When working with complex equipment, it’s essential to have a clear understanding of the individual elements that contribute to its overall functionality. Each component plays a crucial role in ensuring smooth operation, and knowing how these parts interact is key to maintaining the efficiency and longevity of the machine.

The detailed layout of each element offers insight into the internal structure, allowing for easier identification and potential troubleshooting. By familiarizing yourself with this structure, you can quickly address any issues and perform necessary replacements or repairs when needed.

Proper maintenance and a thorough understanding of how everything fits together can significantly extend the life of the equipment. Whether you’re performing routine checks or in-depth repairs, having a reliable overview of each part’s purpose ensures a smoother experience and better results.

Comprehensive Guide to HT131 Components

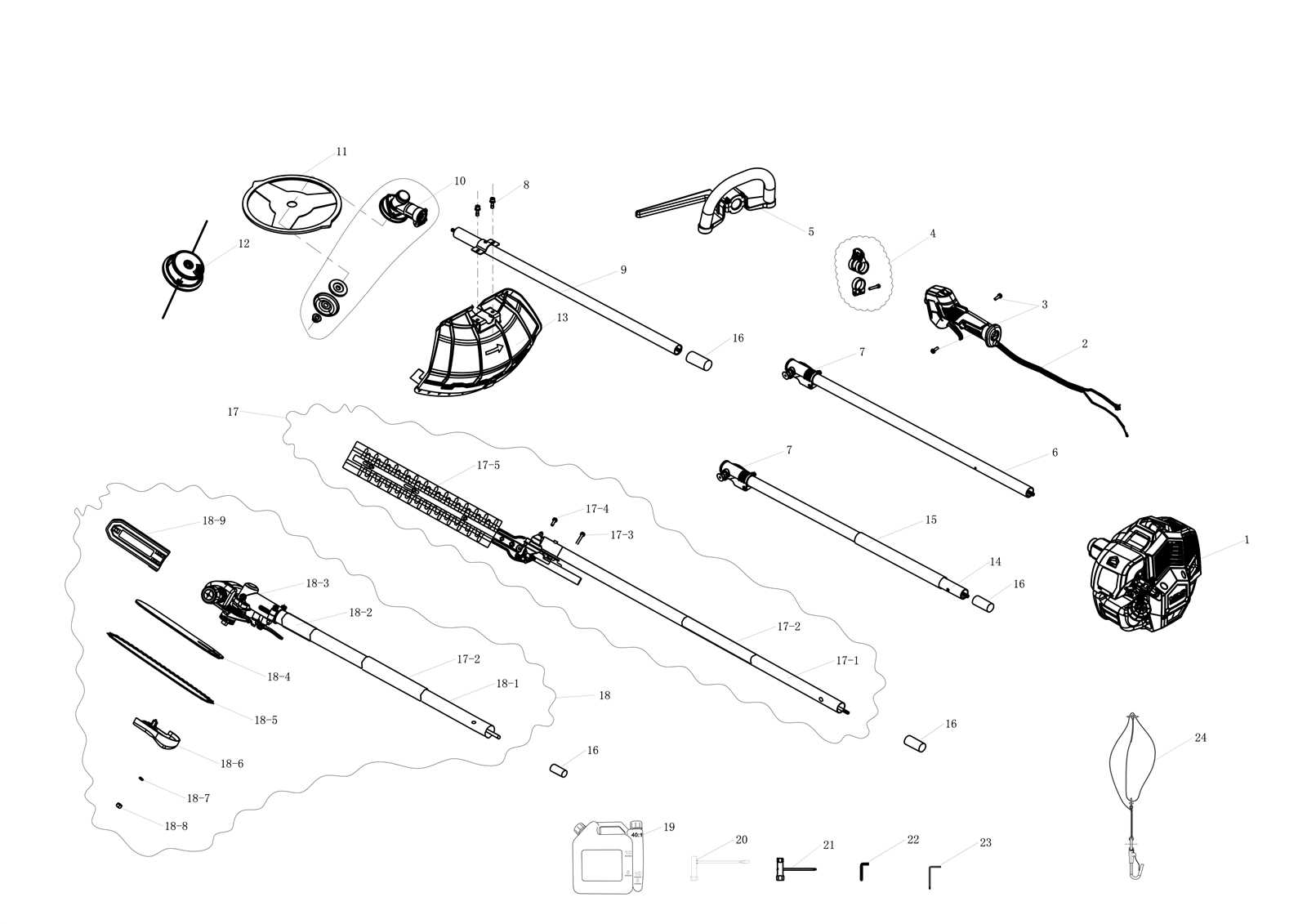

Understanding the key elements of this cutting tool model is essential for ensuring optimal performance and longevity. Each part works together to deliver precise results, and familiarity with these components will help in proper maintenance and troubleshooting.

