When it comes to maintaining snow clearing machinery, having a clear visual representation of its components is essential. This understanding not only enhances the efficiency of repairs but also ensures that every part functions harmoniously, contributing to optimal performance during winter operations.

In this section, we will explore the intricacies of your equipment’s assembly, breaking down each segment into easily identifiable parts. By familiarizing yourself with these elements, you can make informed decisions regarding maintenance, troubleshooting, and necessary replacements.

Moreover, knowing how everything fits together will empower you to tackle challenges head-on, reducing downtime and extending the lifespan of your equipment. With a detailed overview, you’ll feel more confident in handling any issues that may arise during those snowy months.

Overview of the Snow Clearing Machine

This section provides a comprehensive understanding of a powerful snow removal device designed for efficiency and reliability in harsh winter conditions. Equipped with advanced features, it caters to various snow clearing needs, ensuring a seamless experience for users.

Key Features

Among its standout characteristics, this machine boasts a robust engine, adjustable chute, and multiple speed settings. These elements combine to enhance performance and user control, making snow clearing tasks simpler and more effective.

Maintenance and Care

Regular maintenance is essential for optimal performance. Users should focus on checking oil levels, ensuring proper lubrication, and examining the auger and impeller for any signs of wear. Proper care will extend the lifespan of this essential winter tool.

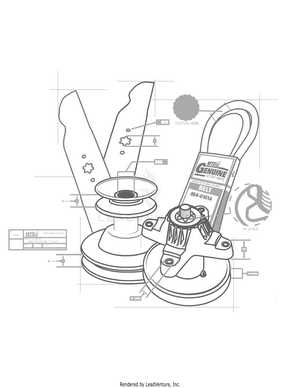

Essential Parts of the Snowblower

Understanding the key components of a snow-clearing machine is crucial for effective operation and maintenance. Each element plays a significant role in ensuring optimal performance during winter months. By familiarizing yourself with these vital pieces, you can enhance your snow removal experience and prolong the lifespan of your equipment.

Key Components

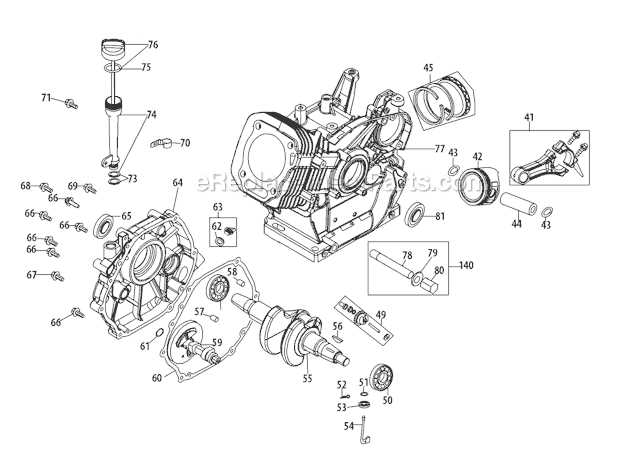

The heart of any snow-clearing device includes the engine, which powers the entire system. A robust motor ensures reliable performance, even in heavy snowfall. Additionally, the auger is responsible for gathering and breaking up the snow, while the impeller directs the cleared material away from the unit. These mechanisms work in unison to deliver efficient results.

Additional Features

Other important elements include the control panel, which allows for user-friendly operation, and the chassis, designed for durability and stability. Understanding the function of each component helps in troubleshooting issues and performing necessary repairs, ensuring that your machine remains in peak condition throughout the winter season.

