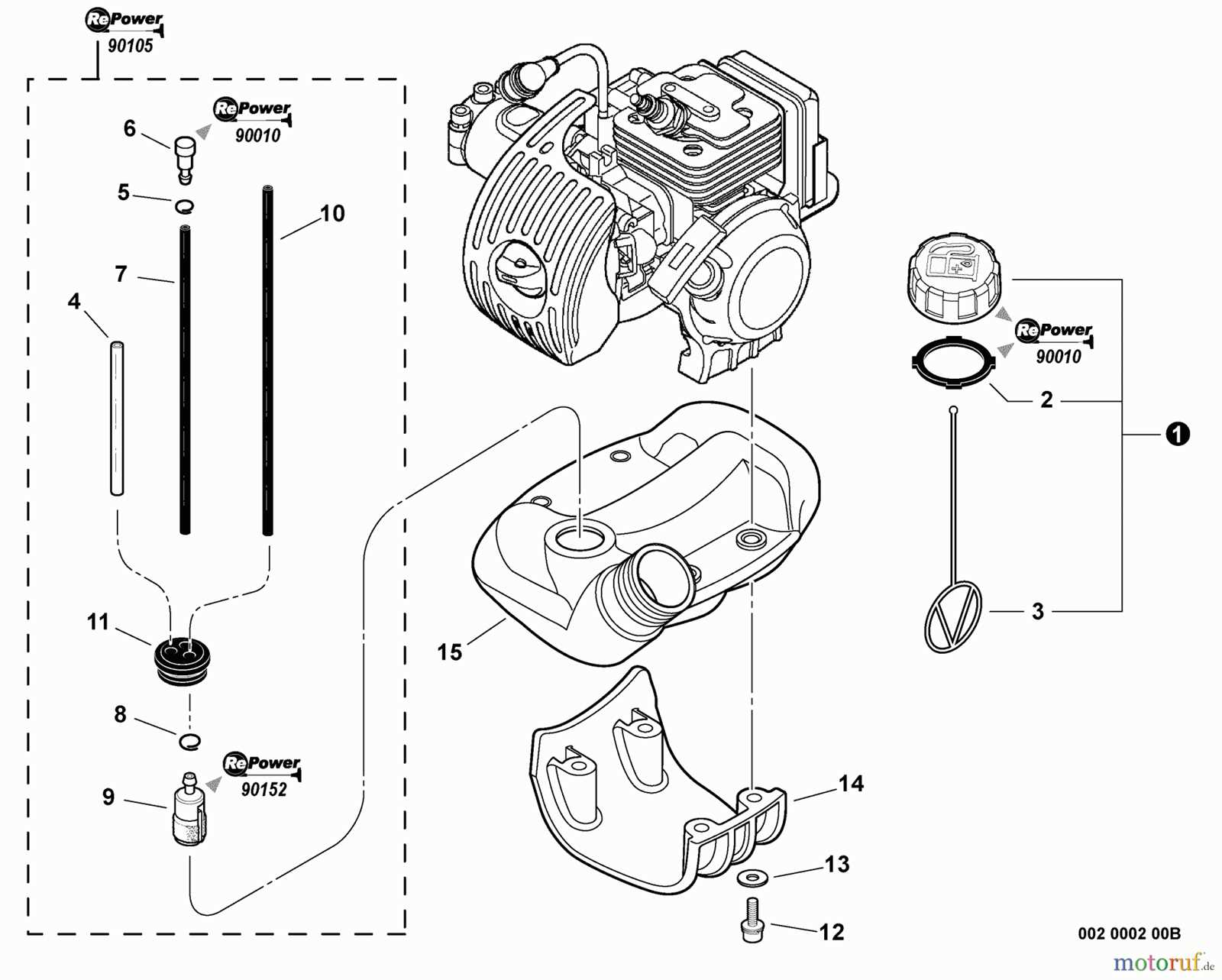

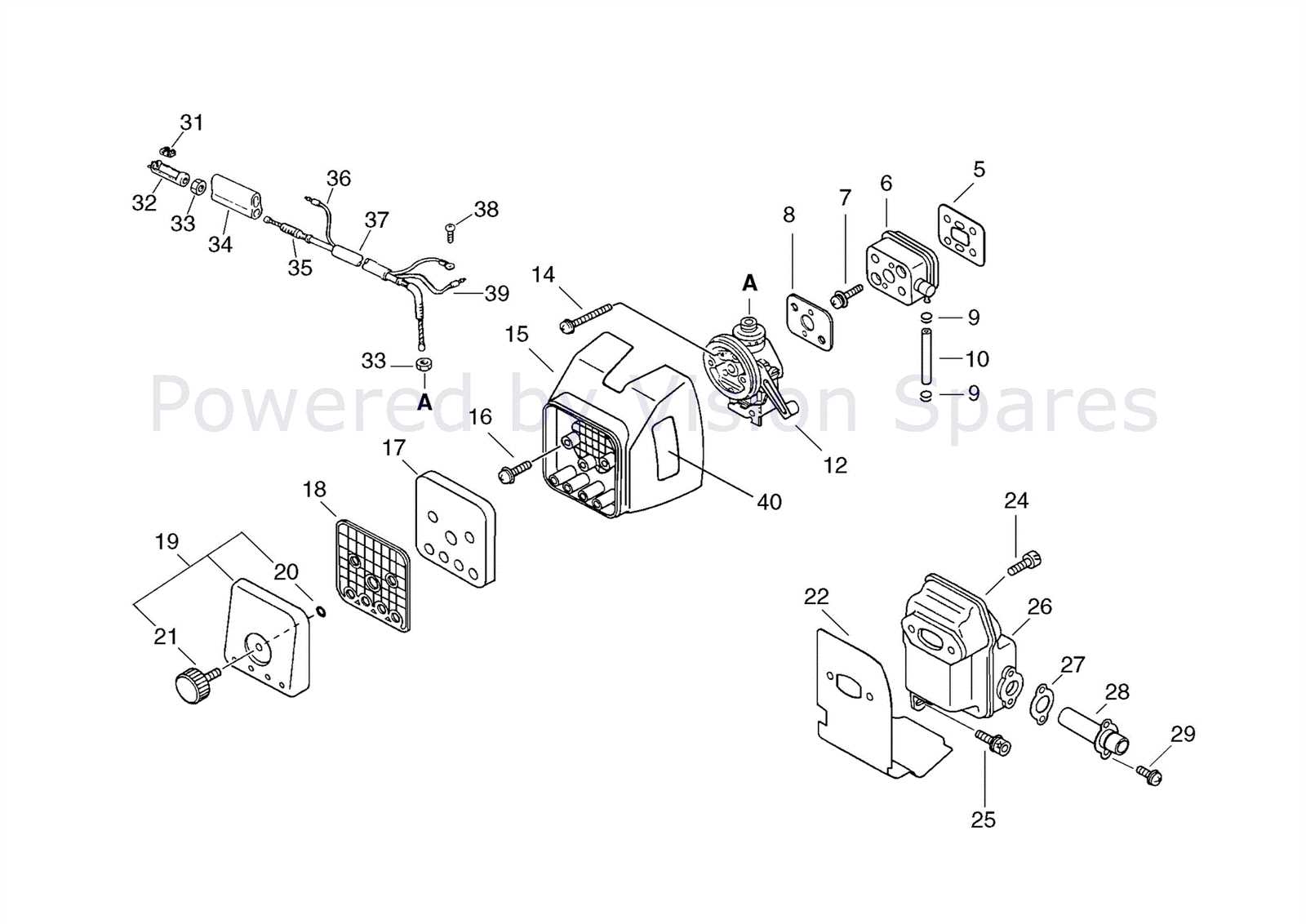

Maintaining outdoor equipment often involves knowing the different components that keep the machine running smoothly. For a grass trimmer, understanding its structure can help in troubleshooting, repairs, and even routine maintenance. By learning how each element interacts, one can better ensure efficient operation and prolong the lifespan of the tool.

In this guide, we will explore the essential elements that make up this garden tool, including the assembly details and functional aspects. Knowing the proper configuration can save time and effort when it comes to replacing elements or performing adjustments. This knowledge not only simplifies upkeep but also enhances safety during use.

