In the realm of heavy-duty lifting equipment, it is essential to comprehend the various elements that contribute to optimal functionality and performance. Knowing the individual components allows users to maintain, troubleshoot, and enhance their equipment effectively. This understanding is crucial for anyone relying on these systems for demanding tasks.

Each segment of the mechanism plays a vital role in ensuring smooth operation. Familiarity with how these parts interact not only aids in better maintenance practices but also empowers users to make informed decisions when selecting upgrades or replacements. By exploring the intricate relationships between these components, one can appreciate the engineering excellence that underpins such powerful machines.

Moreover, having a comprehensive overview of the assembly can help identify potential issues before they escalate, thereby enhancing safety and efficiency. Engaging with the details of each section fosters a deeper appreciation for the technology involved, leading to more effective use and care of the equipment.

This section aims to provide a comprehensive understanding of a powerful mechanical device used for heavy-duty tasks. The focus will be on its key components and functionalities, illustrating how they contribute to the overall performance and efficiency of the equipment.

- Purpose and Applications:

The device is primarily designed for lifting and pulling heavy loads, making it essential for various industries, including:

- Construction sites

- Outdoor recreational activities

- Towing vehicles

- Main Features:

Several notable features enhance its usability and reliability, including:

- High load capacity

- Durable construction materials

- Advanced control mechanisms

- Essential Components:

Understanding the main components is crucial for effective operation and maintenance. These typically include:

- Drum

- Motor

- Gear system

- Controller

- Safety features

- Maintenance Tips:

To ensure longevity and optimal performance, regular maintenance is recommended. Key practices include:

- Routine inspections

- Lubrication of moving parts

- Replacement of worn components

Key Components of Badlands Winch

Understanding the essential elements of a pulling device is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring reliability and performance during demanding tasks. Familiarity with these parts helps users make informed decisions regarding repairs and upgrades.

The following table outlines the primary components and their respective functions:

| Component | Function |

|---|---|

| Motor | Provides the power necessary to operate the mechanism effectively. |

| Gearbox | Transmits power from the motor to the drum, allowing for controlled speed and torque. |

| Drum | Holds the rope or cable, facilitating the winding and unwinding process. |

| Remote Control | Enables convenient operation from a distance, enhancing safety and ease of use. |

| Braking System | Prevents unintended movement and secures the load during operation. |