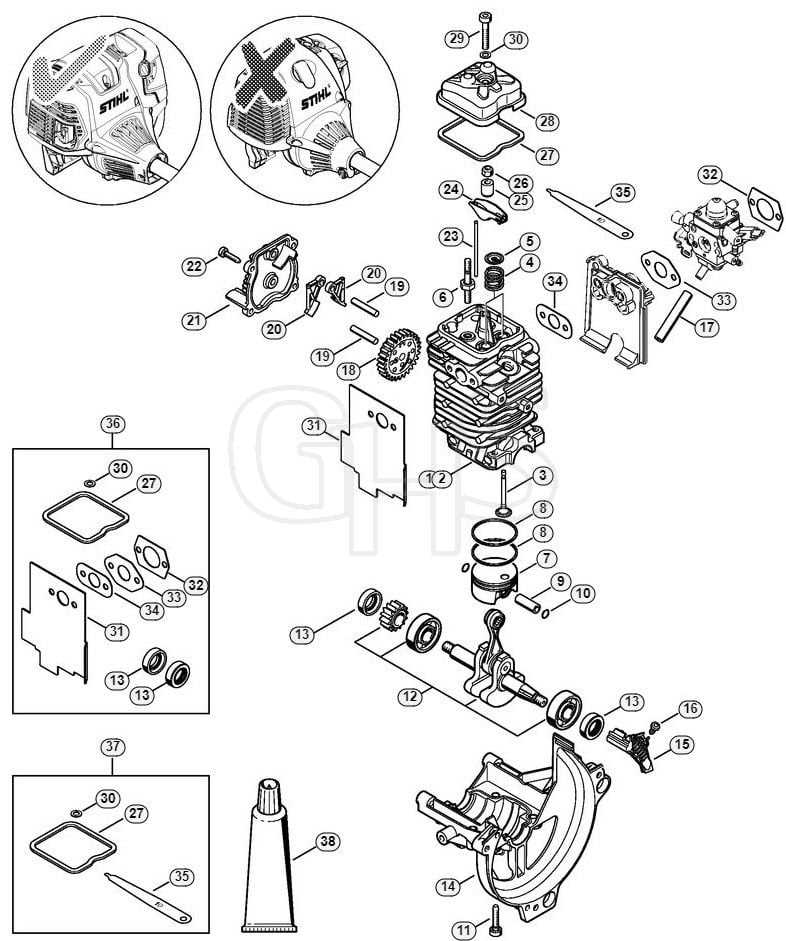

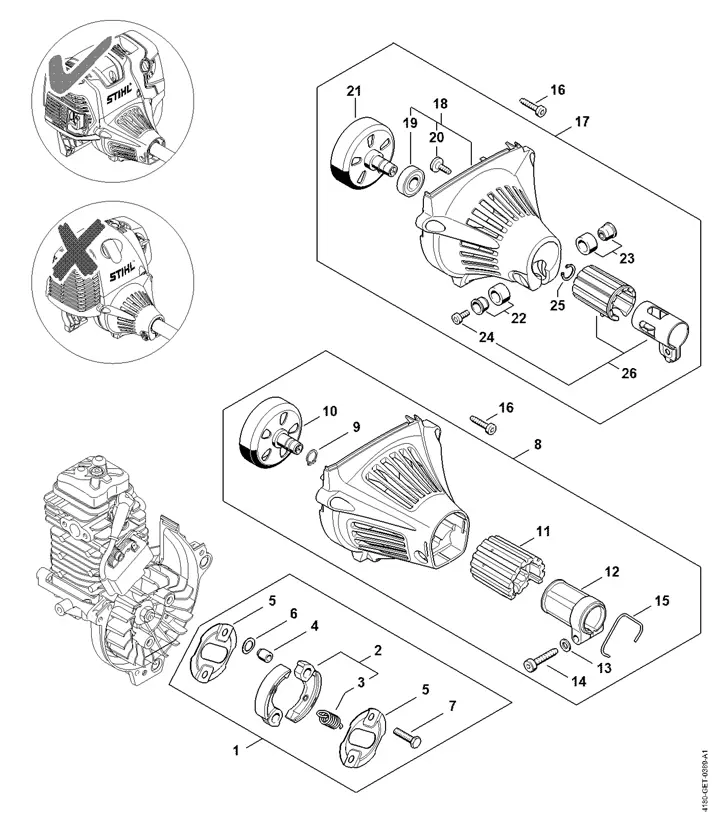

Engine and Power Unit

The engine forms the heart of the tool, providing the necessary power for operation. Regular checks and maintenance of this component can prevent wear and tear, ensuring that the tool continues to run smoothly. Proper fuel mixture and engine cleaning are vital for efficient functioning.

