clean to prevent debris accumulation.

- Lubrication: Ensure all moving parts are adequately lubricated to minimize friction.

- Belts and Hoses: Inspect and replace any damaged belts and hoses promptly.

By adhering to these guidelines, you can ensure your machine operates efficiently and effectively over its lifespan.

Where to Find Replacement Parts

Finding suitable components for machinery maintenance can be a challenging task. Knowing where to look and which resources to utilize can significantly streamline the process. This guide outlines various options for sourcing essential items, ensuring your equipment remains in optimal working condition.

Online Retailers

The internet provides a vast marketplace for sourcing necessary components. Numerous websites specialize in offering a wide range of machinery supplies. These platforms often feature customer reviews, which can help gauge the reliability of the items.

| Website | Specialty |

|---|---|

| ExampleSite1.com | Heavy machinery components |

| ExampleSite2.com | Aftermarket supplies |

| ExampleSite3.com | OEM replacements |

Local Suppliers

Local dealers often carry essential components and may provide personalized assistance. Establishing a relationship with these suppliers can lead to better deals and access to hard-to-find items. Many businesses offer loyalty programs or discounts for frequent customers.

Upgrading Components for Better Performance

Enhancing the efficiency of your machinery involves a strategic approach to improving various elements that contribute to its overall functionality. By replacing outdated or subpar components with higher-quality alternatives, users can achieve noticeable improvements in performance, reliability, and lifespan.

Key Areas for Upgrades

Focusing on specific areas can lead to significant advancements. Here are some crucial components to consider for enhancement:

| Component | Benefits of Upgrading |

|---|---|

| Power Supply | Increases stability and efficiency under heavy loads. |

| Cooling System | Improves temperature management, prolonging the lifespan of internal parts. |

| Drive Mechanism | Enhances speed and precision in operations. |

Considerations for Selection

When selecting components for replacement, it’s essential to assess compatibility, durability, and performance ratings. Investing in quality parts ultimately leads to a more efficient and effective system.

Expert Resources for Further Assistance

For those seeking in-depth support and knowledge related to machinery components, numerous resources are available to enhance understanding and facilitate problem-solving. Engaging with expert advice can streamline repair processes and optimize performance, ensuring equipment operates efficiently.

Online Forums: Joining specialized online communities can provide valuable insights. Members often share experiences, troubleshooting tips, and solutions to common issues. Participating in discussions can enhance your understanding and help you connect with knowledgeable individuals.

Manufacturer Support: Reaching out to the original equipment manufacturer can yield comprehensive assistance. They often provide detailed guides, technical documents, and customer service that can clarify uncertainties and offer tailored solutions.

Technical Manuals: Consulting official manuals is essential for anyone looking to grasp the specifics of machinery. These documents typically include diagrams, specifications, and maintenance schedules that can significantly aid in repairs and upkeep.

Workshops and Training: Enrolling in training programs or workshops can deepen your expertise. These hands-on experiences often cover the latest techniques and best practices, allowing you to learn directly from seasoned professionals.

Videos and Tutorials: Online platforms host a plethora of instructional videos that can visually guide you through various tasks. Watching experts demonstrate repairs or maintenance procedures can be immensely helpful in grasping complex concepts.

By leveraging these resources, individuals can enhance their capabilities, troubleshoot effectively, and maintain machinery with confidence.