The efficient functioning of outdoor machinery relies heavily on the intricate arrangement of its components. A clear visual representation of these elements can greatly enhance one’s ability to maintain and repair the equipment. By exploring such layouts, users can familiarize themselves with the critical parts that contribute to overall performance.

For enthusiasts and professionals alike, having access to detailed illustrations can be a game-changer. These visuals serve as guides, allowing individuals to pinpoint specific components, ensuring that every piece is in optimal condition. Moreover, they facilitate a deeper understanding of how each part interacts within the machine, leading to better upkeep and longevity.

Whether you’re undertaking routine maintenance or addressing more significant issues, a thorough comprehension of the component structure is invaluable. Resources that outline these arrangements empower users to tackle challenges with confidence and precision, ultimately enhancing their experience with outdoor machinery.

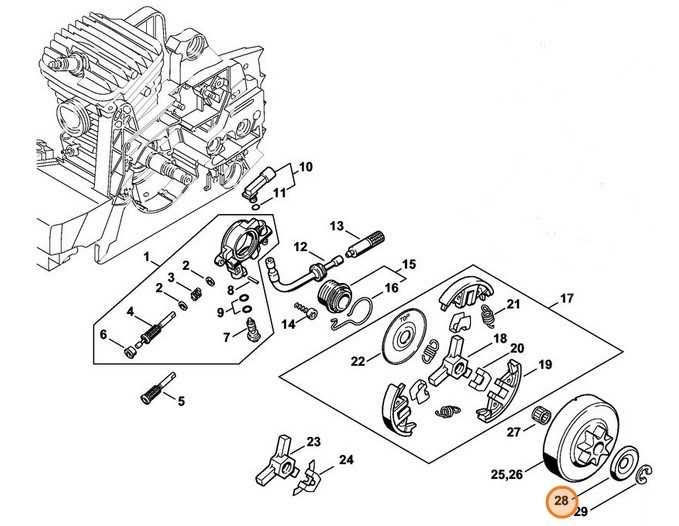

Understanding Stihl 028 WB Components

Exploring the intricate elements of a specific outdoor tool provides insights into its functionality and efficiency. Each component plays a vital role in ensuring optimal performance, contributing to the overall user experience. This knowledge is essential for maintenance and troubleshooting, enhancing longevity and reliability.

Main Elements

Familiarizing yourself with the core components can help in understanding how they interact within the system. Below is a summary of the key parts and their functions:

| Component | Function |

|---|---|

| Engine | Drives the machine, providing necessary power. |

| Fuel System | Stores and delivers fuel to the engine for combustion. |

| Cutting Mechanism | Enables efficient cutting and trimming of materials. |

| Ignition System | Initiates the combustion process within the engine. |

Importance of Each Component

Understanding the significance of each part not only aids in effective troubleshooting but also empowers users to perform routine maintenance. This knowledge ultimately leads to a more effective and enjoyable operation of the tool.

Key Features of Stihl 028 WB

This powerful tool is designed to deliver exceptional performance and reliability for various tasks. Its robust construction ensures longevity, making it suitable for both professional and residential use.

One of the standout attributes is its efficient engine, which provides ample power while maintaining fuel efficiency. Additionally, the ergonomic design enhances user comfort, allowing for prolonged operation without strain.

Another significant feature is its versatility, accommodating a range of attachments that expand its functionality. The easy-to-use controls simplify operation, making it accessible for users of all skill levels.

Moreover, the maintenance aspects are user-friendly, ensuring that upkeep is straightforward and not overly time-consuming. This tool is engineered to tackle demanding jobs with ease, making it a reliable choice for anyone in need of a high-performance machine.

Importance of Parts Diagrams

Visual representations of component layouts are essential tools for understanding the intricate assembly of machinery. They serve as guides, facilitating the identification and organization of various elements within a device, thus ensuring efficient maintenance and repair processes.

Utilizing these illustrations offers numerous benefits, including:

- Enhanced Understanding: Clear visuals help users comprehend the relationship between different components, making it easier to grasp complex structures.

- Efficient Troubleshooting: When issues arise, these representations allow for quick identification of faulty parts, streamlining the repair process.

- Improved Organization: Visual aids assist in keeping track of numerous elements, ensuring that nothing is overlooked during reassembly.