Additionally, we will discuss how various mechanisms work together to deliver optimal performance. Familiarizing oneself with these details can be especially useful when identifying potential issues and finding the right replacements

Identifying Key Parts and Functions

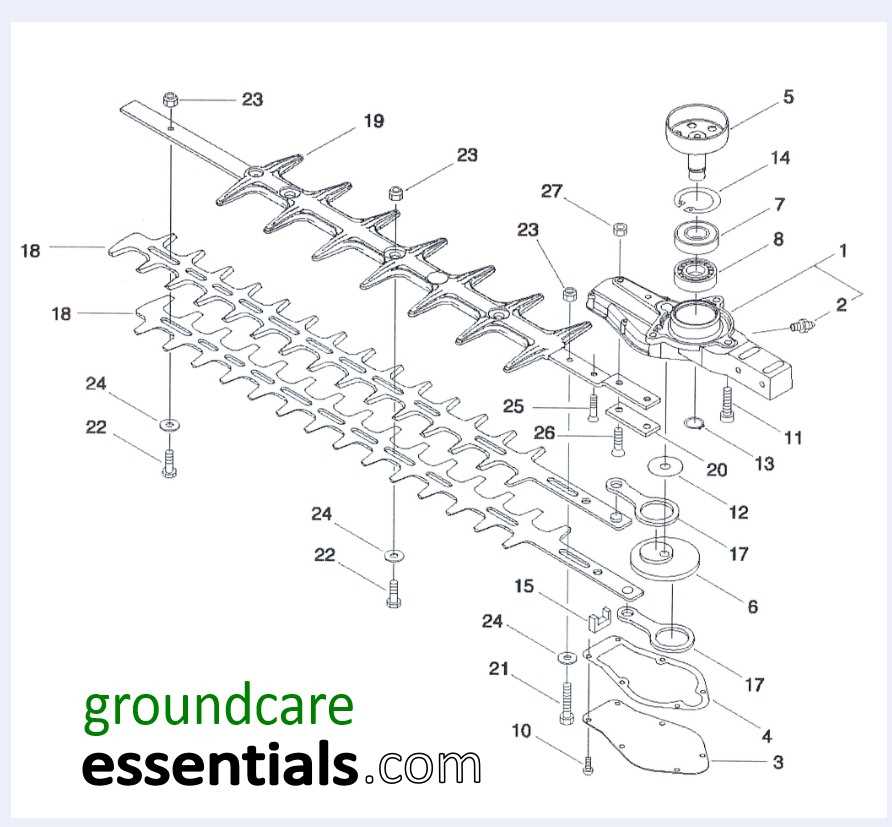

Understanding the essential components and their roles is crucial for anyone looking to maintain or repair a grass-cutting tool. This section provides an overview of the main elements that contribute to the machine’s operation and how they interact with one another.

| Component | Description | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Powerhead | The central unit containing the engine or motor. | Generates the necessary force to drive the cutting mechanism. | ||||||||||||

| Drive Shaft | A long, cylindrical rod connecting the powerhead to the cutting assembly. | Transfers the rotational energy from the engine to the trimmer head. | ||||||||||||