Cutting Mechanism

The cutting system is designed for precision and control. Regular sharpening and lubrication of the cutting mechanism enhance its durability and cutting efficiency. Ensuring the chain is properly adjusted and free of debris also plays a critical role in maintaining peak performance.

Key Parts of the Stihl HT131

The proper maintenance and functioning of this pruning tool depend on several important components that work together. Understanding the main elements is essential for ensuring both efficiency and safety during use.

| Component | Description | ||||||

|---|---|---|---|---|---|---|---|

| Engine | The powerful motor provides the necessary force to drive the cutting mechanism, ensuring smooth operation in tough conditions. | ||||||

| Cutting Blade | Designed for precision and durability, this part makes it possible to trim branches with minimal effort. | ||||||

| Extension Shaft | Allows the user to reach higher areas without the need for ladders, offering both convenience and safety. | ||||||

| Component | Function |

|---|---|

| Cutting Mechanism | Responsible for trimming and cutting, powered by the engine. |

| Power System | Supplies the energy needed to drive the cutting tools. |

| Extension Section | Allows the operator to reach higher

How to Identify HT131 Replacement PartsMaintaining your equipment requires timely replacement of worn-out components. Recognizing which elements need to be changed can extend the lifespan of your machine and ensure its smooth operation. Identifying compatible replacements can be a straightforward process if you understand the specific function and location of each piece. Step 1: Analyze Wear and Tear Step 2: Consult Manufacturer Guidelines Step 3: Match Specifications Maintenance Tips for Stihl HT131 ComponentsProper care and upkeep of any mechanical tool is crucial for ensuring long-term performance and reliability. By following a few simple steps, you can maintain the efficiency of your equipment and prevent unexpected breakdowns. Regular CleaningOne of the most important aspects of maintenance is keeping all parts free from dirt and debris. After each use, make sure to clean the tool thoroughly to remove any buildup. This helps prevent blockages and keeps the components functioning smoothly.

Lubrication and TighteningLubrication is key to minimizing friction between moving elements. Regularly applying a suitable lubricant will extend the lifespan of the equipment. Additionally, ensure that all bolts and fasteners are securely tightened to avoid loose parts during operation.

