When it comes to maintaining small engines, having a clear understanding of how individual elements are positioned and interact with each other is crucial. Each piece plays a vital role in ensuring smooth operation, and knowing where these elements are located helps in both routine upkeep and troubleshooting. A detailed layout can guide even the most complex repairs, making the process much easier.

Recognizing the configuration of essential mechanical elements allows for quicker identification of issues, reducing downtime and preventing potential damage. With a clear layout at hand, the process of assembling or replacing certain items becomes more efficient, ensuring that everything fits perfectly as intended. This knowledge empowers anyone to maintain their equipment with greater confidence and precision.

Overview of Kohler CV16S Engine Components

The engine is composed of several key elements that work together to ensure optimal performance. Each component plays a vital role in the overall functionality, from the core mechanisms driving power generation to the systems that manage fuel and airflow. Understanding how these elements interact helps in maintaining and troubleshooting the machine effectively.

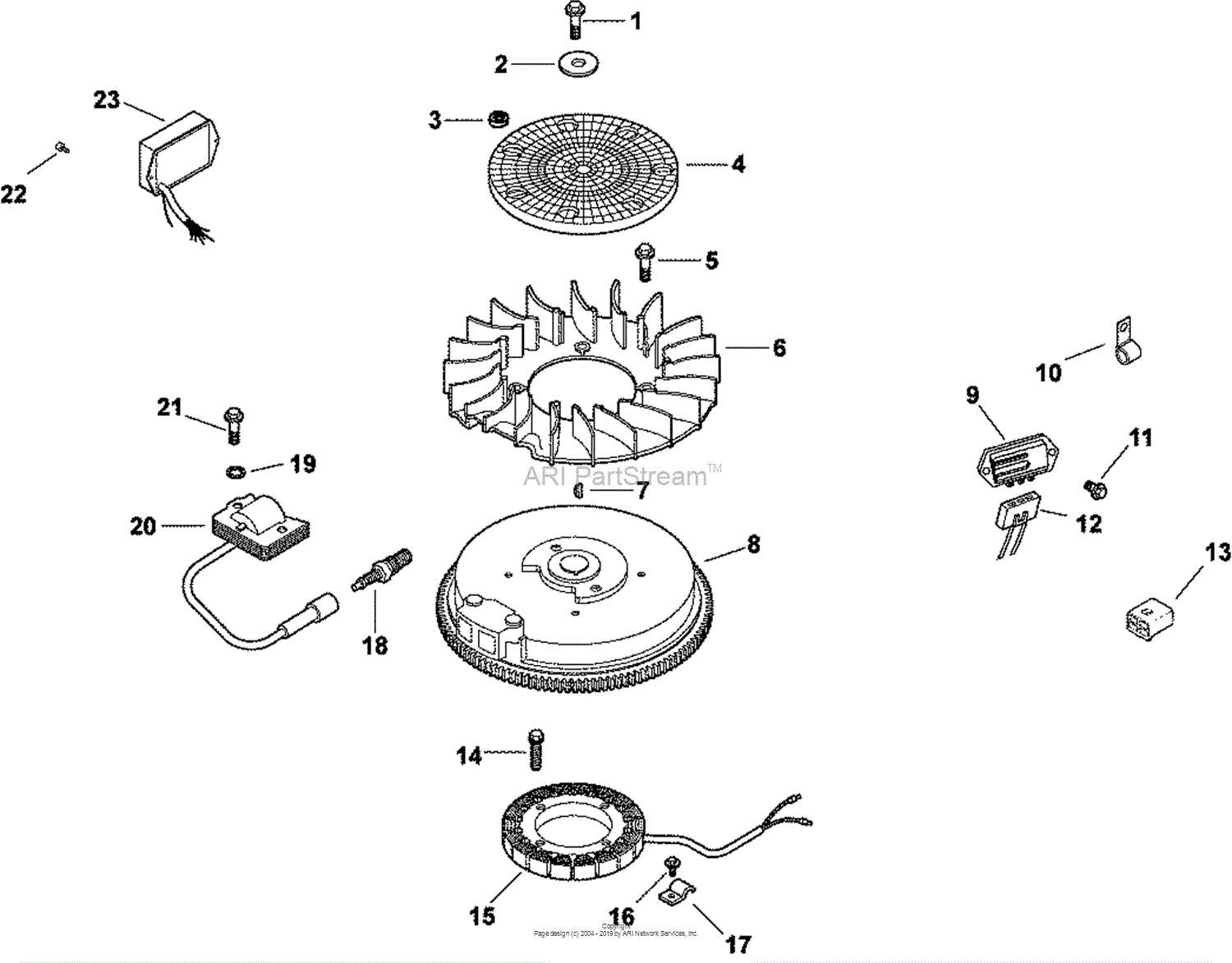

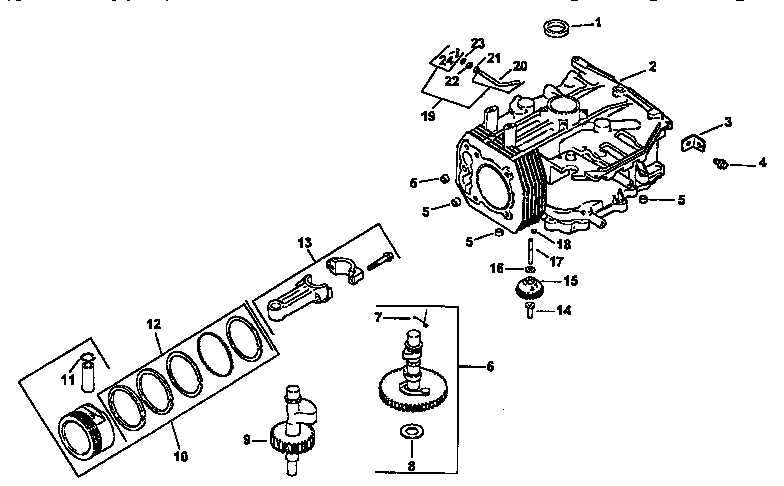

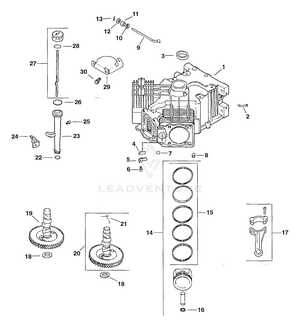

Power Generation Components: The core systems responsible for converting fuel into mechanical energy are crucial for the engine’s operation. These include mechanisms that manage combustion and energy transfer to various moving parts.

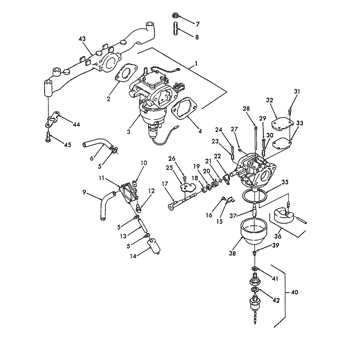

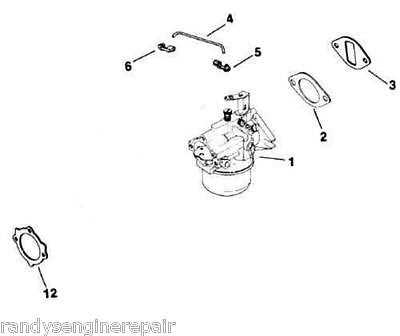

Air and Fuel Management: Proper regulation of air and fuel is essential for efficient functioning. Specific components handle the intake, mixing, and distribution of these elements, ensuring balanced combustion and smooth operation.

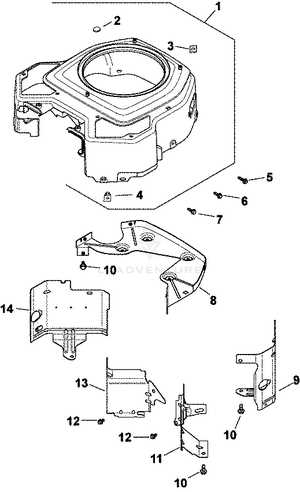

Cooling and Lubrication: To prevent overheating and excessive wear, the engine relies on dedicated systems for cooling and lubrication. These parts work to maintain optimal temperatures and reduce friction between moving components.

