For individuals relying on mobility solutions, understanding the key elements of such equipment is crucial for maintaining functionality and ensuring safety. This guide offers a comprehensive breakdown of the essential components that make up these advanced mechanisms. By exploring each part in detail, users can better grasp the design and operational flow of these devices, helping to extend their lifespan and performance.

Each system consists of a series of interconnected units, each serving a specific role in the overall operation. These components range from basic structural elements to complex mechanical systems designed for seamless movement. Identifying and understanding the function of each piece enables users to make informed decisions about repairs and upgrades.

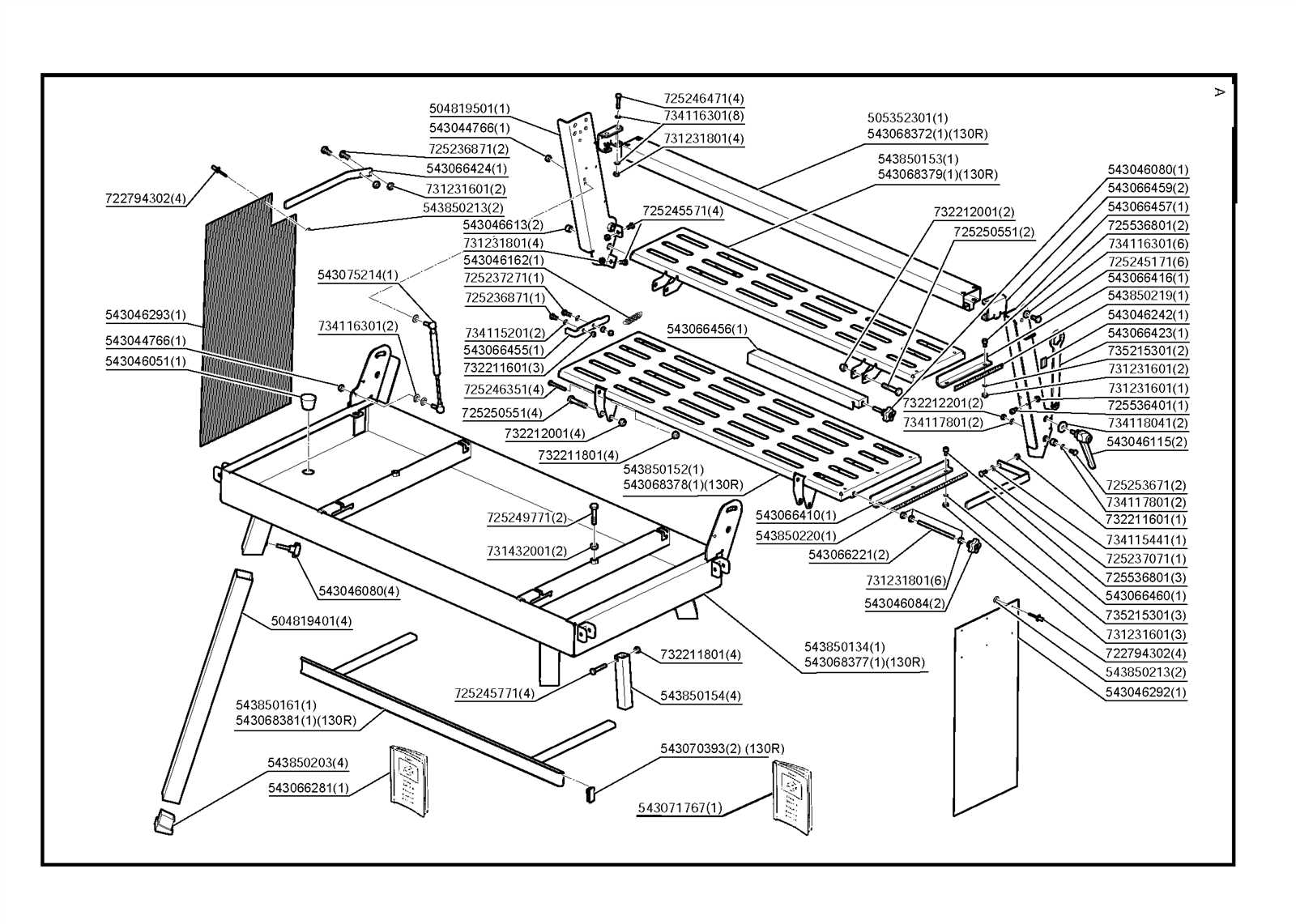

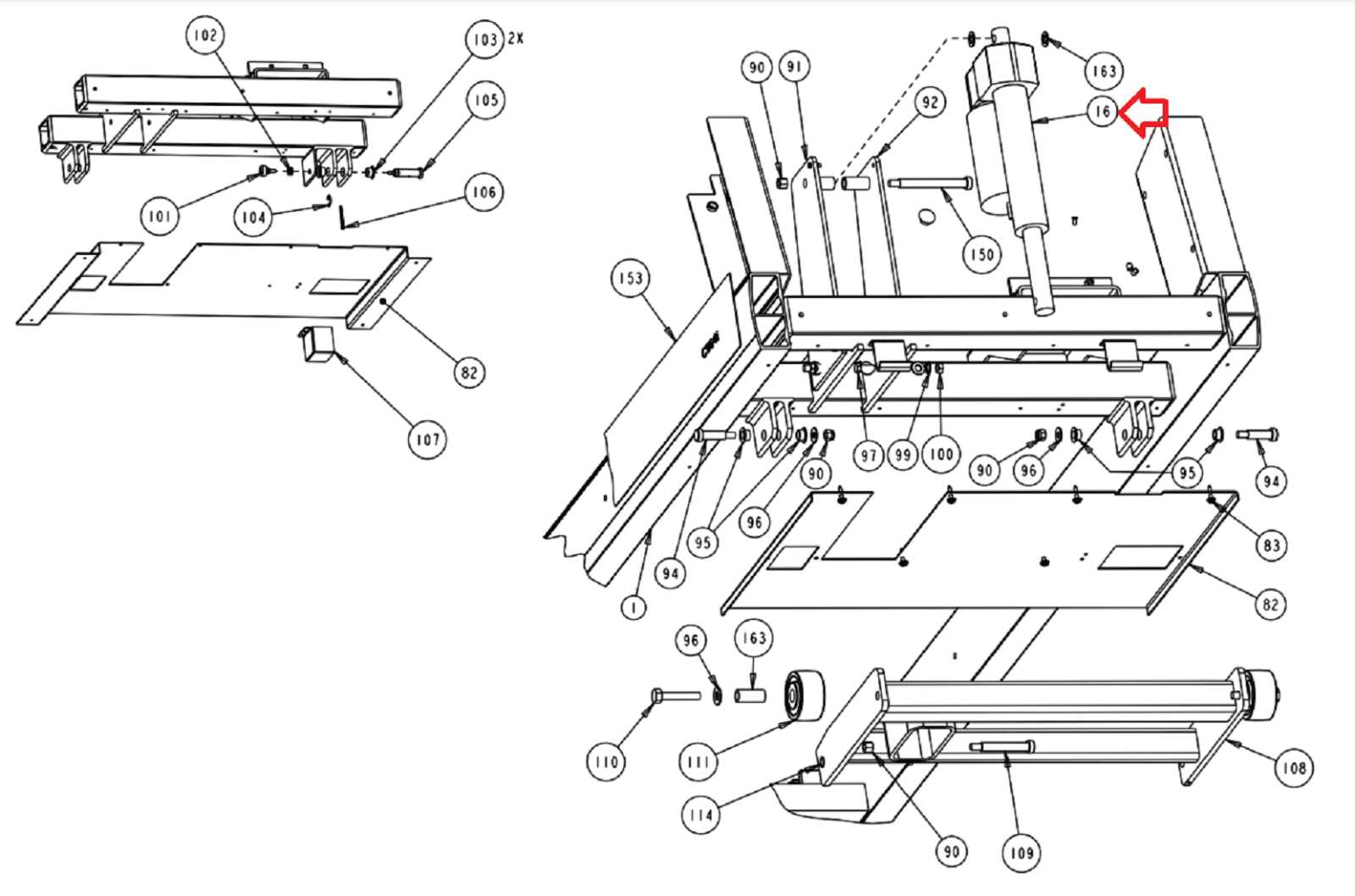

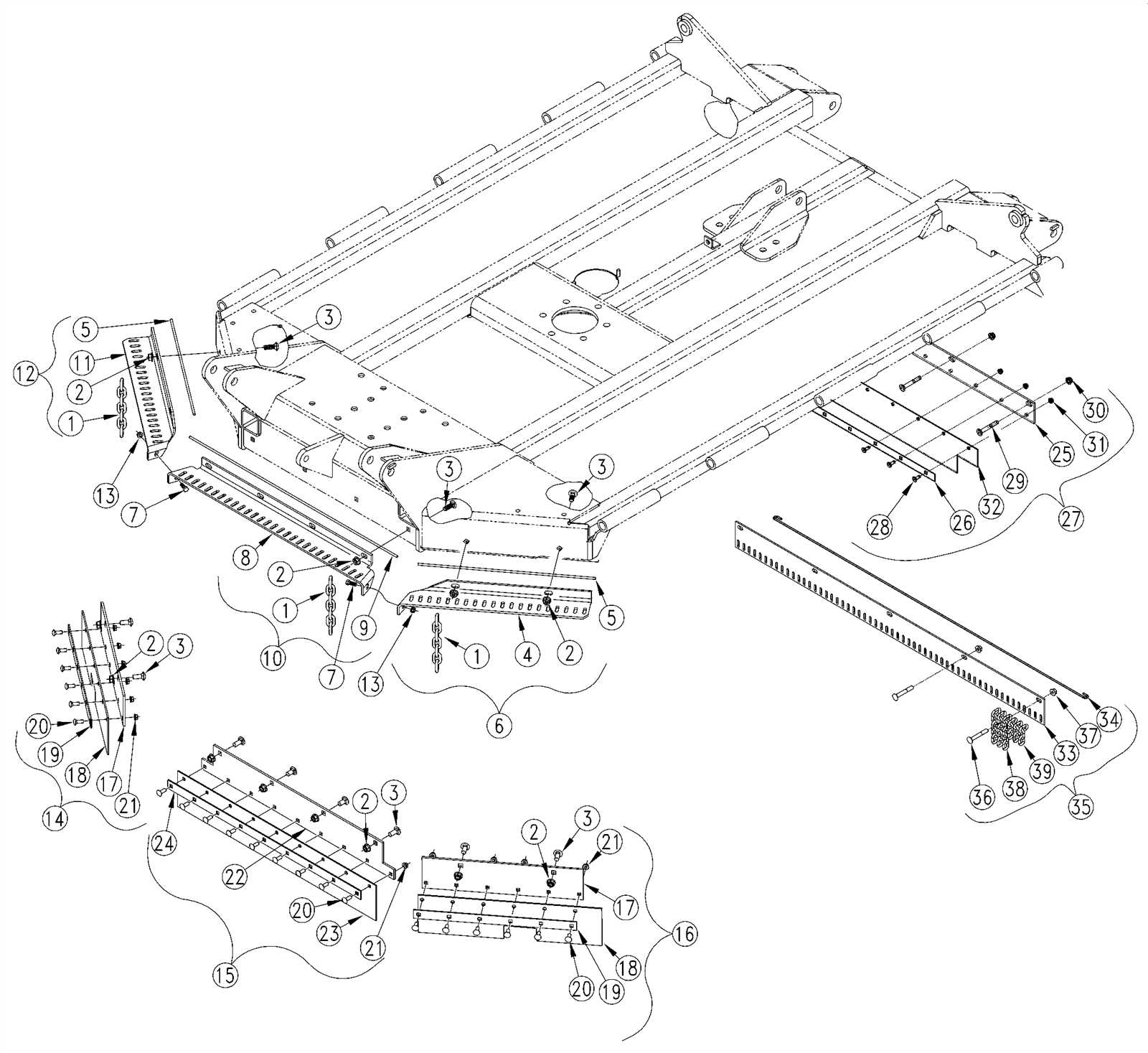

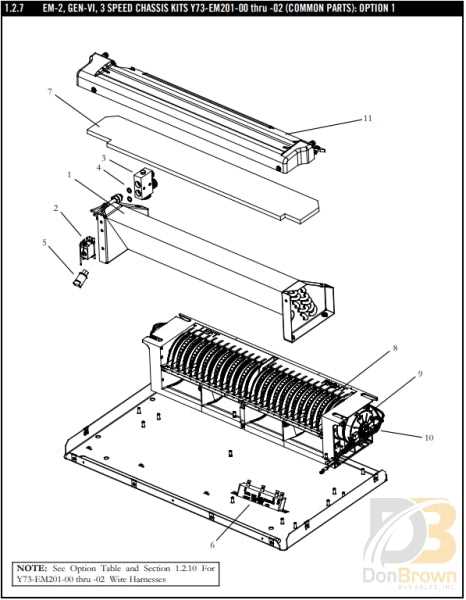