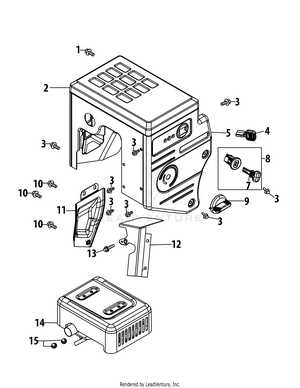

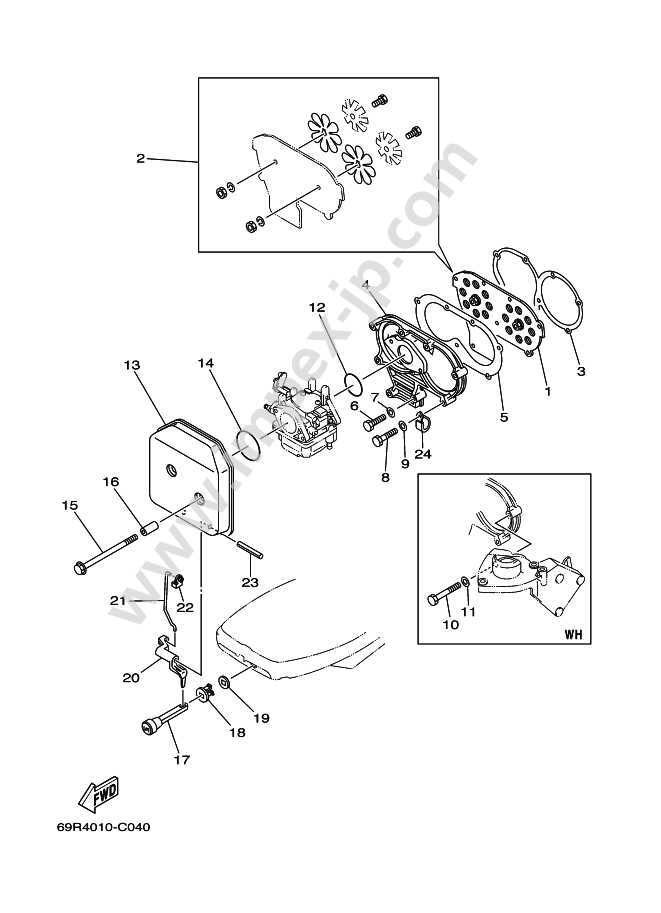

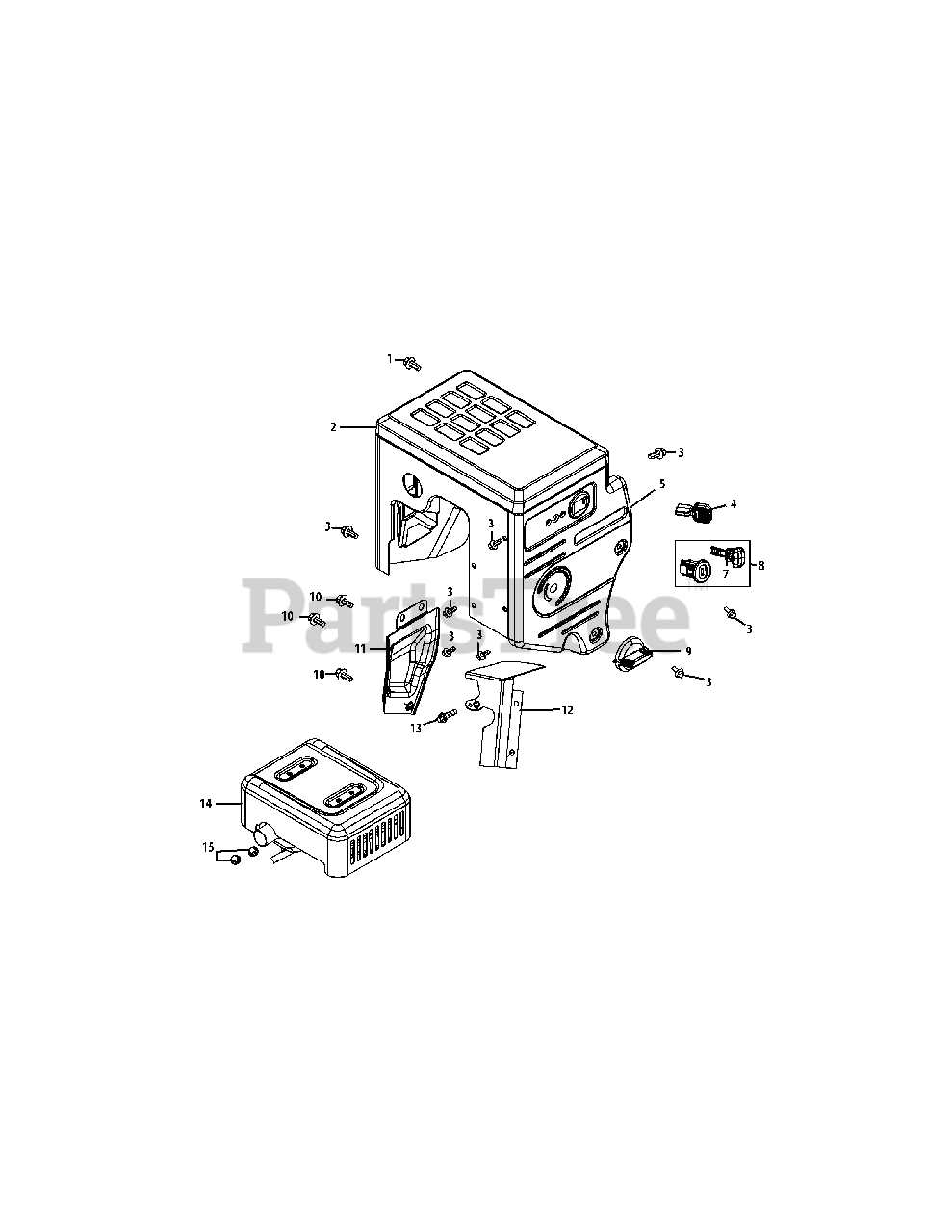

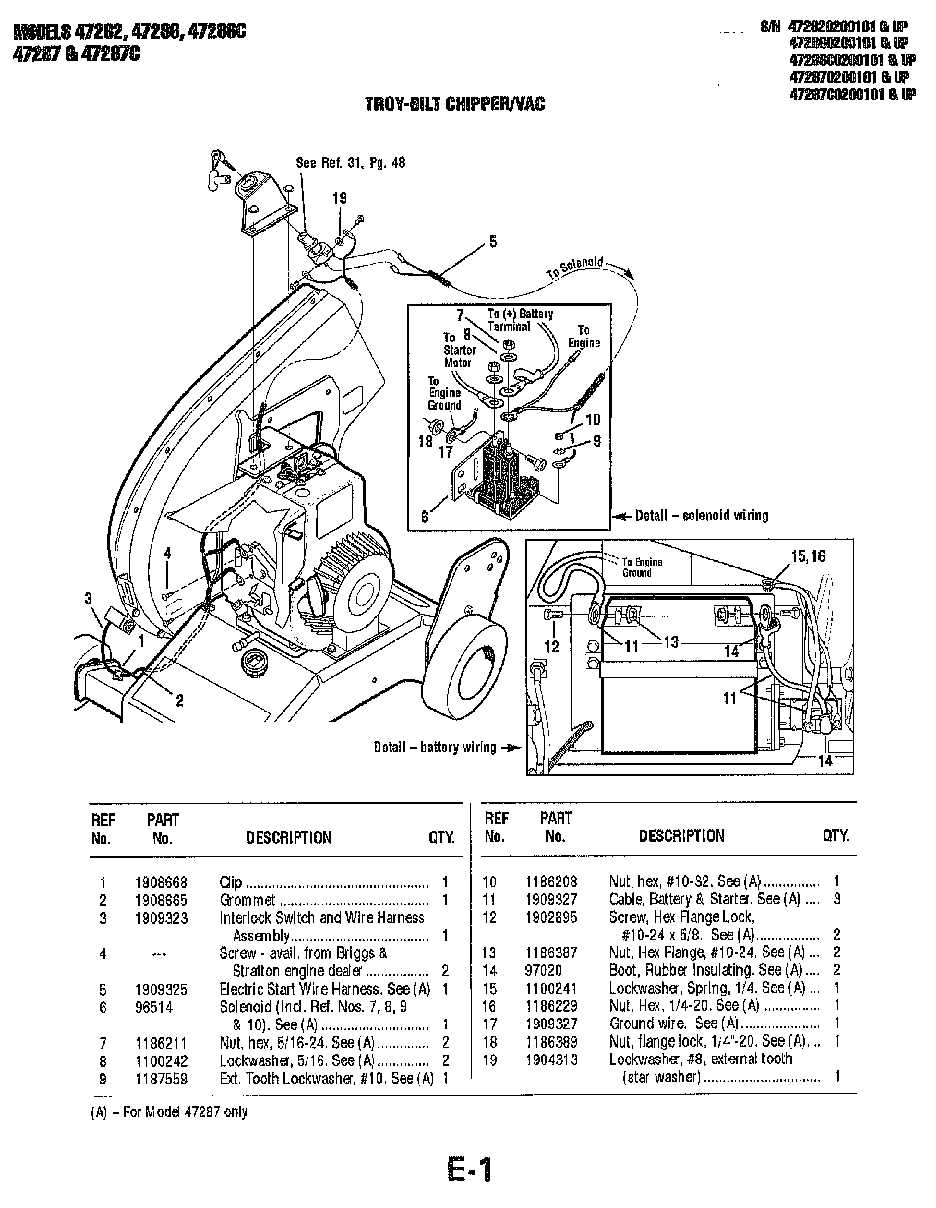

Understanding the Parts Diagram

The visual representation of components within a machine is crucial for maintenance and repair. It serves as a guide to identify each element, facilitating a better understanding of how they work together. This knowledge is essential for both troubleshooting issues and performing routine upkeep.

Key Elements of the Visual Guide

- Labels: Each component is typically labeled for easy identification.

- Connections: Lines may indicate how parts are connected or interact with one another.

- Exploded Views: Some diagrams offer exploded views to show how parts fit together.

- Reference Numbers: Numbers help to correlate with a parts list for ordering replacements.

Benefits of Using a Visual Representation

- Enhanced understanding of the machine’s structure.

- Streamlined repair processes by quickly identifying required components.

