In any machinery, knowing the individual elements and their arrangement is essential for effective maintenance and operation. A comprehensive overview of these components can enhance your ability to troubleshoot and optimize performance. By familiarizing yourself with the intricate layout, you can ensure that your equipment remains in peak condition, ultimately prolonging its lifespan.

Visual representations serve as invaluable resources for anyone looking to grasp the intricate details of their tools. They provide clarity, allowing users to pinpoint specific sections and understand how each part interacts within the whole. This knowledge not only aids in repairs but also empowers operators to make informed decisions regarding upgrades or replacements.

Moreover, having a clear understanding of these components fosters confidence in tackling maintenance tasks. Whether you are a seasoned professional or a casual user, delving into the specifics can transform the way you approach equipment care. Embracing this knowledge is key to ensuring your machinery operates smoothly and efficiently.

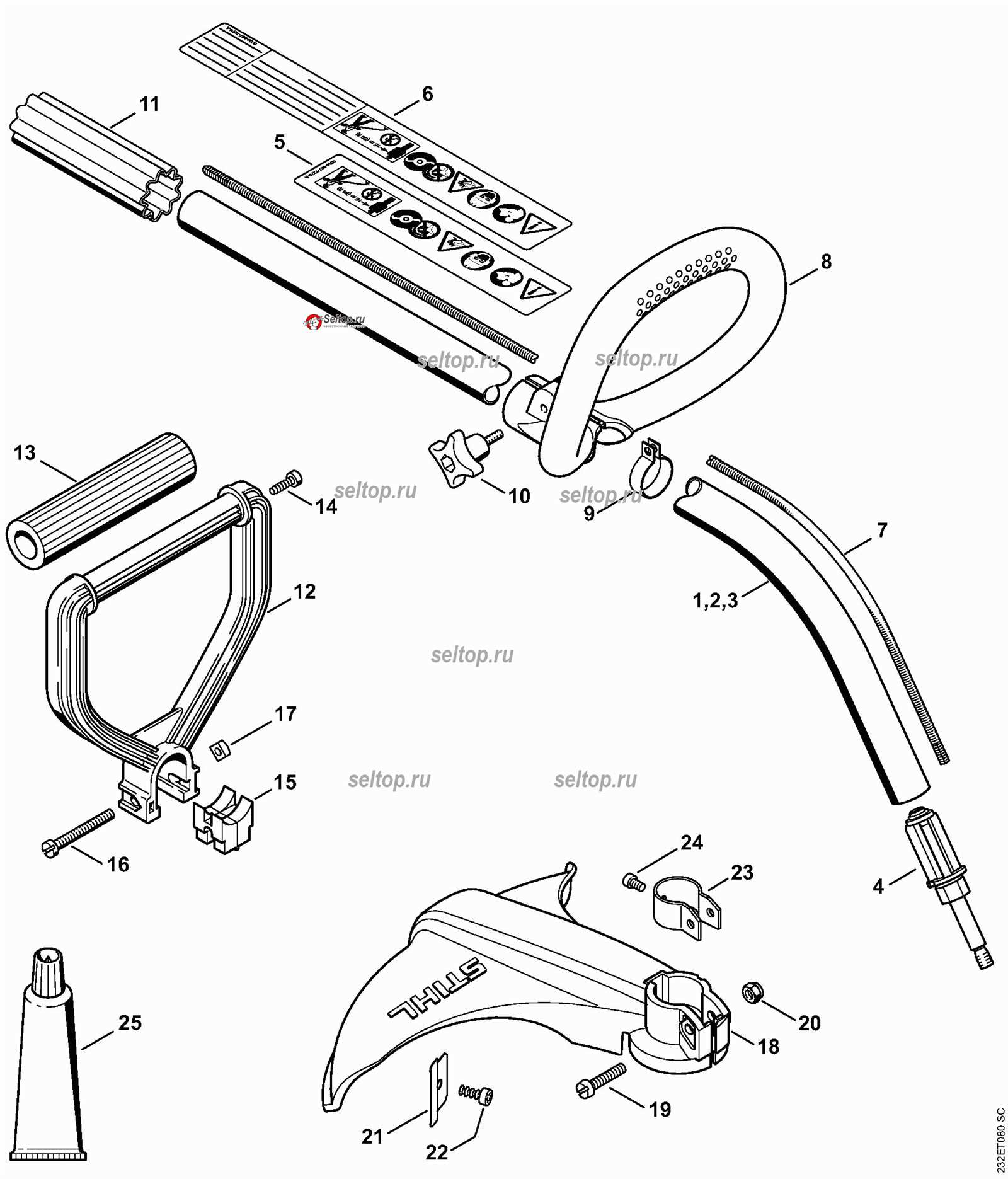

Understanding the Stihl FS45 Diagram

This section aims to explore the intricate layout of components within a specific outdoor power tool, providing insights into its design and functionality. By grasping the arrangement of these elements, users can enhance their maintenance skills and troubleshooting capabilities.

Key aspects to consider include:

- Identification of major elements

- Understanding their interconnections

- Recognizing the importance of each component in overall operation

By delving into these features, users can achieve the ultimate efficiency and longevity from their equipment.

To navigate the configuration effectively, follow these guidelines:

- Begin with a general overview of the tool’s structure.

- Pay attention to the function of each segment.

- Utilize reference materials for detailed exploration.

Ultimately, a solid comprehension of this layout contributes to better performance and user satisfaction.

