When dealing with high-performance cutting machinery, it is crucial to comprehend the various elements that contribute to its efficient operation. A detailed exploration of these components allows users to maintain their equipment effectively and ensure its longevity. Knowledge of individual parts is essential for troubleshooting and repairs, as well as optimizing performance.

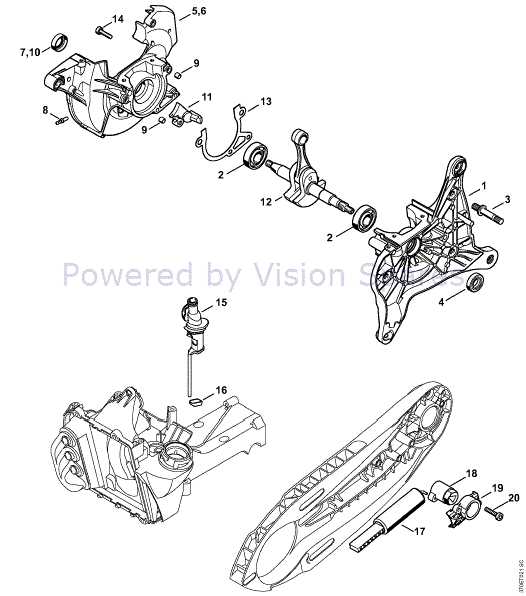

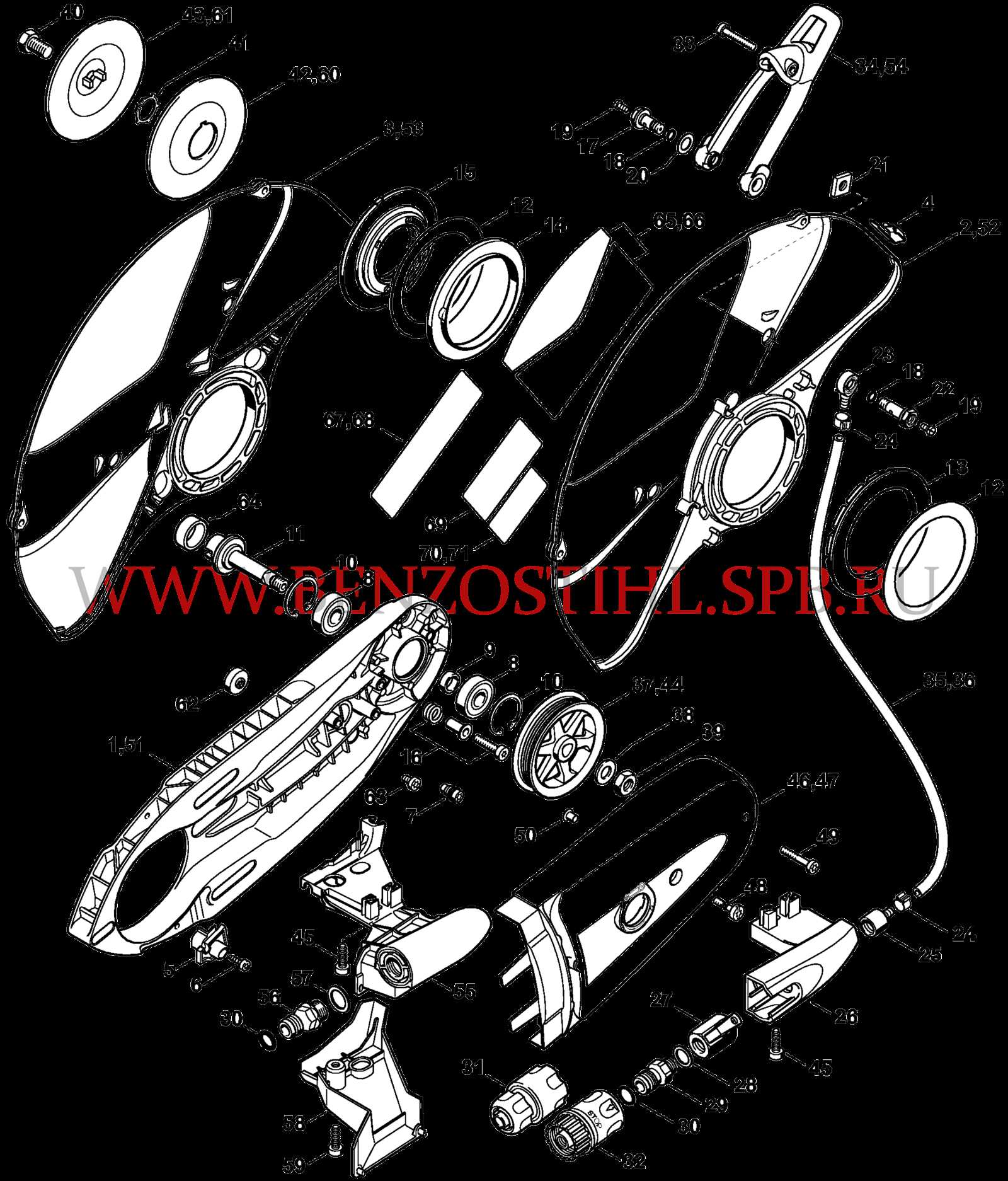

In this section, we will delve into the intricate arrangement of the machinery’s elements. By visualizing how each part interacts within the overall system, users can gain insights into the tool’s functionality. Understanding this relationship not only aids in maintenance but also enhances safety during operation.

For those seeking to enhance their knowledge, comprehensive resources are available that outline these components in detail. Utilizing such resources can facilitate a deeper understanding of the cutting tool’s design and performance, ensuring users can operate their machinery with confidence and expertise.

This section provides a comprehensive insight into a popular cutting tool, highlighting its design, functionality, and notable characteristics. Understanding these features is essential for both potential users and those interested in maintenance and repair.

The tool is renowned for its robust performance and versatility, making it a valuable asset in various applications. Users appreciate its ergonomic design, which ensures comfort during extended use, as well as its powerful engine, delivering impressive cutting capabilities.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a high-performance engine that provides reliable operation for demanding tasks. |

| Weight | Lightweight construction enhances maneuverability and reduces user fatigue. |

| Blade Size | Compatible with various blade sizes, allowing flexibility in cutting applications. |

| Safety Features | Includes essential safety mechanisms to protect the user during operation. |

Understanding the Parts List

A comprehensive inventory of components is essential for effective maintenance and repair of equipment. Familiarity with each element’s function not only aids in troubleshooting but also enhances the overall performance of the machine. This section will explore the significance of component catalogs, guiding users through their various applications and importance.

The Importance of Component Identification

Identifying each piece within the inventory allows for better decision-making regarding repairs and replacements. Recognizing the role of individual elements can lead to:

- Improved efficiency in identifying issues.

- Informed choices for maintenance schedules.

- Enhanced understanding of operational capabilities.

Utilizing the Inventory Effectively

Maximizing the benefits of the component inventory involves understanding how to use it effectively:

- Refer to the list when diagnosing problems to pinpoint the necessary parts.

- Cross-check the inventory during routine inspections to ensure all components are functioning.

- Keep the list accessible for quick reference when ordering replacements.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective maintenance and repair tasks. Well-crafted illustrations serve as essential tools that facilitate a clear understanding of components and their interrelationships. They provide users with the necessary guidance to navigate complex assemblies and ensure that each part is properly aligned and connected.

Accurate visuals not only enhance the user experience but also minimize the risk of errors during assembly or disassembly processes. When individuals have access to detailed images, they can quickly identify the specific elements needed for repairs or replacements. This efficiency ultimately leads to time savings and increased satisfaction.

Moreover, high-quality representations contribute to safety by highlighting potential hazards associated with improper handling or installation. By understanding the correct procedures through these visuals, users can take the necessary precautions to avoid accidents and equipment damage. Therefore, reliable illustrations are indispensable resources that promote both efficiency and safety in various operational contexts.

Common Replacement Parts Explained

In any machinery, certain components are subject to wear and tear due to regular use. Understanding these elements is crucial for maintaining optimal performance and extending the lifespan of the equipment. This section will delve into the most frequently replaced components, providing insight into their functions and importance.

Key Components Overview

Among the essential elements, one often encounters items like filters, blades, and belts. These parts are vital for ensuring the machinery operates efficiently. Regular inspection and timely replacement of these components can prevent malfunctions and improve overall functionality.

Importance of Regular Maintenance

Performing routine checks and replacing worn components not only enhances performance but also promotes safety. Keeping these key parts in good condition minimizes the risk of accidents and equipment failure, ensuring a smooth operational experience.