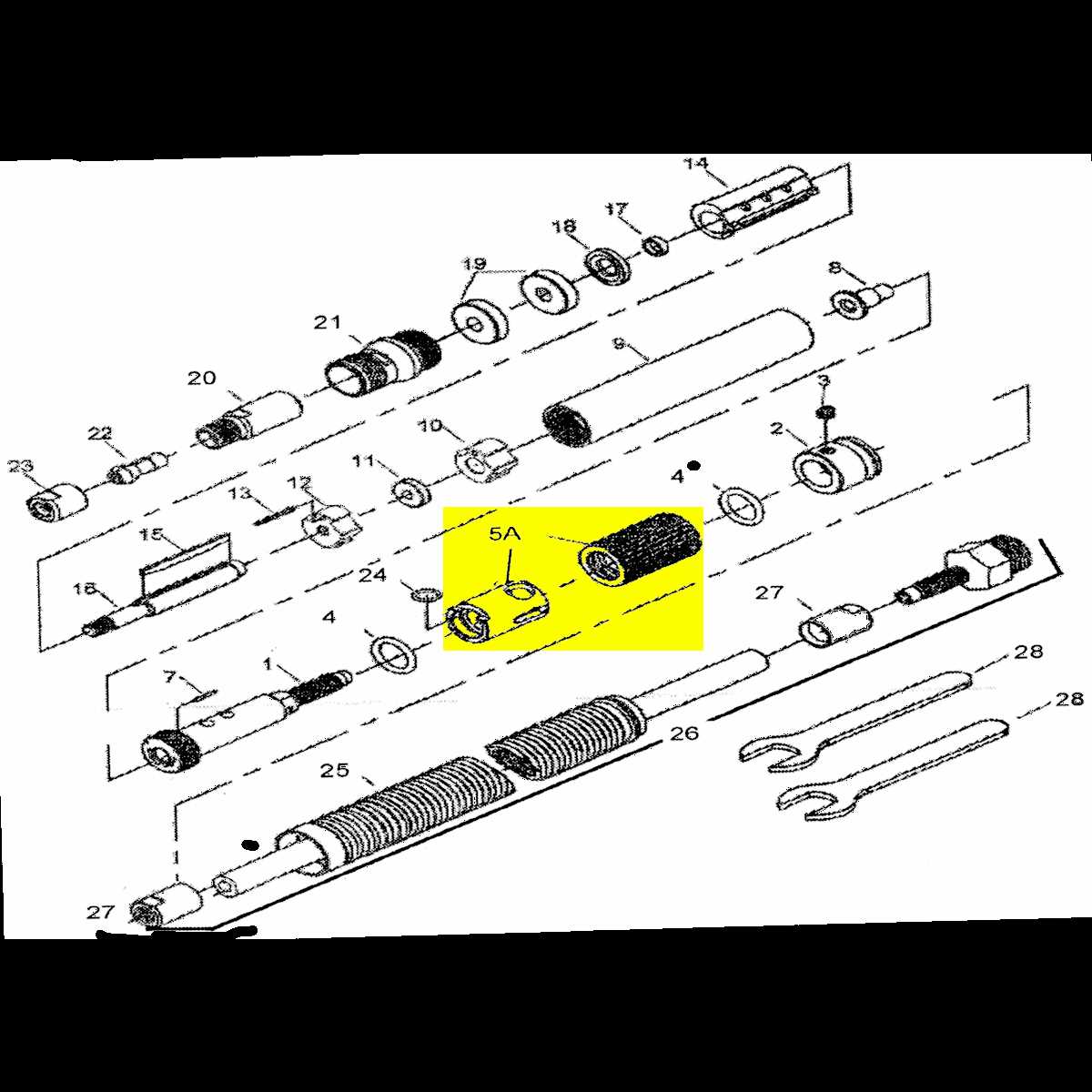

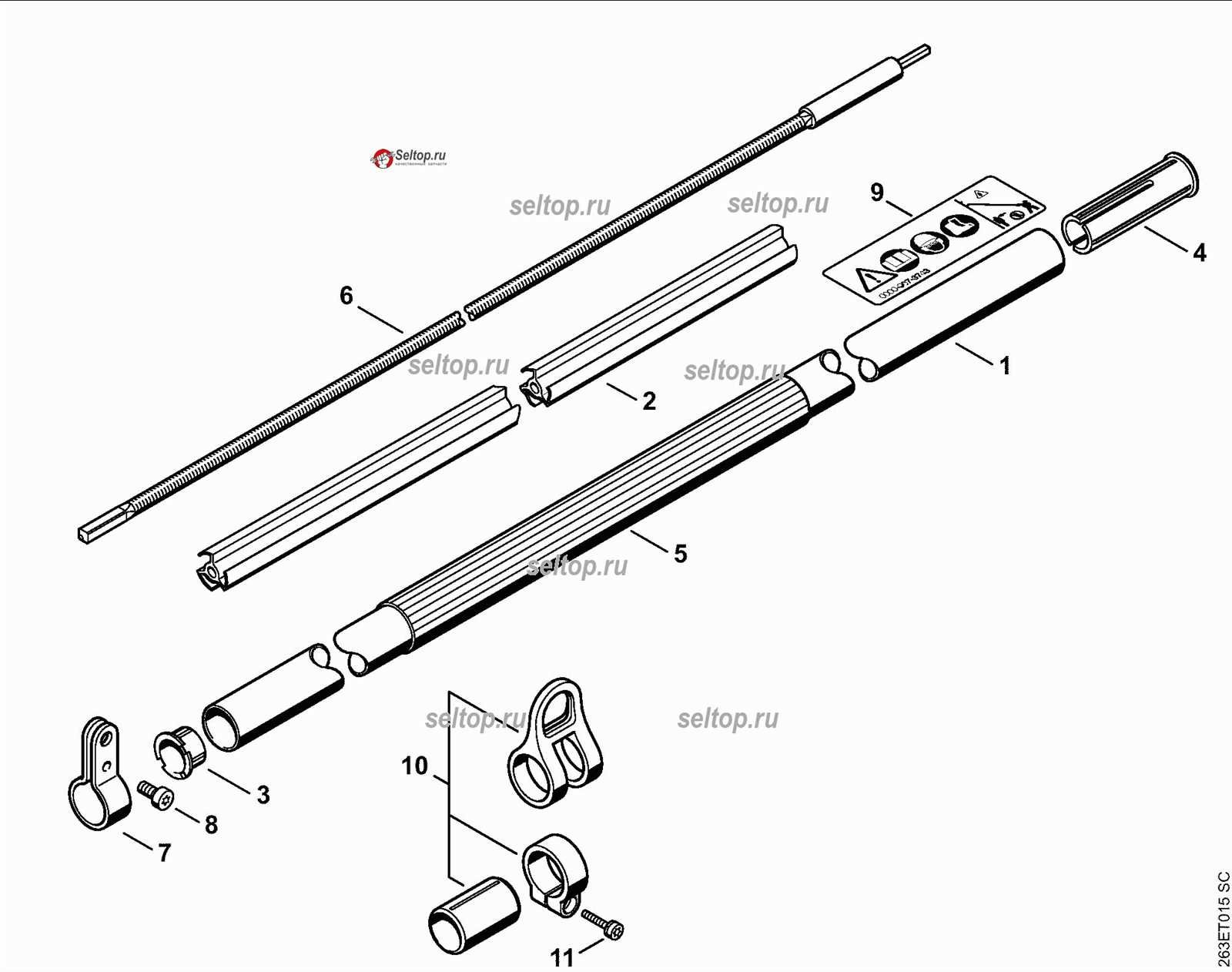

Exploded View of Stihl HT131 Assembly

The detailed illustration of the assembly components provides a clear representation of how each part fits together within the overall structure. This visual guide is essential for understanding the intricate relationships between various elements, facilitating effective maintenance and repairs. In the exploded view, each component is separated and labeled, allowing users to easily identify individual parts and their functions. This approach not only enhances comprehension but also aids in troubleshooting issues that may arise during operation. Understanding the Assembly Familiarizing oneself with the assembly layout is crucial for anyone looking to perform repairs or replacements. By examining this illustration, one can gain insights into the assembly’s configuration, ensuring accurate reassembly after maintenance tasks are completed. Maintenance Tips Regular inspection of components depicted in the illustration is vital for optimal performance. Ensuring that all parts are in good condition and correctly assembled can significantly extend the lifespan of the equipment. Common Issues with HT131 PartsWhen using a particular model of garden equipment, users may encounter various challenges related to its components. Understanding these issues is crucial for maintaining performance and longevity. The following are some frequent problems that may arise with these elements, along with insights into how to address them effectively. Worn-Out Components: Over time, certain elements may show signs of wear, leading to decreased efficiency. Regular inspection can help identify parts that need replacement before they cause further complications. Fuel System Problems: Clogged filters or fuel lines can hinder operation. Keeping the fuel system clean is essential for optimal performance, as obstructions can lead to starting difficulties or stalling. Electrical Failures: Malfunctions in the ignition system can result in starting issues or erratic performance. Checking connections and ensuring that the spark plug is in good condition can help resolve these concerns. Lubrication Issues: Insufficient lubrication can cause excessive friction, leading to premature wear of moving parts. Regular maintenance, including oil changes and grease application, is vital to prevent this issue. Excessive Vibration: If the machinery vibrates excessively during operation, it may indicate an imbalance or loose components. Regularly tightening bolts and checking alignment can mitigate this problem. By being aware of these common challenges and performing routine maintenance, users can enhance the reliability and efficiency of their garden equipment. Where to Find Genuine HT131 Parts