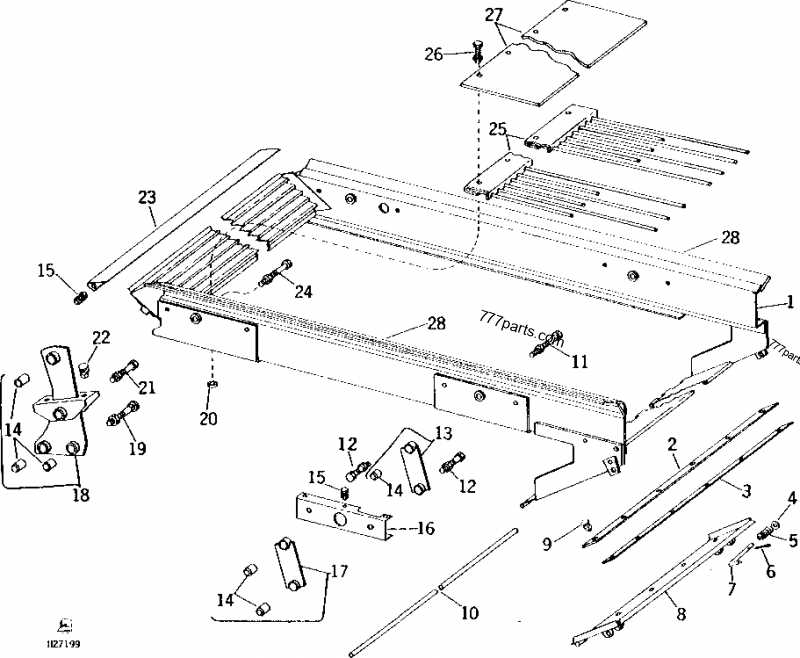

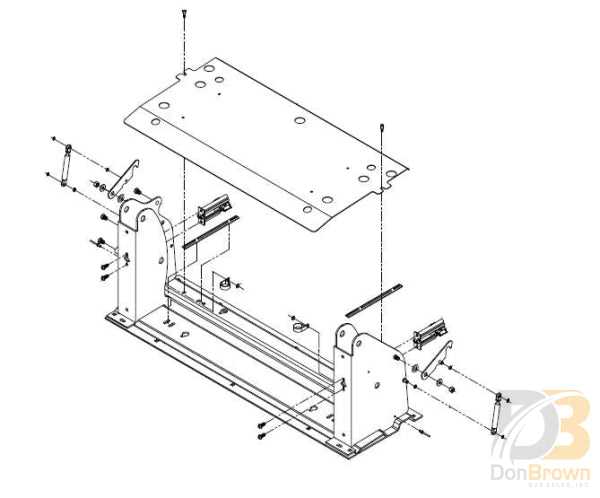

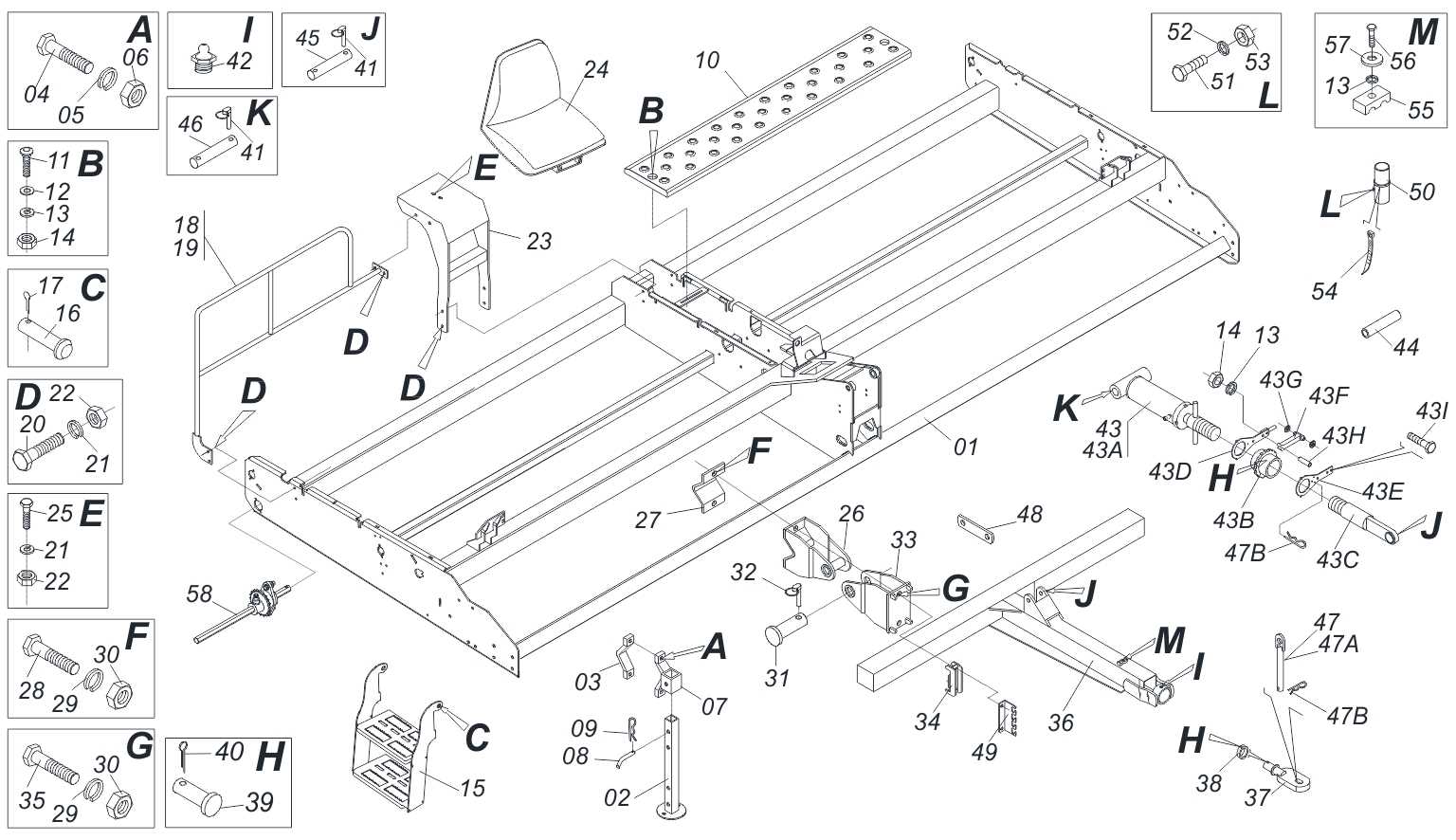

To aid in this process, a detailed schematic serves as a visual reference, clearly mapping out how the various components work together. With this information, users can easily locate and assess any issues that may arise, allowing for quicker troubleshooting and more efficient maintenance. A well-maintained system ensures that mobility devices continue to meet the needs of those who depend on them for everyday tasks.

Understanding Braun Wheelchair Lift Components

When it comes to the operation of mobility aids, a comprehensive understanding of their key elements is essential for proper maintenance and troubleshooting. These systems rely on a series of interconnected components that work together to provide safe and reliable function. From the mechanical systems to electrical parts, each