Maintaining the efficiency of your pruning equipment is crucial for optimal performance. Knowing the individual elements that comprise your tool allows for better upkeep and enhances its longevity. This section aims to provide a comprehensive overview of the various components essential for smooth operation.

As you explore the intricacies of your equipment, you will uncover a wealth of knowledge regarding its functionality. Each segment plays a pivotal role in ensuring that the tool operates effectively, allowing you to achieve your gardening goals with ease. By delving into these details, you will gain insight into how each part contributes to the ultimate performance.

Whether you are a seasoned professional or an enthusiastic hobbyist, understanding these components empowers you to tackle repairs and replacements confidently. This knowledge not only enhances your skill set but also fosters a deeper appreciation for the craftsmanship involved in creating such reliable tools.

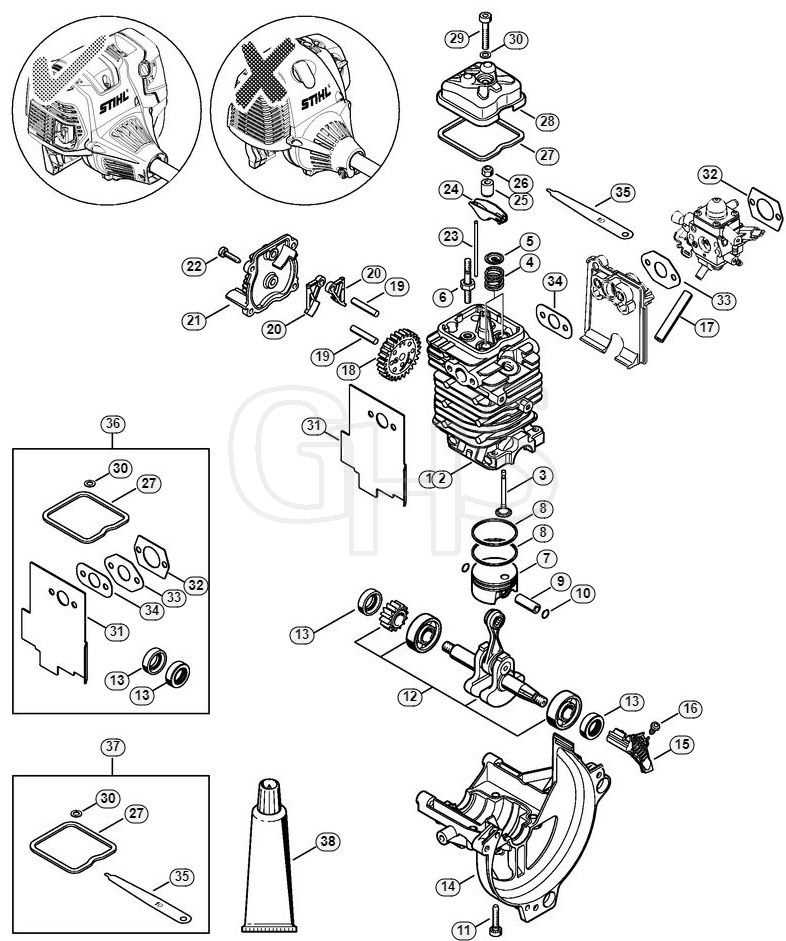

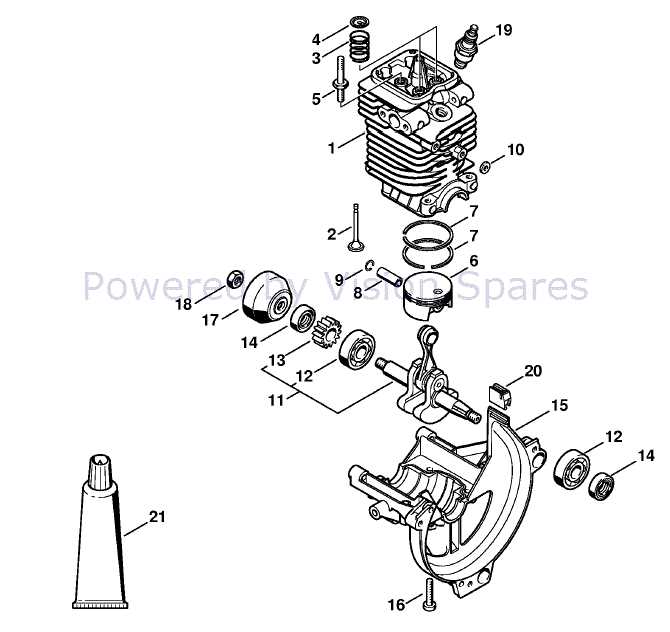

Understanding Stihl HT 131 Components

When it comes to specialized cutting tools, grasping the intricacies of their various elements is essential for optimal performance. Each component plays a vital role in ensuring efficiency and reliability, making knowledge of their functions crucial for users and technicians alike.

The engine serves as the powerhouse, driving the machine’s operations, while the shaft connects the engine to the cutting mechanism, providing stability and control. The cutting head is where the magic happens, enabling precision trimming and pruning. Additionally, the safety features integrated into the design ensure user protection during operation, highlighting the importance of understanding each part’s role in overall functionality.

Familiarity with these elements not only aids in maintenance but also enhances the user experience, allowing for informed decisions when troubleshooting or replacing components.

Key Features of Stihl HT 131

This model is designed to offer exceptional performance and efficiency, making it an ideal choice for those who require reliable equipment for tree maintenance and pruning tasks. Its innovative features enhance user experience while ensuring safety and ease of use.

Performance and Efficiency

- Powerful engine that delivers robust cutting performance.

- Lightweight design for easy maneuverability during extended use.

- Optimized fuel consumption for longer operational time without frequent refueling.

User-Friendly Design

- Adjustable telescopic shaft for customizable reach, accommodating various tree heights.

- Anti-vibration system that minimizes user fatigue during prolonged operation.

- Intuitive controls for straightforward operation, even for novice users.

