In the realm of gardening and landscaping, the functionality of machinery plays a pivotal role in ensuring efficiency and effectiveness. Understanding the various elements that comprise these machines is essential for maintenance, repair, and optimal performance. A thorough grasp of each component not only enhances the user experience but also extends the lifespan of the equipment.

By delving into the intricacies of the construction and arrangement of these devices, users can gain valuable insights into how to troubleshoot issues and make informed decisions regarding repairs or replacements. This knowledge empowers individuals to take charge of their gardening tasks with confidence, knowing that they have the necessary information at their fingertips.

Additionally, familiarizing oneself with the various parts allows for a smoother experience when seeking assistance or sourcing replacements. It bridges the gap between technical jargon and practical application, making it easier to communicate needs and understand solutions. Ultimately, a comprehensive understanding of machine components transforms users into more adept and knowledgeable caretakers of their gardens.

Understanding the Model

This section aims to provide a comprehensive overview of a specific model known for its reliability and functionality. It is designed for users seeking to understand the key components, features, and maintenance requirements of this equipment. Knowledge of these aspects is essential for ensuring optimal performance and longevity.

Key Features

- Engine Specifications: The model is equipped with a powerful engine that enhances its performance in various tasks.

- User-Friendly Design: It features an ergonomic layout that ensures ease of use and comfort during operation.

- Durable Construction: Made from high-quality materials, this model is built to withstand the rigors of frequent use.

Maintenance Tips

- Regular Inspections: Conduct routine checks on all major components to ensure they are functioning correctly.

- Cleanliness: Keep the equipment clean to prevent any build-up that could hinder performance.

- Proper Storage: Store the model in a dry, sheltered location to protect it from weather-related damage.

Key Components of the 13AN77KG011

The assembly of any outdoor equipment relies heavily on several critical elements that contribute to its overall functionality and performance. Understanding these fundamental components is essential for effective maintenance and troubleshooting. Each part plays a specific role, ensuring that the equipment operates smoothly and efficiently, thus enhancing the user experience.

One of the primary components includes the engine, which serves as the powerhouse, driving the entire system. Its performance is pivotal, impacting the efficiency and speed of the machine. Additionally, the transmission system is vital for transferring power from the engine to the wheels, facilitating movement and maneuverability across various terrains.

Another significant element is the cutting mechanism, which determines the effectiveness of the equipment in managing grass or foliage. This system often consists of blades or other cutting tools that require regular inspection and maintenance to ensure optimal performance. Furthermore, the chassis serves as the frame, providing structural integrity and support to all attached components, enhancing durability and stability.

Lastly, the control system, which includes various levers and switches, allows the user to operate the machinery effectively. Understanding the function of each of these components helps in diagnosing issues, performing repairs, and ensuring longevity in operation.

Assembly and Disassembly Guidelines

Proper assembly and disassembly techniques are crucial for maintaining the functionality and longevity of outdoor equipment. Understanding the sequence and methods involved can help avoid common mistakes that may lead to damage or inefficiency. This section provides essential guidelines to ensure that the process is executed smoothly and effectively.

Before starting, ensure that you have all necessary tools and components at hand. Familiarize yourself with the overall structure and layout of the equipment. Begin by consulting any available reference materials that outline the specific steps involved. It is also advisable to work in a clean, organized space to prevent the loss of small components during the process.

When disassembling, take a systematic approach. Begin with the outermost components and work your way inward. This method minimizes the risk of damaging internal parts. As you remove each piece, keep them organized and labeled to facilitate reassembly. It is helpful to take notes or photographs during this phase, as they can serve as valuable references during the reassembly process.

For assembly, reverse the disassembly steps. Ensure that each component is clean and free of debris before reinstallation. Tighten fasteners to the manufacturer’s specifications, as over-tightening can cause damage. Once all components are in place, conduct a thorough inspection to confirm that everything is secure and correctly positioned.

By adhering to these guidelines, you can efficiently manage the assembly and disassembly of your equipment, enhancing its performance and durability over time.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of outdoor equipment requires regular upkeep and attention. Implementing a consistent maintenance routine can significantly extend the life of your machinery while enhancing its efficiency. Understanding the key aspects of care and upkeep will help you enjoy seamless operation and prevent unnecessary breakdowns.

Regular Cleaning

Routine cleaning is essential for keeping machinery in top shape. After each use, remove dirt, grass, and debris from surfaces to prevent buildup. Pay special attention to the air intake and cooling systems, as blockages can hinder performance. A clean exterior also allows for easier inspections and quicker identification of any potential issues.