piece plays a crucial role in ensuring smooth operation and long-term reliability. Knowing how each component contributes to the system allows users to identify potential issues and keep everything running efficiently.

Key Elements of the System

One of the most important aspects to consider when assessing a mobility assistance system is the interaction between the major mechanical and electrical components. These can include the drive mechanisms, support structures, and control interfaces. Each plays a vital role in moving the platform smoothly while ensuring safety and comfort. The mechanism responsible for driving the system is often powered by motors, with precise guidance offered by the support framework. Additionally, electronic control units help regulate operations, often integrating with sensors to guarantee safe operation under various conditions.

Component Overview

| Component | Description | Function |

|---|---|---|

| Drive Motor | A powerful electric motor | Powers the mechanism responsible for vertical movement |

| Support Frame | Sturdy metal framework | Holds the platform securely and supports weight |

| Control Panel | Electronic interface with buttons or switches | Allows user interaction to control movements and settings |

| Hydraulic System | Fluid-based pressure system | Assists with smooth lifting and lowering of the platform |

| Safety Sensors | Proximity and weight sensors | Monitors surroundings for obstacles and detects overloading |

By familiarizing oneself with these essential components, individuals can enhance their understanding of how the system functions and identify areas that may require attention. Regular inspection and maintenance of these elements are key to extending the lifespan and ensuring the consistent performance of the system.

Essential Parts for Braun Lift Systems

Every mobility assistance system relies on a collection of crucial components that ensure smooth and reliable operation. These elements work together to provide the necessary functionality and durability. Understanding these components is key to maintaining the overall efficiency and performance of the system. Each component plays a distinct role in supporting the user’s needs and maintaining the safety and reliability of the device over time.

Key Components for Reliable Operation

The main elements involved in these systems typically include motors, control systems, and hydraulic or mechanical mechanisms. Motors provide the power to move, while control systems manage the movement and ensure proper coordination. Hydraulic or mechanical arms often assist in the lifting or lowering functions, providing stability and strength. Additionally, safety features such as sensors, limit switches, and emergency stop systems ensure user security during operation.

