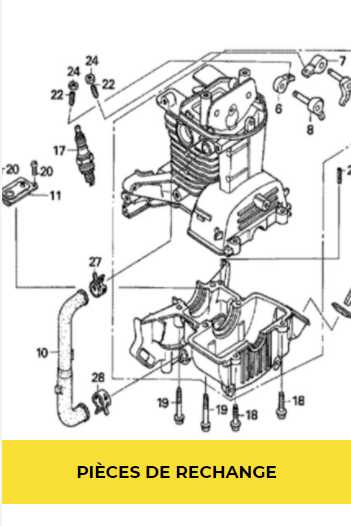

Every machine consists of various elements that work together to ensure optimal performance. Familiarizing yourself with these components is essential for maintaining efficiency and extending the lifespan of your tools. By grasping the arrangement and function of each segment, you can make informed decisions regarding repairs and upgrades.

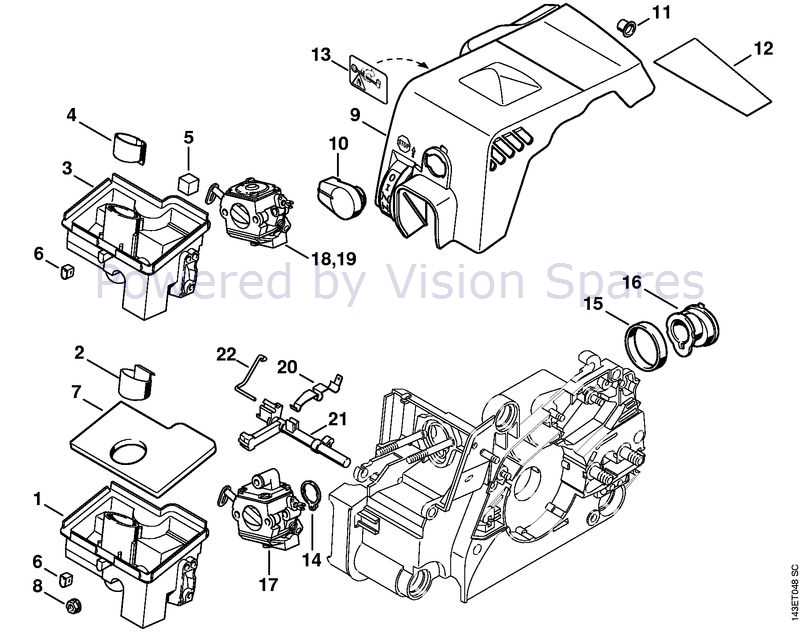

In this section, we will explore a visual representation that outlines the key elements of a specific model. This guide will provide clarity on the intricate assembly, helping you identify individual sections and their roles. Understanding how these pieces interconnect will empower you to troubleshoot issues and enhance your overall experience with the machinery.

Whether you’re an enthusiast or a professional, having a detailed reference for the components is invaluable. This resource aims to simplify your interactions with the machine, ensuring that you can confidently navigate any maintenance or assembly tasks that may arise.

Understanding the Stihl 017 Components

This section aims to provide a comprehensive overview of the various elements that make up a specific model of a power tool. Recognizing the different components is crucial for proper maintenance, troubleshooting, and ensuring optimal performance of the equipment.

Each element plays a vital role in the functionality of the tool, contributing to its overall efficiency. Below are the primary categories of components found in this machinery:

- Engine: The heart of the tool, responsible for generating power and enabling movement.

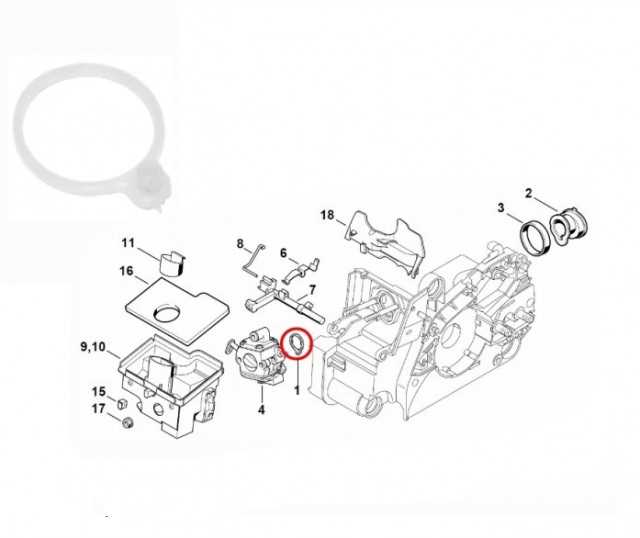

- Fuel System: Includes the tank and carburetor, essential for mixing and delivering fuel to the engine.