Fluid Checks and Changes

Regularly monitoring and replacing fluids is critical for maintaining optimal functionality. Check oil levels, fuel, and other necessary fluids frequently, and follow the manufacturer’s recommendations for changes. Fresh fluids reduce friction and help prevent overheating, ensuring smooth operation and longevity.

Common Issues and Solutions

Every mechanical device may encounter challenges during its operation, affecting performance and reliability. Understanding these frequent problems and their solutions can enhance the longevity and functionality of your equipment. Here are some typical issues users may face and effective strategies to address them.

- Engine Won’t Start

- Check the fuel level to ensure it’s adequate.

- Inspect the spark plug for signs of wear or damage.

- Examine the battery connections for corrosion or looseness.

- Poor Cutting Performance

- Ensure the cutting blade is sharp and free of debris.

- Adjust the cutting height to match the grass length.

- Verify that the engine is running at optimal speed.

- Excessive Vibration

- Check for loose screws or components that may need tightening.

- Inspect the blade for damage or imbalance.

- Ensure the wheels are aligned and secure.

- Fluid Leaks

- Identify the source of the leak, whether it’s oil, fuel, or coolant.

- Replace any worn gaskets or seals that may be causing the leak.

- Check hoses for cracks or damage and replace as necessary.

Addressing these common issues proactively can lead to a more efficient operation and prolong the life of your equipment. Regular maintenance checks and timely repairs are essential in preventing these problems from escalating.