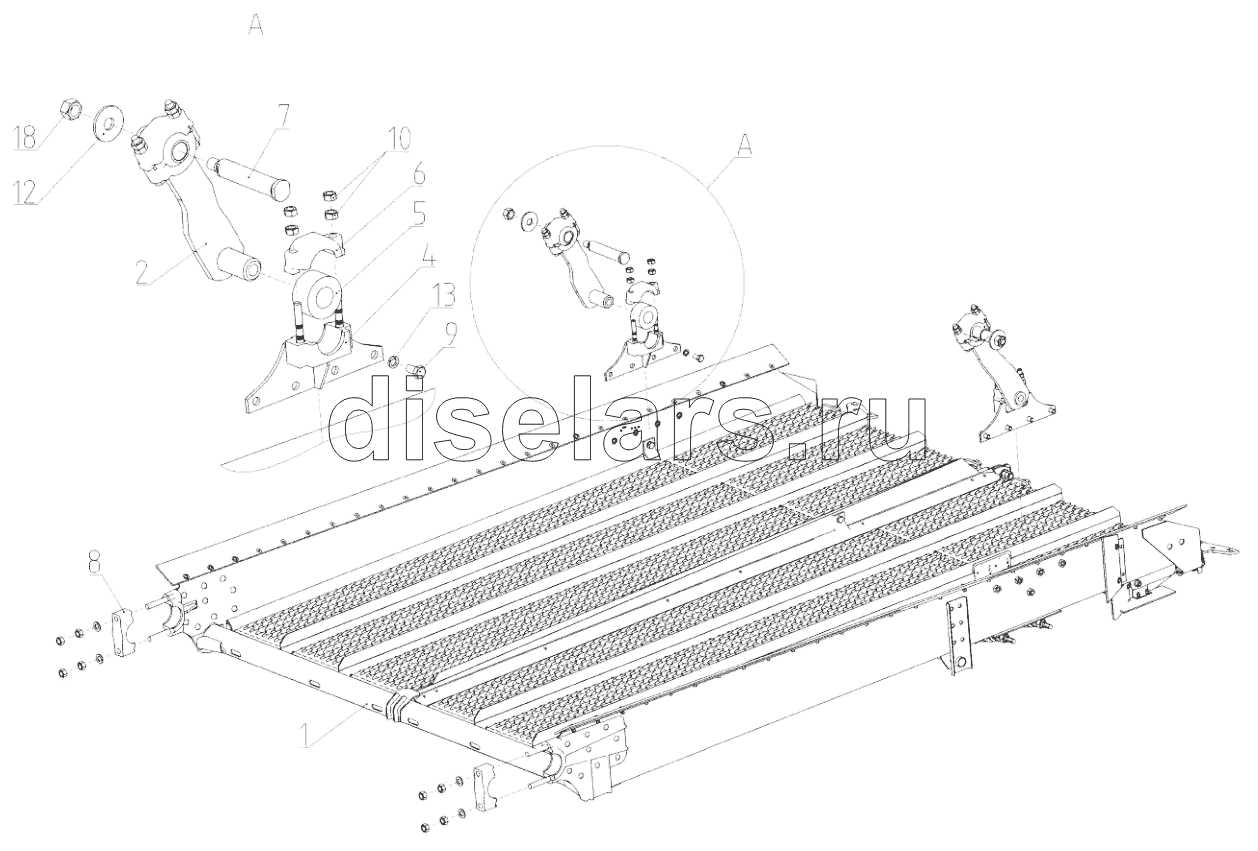

Structural and Support Elements

In addition to the functional components, the structural elements offer essential support and durability. These include frames, supports, and hinges that bear the load and allow for smooth transitions between different levels. Materials used for these structures must be both strong and lightweight to prevent wear and tear, as well as to reduce the overall weight of the system. Regular inspection of these structural elements is critical for maintaining long-term reliability and safety.

How to Identify Braun Lift Diagrams

Understanding the technical illustrations for mobility devices is crucial for proper maintenance and repair. These visual aids typically break down the mechanical components and electrical connections, allowing users to accurately identify individual elements and their placement. Recognizing the right diagrams can simplify troubleshooting and ensure the smooth functioning of the equipment.

Key Features of Technical Illustrations

When you start reviewing technical schematics, certain aspects are essential for quick identification:

- Clear labels for each component

- Logical flow from the start to the end of the assembly

- Distinction between mechanical and electrical parts

- Consistent symbols and notations for wiring and connections

Where to Find Accurate Illustrations

Accurate schematics are usually available through several reliable sources:

- Official manuals provided by the manufacturer

- Authorized repair centers or distributors

- Online technical resources or forums dedicated to mobility equipment

Once you have located the right schematic, cross-reference the part numbers and configurations with your device to ensure compatibility. Properly interpreting these diagrams will help you perform maintenance tasks effectively.

Common Issues in Lift Mechanisms

Various mechanisms designed to assist with vertical transportation often experience issues that can hinder their functionality. These complications range from minor glitches to more severe malfunctions, and addressing them in a timely manner is crucial for maintaining the system’s reliability and safety. Understanding the typical problems that can arise in these systems is the first step toward effective troubleshooting and repair.

