Every outdoor maintenance device is a complex assembly of various elements, each playing a crucial role in its performance. Grasping how these individual parts interconnect and function can significantly enhance your ability to maintain and troubleshoot your equipment. This knowledge not only helps in extending the lifespan of the machine but also ensures optimal efficiency during operation.

In this section, we will delve into a comprehensive overview of the essential elements that make up your device. By examining the layout and organization of these components, you will gain insights into their specific functions and how they contribute to the overall functionality of the machine. Whether you’re a seasoned user or new to outdoor tools, understanding these intricacies can empower you to make informed decisions regarding repairs and upgrades.

Furthermore, familiarizing yourself with the configuration of each part can lead to a more efficient maintenance routine. With this information at your fingertips, you’ll be better equipped to tackle any challenges that arise, ensuring that your equipment remains in peak condition for all your gardening and landscaping tasks.

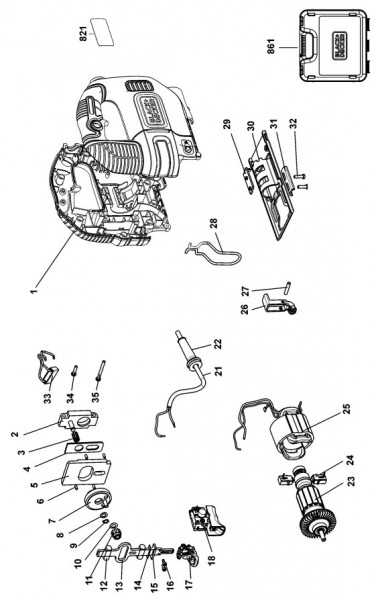

Understanding Stihl KM91R Components

Familiarizing oneself with the various elements of a multi-tool system can significantly enhance its functionality and maintenance. Each component plays a crucial role in ensuring optimal performance, making it essential for users to grasp their individual functions and interrelations.

Engine: At the heart of the system lies the engine, responsible for powering all attachments. Its efficiency directly influences the overall effectiveness of the tool, making proper care vital for longevity.

Gearbox: This mechanism connects the engine to the different implements, allowing for seamless transitions between tasks. Understanding its operation can aid in troubleshooting and maintenance.

Attachments: Various implements can be attached to the base unit, including trimmers, blowers, and edgers. Each attachment is designed for specific tasks, and selecting the right one is essential for achieving the desired results.

Fuel System: The fuel system ensures that the engine receives the proper mixture for combustion. Regular checks can prevent performance issues and maintain efficiency.

Control Handle: The handle provides the user with control and maneuverability. Its ergonomic design can enhance comfort during prolonged use, reducing fatigue.

By gaining a comprehensive understanding of these components, users can optimize their experience, ensuring efficient operation and effective maintenance of their equipment.