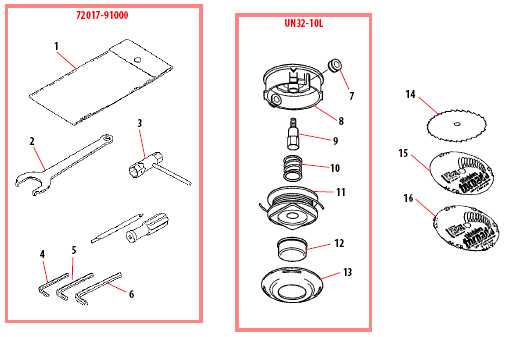

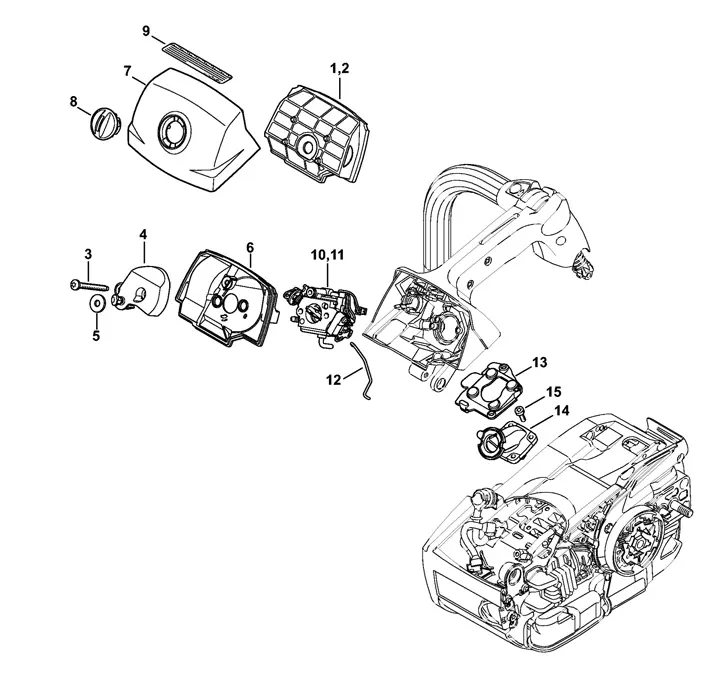

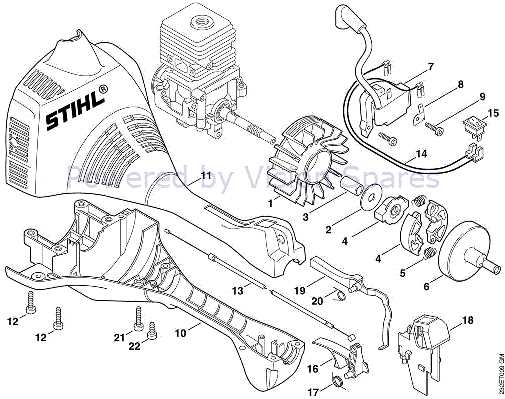

Components of the FS45 Trimmer

The efficient operation of a trimmer relies on a variety of essential elements that work together to deliver performance and reliability. Understanding these components can enhance maintenance practices and improve the overall experience when using the tool.

Key Elements

At the heart of the device lies the engine, responsible for generating the power needed for cutting. The cutting attachment, which can vary in design, is crucial for achieving clean and precise results on various surfaces. Additionally, the fuel system, which includes the tank and filter, ensures a steady supply of energy, while the handle and shaft provide comfort and maneuverability during operation.

Support Structures

Support structures, such as the protective guard, play a vital role in user safety by shielding against debris. The ignition system, comprising spark plug and coil, initiates combustion for smooth functionality. Lastly, the control mechanisms, including the throttle and switch, allow for easy adjustments, enhancing the user experience and ensuring optimal performance.

Benefits of Using Parts Diagrams

Visual representations of components serve as invaluable tools for both professionals and enthusiasts. They provide clarity and enhance understanding of intricate assemblies, ensuring that users can easily identify and locate necessary elements during maintenance or repair tasks.

One significant advantage of these visual aids is the simplification of complex structures. By breaking down each segment into manageable parts, users can efficiently navigate the intricacies of machinery, which reduces the likelihood of errors during reassembly. This not only saves time but also minimizes the potential for damage to the equipment.

Additionally, these representations foster a greater awareness of each element’s function within the overall system. By understanding how components interact, individuals can make informed decisions regarding upgrades or replacements, ultimately improving the performance and longevity of their equipment.