Mechanical Failures

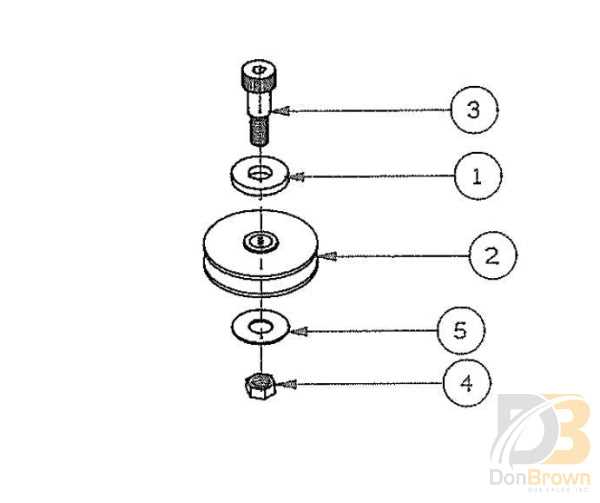

One of the most frequent problems is related to mechanical components. Over time, wear and tear can cause parts like gears, pulleys, or chains to malfunction. Failure to lubricate or improperly maintaining these elements can lead to increased friction, which can cause the system to operate with less efficiency or even seize completely. In some cases, damaged components may need to be replaced to restore functionality.

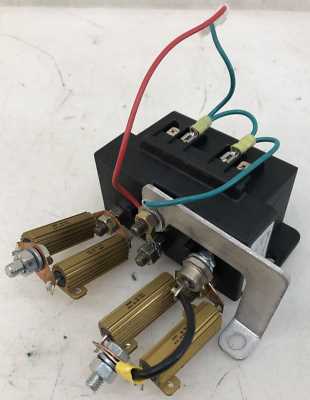

Electrical Malfunctions

Another common issue arises from electrical systems. Wires, connectors, and circuits can become faulty due to corrosion or wear, disrupting the flow of power necessary to operate the mechanism. Sometimes, the control panel or switches may fail, preventing the user from activating or controlling the movement. Regularly checking for electrical faults can help avoid unexpected breakdowns and improve safety.

Repairing Braun Lift with Spare Parts

Maintaining and fixing mobility equipment requires careful attention to detail, especially when dealing with complex machinery. Ensuring that all components are functioning correctly often involves replacing worn-out or damaged elements with compatible replacements. Whether it’s a mechanical malfunction or an electrical issue, identifying the right replacement pieces and performing the proper repair steps is crucial for restoring full functionality.

Understanding the mechanism is the first step in any repair process. Knowing how each component works together helps in pinpointing the exact issue. Once the malfunctioning part is identified, it’s essential to source the correct replacements that meet the required specifications. In some cases, these replacements may need to be ordered from the original manufacturer or a trusted distributor, as compatibility is key to ensuring smooth operation.

Step-by-step repair procedures can be followed to disassemble the equipment safely, replace the necessary parts, and reassemble it correctly. It’s important to handle all parts with care to prevent any damage during the process. Additionally, ensuring that all connections are secure and that there are no obstructions can prevent further issues down the road.

After replacing the faulty components, it’s advisable to test the system thoroughly to ensure everything is working as expected. If problems persist, additional troubleshooting may be necessary to check for overlooked issues or misaligned parts. By using the right replacement items and following the correct procedures, you can extend the lifespan and improve the reliability of the equipment.

Maintenance Tips for Braun Wheelchair Lifts

Regular upkeep of mobility devices designed for easy access is crucial to ensure their longevity and reliable performance. Performing routine checks and addressing minor issues promptly can prevent more significant problems and keep the system functioning smoothly over time. In this section, we will explore practical maintenance advice to help extend the lifespan of your equipment and ensure it operates at peak efficiency.

1. Regular Cleaning and Inspection

One of the most essential aspects of upkeep is cleanliness. Dust, debris, and moisture can accumulate over time and cause wear on sensitive components. Regularly wipe down surfaces and check for any buildup that might obstruct movement. Pay attention to areas where dirt can gather, especially near moving joints and hinges. Keeping the system free of debris will help prevent unnecessary strain on the mechanical parts.

2. Lubrication of Moving Parts

Ensure that all moving components are adequately lubricated to avoid friction, which can lead to premature wear. Use appropriate lubricants designed for mobility equipment. Apply lubricant to joints, gears, and lift mechanisms, following the manufacturer’s guidelines for the recommended products and application frequency. Regular lubrication can make operations smoother and quieter while reducing the risk of component damage.

3. Inspecting Electrical Connections

For electrically operated systems, inspect all electrical connections periodically. Loose or frayed wires can cause power issues or malfunctioning. If you notice any unusual behavior, such as a delayed response or intermittent operation, check the wiring and connections. Ensure all components are properly seated and free from corrosion to maintain a steady power flow.

4. Check Hydraulic Fluid Levels (if applicable)

If your system relies on hydraulics, it’s essential to monitor fluid levels regularly. Low fluid levels can affect the performance of lifting functions. Refer to the user manual for the recommended fluid and check levels frequently, topping up as needed. If you detect any leaks, address them promptly to avoid further complications.