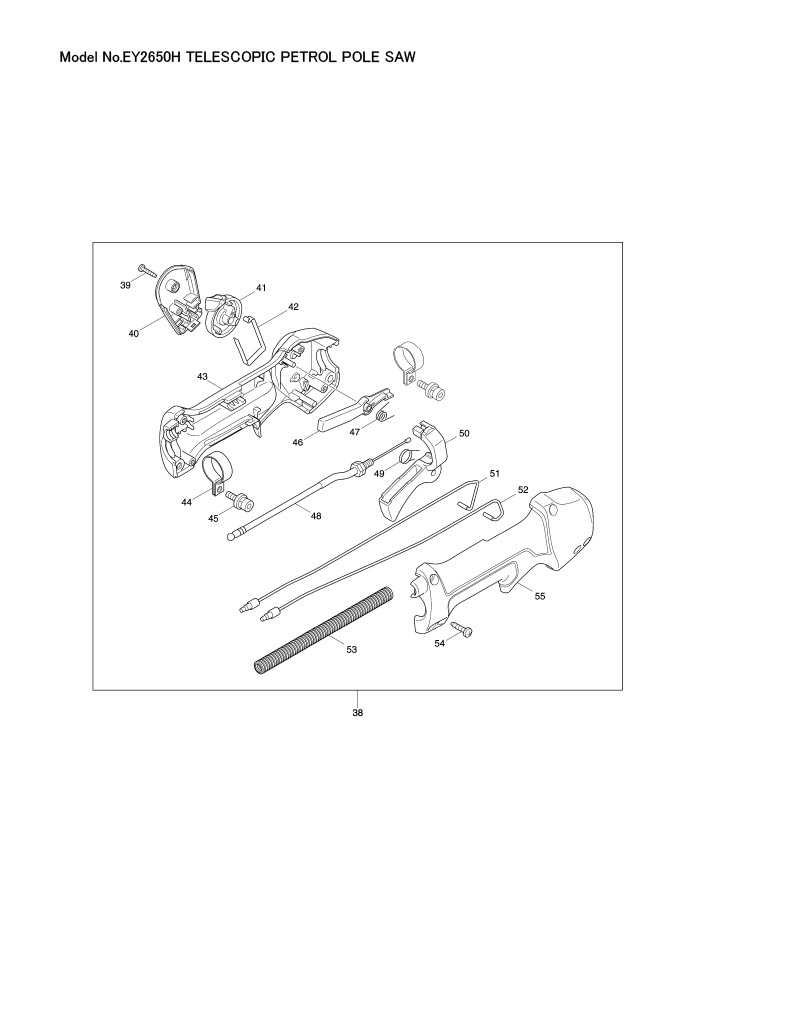

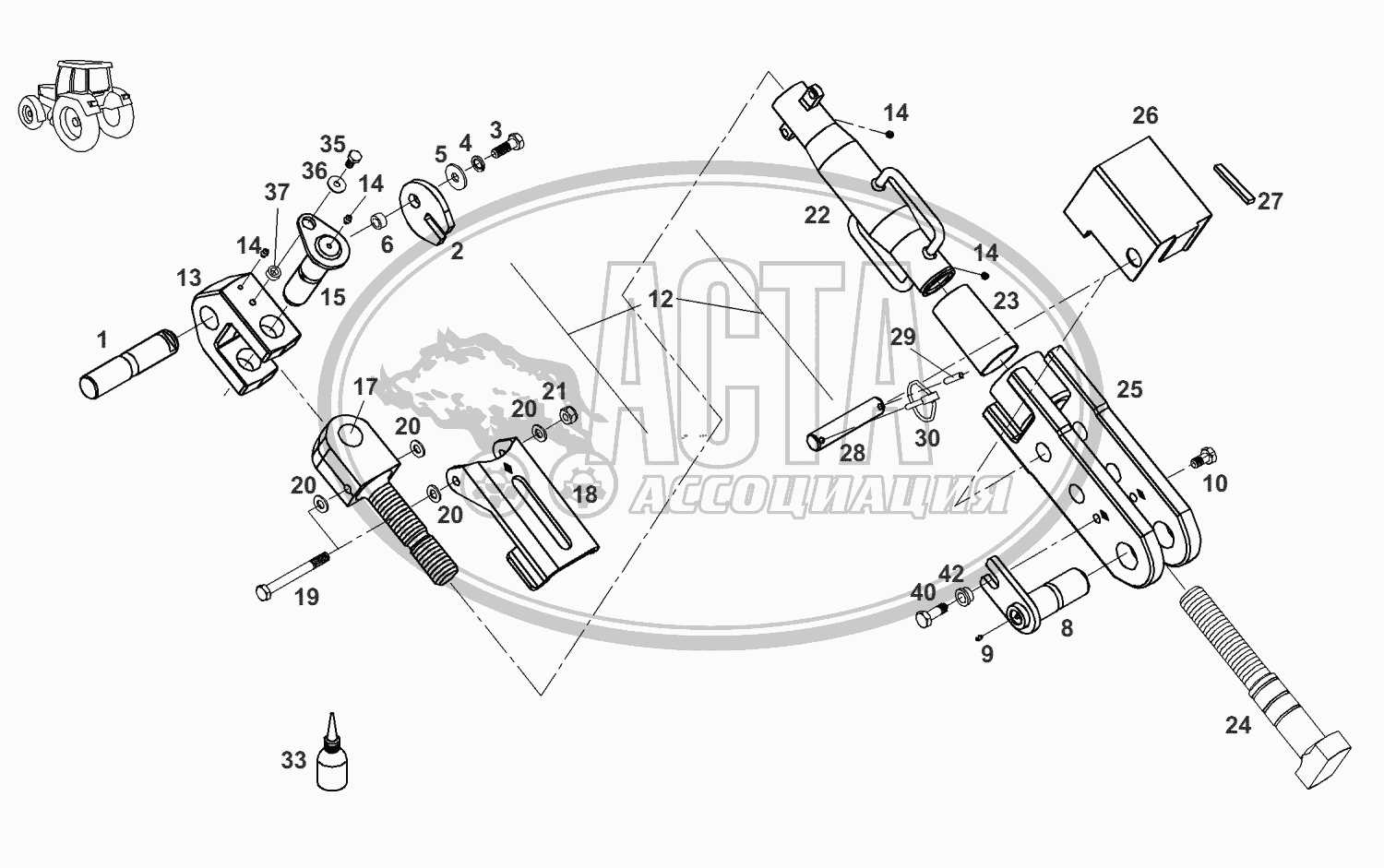

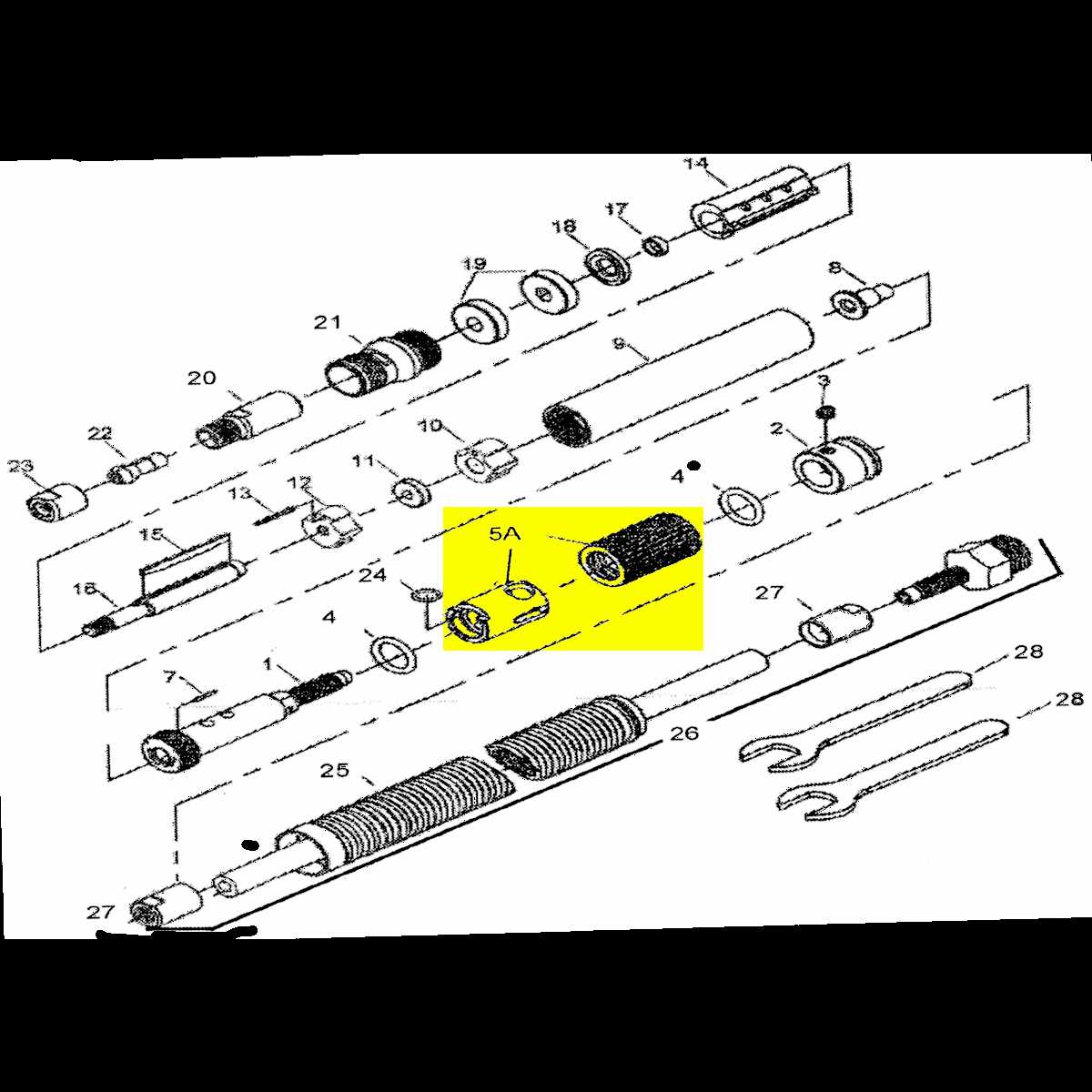

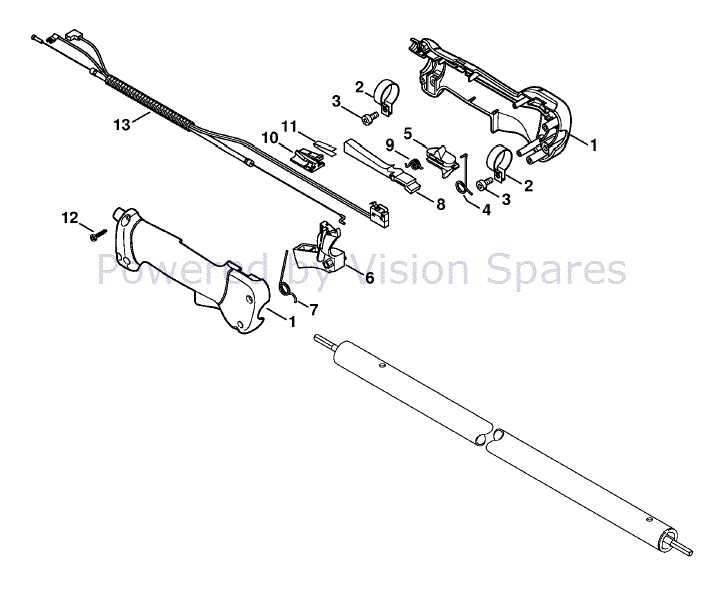

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. They provide users with a clear overview, enabling them to identify each element and its relationship within the assembly. This clarity not only aids in the comprehension of how devices operate but also enhances maintenance and repair processes.

Facilitating Repairs and Maintenance

Having access to detailed illustrations simplifies troubleshooting and repair efforts. Users can easily locate malfunctioning sections, ensuring that the correct adjustments or replacements are made. This minimizes the risk of errors, ultimately leading to more efficient and effective maintenance.

Enhancing User Knowledge

In-depth visual guides contribute significantly to the user’s understanding of their equipment. By studying these representations, individuals can familiarize themselves with the various components, leading to better operational practices. Knowledge gained from such resources empowers users to care for their tools more effectively.