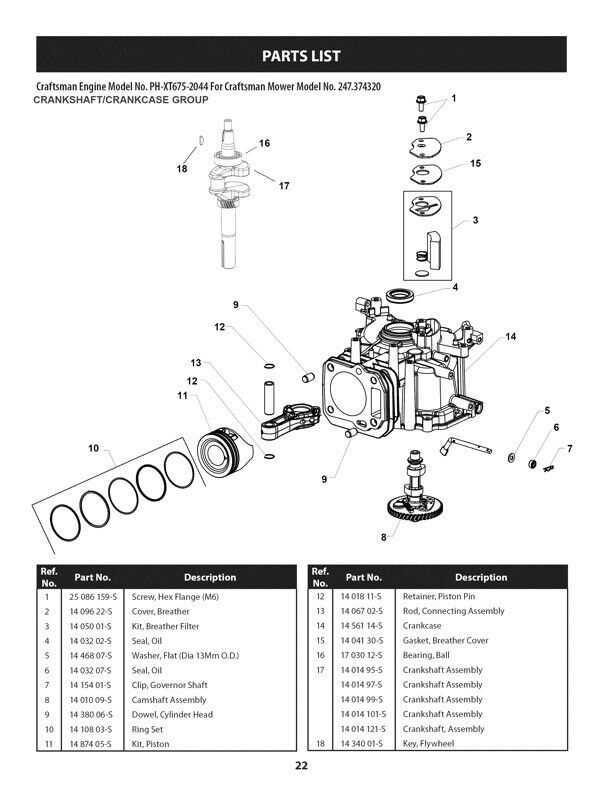

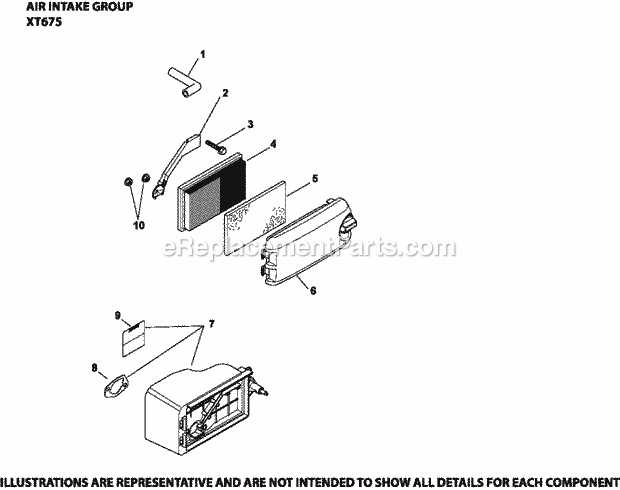

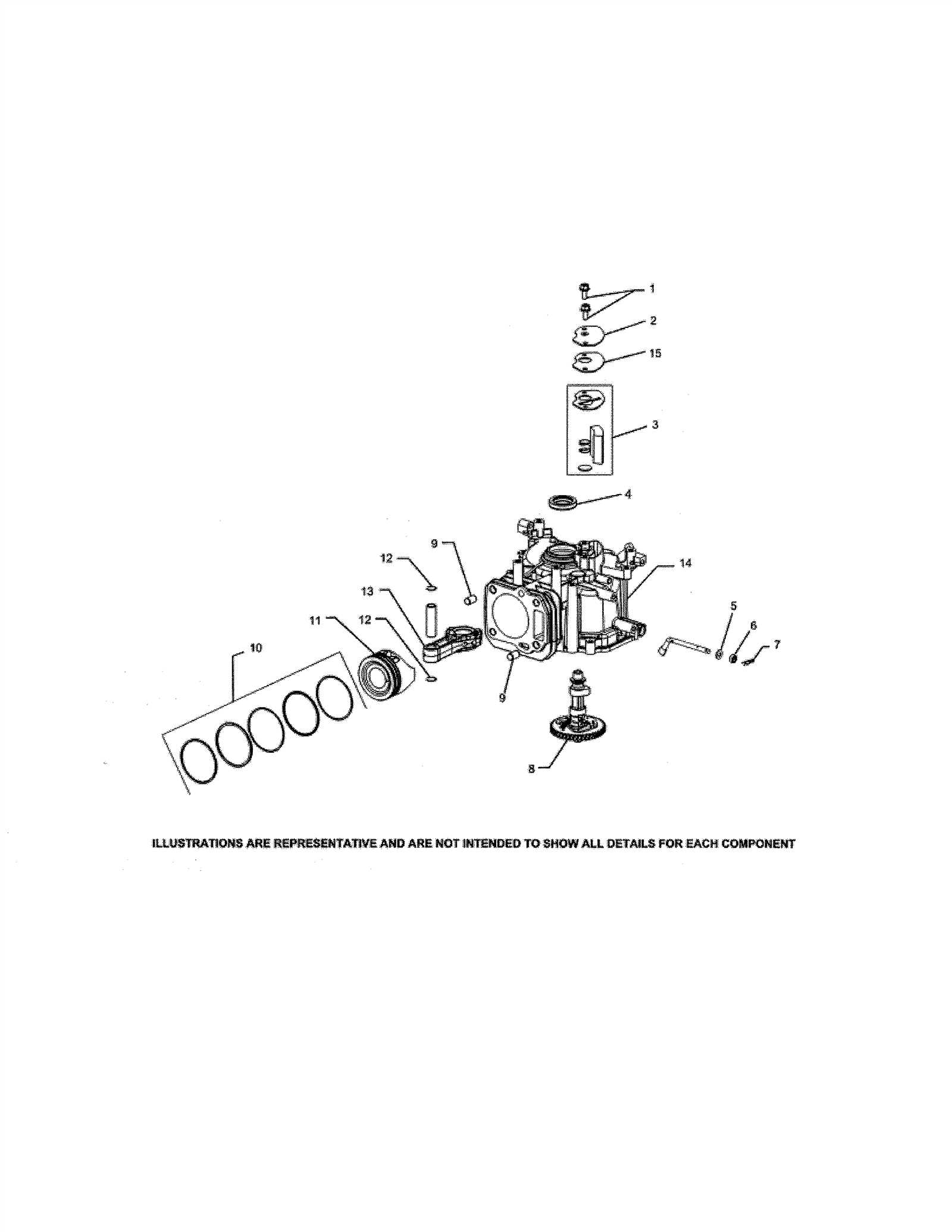

In the world of machinery maintenance and repair, having a clear visual representation of the intricate components that make up an engine is essential. Such illustrations provide invaluable insights into the structure and function of various parts, facilitating efficient troubleshooting and assembly. This resource serves as a guide for enthusiasts and professionals alike, enabling them to navigate through the complexities of engine configurations with ease.

Identifying key elements within an engine is crucial for effective management and repair. By examining detailed illustrations, users can quickly locate necessary components, understand their relationships, and pinpoint areas that may require attention. This knowledge empowers individuals to approach their tasks with confidence, whether they are performing routine maintenance or addressing specific issues.

Moreover, these visual aids not only enhance understanding but also streamline the repair process. With clear depictions of each component, users can ensure that they are using the correct parts and tools, reducing the risk of errors. Ultimately, this comprehensive understanding fosters greater efficiency and longevity in engine performance, making it a vital aspect of any maintenance routine.

Kohler PH-XT675 Overview

This engine model is designed to deliver exceptional performance for various outdoor power equipment. It combines advanced engineering with durable components, ensuring reliability and efficiency across a wide range of applications. Whether for residential or commercial use, this unit is built to meet the demands of tough environments while maintaining ease of operation and minimal maintenance.

Engine Capacity plays a crucial role in its overall functionality. With a robust displacement, the unit provides optimal power output to handle tasks requiring sustained performance. The design ensures that fuel consumption remains efficient, offering a balance between power and economy. With high torque and smooth operation, it is well-suited for heavy-duty machinery and tools.

The build quality of this engine highlights the use of top-grade materials, contributing to its long-lasting service life. From the ignition system to the cooling components, every part is designed to withstand extreme conditions while ensuring ease of repair when necessary. Maintenance and servicing are straightforward, making this unit an excellent choice for those seeking a reliable solution with minimal downtime.

Importance of Parts Diagrams

Understanding the structure and components of any mechanical system is crucial for efficient maintenance and repair. A visual representation of these elements offers significant advantages for both professionals and hobbyists alike. Such tools enable users to easily identify individual pieces, comprehend their interconnections, and follow step-by-step instructions for proper assembly or disassembly.

Enhanced Troubleshooting

With a clear illustration, diagnosing issues becomes much simpler. When problems arise, having access to a visual reference helps to quickly pinpoint malfunctioning components, saving both time and resources. This can be especially helpful in complex machines where numerous parts may be interdependent.