- Time-Saving: With a reference point, users can significantly reduce the time spent searching for specific components or understanding how they fit together.

- Cost-Effectiveness: By minimizing errors and the time needed for repairs, these tools can ultimately lead to cost savings in maintenance efforts.

In conclusion, effective illustrations of component layouts are invaluable resources that contribute to more informed and efficient handling of machinery, promoting longevity and optimal performance.

Common Issues with Stihl 028 WB

When operating outdoor power equipment, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems can aid in prompt resolution and maintenance, ensuring that the tool operates smoothly.

Engine Performance Problems

One frequent issue involves the engine not starting or running irregularly. This can stem from several factors, including clogged air filters or fuel lines, improper fuel mixture, or spark plug malfunctions. Regular maintenance, such as cleaning or replacing filters and checking the fuel composition, can help mitigate these issues.

Chain and Bar Wear

Excessive wear on the cutting chain and guide bar can also occur. Symptoms include poor cutting performance or the chain slipping. Keeping the chain sharpened and properly tensioned is crucial. Additionally, using appropriate lubricant can significantly extend the lifespan of these components.

Addressing these common problems promptly can enhance the longevity and efficiency of the equipment, making it a reliable tool for any user.

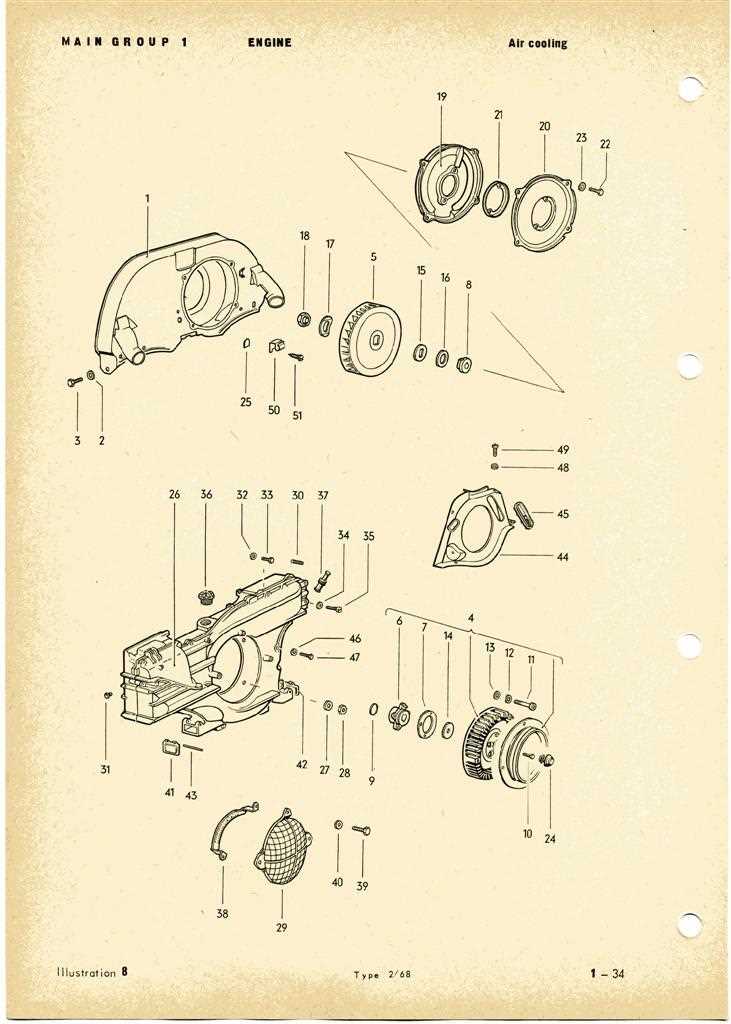

How to Interpret Parts Diagrams

Understanding technical illustrations is essential for anyone involved in maintenance or repair tasks. These visual representations serve as invaluable resources, providing clarity on how various components interact within a system. By learning to read these graphics effectively, you can streamline your work and ensure that repairs are done accurately.

Decoding the Visual Elements

Every illustration includes specific symbols and numbers that correspond to various components. Take the time to familiarize yourself with the legend, which usually explains the markings used. Colors often signify different categories, such as electrical versus mechanical parts. Additionally, numbers typically indicate the order of assembly or disassembly, which is crucial for successful repairs.