- Improved ability to diagnose problems effectively.

- Facilitated communication with service professionals when issues arise.

Utilizing this visual resource not only promotes effective repairs but also extends the life of the equipment through informed maintenance practices.

Common Issues and Solutions

Many users encounter typical challenges with their snow-clearing equipment, often leading to frustration. Understanding these issues and their remedies can enhance performance and extend the machine’s lifespan.

- Engine Won’t Start

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for wear or damage.

- Verify the ignition system is functioning properly.

- Insufficient Clearing Power

- Examine the auger for obstructions.

- Ensure the shear pins are intact and not broken.

- Adjust the chute direction to optimize snow discharge.

- Difficulty in Maneuvering

- Check the tire pressure and inflate if necessary.

- Inspect the drive belt for wear or damage.

- Ensure the control levers are functioning smoothly.

Addressing these common issues promptly can lead to an ultimate improvement in efficiency and satisfaction with your equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires regular upkeep and attention. Implementing a few simple maintenance practices can significantly extend the life of your machine, reduce the likelihood of unexpected failures, and enhance overall performance.

Start with routine inspections to identify any wear or damage. Checking components such as belts, filters, and spark plugs regularly can prevent minor issues from escalating into major repairs. Cleaning the exterior and internal parts helps remove debris and prevents corrosion, contributing to better functionality.

Always refer to the manufacturer’s guidelines for recommended maintenance schedules. Changing oil and fluids at specified intervals is crucial for optimal operation. Using high-quality lubricants can minimize friction and wear, further prolonging the life of moving parts.