Accurate Replacements and Assembly

When replacing damaged or worn-out pieces, a detailed visual guide ensures that each element is correctly identified and positioned. This not only prevents errors but also guarantees the system’s overall functionality after repairs. Correct reassembly is critical for ensuring optimal performance and longevity of the machinery.

Clear visuals promote accuracy and facilitate a deeper understanding of how each part contributes to the overall operation of the machine, leading to more informed decisions and effective repairs.

Identifying Key Components

Understanding the fundamental elements of any mechanical system is essential for effective maintenance and troubleshooting. Each component plays a specific role, contributing to the overall functionality and performance. By recognizing these crucial parts, users can ensure proper operation and longevity of their equipment.

Essential Elements

Among the various components, some stand out as particularly vital. The engine serves as the heart of the machine, providing the necessary power for operation. Additionally, the fuel system is critical for ensuring optimal performance, as it regulates the delivery of energy. Other important elements include the electrical system, responsible for ignition and control, and the cooling system, which prevents overheating during operation.

Recognizing Signs of Wear

Awareness of how these elements can degrade over time is crucial for effective management. Look for unusual noises, leaks, or decreased efficiency as indicators of potential issues. Regular inspections can help identify problems early, enabling timely repairs and reducing the risk of more significant damage.

Maintenance Tips for Kohler Engines

Regular upkeep is essential for ensuring optimal performance and longevity of your power equipment. By following a few key practices, you can significantly enhance the reliability of your engine.

- Check and change the oil regularly to prevent wear and tear.

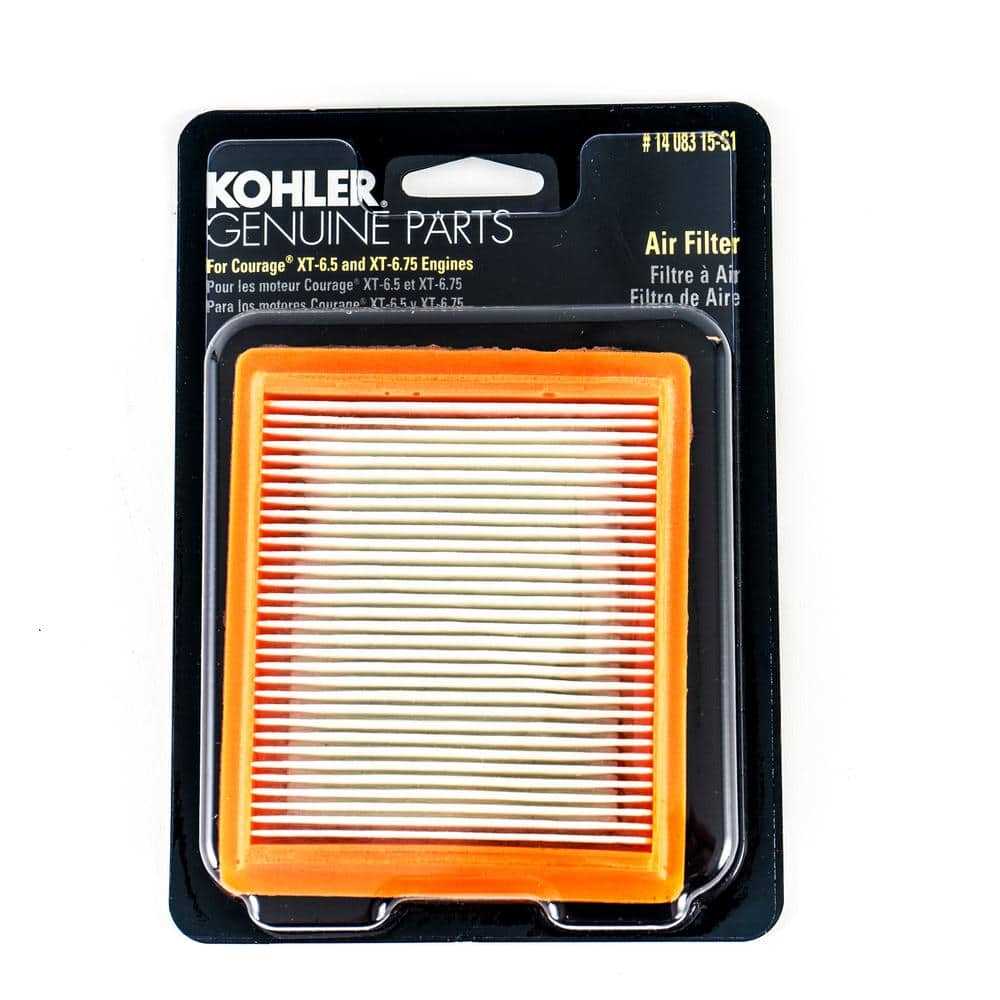

- Inspect air filters and clean or replace them as needed.