Cross-Referencing with Lists

Alongside these illustrations, there may be accompanying lists that provide detailed descriptions of each component. Use these lists to cross-reference the visuals, ensuring you understand what each part does and how it fits into the larger assembly. This dual approach helps in identifying what you need for repairs and can prevent errors in reassembly.

Where to Find PDF Resources

Locating reliable documents and manuals for various equipment can enhance your understanding and maintenance capabilities. There are several effective avenues to explore when searching for these valuable resources.

- Official Manufacturer Websites: Most companies provide a dedicated section for manuals and documentation. This is often the most trustworthy source for accurate information.

- Online Forums and Communities: Joining specialized forums can connect you with enthusiasts and experts who may share links or files.

- Document Sharing Platforms: Websites that host user-uploaded files may have the materials you need. Always verify the reliability of the source.

- Retailers and Dealers: Authorized dealers often have access to technical documents and may assist customers in obtaining them.

By utilizing these resources, you can effectively access the information necessary for your equipment maintenance and operation.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor power equipment requires consistent and thoughtful upkeep. By following a few key practices, you can extend the lifespan of your machine and maintain its peak performance. Regular attention to maintenance not only helps in avoiding costly repairs but also enhances the overall functionality of the tool.

First, always refer to the manufacturer’s guidelines for specific care instructions. These recommendations are tailored to optimize performance and ensure safety. Regularly inspect your equipment for wear and tear, paying particular attention to crucial components such as filters, spark plugs, and blades. Replacing worn parts promptly can prevent further damage and enhance reliability.

Additionally, keep your tools clean and free of debris. Dirt and grime can impede functionality and lead to overheating or other mechanical issues. After each use, wipe down surfaces and check for any obstructions. Lubricating moving parts at regular intervals will also reduce friction, promoting smoother operation and preventing premature wear.

Finally, store your equipment in a dry, protected space when not in use. Proper storage conditions help prevent rust and other environmental damage. Following these simple yet effective practices will help ensure your outdoor equipment remains in excellent condition for years to come.

Upgrading Components for Performance

Enhancing the functionality of outdoor power equipment can significantly improve its efficiency and overall effectiveness. By focusing on specific elements, users can experience increased power output, better fuel economy, and extended lifespan of their machines. This section explores various upgrades that can lead to remarkable performance improvements.

Key Components to Consider

- Air Filters: Upgrading to a high-flow air filter can enhance airflow, leading to better combustion and increased power.

- Fuel System: Installing a high-performance fuel pump can ensure optimal fuel delivery, contributing to smoother operation and improved efficiency.

- Exhaust Systems: A performance exhaust can reduce back pressure, allowing the engine to expel gases more effectively and enhancing overall power.

- Spark Plugs: Switching to premium spark plugs can improve ignition efficiency, resulting in better acceleration and reduced emissions.

Benefits of Upgrading

- Enhanced Power: Upgraded components often lead to noticeable increases in engine output.

- Improved Efficiency: Many enhancements can contribute to better fuel utilization, saving money in the long run.

- Longevity: High-quality parts may offer greater durability, reducing the need for frequent replacements.

- Customizability: Users can tailor upgrades to meet specific needs, whether for professional use or personal projects.

Investing in these enhancements not only elevates performance but also enriches the overall user experience, making tasks easier and more enjoyable.

Comparing Stihl 028 WB Models

This section explores the various iterations of a popular tool, highlighting key differences and similarities. Understanding these variations can assist users in making informed decisions based on their specific needs and preferences.

Model Variations: Each version of the tool has unique features that cater to different applications. For instance, some may prioritize lightweight design, while others focus on enhanced power output. Assessing these characteristics helps users select the best fit for their tasks.

Performance Metrics: Performance can vary significantly among the models. Factors such as engine size, fuel efficiency, and handling ease play crucial roles in determining which version excels in particular environments. Evaluating these metrics ensures optimal performance and user satisfaction.

Durability and Maintenance: Longevity is another critical aspect to consider. Certain models may be built with sturdier materials or designed for easier maintenance, impacting overall user experience. Comparing durability features can save time and resources in the long run.