The inner workings of a powerful cutting tool are crucial for its optimal performance and longevity. Each element plays a specific role, contributing to the efficiency and reliability that users depend on. A comprehensive overview of these components reveals how they interact and function together to enhance the overall capability of the machine.

In the following sections, we will explore the individual sections of this tool, outlining their functions and importance. By delving into each component’s design, we can better appreciate how they contribute to the tool’s effectiveness. This knowledge is essential for maintenance, troubleshooting, and any necessary repairs.

Understanding these intricate details not only empowers users to make informed decisions regarding upkeep but also fosters a deeper connection with their equipment. Whether you are a professional or an enthusiast, grasping the nuances of these elements can significantly enhance your experience and skill in utilizing the tool.

This section delves into the essential characteristics that define the high-performance chainsaw. Understanding its components is crucial for effective maintenance and operation. This powerful tool is designed for both professional and casual users, providing exceptional reliability and efficiency in various cutting tasks.

Key Characteristics

- Robust engine capacity for enhanced power delivery

- Advanced vibration damping system for user comfort

- Lightweight construction for improved maneuverability

- Precision cutting capabilities for various applications

Functional Aspects

- Ergonomic design to reduce user fatigue during extended use

- Easy access to vital components for straightforward maintenance

- Durable materials that withstand rigorous working conditions

Common Issues and Solutions

When working with high-performance outdoor equipment, users may encounter a variety of challenges that can affect operation and efficiency. Understanding these common problems and their corresponding solutions can greatly enhance performance and prolong the life of the machinery.

| Issue | Possible Cause | Solution |

|---|---|---|

| Difficulty Starting | Clogged air filter or fuel line | Inspect and clean or replace air filter; check fuel line for blockages. |

| Poor Performance | Worn spark plug or incorrect fuel mixture | Replace spark plug; ensure correct fuel-to-oil ratio is maintained. |

| Excessive Vibration | Loose components or damaged anti-vibration system | Tighten all screws and bolts; inspect anti-vibration mounts for wear. |

| Overheating | Insufficient lubrication or clogged cooling fins | Ensure proper oil levels; clean cooling fins to allow adequate airflow. |

| Chain Stopping | Chain tension too tight or dull chain | Adjust chain tension; sharpen or replace the chain as necessary. |

Identifying Key Components

Understanding the essential elements of a chainsaw can significantly enhance maintenance and repair efforts. Recognizing each part’s function and location helps users troubleshoot issues effectively and ensure optimal performance.

Powerhead is the core of the equipment, housing the engine and vital controls. This component is crucial for overall functionality, converting fuel into mechanical energy.

Guide bar serves as the main support structure for the cutting chain. Its length and design directly impact the cutting efficiency and maneuverability.

Chain assembly consists of interconnected links that rotate around the guide bar, providing the cutting action. Regular inspection and maintenance of this component are necessary to prevent wear and ensure safe operation.

Fuel system, including the tank and carburetor, plays a pivotal role in supplying the engine with the necessary fuel-air mixture. Proper functioning of this system is essential for reliable starting and efficient operation.

Familiarity with these critical components enables users to address common problems and enhance the longevity of their equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular care and attention. Proper maintenance not only enhances performance but also minimizes the risk of unexpected failures. By adhering to a few key practices, you can keep your tools in optimal condition and ready for use whenever needed.

Regular Cleaning and Inspection

Routine cleaning is essential to remove debris and prevent buildup that can affect functionality. Regularly inspect components for wear and tear, looking for signs of damage or excessive friction. Addressing minor issues promptly can prevent more significant problems down the line.

Proper Lubrication and Storage

Lubrication plays a crucial role in maintaining the efficiency of moving parts. Use appropriate oils and lubricants as recommended to ensure smooth operation. Additionally, storing your equipment in a dry, sheltered location protects it from environmental damage and extends its lifespan.

