In the realm of automotive engineering, a comprehensive understanding of the various elements involved in fuel delivery mechanisms is crucial for optimal performance. These intricate systems play a vital role in ensuring that engines receive the correct amount of fuel at the right moment, thereby enhancing efficiency and reducing emissions. Analyzing the structure and functionality of these components allows for better maintenance and troubleshooting practices.

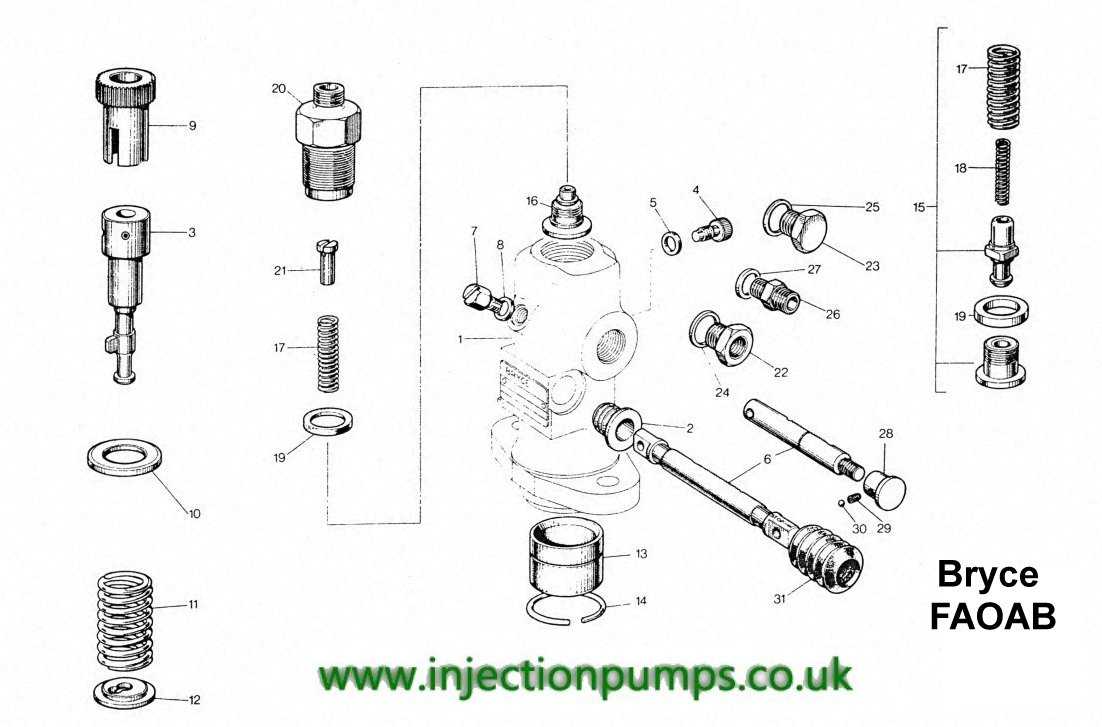

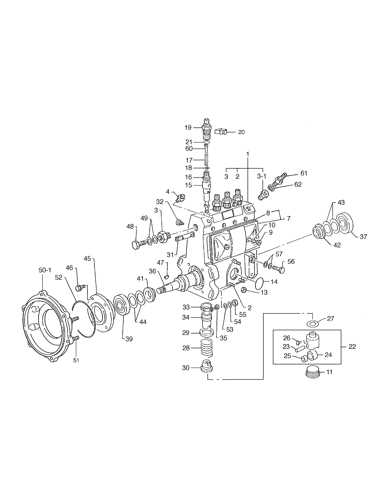

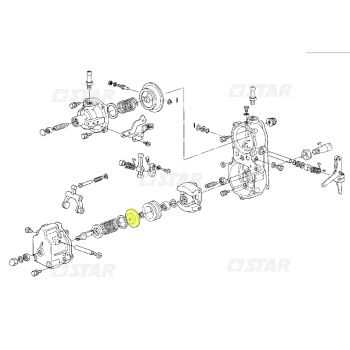

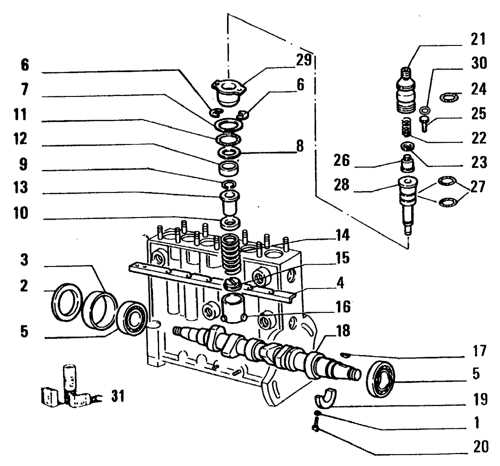

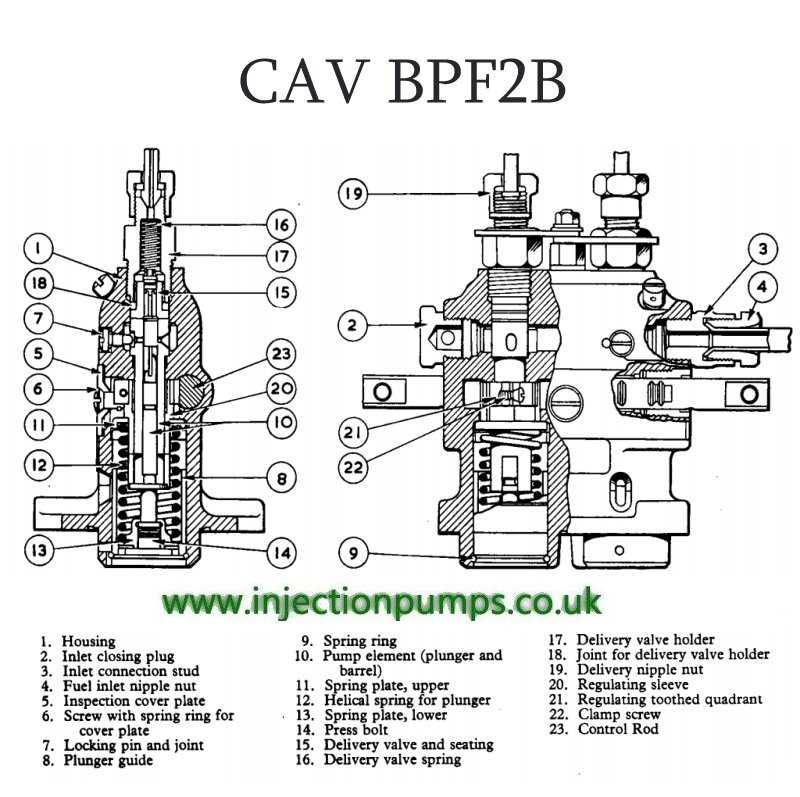

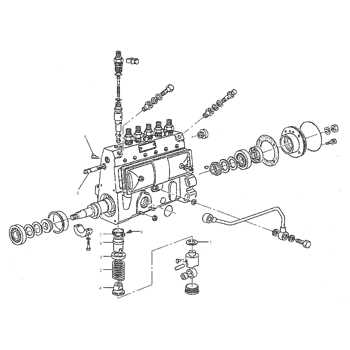

One of the key aspects of mastering these systems is familiarity with their intricate schematics. Visual representations of component arrangements provide valuable insights into how each element interacts within the assembly. By studying these layouts, technicians can pinpoint issues, streamline repairs, and ensure that every part functions harmoniously.

Furthermore, delving into the specifics of these systems highlights the importance of precision engineering. Each element is designed to perform distinct functions, and understanding their roles facilitates a deeper appreciation of the overall system’s complexity. This knowledge not only aids in effective repair strategies but also informs best practices for routine maintenance, ultimately extending the lifespan of the machinery.

Understanding Zexel Injection Pump Components

Grasping the intricacies of fuel delivery systems is essential for anyone involved in automotive maintenance or engineering. Each element plays a crucial role in the overall functionality, ensuring efficient operation and performance. This section aims to illuminate the various components and their interconnections within the assembly.

Key components include:

- Fuel metering device

- Drive mechanism

- Pressure regulation unit

- Return flow circuit

- Control valves

Each of these parts serves specific functions:

- Fuel metering device: This unit regulates the amount of fuel delivered to the engine based on demand.

- Drive mechanism: Converts rotational energy into the necessary movement to operate other components.

- Pressure regulation unit: Maintains optimal pressure within the system, preventing damage and ensuring efficiency.