- Examine spark plugs and replace them if they show signs of damage or wear.

- Keep fuel systems clean and free of debris.

Additionally, it’s wise to delve into the maintenance schedule provided by the manufacturer for the ultimate guidance on timing and specific tasks.

- Inspect belts and hoses for cracks or wear.

- Sharpen or replace blades to maintain cutting efficiency.

- Store equipment properly to prevent damage from weather or pests.

By adhering to these suggestions, you’ll ensure that your engine operates smoothly for years to come.

Common Issues and Solutions

In the realm of equipment maintenance, users often encounter a variety of challenges that can hinder performance. Understanding these common problems and their remedies is essential for ensuring longevity and efficiency.

Frequent Performance Issues

One of the most prevalent issues is inconsistent operation. This can stem from various factors such as clogged components or insufficient lubrication. Regular inspection and cleaning can significantly improve functionality, while ensuring all moving parts are adequately lubricated enhances overall performance.

Leaking Components

Another common concern is leakage, often caused by worn seals or loose connections. To resolve this, it is crucial to check all joints and replace any damaged seals promptly. Regular maintenance checks can help identify potential leaks before they escalate.

Where to Find Replacement Parts

Finding the right components for your equipment can be a straightforward process if you know where to look. Various resources are available to help you locate high-quality replacements that ensure your machinery operates efficiently. Understanding these sources can save you time and effort in your search.

One of the best places to start is with authorized dealers. These outlets often have a comprehensive selection of authentic components and can provide valuable assistance in identifying the right items for your needs. Additionally, visiting the manufacturer’s official website can yield useful information regarding product specifications and availability.

Online marketplaces and specialized retail websites also offer a wide range of options. Be sure to check customer reviews and seller ratings to ensure you are purchasing from reputable sources. Below is a comparison of various avenues for sourcing your necessary components:

| Source | Advantages | Disadvantages |

|---|---|---|

| Authorized Dealers | Authenticity, expert advice | Higher prices |

| Manufacturer’s Website | Direct source, reliable information | Limited selection |

| Online Marketplaces | Variety, competitive prices | Quality can vary |

| Local Repair Shops | Personalized service, expertise | Limited inventory |

By exploring these different avenues, you can find the right solutions to keep your equipment running smoothly.

Using the Diagram Effectively

Understanding the visual representation of components is essential for efficient assembly, maintenance, and troubleshooting. Utilizing these illustrations can significantly enhance your workflow and ensure that each part is correctly identified and handled.

- Study the layout carefully to familiarize yourself with the arrangement of elements.

- Cross-reference each section with your physical components to avoid confusion.

- Highlight or note critical areas that require special attention during installation or repair.

By adopting a methodical approach, you can enhance accuracy and reduce errors, ultimately leading to more successful outcomes.

Customer Reviews and Experiences

When it comes to purchasing and maintaining complex equipment, the experiences of previous users can provide invaluable insights. In this section, we will explore what customers have to say about the performance, reliability, and ease of use of the product in question. Real-world feedback from those who have already invested in this machinery offers a unique perspective on both its advantages and potential challenges.

Positive Feedback

Many users have shared their satisfaction with the overall performance, citing ease of installation and smooth operation as standout features. The following points summarize the most frequently mentioned benefits:

- Reliable functionality under various conditions

- Easy assembly and user-friendly setup

- Durability and longevity, even with frequent use

- Efficient operation with minimal maintenance requirements

- Cost-effectiveness compared to alternatives

Challenges and Concerns

However, some customers have noted a few areas where the equipment could be improved. These concerns include:

- Occasional difficulty in obtaining replacement components

- Challenges with the initial setup for less experienced users

- Some issues with compatibility when paired with certain accessories

Despite these challenges, most users believe the overall benefits far outweigh any drawbacks. Many have found that these issues are manageable with proper guidance or by seeking support from the manufacturer or professional services.