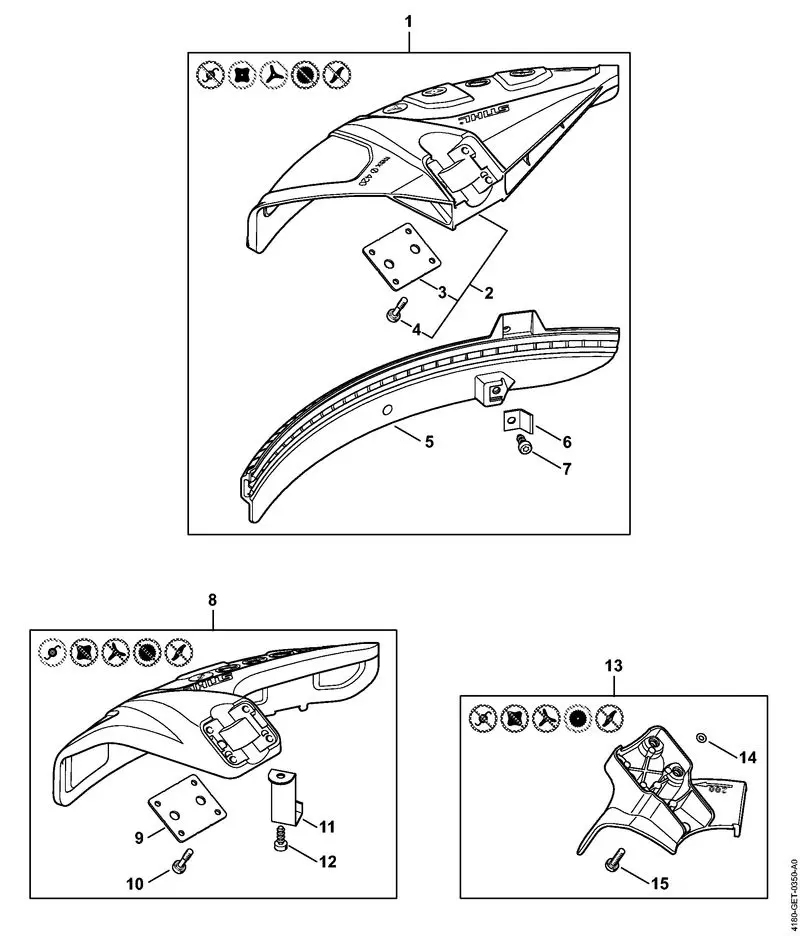

Importance of Parts Diagrams

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations that break down these elements play a crucial role in facilitating this process. They not only provide clarity but also enhance the efficiency of troubleshooting and assembly tasks.

Benefits of Visual Representations

- Enhanced Understanding: Visual aids allow users to easily identify and locate specific elements, reducing confusion during repairs.

- Streamlined Repairs: Having a clear overview of the components helps in quickly diagnosing issues and implementing solutions.

- Improved Communication: Shared visuals can bridge gaps in understanding among technicians, making collaboration smoother.

- Time Efficiency: Familiarity with layouts can significantly cut down the time needed for maintenance tasks.

Application in Maintenance

- Identification: Recognizing worn or damaged components becomes straightforward with clear visuals.

- Ordering Parts: Accurate representation ensures that the correct replacements are sourced without errors.

- Reassembly: Following a visual guide makes reassembly intuitive, reducing the risk of mistakes.

Incorporating these visual tools into maintenance practices ultimately leads to improved performance and longevity of equipment.

Common Issues with KM91R Parts

Maintenance tools often encounter specific challenges that can hinder their performance. Understanding these common problems can help users effectively address issues, ensuring longevity and reliability. Several components may wear out or malfunction over time, leading to decreased efficiency and increased frustration.

Wear and Tear: Components such as cutting heads and drive shafts are subjected to significant stress during use. Over time, this can lead to premature wear, resulting in reduced cutting performance. Regular inspection and timely replacement are essential to avoid complications.

Fuel System Problems: Clogged filters or faulty lines can impede fuel flow, causing the engine to sputter or stall. Ensuring that the fuel system is clean and well-maintained is crucial for optimal operation. Users should regularly check for blockages or leaks.

Electrical Issues: Ignition systems may experience faults that prevent the engine from starting. Corroded connections or damaged wiring can lead to significant issues. Maintaining a clean and secure electrical system is vital for reliable performance.

Vibration Damage: Excessive vibrations can lead to loose fittings and misalignments in various components. Regularly tightening screws and bolts can help mitigate this issue, preventing further damage and ensuring safe operation.

By recognizing these common challenges, users can take proactive measures to maintain their equipment, enhancing performance and extending its lifespan.

How to Access the Parts Diagram

Understanding the layout of components is essential for effective maintenance and repairs. Accessing the schematic representation of the equipment can greatly assist in identifying parts and their functions.

To obtain this visual reference, follow these steps:

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Look for a link to product manuals or schematics.

- Enter the model number of your equipment in the search bar.

- Select the appropriate model from the search results.

- Download or view the relevant schematic.

Additionally, third-party websites may offer similar resources. Be sure to verify the credibility of these sources before use.

Once you have the schematic, you can easily identify each component, making repairs and maintenance more straightforward.