- Return flow circuit: Directs excess fuel back to the tank, aiding in temperature regulation and efficiency.

- Control valves: Manage flow direction and volume, crucial for adapting to varying engine conditions.

Understanding these elements is vital for diagnosing issues and performing effective maintenance. A thorough knowledge of their functions and interactions will lead to better performance and longevity of the system.

Functionality of the Injection Pump

The essence of this device lies in its ability to regulate the flow and delivery of fuel, ensuring optimal performance of the engine. This mechanism plays a crucial role in the overall efficiency and power output, contributing significantly to the vehicle’s functionality.

| Key Component | Function |

|---|---|

| Delivery Valve | Controls the flow of fuel into the combustion chamber. |

| Piston | Pressurizes the fuel for effective atomization. |

| Timing Mechanism | Ensures fuel is delivered at the correct moment for combustion. |

| Governor | Regulates engine speed and maintains stability. |

By understanding the roles of each component, one can delve into the ultimate intricacies of how this essential system operates within an engine.

Key Parts of Zexel Pumps

This section delves into the essential components that contribute to the efficient functioning of fuel delivery systems. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal performance in various applications.

| Component | Description |

|---|---|

| Feed Pump | Responsible for drawing fuel from the tank and supplying it to the system at a regulated pressure. |

| Control Unit | Regulates the amount of fuel delivered based on engine demand, adjusting flow as needed for efficiency. |

| Plunger | Creates pressure within the system, facilitating the delivery of fuel into the combustion chamber. |

| Timing Mechanism | Ensures that fuel is injected at the precise moment during the engine cycle for optimal combustion. |

| Nozzle | Atomizes the fuel, allowing for better mixing with air and enhancing combustion efficiency. |

Common Issues with Zexel Pumps

In the realm of fuel delivery systems, certain challenges can arise, impacting performance and efficiency. Recognizing these common difficulties can aid in effective troubleshooting and maintenance, ensuring optimal functionality over time.