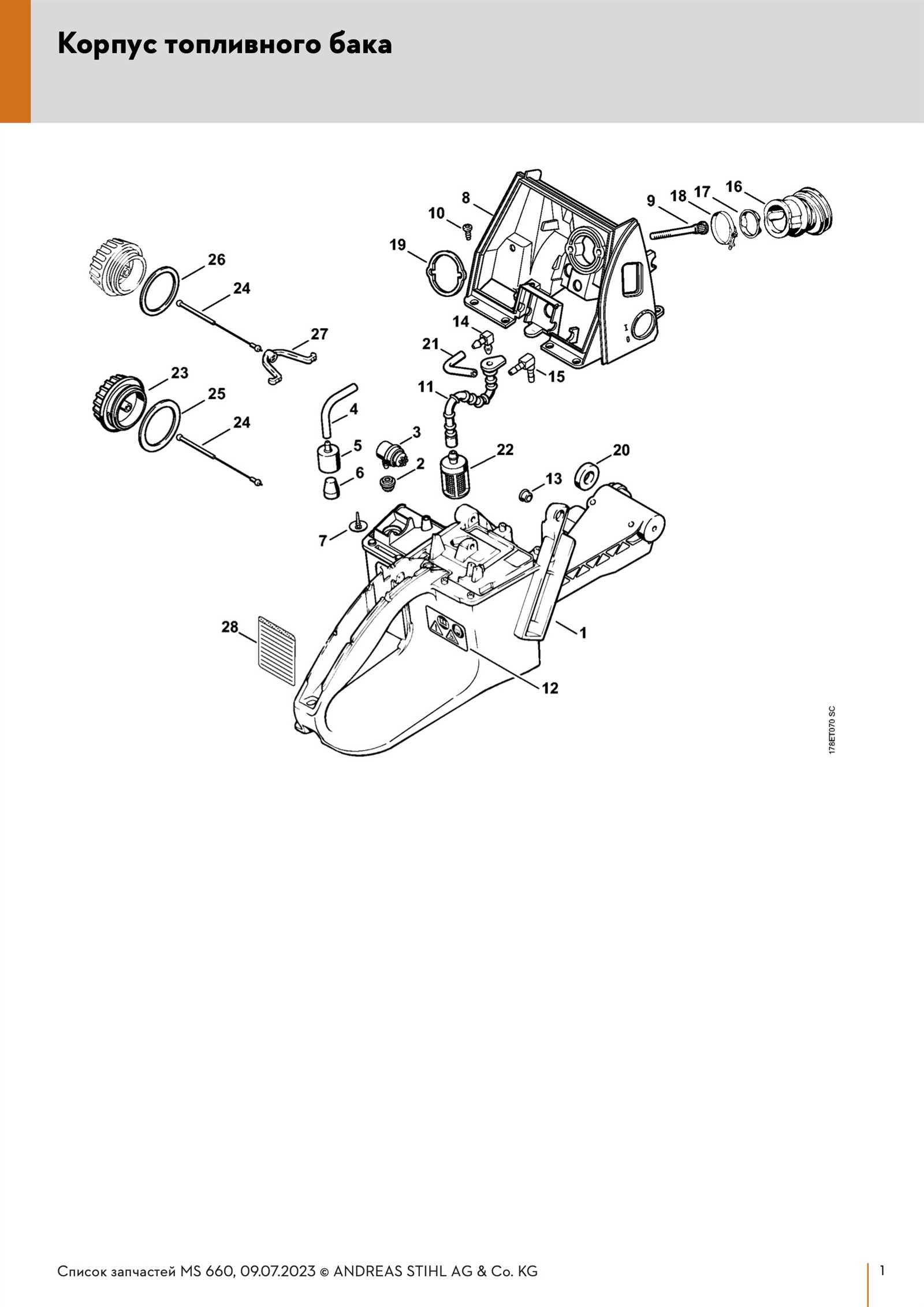

Understanding the Parts Layout

In any machinery, a clear representation of the components is essential for efficient operation and maintenance. This section delves into the configuration of various elements, highlighting their relationships and functions within the system. A comprehensive understanding of how these components are arranged aids in troubleshooting, repairs, and overall familiarity with the equipment.