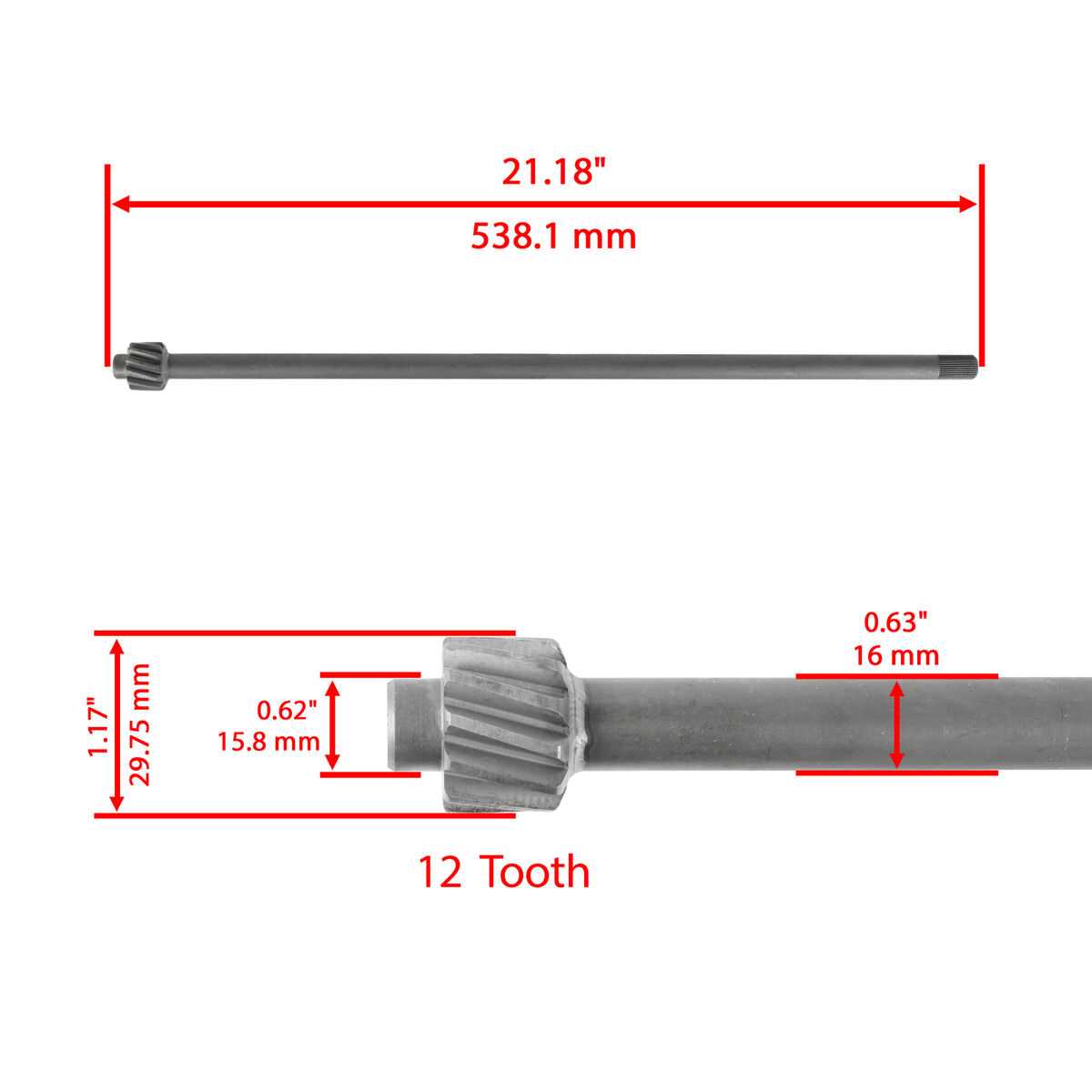

Replacement Parts Availability

Ensuring the seamless operation of outdoor equipment often requires access to various components. Availability of these elements is crucial for maintenance and repair, allowing users to keep their machinery in optimal condition. Fortunately, there are several avenues through which these essential items can be sourced, providing a range of options for consumers.

Sources for Components

Replacement items can be acquired from multiple sources, including authorized dealers, online retailers, and local hardware stores. Each option offers unique advantages, such as product variety, pricing, and convenience. Here’s a comparison of popular sourcing channels:

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine components, expert advice | Higher prices, limited availability |

| Online Retailers | Wide selection, competitive pricing | Shipping times, quality variation |

| Local Hardware Stores | Immediate availability, no shipping costs | Limited inventory, potential higher costs |

Considerations When Purchasing

When seeking to replace components, it is essential to ensure compatibility with existing equipment. Cross-referencing part numbers and consulting with experts can help mitigate issues related to fit and function. Additionally, evaluating the warranty and return policies from suppliers can safeguard against potential dissatisfaction.