For those in search of authentic components for their outdoor equipment, knowing the right sources is crucial. Quality replacements ensure that your machine operates efficiently and lasts longer, providing the performance you expect. Authorized Dealers

One of the most reliable ways to obtain original components is through authorized dealers. These retailers offer a wide selection of certified replacements and often have knowledgeable staff who can assist you in finding the correct item for your specific model. Official Online StoresAnother excellent option is to explore official online platforms dedicated to selling equipment accessories. These websites typically feature comprehensive catalogs, allowing you to browse through various items conveniently. Additionally, you can often find customer reviews, which can guide your purchasing decisions. Guide to Replacing Stihl HT131 ComponentsReplacing components of a power tool can significantly enhance its performance and extend its lifespan. This section provides an overview of the essential steps and considerations when substituting various elements of your equipment. Proper maintenance not only ensures optimal functionality but also helps in preventing potential issues that may arise from wear and tear. Before starting the replacement process, gather the necessary tools and new components. It is advisable to consult the user manual or online resources specific to your equipment model for guidance. Familiarize yourself with the location and function of each part to ensure a smooth replacement process. Begin by disconnecting the power source to avoid any accidents. Carefully remove the components that need replacement, taking note of their arrangement for easier reassembly. Once the old parts are out, install the new ones in the same configuration. Ensure that each piece is securely fastened and properly aligned to maintain the integrity of the tool. After the new components are installed, reconnect the power source and test the tool to confirm that it operates correctly. Regular maintenance checks and timely replacements can prevent more significant issues in the future, ultimately enhancing your tool’s efficiency. |