- Fuel Contamination: The presence of impurities can cause clogs and reduced efficiency, leading to significant performance issues.

- Wear and Tear: Over time, components may deteriorate, resulting in leaks and inconsistent operation.

- Timing Issues: Misalignment in the timing of the mechanism can lead to poor combustion and increased emissions.

Addressing these problems promptly can help maintain the system’s integrity and prolong its lifespan.

- Regular Inspections: Routine checks can help identify wear early.

- Quality Fuel: Using clean, high-quality fuel can minimize contamination risks.

- Professional Servicing: Seeking expert assistance for complex issues ensures proper handling and repairs.

Maintenance Tips for Longevity

Ensuring the extended lifespan of mechanical components requires regular attention and proper care. Implementing a consistent maintenance routine can significantly enhance performance and reduce the risk of failures. This section offers practical suggestions to keep your systems running smoothly and efficiently over time.

Regular Inspections

Frequent evaluations are essential for identifying potential issues before they escalate. Look for signs of wear, leaks, or unusual noises. Early detection allows for timely interventions, preventing costly repairs or replacements down the line.

Proper Lubrication

Maintaining adequate lubrication is crucial for reducing friction and wear. Use the recommended lubricants and adhere to the specified intervals for application. Regularly check lubricant levels and ensure that all moving parts are adequately coated to promote seamless operation.

Incorporating these practices into your routine will help extend the life of your equipment and maintain optimal functionality.

Identifying Pump Diagrams Online

Locating detailed schematics and illustrations for various mechanical systems can be a straightforward process with the right approach. Understanding how to navigate online resources effectively can save time and enhance your ability to troubleshoot or repair machinery. Utilizing specific keywords and filters can help you find the most relevant visuals and manuals tailored to your needs.

Key Resources for Finding Visuals

There are several platforms that specialize in providing technical drawings and schematics. These resources often include user forums, technical databases, and official manufacturer websites. Exploring these avenues can lead to a wealth of information.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often offer downloadable manuals and technical guides. |

| User Forums | Community-driven platforms where users share knowledge and files. |

| Technical Databases | Comprehensive repositories with search functionalities for schematics. |

Search Techniques for Success

When searching for illustrations, using precise terms related to the specific mechanical system can yield better results. Additionally, including the model number or part specifics will refine the search, helping you to locate the exact visual representation you need.

How to Read Pump Diagrams

Understanding technical illustrations is essential for effective maintenance and troubleshooting. These visuals often serve as guides to the intricate components and their relationships within a system. Mastering how to interpret these representations can enhance your ability to diagnose issues and carry out repairs with confidence.

First, familiarize yourself with the symbols used in the illustration. Each icon typically represents a specific component, and knowing what they signify is crucial. Pay attention to labels and legends, as they provide additional context and clarification.

Next, observe the connections between the elements. Arrows and lines indicate flow directions or interactions, guiding you on how the system operates. Understanding these pathways can reveal potential points of failure or areas requiring attention.

Finally, consider the overall layout. A well-organized visual will allow you to trace processes easily. By developing a systematic approach to analyzing these illustrations, you can significantly improve your troubleshooting skills and ensure the system’s optimal performance.

Importance of Quality Replacement Parts

Ensuring the reliability and efficiency of any machinery relies heavily on the components used. High-quality replacements not only enhance performance but also prolong the lifespan of the equipment. Utilizing substandard alternatives can lead to frequent breakdowns and increased maintenance costs, undermining operational efficiency.

Performance and Efficiency

Quality components are designed to meet stringent specifications, guaranteeing optimal functionality. Investing in superior replacements results in improved efficiency, which can significantly impact productivity. Consistent performance reduces the likelihood of unexpected failures, allowing for smoother operations.

Cost-Effectiveness

While cheaper options may seem appealing initially, they often lead to higher expenses in the long run due to repairs and replacements. Choosing reliable components ultimately saves money and resources, making it a more wise investment for any operation.

Comparing Zexel with Other Brands

This section explores the differences and similarities between a specific manufacturer and its competitors in the fuel delivery sector. By examining performance, reliability, and technological advancements, we can better understand what sets these brands apart in the marketplace.

Performance Metrics

When assessing efficiency, brands often demonstrate varying levels of reliability under different operational conditions. Analyzing fuel efficiency and maintenance intervals can provide insight into overall performance.

Technological Innovations

Technological advancements play a crucial role in distinguishing manufacturers. Innovative designs and features can enhance user experience and longevity of the components.

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Fuel Efficiency | 85% | 80% | 90% |

| Maintenance Frequency | 5000 miles | 6000 miles | 7000 miles |

| Warranty Period | 2 years | 1 year | 3 years |