Component Relationships

The arrangement of elements plays a crucial role in the machine’s performance. Each piece is strategically positioned to ensure optimal functionality, allowing for seamless interaction between parts. Recognizing these connections can lead to better maintenance practices and enhance the lifespan of the equipment.

Visual Reference Table

| Component Name | Function | Location |

|---|---|---|

| Engine | Drives the machine | Central position |

| Air Filter | Prevents dirt entry | Adjacent to the engine |

| Fuel Tank | Holds the fuel | Rear section |

| Chain Brake | Increases safety | Near the handle |

| Bar | Guides the cutting chain | Front of the assembly |

Replacement Parts Availability

Access to high-quality components is crucial for maintaining and repairing outdoor power tools. Finding reliable replacements ensures optimal performance and longevity of the equipment. A well-stocked supply of these essential elements can greatly enhance the user’s experience and minimize downtime.

Several avenues exist for acquiring necessary components. Authorized dealers typically offer a wide selection, ensuring that customers receive authentic items that meet the manufacturer’s specifications. Additionally, numerous online platforms provide options for sourcing these crucial elements, often at competitive prices. It is advisable to compare different suppliers to secure the best deals.

When seeking replacements, users should consider factors such as compatibility and quality. Investing in reputable brands can lead to better performance and durability. Furthermore, checking customer reviews can provide insights into the reliability of specific items, aiding in informed decision-making.

In conclusion, ensuring availability of essential components plays a vital role in the maintenance of outdoor equipment. By exploring various sources and considering quality, users can effectively prolong the life of their tools.

How to Read the Diagram

Understanding a schematic representation of components can greatly enhance your ability to maintain and repair equipment. By familiarizing yourself with the symbols and notations used, you can efficiently identify individual elements and their relationships within the system. This knowledge allows you to troubleshoot issues more effectively and ensures you have the necessary information for successful repairs.

Begin by examining the layout: Most illustrations provide a visual overview of the entire assembly. Take note of the arrangement and grouping of parts, which can indicate how they interact with one another. Look for clusters of similar items, as they may represent related functions or systems.

Identify symbols: Each representation typically uses specific icons to denote various components. Refer to the accompanying legend or key, if available, to understand what each symbol signifies. This is crucial for accurately interpreting the information presented.

Trace connections: Follow the lines or arrows that illustrate how components connect and communicate. These pathways are vital for understanding the flow of energy or data throughout the system. Recognizing these links helps in diagnosing potential failures or conflicts.

Refer to numerical references: Often, components are numbered for easy identification. Pay attention to these numbers, as they may correspond to a list of specifications or further details about each element. This additional information can be invaluable during repairs.

By mastering these techniques, you can confidently navigate any schematic representation, leading to more effective maintenance and repair practices.

Popular Upgrades and Modifications

Enhancing performance and versatility can significantly improve the functionality of your chainsaw. Many enthusiasts look for ways to optimize their equipment to achieve greater efficiency, durability, and user comfort. Here are some popular modifications that can help you achieve these goals.

- High-Performance Air Filter: Upgrading to a premium air filter can improve airflow, allowing the engine to breathe better and operate more efficiently.

- Exhaust System Upgrade: Replacing the stock exhaust with a performance exhaust can enhance power output and provide a deeper sound.

- Carburetor Tuning: Fine-tuning the carburetor settings can lead to improved fuel efficiency and better throttle response.

- Bar and Chain Upgrade: Switching to a different bar and chain combination can provide faster cutting speeds and greater cutting accuracy.

- Anti-Vibration Handle Inserts: Installing inserts can reduce fatigue during extended use, improving comfort and control.

- Modified Ignition System: Upgrading to a performance ignition system can improve starting reliability and enhance overall engine performance.

These enhancements not only boost the overall capability of the equipment but also allow users to tailor their tools to meet specific tasks and preferences. Always ensure that modifications comply with safety regulations and maintenance standards for optimal performance.