Trimmer Head

Replacing Worn-Out Trimmer Components

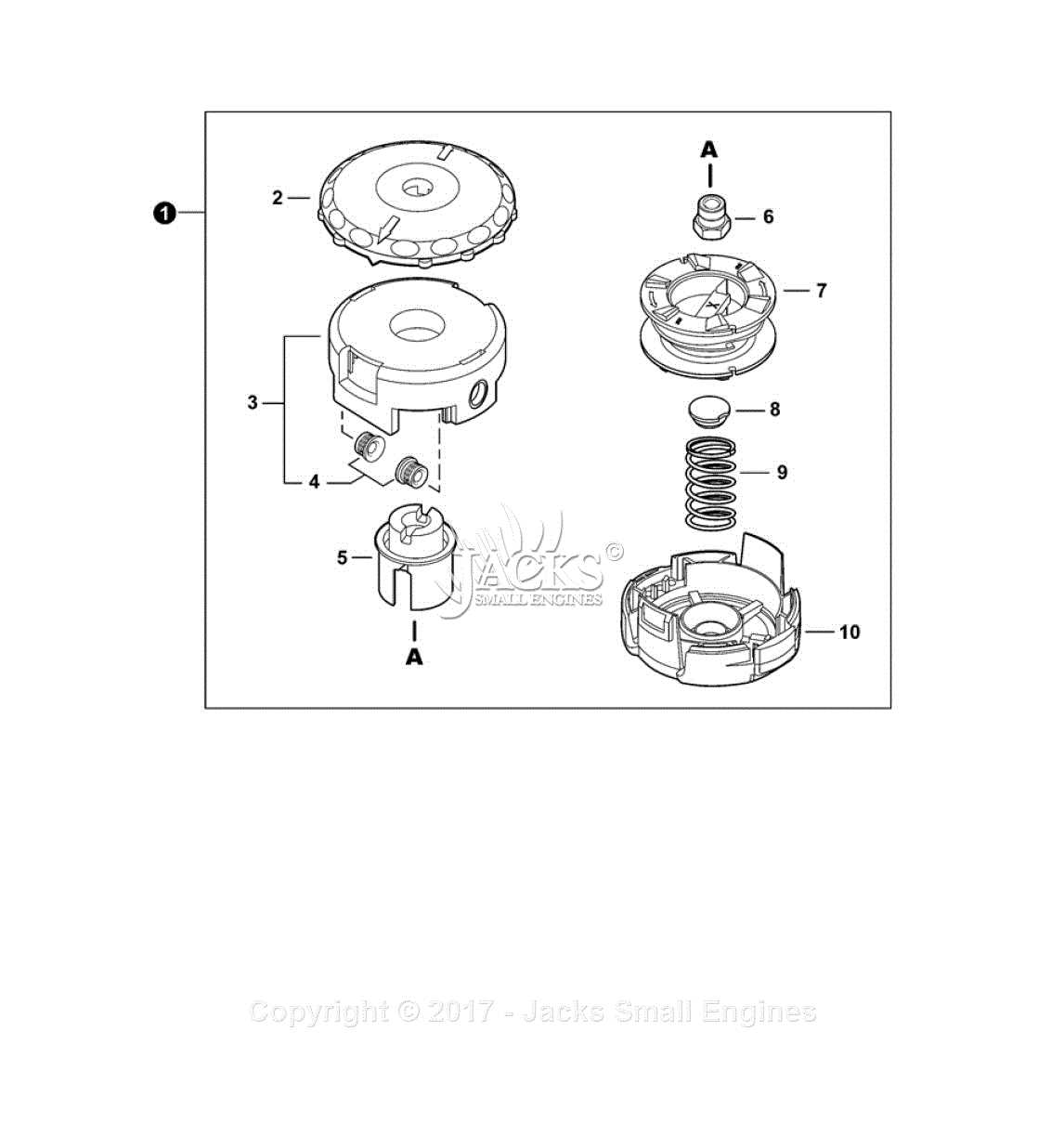

Over time, the components of a grass trimmer can become damaged or experience normal wear and tear, reducing the efficiency of the tool. Regular maintenance, including the replacement of worn-out parts, is essential for keeping the device running smoothly and extending its lifespan. This section provides an overview of the process for swapping out commonly affected trimmer components, ensuring reliable performance during lawn care tasks. Identifying Commonly Worn Components

Trimmers have several parts that are prone to wear due to constant contact with tough grass and debris. Commonly affected components include the cutting line, spool, and bump head. The cutting line gradually shortens with use and may need frequent replacement, while the spool can crack or become misaligned. The bump head, used to feed more line, can also wear out or get damaged, making it necessary to inspect these elements regularly. Maintenance Tips for Longevity

|

| Tool | Description |

|---|---|

| Screwdriver Set | Used for driving screws into place or removing them from components. |

| Socket Wrench | Helps in loosening or tightening nuts and bolts quickly. |

| Utility Knife | Useful for cutting any bindings or materials that may obstruct access. |

| Pliers | Assist in gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Measuring Tape | For measuring spaces and ensuring proper fitting of components. |

