In this guide, we will explore the essential elements that make up a powerful outdoor tool designed for managing debris and maintaining cleanliness in various environments. These devices are built to handle demanding tasks, and understanding how their internal mechanisms work together is crucial for efficient operation and maintenance.

Whether you are looking to perform routine upkeep or need to replace certain components, having a clear understanding of the overall structure and how each piece fits within the system can save time and ensure your equipment runs smoothly. In the following sections, we will break down the main elements, offering insights into their function and placement.

By gaining a deeper knowledge of how these essential pieces interact, users can extend the lifespan of their equipment, improve its performance

Overview of the Stihl SH86C Components

This high-performance tool consists of various elements that work together to ensure efficient operation. Each part plays a crucial role in delivering the desired functionality, from power generation to airflow control. The overall design is built for durability and ease of use, providing users with a seamless experience in managing outdoor tasks. With thoughtful engineering, the individual components come together to form a reliable and effective machine.

The system’s structure includes sections responsible for the collection of debris, air filtering, and user controls. These pieces are carefully integrated to offer both convenience and precision. The modular layout also allows for easy mainte

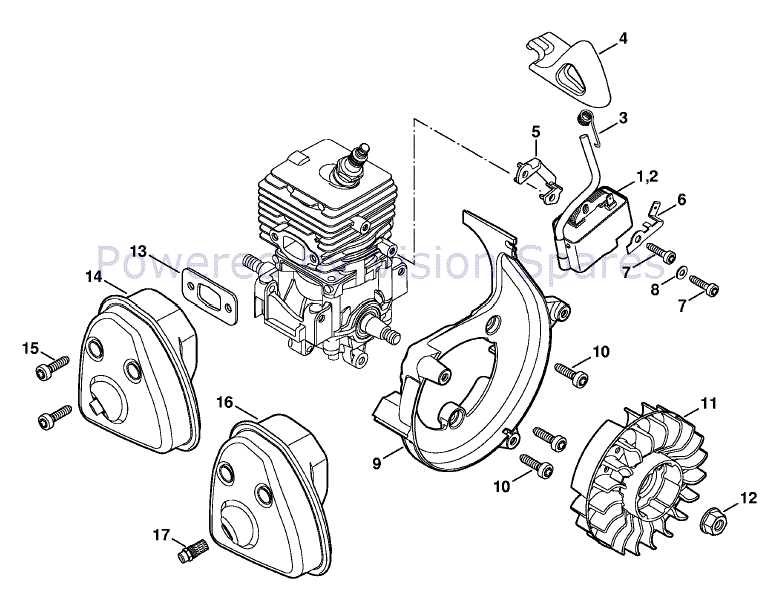

Key Internal Parts of the Blower

The internal components of a blower are essential for its performance and efficiency. Each element works together to ensure smooth operation and reliable output. Understanding these core pieces helps in maintaining and troubleshooting the machine when necessary.

- Engine Unit: The heart of the machine, responsible for generating the necessary power to operate the blower effectively.

- Impeller: This rotating component plays a critical role in creating the airflow by drawing in air and expelling it through the outlet.

- Air Intake System: A crucial assembly that ensures a steady flow of air into the machine, preventing debris from entering sensitive areas.

- Fuel and Exhaust System: These systems manage the flow of fuel and the expulsion of exhaust gases, ensuring optimal engine performance.