Moreover, having a visual reference promotes confidence in tackling repairs. Users can approach tasks with a clearer mindset, knowing they have a reliable guide at hand. This empowerment encourages more frequent maintenance, contributing to better care and efficiency of tools over time.

In summary, utilizing visual representations enhances comprehension, streamlines repairs, and cultivates a proactive attitude toward equipment management. These benefits combine to create a more efficient and knowledgeable user experience.

Common Issues with FS45 Parts

When it comes to outdoor power tools, certain components may frequently encounter problems that can affect overall performance. Understanding these issues is essential for maintaining optimal functionality and ensuring longevity. By recognizing common faults, users can take proactive measures to address them and enhance their equipment’s reliability.

Frequent Mechanical Failures

One of the most prevalent concerns involves mechanical breakdowns that can stem from wear and tear over time. Elements such as the drive shaft and spool can become compromised, leading to reduced efficiency and potential operational failures. Regular inspections and timely replacements can mitigate these risks and keep the equipment running smoothly.

Fuel System Complications

Another critical area prone to challenges is the fuel delivery system. Clogs and leaks can occur, often due to old or contaminated fuel. This not only impacts performance but may also cause damage to other components if not addressed promptly. Ensuring clean fuel and regular maintenance can prevent such complications, promoting a hassle-free experience.

How to Read the Diagram

Understanding a visual representation of components can enhance your ability to maintain and repair equipment effectively. This section provides insights into interpreting such illustrations, making the process of identification and assembly much more straightforward.

Key Elements to Identify

Familiarizing yourself with common features is essential. Look for symbols and lines that indicate connections, as well as labels that specify the function of each element.