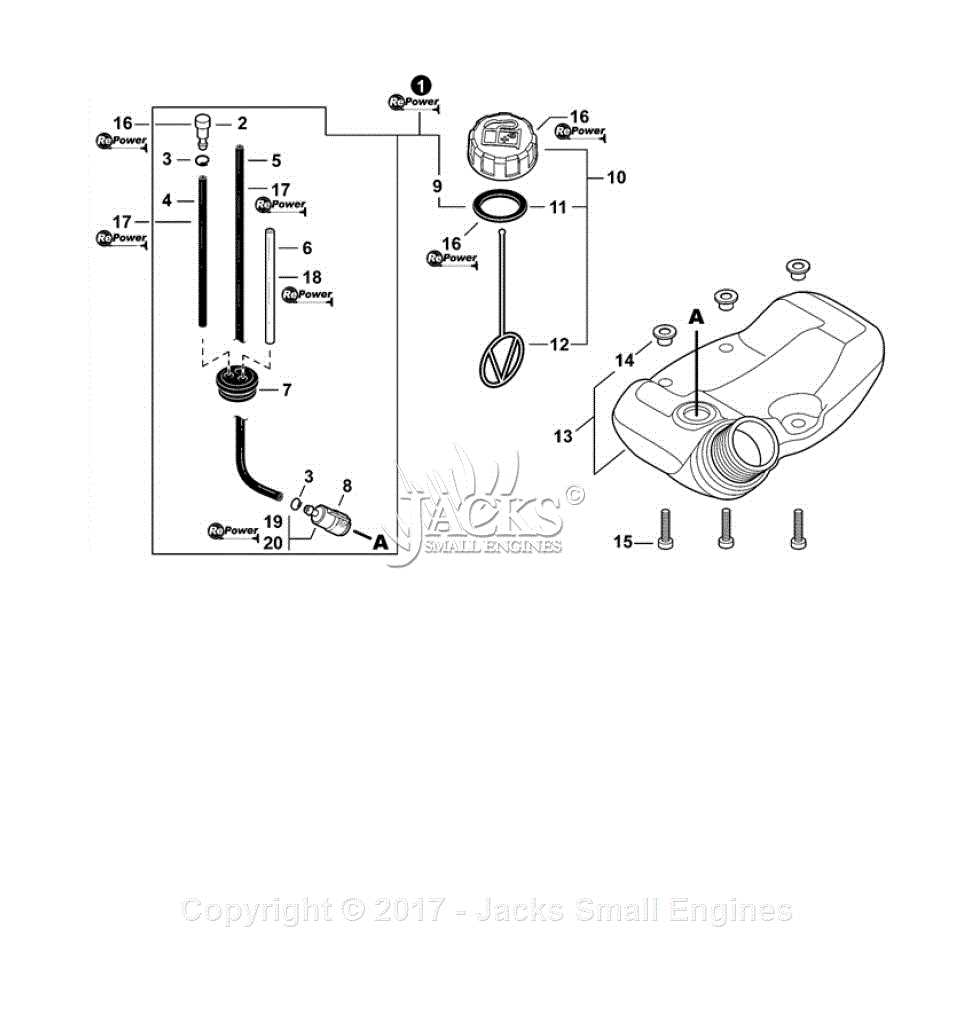

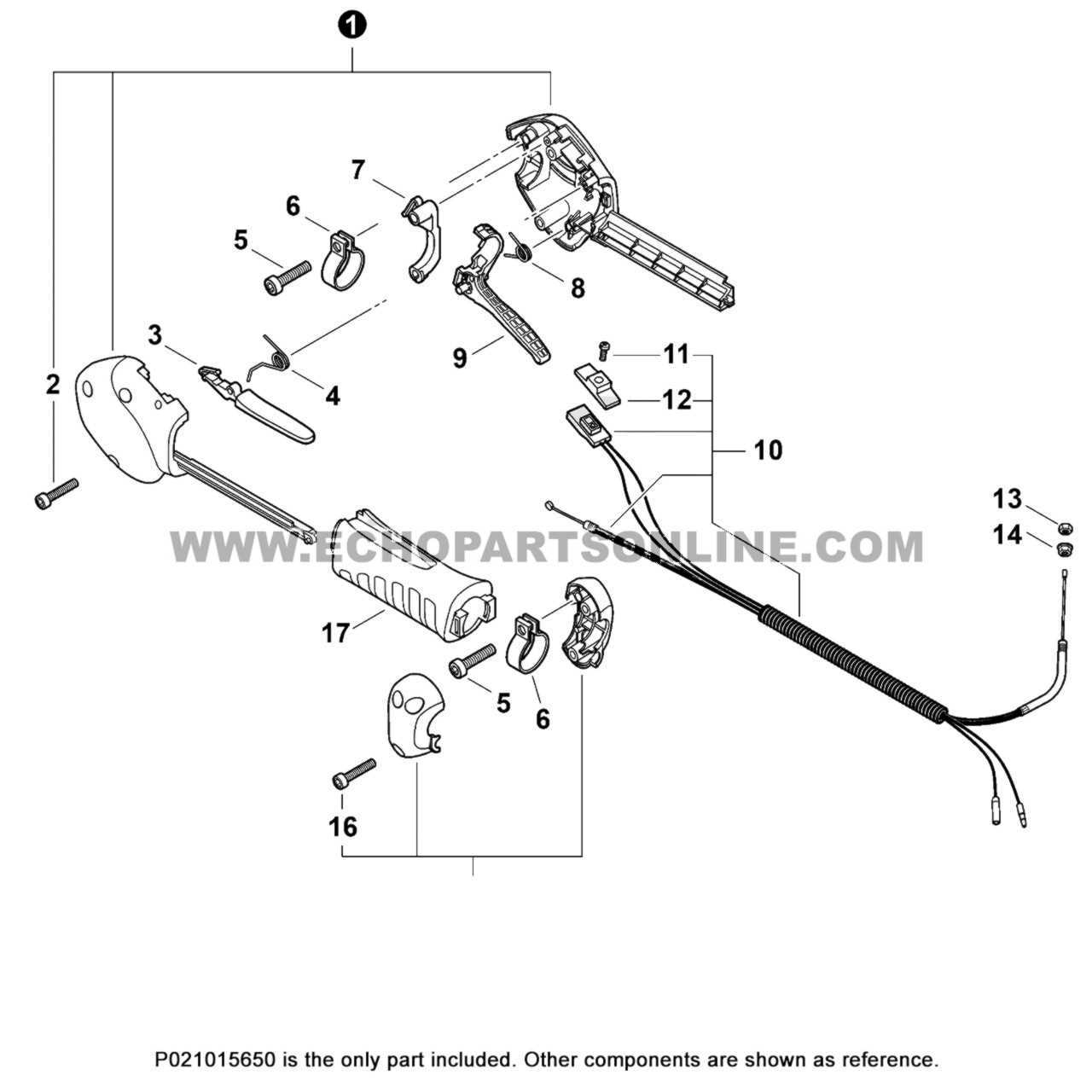

Where to Find Echo Parts Diagrams

Locating detailed illustrations for specific components of outdoor power equipment can significantly aid in maintenance and repairs. These visual references provide essential information for identifying individual elements and understanding their arrangement within the machine. Having access to these resources can enhance your ability to troubleshoot issues effectively.

One of the most reliable sources for these illustrations is the manufacturer’s official website. Typically, they offer a comprehensive resource section that includes various technical documents, such as schematics and assembly guides. Additionally, authorized dealers and repair shops often maintain a database of these references, providing personalized assistance when necessary.

Online forums and community groups dedicated to outdoor equipment are another excellent avenue to explore. Members frequently share links to valuable resources, including manuals and component layouts. Engaging with fellow enthusiasts can also provide insights into common issues and solutions related to specific machinery.

For those seeking alternative options, numerous third-party websites specialize in providing access to repair guides and component diagrams for various brands. While using these sources, ensure they are reputable and up-to-date to avoid discrepancies in the information.

In summary, a combination of official manufacturer resources, community support, and third-party websites can provide the necessary illustrations for maintaining and repairing outdoor machinery effectively. Taking the time to locate these resources can result in a more efficient and informed approach to equipment care.