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of equipment. These visual guides provide crucial information about components, their arrangement, and how they fit together. Grasping the basics of these illustrations can simplify the troubleshooting process and ensure successful reassembly.

Key Elements to Identify

When examining these visuals, focus on several important aspects:

| Element | Description |

|---|---|

| Reference Numbers | Each part is usually assigned a unique identifier for easy tracking. |

| Labels | Clear descriptions accompany components to aid understanding. |

| Connections | Arrows or lines may indicate how parts are linked or interact with one another. |

| Legend | A key that explains symbols or color coding used in the illustration. |

Tips for Effective Interpretation

To enhance your ability to read these visuals, consider the following tips:

- Familiarize yourself with common symbols and notations used in technical illustrations.

- Take your time to correlate the visual information with the actual components.

- Refer to the accompanying documentation for additional context and details.

Common Replacement Parts for HT 131

When it comes to maintaining outdoor power equipment, certain components tend to wear out over time due to regular use. Understanding which elements are most frequently replaced can help ensure your tool operates efficiently and reliably. Here are some key items that are often subject to replacement, ensuring your equipment remains in top condition.

Fuel Filter: A clean fuel filter is essential for optimal engine performance. Over time, debris can clog this component, leading to reduced efficiency and potential damage to the engine. Regularly replacing the fuel filter can prevent these issues.

Air Filter: The air filter plays a crucial role in maintaining the correct air-to-fuel ratio. A dirty or clogged air filter can restrict airflow, resulting in poor engine performance. Changing this filter periodically is vital for maintaining peak functionality.

Spark Plug: The spark plug is critical for igniting the fuel-air mixture in the engine. Worn or fouled spark plugs can cause starting difficulties and affect overall engine performance. Regular checks and replacements can enhance the reliability of your equipment.

Chain and Bar: For those using saw attachments, the chain and bar can experience significant wear. Ensuring these components are sharp and in good condition is essential for effective cutting performance. Regular maintenance and timely replacement can prevent operational issues.

Throttle Trigger: The throttle trigger is integral to controlling engine speed. If it becomes sticky or unresponsive, it may need to be replaced to maintain proper functionality and safety during operation.

By staying informed about these frequently replaced components, users can enhance the longevity and performance of their outdoor equipment. Regular maintenance checks will ensure that each element functions optimally, keeping your tool ready for any task.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular attention not only enhances performance but also extends the lifespan of the machine, allowing you to get the most value from your investment.

Regular Cleaning: After each use, take the time to clean the exterior and internal components of your equipment. Debris and residue can lead to wear and tear, so use a brush or compressed air to remove any buildup.