Utilizing the Information

Once you’ve grasped the layout, apply this knowledge when disassembling or reassembling your machine. This can prevent errors and ensure that everything fits together seamlessly.

| Feature | Description |

|---|---|

| Labeling | Indicates the name and function of each component. |

| Connection Lines | Shows how different parts interact or connect with each other. |

| Legend | Explains symbols used throughout the illustration. |

Where to Find Replacement Parts

Locating the necessary components for maintenance or repair can be a straightforward process if you know where to look. Whether you need a specific item for your outdoor equipment or are planning a general upkeep, several reliable sources are available to help you acquire what you need.

Authorized Dealers

Visiting an authorized dealer is one of the most effective ways to find genuine components. These outlets typically carry a wide selection of items tailored to your equipment. Additionally, staff members are usually knowledgeable and can assist you in identifying the correct pieces for your needs.

Online Retailers

Another convenient option is to explore online retailers that specialize in outdoor tools and accessories. Many websites offer a comprehensive catalog, allowing you to search for specific components by model number or description. Be sure to check customer reviews and ratings to ensure you’re purchasing from a reputable source.

Maintenance Tips for FS45 Users

Proper upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. Regular maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. By following a few key practices, you can keep your device running smoothly and effectively.

Start with routine cleaning after each use. Remove any debris or grass clippings that may accumulate, particularly around the cutting head and air intake. This prevents overheating and maintains optimal airflow. Additionally, check the fuel system regularly. Using fresh fuel and replacing any old or stale mixtures will improve combustion and overall functionality.

Inspect the cutting components frequently. Dull blades can hinder performance, so sharpening or replacing them as needed is crucial. Moreover, ensure that all connections and fasteners are secure to avoid any operational issues during use.

Don’t forget about the air filter; a clean filter is vital for efficient engine performance. Replace or clean it periodically, depending on usage frequency. Lastly, always refer to the manufacturer’s guidelines for any specific maintenance schedules to keep your equipment in top condition.

Comparing FS45 with Other Models

When evaluating different models in the same category, it’s essential to consider their unique features, performance metrics, and suitability for various tasks. This analysis helps users determine which machine best meets their needs, particularly in terms of efficiency, handling, and overall functionality.

Performance Comparison

Each model offers varying levels of power and efficiency, which can significantly impact user experience. Understanding the differences in engine specifications, weight, and ergonomics is crucial for making an informed choice.

| Model | Engine Power (cc) | Weight (lbs) | Cutting Width (in) |

|---|---|---|---|

| Model A | 25.4 | 10.5 | 16 |

| Model B | 30.1 | 11.2 | 18 |

| Model C | 27.2 | 10.0 | 15 |

Usability and Features

In addition to performance metrics, usability plays a significant role in determining which model is preferable. Factors such as ease of handling, vibration reduction, and user-friendly controls can enhance the overall experience and productivity.

DIY Repairs Using the Diagram

Understanding the layout of your equipment can significantly simplify the repair process. By familiarizing yourself with the various components, you can identify issues more efficiently and tackle fixes independently. This section explores how to utilize visual references for successful maintenance and repair tasks.

Identifying Common Issues

Before diving into repairs, it’s essential to recognize frequent problems that can arise. Issues may include starting difficulties, decreased performance, or unusual noises. By knowing where each element is located, you can troubleshoot effectively.

Step-by-Step Repair Guide

Once you’ve identified the issue, follow a systematic approach for repairs. Start by gathering the necessary tools and components for the job. Consult the visual reference to locate the specific areas requiring attention. Below is a simplified guide to assist in your repair process:

| Step | Action |

|---|---|

| 1 | Disconnect the power source to ensure safety. |

| 2 | Refer to the visual reference to locate the affected component. |

| 3 | Carefully disassemble any necessary parts for access. |

| 4 | Inspect the component for wear or damage and replace if needed. |

| 5 | Reassemble the parts, ensuring everything is secured properly. |

| 6 | Reconnect the power source and test the equipment. |

By following these steps and utilizing a clear visual reference, you can confidently perform repairs and extend the lifespan of your equipment.