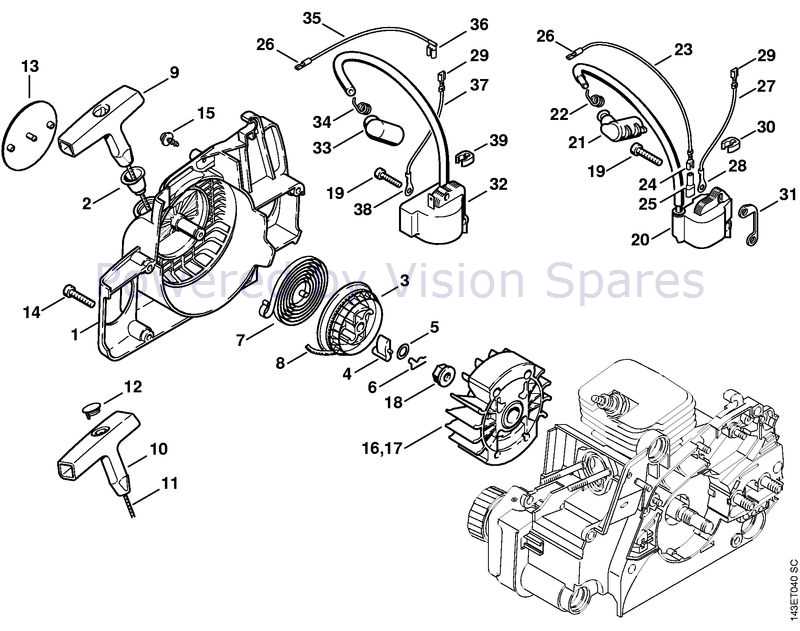

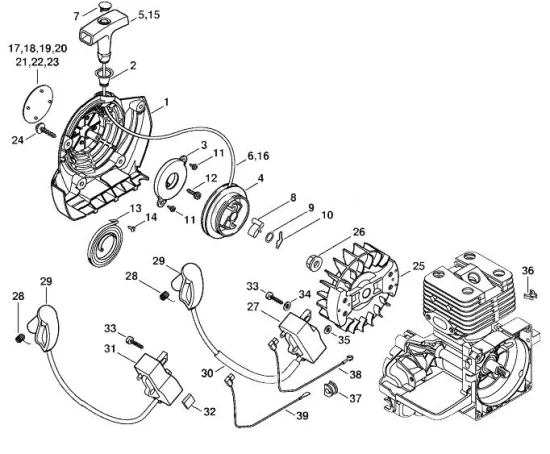

- Ignition System: Comprising the spark plug and ignition coil, this system is critical for starting and running the engine.

- Cutting Mechanism: This section involves the chain and bar, which perform the actual cutting tasks.

- Handle and Housing: Provides user control and protects internal components from damage.

Understanding these components will enhance your ability to operate and maintain the tool effectively. Regular inspections and knowledge of each part can lead to better performance and longevity of the equipment.

Importance of Parts Diagrams

Understanding the intricate layout of a machine is essential for effective maintenance and repair. Visual representations serve as valuable tools for identifying components and their interconnections, facilitating easier troubleshooting and assembly. By utilizing these graphical aids, users can enhance their comprehension of the device’s structure, leading to more efficient handling and fewer mistakes during repairs.

Enhanced Understanding

Visual aids simplify complex systems, making it easier to grasp how various elements interact. This clarity allows technicians and hobbyists alike to approach maintenance tasks with confidence. When the arrangement of each segment is clear, the risk of errors is significantly reduced, promoting a more successful repair experience.

Facilitating Repairs

Using a visual representation of components not only aids in the identification of parts but also streamlines the repair process. Technicians can quickly reference the layout to locate specific elements without wasting time searching through manuals or guessing. This efficiency ultimately saves time and resources, making repairs more cost-effective.

| Benefits | Details |

|---|---|

| Improved Clarity | Visual aids help simplify complex structures for better understanding. |

| Time Efficiency | Quick access to layout information reduces repair time. |

| Reduced Errors | Clear identification of components minimizes mistakes during repairs. |

Identifying Common Stihl 017 Issues

Understanding the typical problems that can arise with your equipment is essential for maintaining optimal performance. Various factors can lead to malfunctions, affecting the efficiency and longevity of your device. By recognizing these issues early, users can ensure timely repairs and enhance their machine’s functionality.

1. Difficulty Starting: One of the most frequent complaints is the inability to start the engine. This can result from issues such as fuel delivery problems, a clogged air filter, or a faulty spark plug.

2. Poor Acceleration: If the device struggles to accelerate, it may indicate fuel mixture problems or air leaks in the fuel system. Checking for obstructions in the carburetor can also be beneficial.

3. Excessive Vibration: An unusual level of vibration during operation can signal loose components or misalignment. Ensuring that all parts are secure and well-maintained can mitigate this issue.

4. Smoke Emission: If excessive smoke is emitted, it could mean an oil leak or an incorrect fuel mix. Monitoring fluid levels and using the appropriate mixture can help prevent this problem.

5. Chain Stopping: A chain that frequently stops may indicate dull teeth or insufficient lubrication. Regular maintenance and timely sharpening are crucial to avoid disruptions during use.

By being aware of these common challenges, users can take proactive measures to keep their equipment running smoothly and efficiently.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing common issues with your device. Following a structured methodology can help ensure that you address problems effectively while minimizing the risk of further complications. Each step is designed to guide you through the repair process, making it easier for you to achieve optimal results.