Store your equipment in a dry, sheltered area when not in use. This protects it from harsh weather conditions that could cause deterioration. Additionally, consider winterizing your machine to safeguard against cold temperatures and ensure it is ready for the next season.

Finally, keeping detailed records of all maintenance activities will help you track performance trends and identify potential issues early on. By following these tips, you can enjoy reliable operation and maximize the longevity of your equipment.

Where to Find Replacement Parts

Locating components for your outdoor equipment can be a straightforward process if you know where to look. Various resources are available that cater to different needs, ensuring that you can find the specific items required to keep your machinery running smoothly.

Online Retailers

One of the most convenient options is to explore online marketplaces. Numerous websites specialize in equipment components, offering a wide selection and competitive pricing. Make sure to check customer reviews and ratings to ensure you’re purchasing from a reputable source.

Local Dealers and Service Centers

For those who prefer a more personal touch, visiting local dealers or service centers can be beneficial. These establishments often carry a range of components and can provide expert advice on compatibility and installation. Additionally, they may have access to exclusive items not readily available online.

Tip: Always have the model number and other relevant details on hand when searching for components to ensure accuracy and ease in finding the right match.

Remember to compare prices and options across different platforms to get the best deal possible!

Assembly Instructions for Users

This section aims to guide users through the process of assembling their outdoor equipment efficiently. Following these steps will ensure that each component fits together seamlessly, maximizing performance and longevity.

1. Preparation: Before starting, gather all necessary tools and components. Refer to the accompanying list to ensure nothing is missing.

2. Base Assembly: Begin by connecting the base parts. Align the sections carefully and secure them with the provided fasteners. Ensure everything is tightened to avoid instability.

3. Handle Installation: Attach the handle components next. Position them correctly and fasten securely, making sure they are comfortable for operation.

4. Accessory Attachment: If applicable, install any additional accessories according to the provided instructions. This step may enhance functionality and ease of use.

5. Final Checks: Once assembled, conduct a thorough inspection. Verify that all parts are secure and functioning as intended before the initial use.

By following these instructions, users can confidently assemble their equipment, ensuring optimal performance and safety.

Customer Reviews and Feedback

This section aims to provide insights into user experiences and opinions regarding the equipment in question. Feedback from customers plays a crucial role in understanding the performance, reliability, and overall satisfaction associated with the product.

Many users have expressed appreciation for the efficiency and effectiveness of the machine, highlighting its ability to handle various tasks with ease. Positive remarks often focus on its durability and the convenience it offers during harsh weather conditions. Customers frequently mention how easy it is to operate, making it suitable for both experienced users and beginners alike.

On the other hand, some constructive criticisms have been noted. A few users reported challenges with specific components, suggesting that improvements could enhance functionality. Common feedback points include the need for clearer instructions and better accessibility of replacement components.

Overall, the range of reviews reflects a balanced view, where the strengths of the product shine through, while suggestions for improvement indicate a desire for continued enhancement. This feedback serves as a valuable resource for prospective buyers and manufacturers alike.

Comparing Models in the Series

When selecting a machine from a specific lineup, it’s essential to understand the differences and similarities between the various models. Each variant is designed to meet diverse needs, from residential use to more demanding applications. By examining these distinctions, users can make informed decisions based on their specific requirements and preferences.

Performance Characteristics

The performance of each unit can vary significantly. Some models offer higher power outputs, making them suitable for heavy-duty tasks, while others may prioritize fuel efficiency and ease of use. Comparing specifications such as engine size, output capacity, and operational features can help determine the best fit for individual users.

Features and Innovations

Innovative features often distinguish one model from another. From enhanced maneuverability to advanced starting systems, each design may incorporate unique elements aimed at improving user experience. Assessing these features allows potential buyers to identify which options best align with their operational preferences and comfort levels.