How to Access the PDF Diagram

Obtaining a visual representation of equipment components is essential for effective maintenance and repair tasks. This guide outlines the steps to retrieve an electronic version of the schematic for your machinery, ensuring you have the right resources at hand for your projects.

To begin, visit the official website of the manufacturer, where a wealth of resources is available for users. Look for the section dedicated to documentation or resources. You may need to enter the specific model or product name to narrow down your search.

Once you locate the relevant section, check for downloadable files that contain the desired schematic. Often, these files are categorized for user convenience, making it easier to find what you need. Ensure your device is connected to a stable internet connection to facilitate a smooth download process.

After downloading the file, it is advisable to save it in a designated folder for easy access. You can then view the schematic using a compatible software application on your device, which allows for zooming in on details for better clarity during your repair or maintenance tasks.

In summary, accessing an electronic representation of equipment components involves visiting the manufacturer’s site, locating the appropriate resources, and downloading the relevant file. This will enable you to maintain and repair your machinery effectively.

Maintenance Tips for TS420 Components

Proper upkeep of machinery elements is crucial for ensuring optimal performance and longevity. Regular maintenance not only helps in identifying potential issues early but also enhances the efficiency of the equipment. Here are some essential tips to maintain various components effectively.

Regular Inspections

Conduct routine inspections of the machinery to check for wear and tear. Look for any signs of damage or unusual wear on moving parts, and replace them if necessary. Keeping a maintenance log can help track the condition of various components and the frequency of maintenance performed.

Cleaning and Lubrication

Maintaining cleanliness is vital for the smooth operation of the equipment. Regularly clean the surfaces to remove dust, debris, and other contaminants. Additionally, ensure that all moving parts are adequately lubricated to reduce friction and prevent overheating. Use the recommended lubricants for optimal results.

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components and their functionality. Understanding these elements can enhance maintenance and operational efficiency, ensuring that users make informed decisions when handling their equipment.

Common Inquiries

Here are some frequently asked questions related to components:

| Question | Answer |

|---|---|

| What should I do if a component is damaged? | Assess the damage and consult the user manual for guidance on replacement or repair procedures. |

| How can I identify the right component for my model? | Refer to the manufacturer’s specifications and consult authorized dealers for accurate identification. |

| Is it necessary to use original components? | Using original components is recommended to ensure compatibility and maintain warranty conditions. |

Maintenance Tips

Regular checks on components can prevent issues and extend the lifespan of your equipment. Here are some essential tips:

- Inspect components regularly for wear and tear.

- Keep the equipment clean to avoid debris buildup.

- Follow the manufacturer’s maintenance schedule for optimal performance.

Where to Buy Genuine Parts

When it comes to maintaining your equipment, acquiring authentic components is essential for optimal performance and longevity. Ensuring that you obtain high-quality replacements will not only enhance efficiency but also contribute to the safety of your machinery.

Authorized Dealers

The most reliable source for obtaining authentic replacements is through authorized distributors. These sellers are certified to provide genuine items and often offer a warranty, ensuring that your investment is protected. Look for local retailers that specialize in outdoor equipment or machinery; they typically have knowledgeable staff who can assist you in finding the right components.

Online Retailers

Numerous online platforms specialize in selling genuine replacements. Websites dedicated to machinery often feature extensive catalogs, allowing you to compare different options easily. When shopping online, always verify the credibility of the seller and read reviews from previous customers to ensure you are purchasing from a trustworthy source.

Impact of Proper Parts Usage

Utilizing the correct components in machinery plays a crucial role in ensuring optimal performance and longevity. Each element of a system is designed to work in harmony with others, leading to enhanced efficiency and reduced wear over time. When compatible parts are employed, users can expect a significant improvement in functionality and reliability.

Here are some key advantages of employing appropriate components:

- Increased Efficiency: Well-matched elements enhance overall system performance, reducing energy consumption and improving output.

- Extended Lifespan: Using the right components minimizes stress and wear on machinery, leading to a longer operational life.

- Safety Enhancement: Correctly functioning parts contribute to a safer working environment, reducing the risk of accidents and malfunctions.

- Cost Savings: Investing in suitable components can lower maintenance costs and prevent premature failures, saving money in the long run.

In conclusion, ensuring the correct utilization of components is vital for maintaining the efficiency, safety, and longevity of machinery. It is essential to prioritize compatibility to achieve the best results.