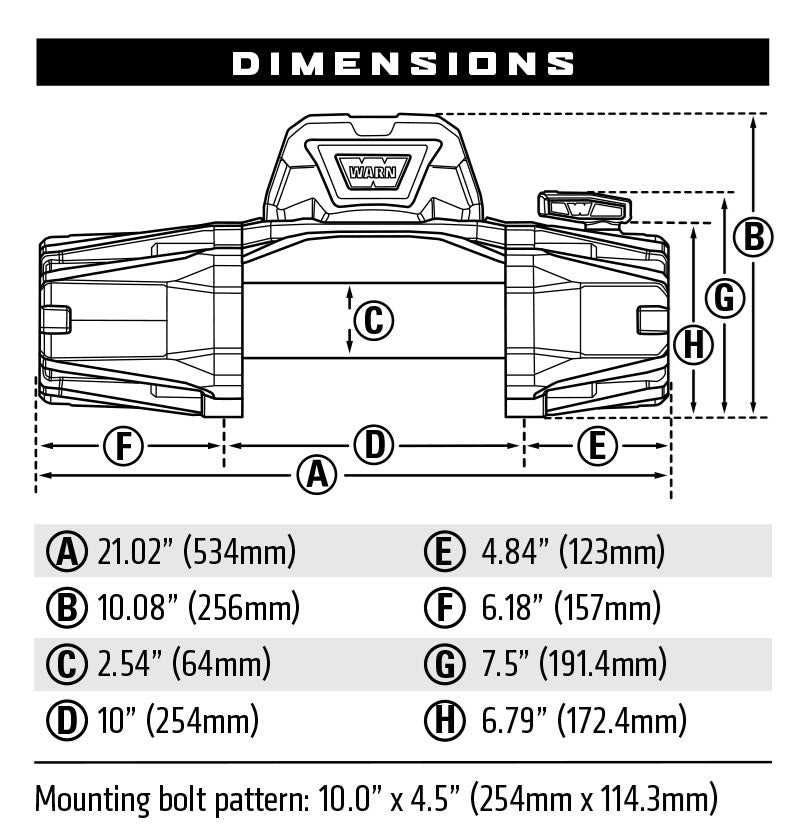

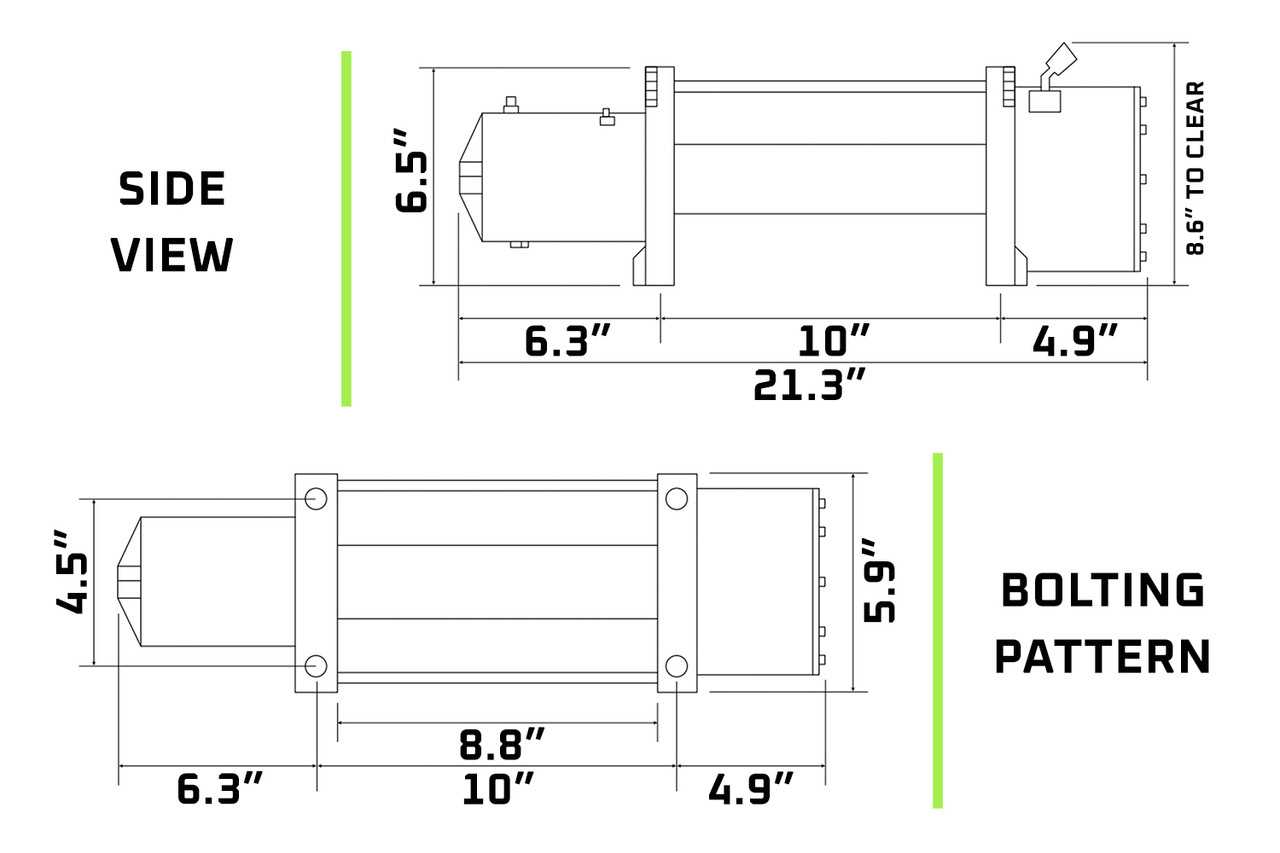

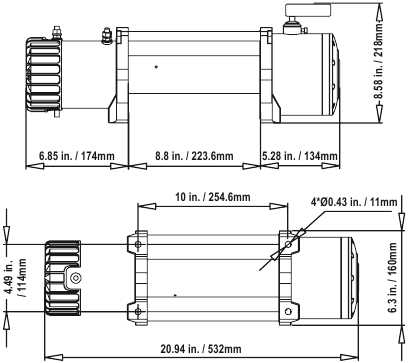

Understanding the Parts Diagram

This section delves into the essential components of the assembly, offering insights into their functionality and relationships. Recognizing each element’s role is crucial for effective operation and maintenance.

When examining the schematic representation, consider the following key aspects:

- Identification of Components: Each item is labeled to facilitate quick reference, helping users identify necessary parts efficiently.