5. Test Operational Functionality

Performing routine functional tests can help identify issues before they become critical. Test the entire system periodically, ensuring that all movements and adjustments are smooth and as expected. Listen for unusual sounds or observe any irregular motions that might indicate internal problems. Early detection allows for faster repairs, minimizing downtime.

6. Schedule Professional Inspections

While regular home maintenance is essential, having a professional technician inspect the system at least once a year is highly recommended. Technicians have the expertise to detect subtle issues that might not be visible during regular checks. They can also perform more thorough inspections and make necessary adjustments to ensure everything is in top condition.

Choosing Quality Replacement Parts

When maintaining or repairing mobility equipment, selecting the right components is essential for ensuring reliability, safety, and optimal performance. The longevity of any mechanical system depends largely on the quality of its individual elements. Making the right choice can help avoid frequent repairs and ensure smooth operation over time. Understanding the key aspects of component selection is crucial to achieving these goals.

Why Quality Matters

Opting for high-quality replacements offers numerous advantages. High-grade materials and precision engineering guarantee better durability and a reduced likelihood of malfunction. Cheaper alternatives may appear cost-effective initially, but they often fail to meet performance standards, leading to additional expenses in the long run. Investing in quality ensures peace of mind and long-term functionality.

Key Factors to Consider

When selecting components, several factors should be considered. First, ensure compatibility with the system, as mismatched elements can cause improper operation. Second, look for parts that adhere to industry standards, as these are designed to meet rigorous safety and performance criteria. Lastly, consider the manufacturer’s reputation–well-established brands tend to offer more reliable and long-lasting solutions.

In summary, choosing premium-grade replacements is an investment that ensures the longevity and efficiency of your equipment. Careful selection, based on quality and compatibility, is key to keeping the system operating at its best.

Understanding Lift Wiring and Electrical System

The electrical components that power mobility platforms are critical for their functionality and safety. A well-organized system ensures that all functions operate smoothly, from raising and lowering mechanisms to safety features. Understanding the wiring and electrical setup helps users troubleshoot problems, perform maintenance, and ensure optimal performance. Knowledge of how energy flows through the system is key to its proper care and longevity.

At the core of any mobility device is its power supply, which delivers the necessary energy to various electric motors and control units. These systems typically rely on batteries, which store energy for later use. The battery connects to a series of electrical circuits that distribute power throughout the device, ensuring that each component, such as the motor and safety sensors, operates efficiently.

The wiring harness is the lifeline for these electrical components. It consists of cables that interconnect various parts of the system, ensuring that signals and power are properly transmitted. An effective wiring system is designed to prevent short circuits and overloads, which could compromise the performance or safety of the system.

Control mechanisms play an important role in directing the flow of electricity. Switches, relays, and controllers allow the user to interact with the system, managing different speeds, directions, and safety features. These controls are typically linked to an electronic control board, which acts as the brain, receiving inputs and sending signals to the corresponding components.

Lastly, safety features are integrated into the electrical setup, such as emergency stop buttons, overload protection, and backup systems. These elements ensure that in case of malfunction or power loss, the system behaves predictably, minimizing risk for the user. Proper understanding of these electrical aspects can help prevent system failures and ensure reliable operation.

Installing Braun Lift Safely and Efficiently

Ensuring a safe and effective installation of mobility assistance devices requires careful planning, precise execution, and attention to detail. Proper setup guarantees that the system operates smoothly and provides reliable support over time. This section outlines the key steps to install these mobility aids while ensuring user safety and optimal functionality.

The installation process involves several crucial stages. From preparing the space to aligning and securing the components, each step contributes to a successful setup. It’s essential to follow manufacturer guidelines, use appropriate tools, and verify the installation regularly to avoid potential issues. The following table summarizes these steps for easy reference:

| Step | Description |

|---|---|

| 1. Preparation | Ensure the area is clear and accessible, with adequate space for the installation. Gather all necessary tools and equipment. |

| 2. Assembly | Assemble the main framework according to the manual. Make sure all parts fit together securely and are aligned correctly. |

| 3. Securing Components | Fasten all elements firmly to the mounting surface, ensuring they are level and stable. Double-check connections to prevent loosening over time. |

| 4. Power Setup | Connect electrical components, making sure all wiring is routed safely and is free from obstruction. Test the power supply. |

| 5. Testing | Perform a series of tests to verify that the system operates smoothly and consistently. Check for any irregularities and adjust settings if needed. |

| 6. Safety Check | Ensure all safety features are functioning as expected. Confirm that there are no hazards in the vicinity of the installation. |

By following these organized steps, the installation process can be completed with precision and efficiency, ensuring both the functionality of the system and the safety of its users.