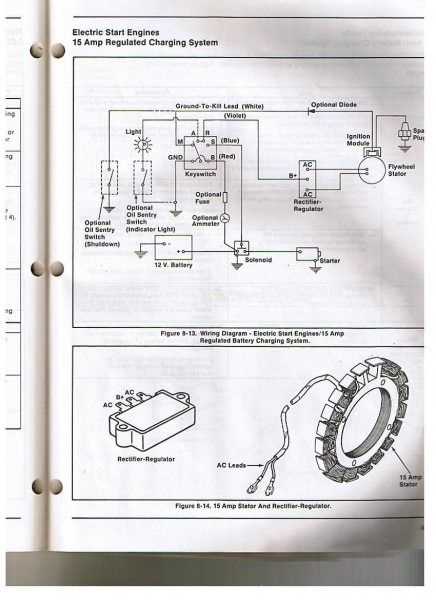

Control Systems: Modern engines are equipped with systems that monitor and adjust performance in real time. These include sensors and regula

Key Features of the Kohler CV16S Model

This engine is widely known for its reliability, efficiency, and practical applications. Built to endure demanding tasks, it offers several attributes that make it a preferred choice in various mechanical systems. Below, we will explore some of the most notable characteristics that define this power unit.

Engine Durability

- Designed to withstand heavy workloads and long operating hours without sacrificing performance.

- Built with high-quality materials that ensure a longer operational life.

- Low maintenance requirements, reducing downtime and service costs.

Efficient Power Output

The engine is recognized for delivering consistent and efficient power, allowing for optimal performance in different settings. Whether used in stationary or mobile applications, its output remains stable even under varying conditions.

- High fuel efficiency, leading to cost savings over time.

- Steady torque delivery, providing smooth and reliable operation.

- Optimized for lower emissions, contributing to a more environmentally friendly performance.

Understanding the Function of Engine Parts

Engines rely on a variety of components working together to ensure smooth operation and power generation. Each part has a specific role in maintaining efficiency and performance, from enabling the flow of fuel to managing temperature and ensuring proper lubrication. The interaction between these elements is critical to ensure optimal functionality.

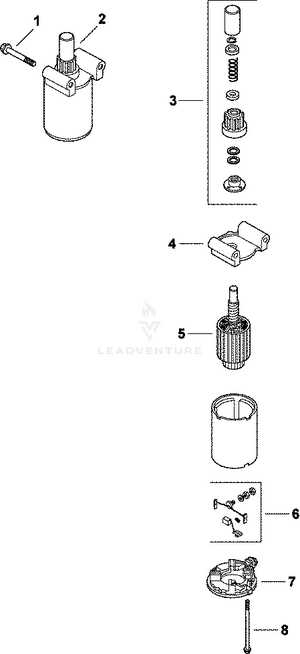

The Role of the Fuel System

The fuel system is responsible for delivering the right mixture of fuel and air to the combustion chamber. This process is essential for generating the energy needed to power the engine. Ensuring a balanced mix allows for efficient energy conversion and contributes to overall performance.

Cooling and Lubrication Systems

Cooling and lubrication are two vital systems that help maintain the engine’s longevity. The cooling system regulates temperature, preventing overheating during operation. Meanwhile, the lubrication system ensures that moving parts work together smoothly by reducing friction, ultimately extending the life of the engine.

Identifying Common Issues with CV16S Parts

Understanding potential malfunctions within mechanical components is crucial for maintaining consistent performance. By identifying frequent trouble areas, it’s possible to take preventative action and reduce downtime. Let’s explore some common weak points and how they may affect the system.

| Issue | Description | Possible Solutions |

|---|---|---|

| Irregular Performance | The system may exhibit fluctuating power output or fail to start smoothly, often linked to air intake or fuel-related concerns. | Inspect filters, fuel lines, and ensure proper air circulation. |

| Overheating | Excessive heat build-up can lead to significant wear and damage over time, potentially caused by improper lubrication or clogged cooling pathways. | Regularly check oil levels and clean cooling fins to prevent blockages. |