Gather Necessary Tools

Before starting the repair, it’s essential to collect all required tools and components. Ensure you have a reliable set of screwdrivers, wrenches, and replacement elements on hand. A clean workspace will facilitate an efficient repair process and prevent the loss of small parts.

Follow the Repair Steps

Begin by carefully disassembling the unit, taking note of how each component is fitted together. Documenting the arrangement can be beneficial when reassembling. Inspect each part for damage, and replace any defective components as needed. Once repairs are completed, reassemble the device meticulously, ensuring that all parts are securely fastened. Finally, conduct a functionality test to confirm that the repair was successful.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Understanding where to locate these original items can save you time and money while guaranteeing compatibility and reliability.

Here are some reliable avenues to explore:

- Authorized Dealers: Visiting a certified retailer is one of the best ways to obtain authentic items. These establishments often have trained staff who can provide assistance and advice tailored to your needs.

- Official Website: Many manufacturers have an online platform where you can browse and purchase genuine components directly. This option often features detailed product descriptions to help you make informed choices.

- Reputable Online Marketplaces: While shopping online, ensure that the platform is well-known and trusted. Look for sellers who specialize in original items and have positive customer feedback.

- Local Repair Shops: Sometimes, local technicians have access to authentic components or can assist you in ordering them. Establishing a relationship with a trusted shop can lead to valuable insights and recommendations.

By exploring these options, you can ensure that your equipment remains in top condition with the right components. Always prioritize quality and authenticity to maintain the performance and safety of your machinery.

Tools Needed for Maintenance

Regular upkeep of your equipment is essential to ensure its longevity and optimal performance. Having the right tools on hand not only simplifies the maintenance process but also enhances the efficiency of your tasks. Below is a comprehensive list of essential tools you will need to perform maintenance effectively.

Essential Tools

- Wrench set: Useful for tightening and loosening various nuts and bolts.

- Screwdriver set: A variety of sizes and types (flathead and Phillips) will help access different components.

- Socket set: Ideal for quickly removing and installing fasteners.

- Filtration tools: Needed for cleaning and replacing filters to maintain proper airflow.

Additional Supplies

- Lubricants: Ensure smooth operation of moving parts.

- Cleaning brushes: Helpful for removing dirt and debris from hard-to-reach areas.

- Safety equipment: Goggles and gloves to protect yourself during maintenance tasks.

- Measuring tools: Calipers or rulers for precise adjustments and replacements.

Having these tools readily available will facilitate a seamless maintenance experience, allowing you to keep your equipment in top shape.

Frequently Asked Questions

This section addresses common inquiries related to the components and assembly of a popular outdoor power tool. It aims to provide clarity and support for users seeking guidance on maintenance, repair, and optimal usage of their equipment.

What should I do if I cannot find a specific component for my tool?

If you’re struggling to locate a particular part, consider checking with authorized retailers or online marketplaces that specialize in outdoor equipment. It may also be helpful to consult user manuals or community forums for alternative sources.

How can I ensure that I am using the correct components?

To verify compatibility, always refer to the manufacturer’s specifications or documentation. Cross-checking model numbers and part identifiers can prevent potential issues during assembly or operation.

Are there any tips for maintaining my equipment?

Regular maintenance is key to prolonging the lifespan of your tool. Ensure you clean it after each use, perform routine inspections, and replace worn components promptly to maintain optimal performance.

What should I do if my equipment is not functioning properly?

If you encounter issues, start by checking common problems such as fuel supply, air filter condition, and spark plug functionality. If the problem persists, consulting a professional technician may be necessary for in-depth diagnosis and repair.

Customer Reviews on Stihl 017

This section focuses on user experiences with a popular model in the gardening tools category. Many enthusiasts and professionals share their thoughts on performance, durability, and overall satisfaction. Reviews provide valuable insights into how well this equipment meets the needs of its users.

| Reviewer | Rating | Comments |

|---|---|---|

| John D. | 5/5 | Excellent tool for heavy-duty tasks. Easy to start and maintain! |

| Emily R. | 4/5 | Great performance but a bit heavier than expected. |

| Mike L. | 3/5 | Decent for occasional use, but not as powerful as I hoped. |

| Sarah T. | 5/5 | Love this tool! It has made my yard work much easier. |

| David P. | 4/5 | Good value for money. I recommend it to friends. |

Comparing Stihl 017 with Other Models

When evaluating the efficiency and performance of a particular model, it is essential to consider its features and specifications in relation to other similar devices. This comparison allows users to make informed decisions based on their specific needs and preferences.

Performance and Efficiency

The model in question offers impressive power and operational efficiency, making it suitable for various tasks. In contrast, some other devices may focus more on lightweight design or enhanced fuel efficiency. Users seeking robust performance may find that this model outperforms its counterparts in challenging conditions, while others might excel in ease of handling and maneuverability.

Durability and Maintenance

Another critical factor is the durability of the equipment. This particular model is designed with high-quality materials that enhance its longevity. While some alternatives may offer comparable performance, they often require more frequent maintenance or replacement parts. Evaluating these aspects can significantly impact the overall user experience and satisfaction.