- Filter housing

- Pre-filter layer

- Main filter

- Sealing components

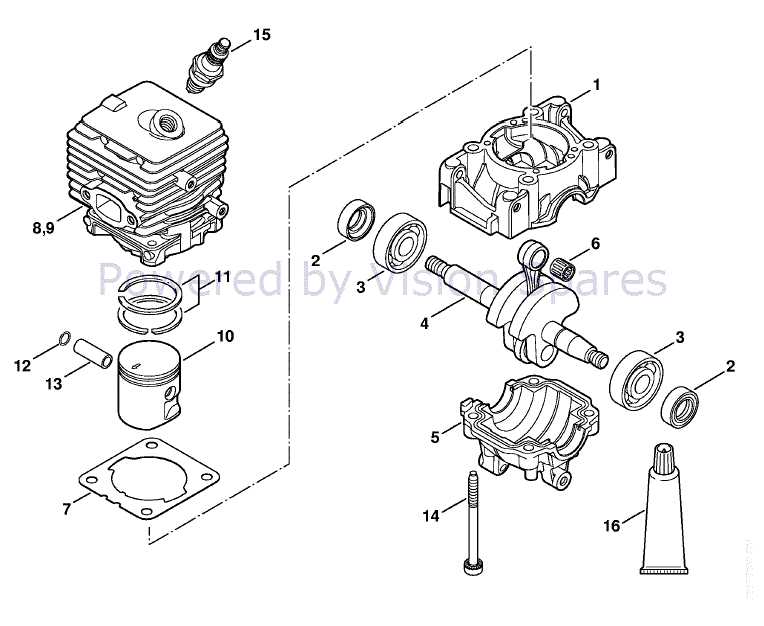

Understanding the Engine Assembly

The engine is the core component that powers the entire machine, transforming energy into mechanical force. A well-organized system of moving parts ensures the engine operates efficiently, driving the necessary mechanisms. Comprehending how these elements work together is essential for both proper maintenance and long-term functionality.

Key Components of the Engine

At the heart of the engine are several critical elements, including the combustion chamber, piston, and crankshaft. Each plays a pivotal role in generating the power needed for operation. The precise interaction between these components ensures smooth performance, with proper timing being a crucial factor.

Ensuring Longevity Through Regular Maintenance

Routine upkeep of the engine’s components, such as lubricating moving parts and cleaning filters

Air Filtration System Breakdown

The air filtration system is crucial for ensuring clean airflow and maintaining the performance of the equipment. This section covers how the system operates, the key components involved, and their role in the overall functionality. By preventing debris and dust from entering sensitive areas, the system helps extend the lifespan of the device.

Key Components

Maintenance Tips

- Regularly inspect the filters for dust buildup.

- Replace or clean filters as recommended.

- Ensure a proper seal to prevent

Fuel Tank and Lines Explained

The fuel system is a critical component in ensuring that engines operate efficiently. The tank holds the liquid fuel, while the lines transport it to the motor, making the system an essential link in the machine’s performance. Understanding the basic function and structure of the tank and its connecting lines helps in identifying potential issues and maintaining the device.

Fuel Tank Structure

The fuel tank is designed to securely contain the liquid, preventing leaks and ensuring the correct amount is supplied to the engine. Its materials are built to withstand both pressure and environmental elements, offering durability. Inside, baffles may be used to stabilize the fuel during movement, ensuring a consistent flow.

Fuel Lines and Their Role

Fuel lines are responsible for carrying the fuel from the tank to the engine. These tubes need to remain flexible but strong eno