Essential Maintenance for KM91R

Regular upkeep is crucial for ensuring the longevity and optimal performance of your equipment. Implementing a consistent maintenance routine not only enhances efficiency but also prevents potential issues that could arise from neglect. This section outlines key practices to keep your machine running smoothly and reliably.

Routine Checks

Conducting frequent inspections can help identify wear and tear before it escalates. Focus on the following components during your checks:

| Component | Maintenance Tip |

|---|---|

| Air Filter | Clean or replace as needed to ensure proper airflow. |

| Spark Plug | Inspect regularly and replace if worn to ensure efficient ignition. |

| Fuel System | Check for leaks and replace old fuel to avoid starting issues. |

| Blades or Cutting Attachments | Sharpen or replace to maintain cutting efficiency. |

Seasonal Maintenance

In addition to routine checks, it’s beneficial to perform more comprehensive maintenance tasks with the changing seasons. This proactive approach can help prepare your equipment for varying conditions.

| Season | Maintenance Action |

|---|---|

| Spring | Clean and lubricate all moving parts. |

| Summer | Monitor cooling systems and clean debris from vents. |

| Autumn | Inspect and winterize to protect against cold weather. |

| Winter | Store in a dry place and check for any corrosion. |

Adhering to these maintenance practices will ensure your equipment remains in excellent condition, maximizing both its performance and lifespan.