Routine Inspections: Frequently check the various elements of your tool, including filters, spark plugs, and cutting attachments. Identifying and addressing wear early can prevent more significant issues down the line.

Proper Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction, enhances efficiency, and minimizes the risk of overheating. Use the recommended lubricants for optimal results.

Storage Practices: Store your equipment in a dry, protected area to shield it from moisture and extreme temperatures. This helps prevent rust and deterioration of materials, ensuring your tool remains in excellent condition.

Follow Manufacturer Guidelines: Always adhere to the maintenance schedule and recommendations provided by the manufacturer. These guidelines are designed to optimize performance and longevity, ensuring that your equipment runs smoothly for years to come.

Where to Find Genuine Parts

When it comes to maintaining outdoor power tools, ensuring the use of authentic components is essential for optimal performance and longevity. Genuine items provide the reliability and precision that aftermarket options often lack. Understanding where to source these products can save time and enhance the overall effectiveness of your equipment.

Official Retailers are the most trustworthy sources for authentic components. Many manufacturers have authorized dealers that stock a comprehensive selection of items. These establishments often provide expert guidance, ensuring you choose the correct components for your specific model.

Online Stores dedicated to outdoor equipment often feature a wide range of original items. When shopping online, look for reputable websites that guarantee the authenticity of their inventory. Reading customer reviews can also help in identifying reliable sources.

Manufacturer’s Website is another excellent option for locating genuine components. Most companies have a dedicated section for parts, allowing users to search by model number. This direct approach ensures you receive authentic items straight from the source.

Local Repair Shops can also be valuable resources. Many authorized service centers not only provide repairs but also sell genuine components. Building a relationship with these professionals can lead to personalized advice and support for your equipment maintenance.

Troubleshooting Common Issues

When operating a pole pruner, encountering problems is not uncommon. Understanding the typical challenges can greatly enhance your experience and ensure optimal performance. This section will guide you through some frequent difficulties and their solutions, helping you get back to work efficiently.

1. Engine Won’t Start

If the engine fails to ignite, several factors could be at play:

- Check the fuel level and quality. Ensure you are using fresh fuel.

- Inspect the spark plug for wear or damage. Replace it if necessary.

- Examine the air filter for clogs. Clean or replace it to allow proper airflow.

- Ensure the choke is in the correct position based on the temperature.

2. Poor Cutting Performance

Suboptimal cutting may result from various issues. Consider the following checks:

- Inspect the cutting head for dull or damaged blades. Sharpen or replace them as needed.

- Check the tension of the cutting line. Adjust if it is too loose or too tight.

- Ensure the correct attachment is being used for the task at hand.

- Examine the fuel mixture; an incorrect ratio can affect performance.

Upgrades and Accessories for Performance

Enhancing the capabilities of your equipment can significantly improve its efficiency and longevity. Whether you are a professional user or an enthusiastic hobbyist, incorporating specific modifications and add-ons can elevate your overall experience. This section explores various options that can help maximize the performance of your tool, making tasks easier and more effective.

Engine Enhancements: Upgrading the engine components can lead to better power output and fuel efficiency. Consider options such as high-performance air filters and exhaust systems that allow for improved airflow. These upgrades not only increase performance but also help in maintaining the engine’s health over time.

Cutting Tools: The choice of cutting tools can make a significant difference in how your device performs. Investing in premium quality blades or chains designed for specific tasks can enhance cutting precision and speed. Look for accessories that offer durability and ease of maintenance to ensure optimal results.

Ergonomic Features: Comfort plays a crucial role in the effectiveness of any tool. Upgrading to ergonomic handles or straps can reduce fatigue during extended use. Additionally, vibration dampening features can further improve user experience by minimizing strain on the hands and arms.

Maintenance Kits: Regular upkeep is essential for maintaining high performance. Consider investing in comprehensive maintenance kits that include essential tools and lubricants. Keeping your equipment in peak condition not only extends its life but also ensures it operates at its best.

Safety Accessories: Enhancing performance should never come at the cost of safety. Adding protective gear such as goggles, gloves, and helmets is vital. Safety accessories not only protect you but also promote confidence while operating your equipment.

By exploring these upgrades and accessories, you can tailor your tool to better meet your specific needs, ensuring that it operates at maximum efficiency and provides you with the best possible results.