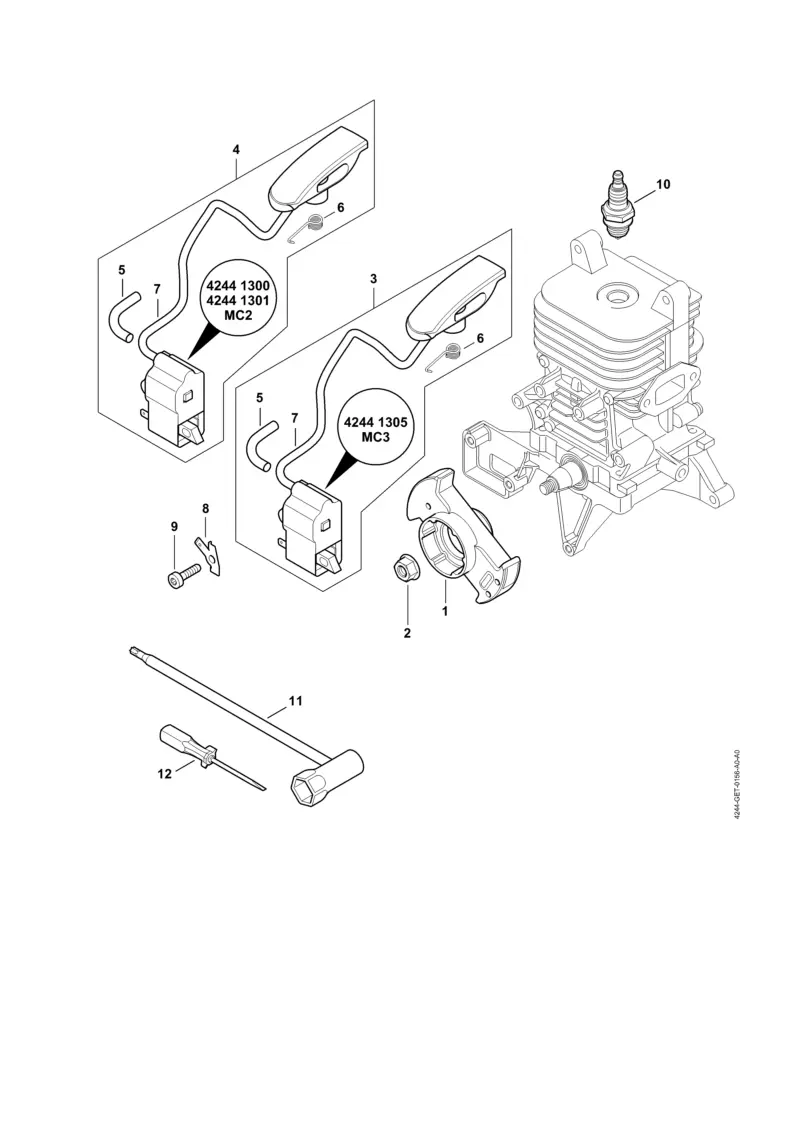

Exploring the Ignition System

The ignition system is a crucial component of any combustion engine, responsible for generating the spark necessary to ignite the fuel-air mixture. Understanding its various elements and functions can help in diagnosing issues and ensuring optimal performance. This system includes multiple parts working in harmony to deliver reliable starting and consistent operation.

Components of the Ignition System

At the heart of the ignition system lies the ignition coil, which transforms low voltage from the battery into high voltage required to create a spark. This high voltage is then directed to the spark plug, where it ignites the fuel-air mixture in the engine’s combustion chamber. Additional elements, such as the ignition switch and control module, play vital roles in managing the timing and operation of the ignition process.

Troubleshooting Common Issues

Common problems within the ignition system can manifest as difficulty starting the engine, misfires, or irregular engine performance. Conducting regular inspections and maintenance can help identify worn components, loose connections, or faulty coils that may hinder the system’s efficiency. Ensuring each part operates correctly contributes significantly to the overall functionality of the engine.

Handle and Control Features

The ergonomic design of the handle and control mechanisms is essential for providing comfort and ease of use during operation. These features play a crucial role in ensuring optimal maneuverability and reducing fatigue for the operator. A well-thought-out layout allows for quick access to the controls, enabling efficient adjustments while working.

Ergonomic Handle Design

The handles are designed to fit comfortably in the user’s hand, minimizing strain during prolonged usage. Their shape and texture provide a secure grip, enhancing control and stability. This design not only improves handling but also contributes to overall user satisfaction.

Control Mechanisms

Control features are strategically placed to facilitate seamless operation. With intuitive placements, users can easily adjust settings without removing their hands from the handle. This ensures a safe and efficient working environment, allowing for quick responses to varying conditions.

Feature Description Comfort Grip Soft, textured material that reduces hand fatigue. Throttle Control Easy-to-reach lever for quick speed adjustments. Safety Switch Prevents accidental starting for enhanced safety. Adjustable Handle Allows customization for different user heights. Maintenance for Optimal Performance

Regular upkeep is essential to ensure that your equipment operates efficiently and remains in top condition. By following a structured maintenance routine, you can enhance the lifespan of your device and maintain its effectiveness, resulting in better performance during use.

Routine Check-ups

- Inspect the air filter regularly to prevent dust and debris from affecting engine performance.

- Examine the fuel lines and connections for any signs of wear or leaks.

- Ensure that all screws and bolts are tightened to prevent parts from loosening during operation.

Cleaning Procedures

- Clean the exterior surfaces after each use to remove dirt and residues.

- Remove the spark plug and clean it to ensure proper ignition.

- Check and clear any clogs in the exhaust to allow for optimal airflow.

Common Replacement Parts for Repairs

Maintaining outdoor power equipment often requires replacing certain components to ensure optimal performance. Knowing which elements are frequently needed for repairs can help users manage their equipment effectively and reduce downtime.

- Air Filters: Essential for maintaining engine efficiency by keeping dirt and debris from entering the combustion chamber.

- Fuel Lines: Vital for transporting fuel from the tank to the engine, often subject to wear and tear.

- Carburetors: Key components that mix air and fuel for combustion; they may require servicing or replacement due to clogging or damage.

- Spark Plugs: Crucial for ignition, these components need periodic replacement to ensure reliable starts and efficient operation.

- Blades and Cutting Edges: Important for maintaining the effectiveness of cutting tools, these may dull or chip over time and require sharpening or replacement.

- Throttle Cables: These control the engine speed and can fray or break, necessitating replacement for proper functionality.

- Drive Belts: Critical for transferring power from the engine to various attachments; worn belts can lead to decreased performance.

Having a stock of these commonly replaced elements can streamline maintenance efforts, ensuring that equipment remains in good working condition and ready for use when needed.