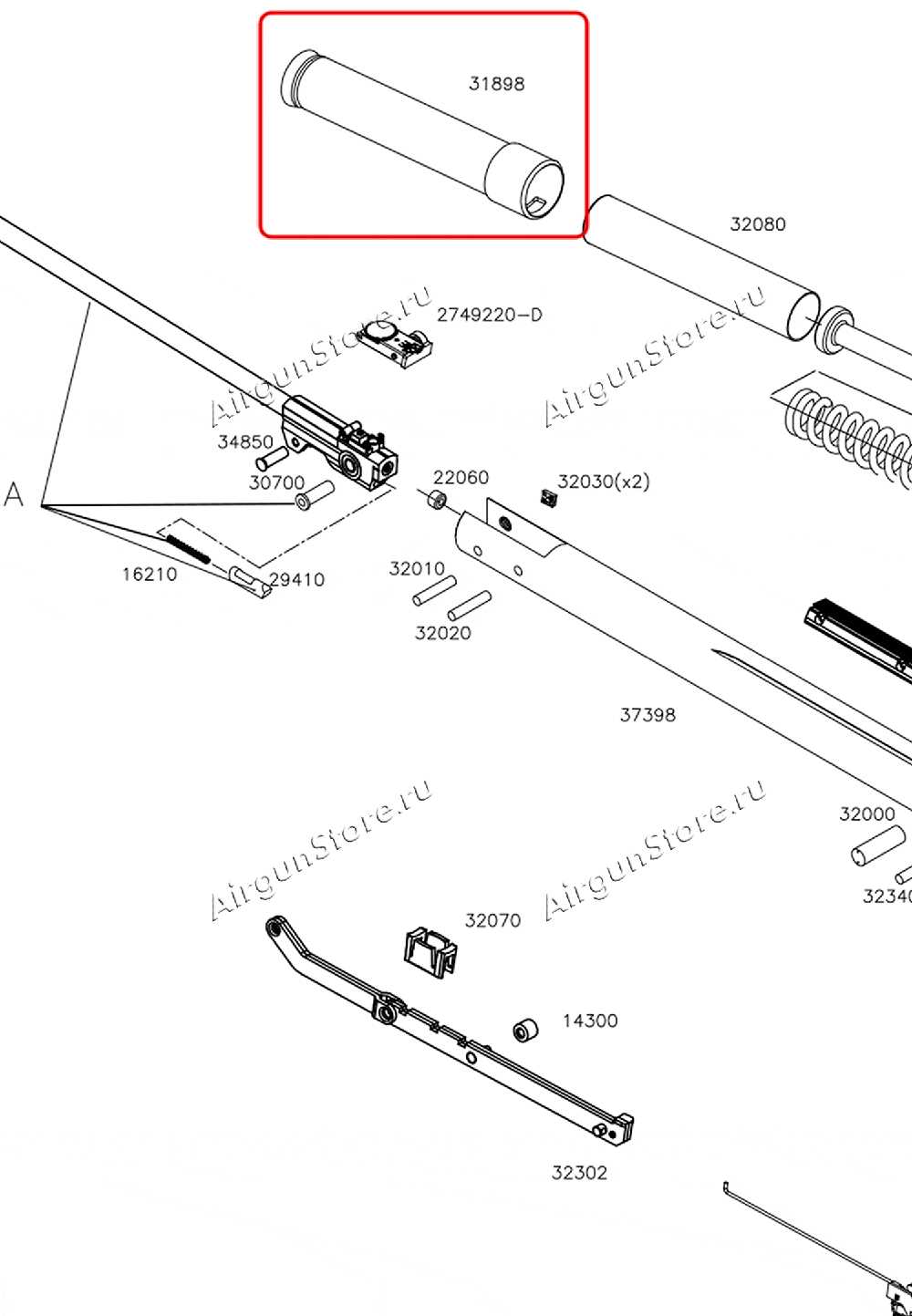

Identifying Replacement Parts Easily

Finding the right components for your equipment can often seem challenging. However, understanding the basic structure and function of each element can streamline the process significantly. By familiarizing yourself with common terminologies and visual aids, you can quickly locate the necessary items for maintenance and repair.

To assist in this task, a clear reference guide can prove invaluable. Below is a simple table outlining some of the essential elements you may encounter, along with their descriptions and potential alternatives.

| Component Name | Description | Alternative Options |

|---|---|---|

| Engine Cover | Protects internal mechanisms and enhances airflow. | Aftermarket covers, customized options. |

| Trimmer Head | Holds and dispenses cutting line efficiently. | Universal heads, heavy-duty variants. |

| Throttle Trigger | Controls engine speed for optimal performance. | Adjustable triggers, ergonomic designs. |

| Fuel Tank | Stores fuel for engine operation. | Compatible tanks, larger capacity models. |

Utilizing resources such as online forums, manufacturer manuals, and community advice can further enhance your ability to identify and acquire the right components. With a bit of knowledge and the right tools, maintaining your equipment can become a straightforward task.

Where to Buy Stihl Parts

Finding the right components for your outdoor equipment is essential for maintaining performance and longevity. Whether you’re in need of replacements or upgrades, there are several reliable sources to explore for acquiring the necessary items.

- Authorized Dealers: These retailers provide genuine components and often have knowledgeable staff who can assist you in finding exactly what you need.

- Online Marketplaces: Websites like Amazon and eBay feature a wide variety of options, often at competitive prices. Be sure to check seller ratings and reviews.

- Manufacturer’s Website: Visiting the official site allows you to access a comprehensive catalog of products, ensuring authenticity and availability.

- Local Hardware Stores: Many neighborhood shops carry a selection of items. It’s worth visiting to see if they have what you’re looking for.

- Specialty Repair Shops: These establishments often stock a range of components and can provide expert advice and support.

Regardless of where you choose to shop, always prioritize quality to ensure your equipment functions optimally.

Upgrades and Accessories for KM91R

Enhancing the performance and versatility of your outdoor power equipment can significantly improve your gardening and landscaping tasks. Various modifications and supplementary tools are available that can elevate functionality, ensuring that your machine meets your specific needs while maximizing efficiency.

Performance Enhancements

One of the most effective ways to boost productivity is by investing in high-quality attachments. Options such as brush cutters, hedge trimmers, and edgers allow for a range of applications, enabling you to tackle different types of vegetation with ease. Additionally, upgrading the cutting head or blade can provide a sharper, more precise cut, reducing the time spent on each job.

Comfort and Usability Accessories

Improving user comfort is essential for long-term operation. Ergonomic handles and harnesses can reduce fatigue during extended use, allowing you to work efficiently. Moreover, maintenance tools like specialized wrenches and lubricants ensure that your equipment remains in optimal condition, enhancing longevity and reliability.