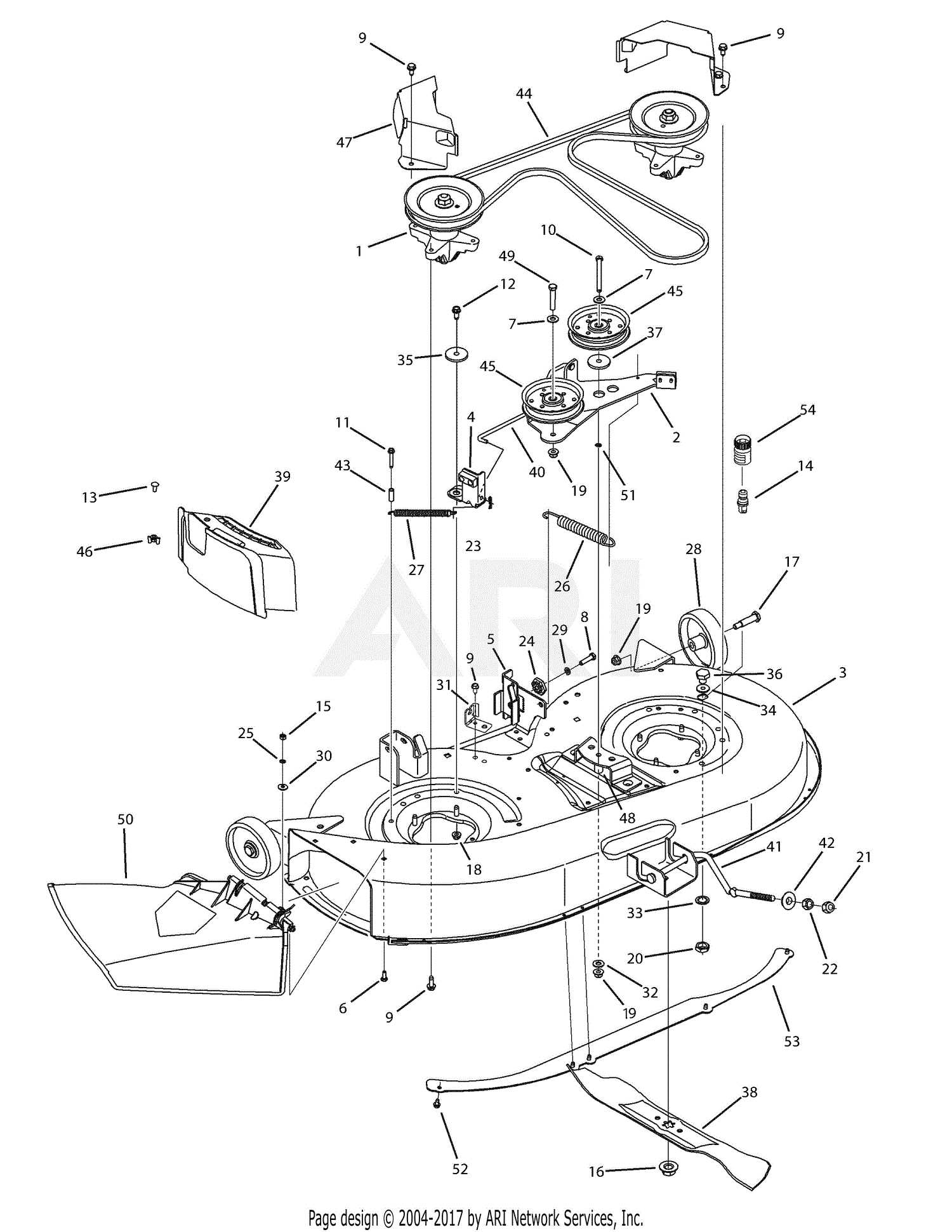

Utilizing Diagrams for Repairs

When it comes to maintenance tasks, visual representations serve as invaluable tools that simplify complex processes. These illustrations provide a clear overview of components and their interconnections, enabling individuals to troubleshoot and execute repairs with confidence. Whether dealing with mechanical devices or intricate systems, leveraging these visual guides can significantly enhance the efficiency and accuracy of repair efforts.

Employing visual aids allows users to understand the arrangement of elements, identify the necessary tools, and recognize potential issues before they escalate. Furthermore, these representations facilitate a systematic approach to disassembly and reassembly, ensuring that every part is correctly positioned during the process. Here is a basic overview of how visual aids can be utilized in repair tasks:

| Step | Description |

|---|---|

| 1 | Review the visual representation to familiarize yourself with the layout of components. |

| 2 | Gather the necessary tools and materials based on the visual guide. |

| 3 | Follow the illustrated steps to disassemble the device carefully. |

| 4 | Inspect each component for wear or damage, referencing the visual guide for identification. |

| 5 | Replace any faulty parts and follow the visual guide to reassemble the device. |

Incorporating visual representations into repair procedures not only streamlines the process but also empowers users to tackle maintenance tasks with greater assurance. By understanding how to read and utilize these aids, individuals can save time, reduce errors, and extend the lifespan of their equipment.

Safety Precautions During Repairs

When undertaking maintenance or fixing machinery, it is crucial to prioritize safety to prevent accidents and injuries. Following proper guidelines not only protects the individual performing the work but also ensures that the equipment remains in optimal condition. A careful approach can mitigate risks associated with mechanical repairs.

Essential Safety Gear

Wearing appropriate protective equipment is vital when conducting repairs. This gear can significantly reduce the risk of injuries resulting from accidental contact with sharp edges or moving parts. The following table outlines the recommended protective items:

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and harmful substances. |

| Gloves | Prevents cuts and abrasions from sharp components. |

| Steel-Toed Boots | Offers foot protection against heavy objects. |

| Ear Protection | Reduces noise exposure from loud machinery. |

| Respirator Mask | Protects against inhalation of harmful fumes and dust. |

Proper Tools and Workspace Organization

Ensuring that tools are in good condition and readily accessible enhances safety during repairs. An organized workspace minimizes the chance of accidents caused by tripping or misplacing tools. Always check that tools are suitable for the task and free of defects before use.

Resources for Further Assistance

When dealing with equipment maintenance and repairs, having access to reliable information is essential. Whether you need to troubleshoot issues or seek replacement components, numerous resources can provide guidance and support. Utilizing these avenues can help ensure that your machinery remains in optimal condition.

Online Forums and Communities

Engaging with online platforms dedicated to equipment enthusiasts can be incredibly beneficial. These communities often share valuable insights, tips, and personal experiences related to maintenance and repairs. Below is a table highlighting some popular forums where you can find help:

| Forum Name | Website |

|---|---|

| GardenWeb | www.gardenweb.com |

| Reddit – Lawn Care | www.reddit.com/r/lawncare/ |

| MyTractorForum | www.mytractorforum.com |

Manufacturer Support and Documentation

Consulting the manufacturer’s website can provide access to official resources such as manuals, troubleshooting guides, and customer service contact information. These documents are essential for understanding your equipment’s specifications and maintenance requirements. Below is a table with some useful links:

| Manufacturer | Support Link |

|---|---|

| Equipment Manufacturer A | www.equipmentmanufacturer |