- Functional Relationships: The arrangement illustrates how components interact, showcasing their interconnectedness.

- Maintenance Guidelines: Understanding the layout aids in identifying parts that require regular upkeep, ensuring optimal performance.

By familiarizing yourself with the assembly representation, you can enhance your knowledge and ability to manage the equipment effectively.

Maintenance Tips for Your Winch

Ensuring the longevity and optimal performance of your hoisting equipment requires regular care and attention. Proper maintenance not only enhances functionality but also ensures safety during operations.

Regular Inspection: Periodically examine all components for signs of wear or damage. Look for fraying cables, rust, or any signs of malfunction. Early detection of issues can prevent further damage.

Lubrication: Keep moving parts well-lubricated to reduce friction and wear. Use the manufacturer-recommended lubricant to ensure compatibility and effectiveness.

Cleaning: After use, clean the equipment thoroughly to remove dirt, debris, and moisture. This prevents corrosion and ensures smooth operation. Use a soft brush and a damp cloth to wipe down surfaces.

Storage: When not in use, store your equipment in a dry, sheltered area to protect it from environmental factors. Consider using a protective cover to shield it from dust and moisture.

Follow Manufacturer Guidelines: Always adhere to the maintenance schedule and instructions provided by the manufacturer. This ensures that you perform necessary tasks at the right intervals and maintain warranty coverage.

Common Issues with Winch Parts

Mechanical devices often encounter various challenges that can affect their functionality and reliability. Understanding these common problems is essential for maintaining performance and ensuring longevity. Identifying the symptoms early can help prevent more significant issues down the line.

Frequent Mechanical Problems

- Overheating due to excessive load or prolonged use.

- Noise or grinding sounds indicating wear or misalignment.

- Electrical failures from poor connections or corroded components.

- Insufficient pulling strength caused by worn-out gears or cables.

Maintenance Tips

- Regularly inspect components for wear and tear.

- Keep connections clean and free from moisture.

- Lubricate moving parts to minimize friction.

- Test the device periodically to ensure all functions operate smoothly.

Replacement Parts for Badlands Winch

Maintaining and restoring a heavy-duty hauling mechanism requires attention to various components that ensure optimal performance. Having reliable substitutes on hand is crucial for those who depend on their equipment for demanding tasks. This section outlines essential elements needed to keep your machinery running smoothly.

Essential Components

Key elements play a vital role in the efficiency of your equipment. Regular inspection of items such as the motor, control switch, and gear assembly is recommended. Each of these elements should be readily available for quick replacement to minimize downtime.

Finding Quality Replacements

When searching for quality substitutes, consider factors like durability and compatibility. It’s beneficial to choose parts from reputable suppliers to ensure longevity and reliability. Additionally, consulting user manuals or guides can aid in identifying the correct specifications for each component.

Installing New Components Safely

Ensuring the proper installation of new elements is crucial for maintaining optimal functionality and safety. This process requires careful planning and attention to detail to avoid any potential hazards. By following best practices and utilizing the right tools, individuals can successfully integrate new components while minimizing risks.

Preparation and Safety Precautions

Before commencing the installation, it is essential to prepare the workspace. Ensure that the area is well-lit and free of clutter. Additionally, wearing appropriate safety gear, such as gloves and goggles, can protect against unforeseen accidents. Identifying and organizing all necessary tools beforehand will facilitate a smoother installation process.

Following Manufacturer Guidelines

Consulting the manufacturer’s instructions is vital to ensure compatibility and correct placement of each component. Adhering to these guidelines not only enhances performance but also prolongs the lifespan of the equipment. Taking the time to read and understand the directions can prevent costly mistakes and ensure a safe and efficient installation.

Upgrading Your Winch System

Enhancing your hauling system can significantly improve its efficiency and performance. By upgrading various components, you can achieve better reliability and strength, ensuring your equipment is ready for any challenge. This process not only increases the operational capacity but also extends the lifespan of your gear.

Key Components to Consider

- Motor: A powerful motor can enhance speed and efficiency during operation.

- Control System: A modern control setup offers improved responsiveness and ease of use.

- Cable: Upgrading to a stronger or more durable cable can prevent potential failures during heavy use.

- Mounting Bracket: A reinforced bracket ensures stability and security during operations.

Installation Tips

- Ensure all components are compatible with each other before purchase.

- Follow manufacturer instructions for installation to maintain safety standards.

- Test the system thoroughly after installation to confirm everything functions correctly.

- Regularly inspect and maintain the upgraded components to ensure longevity.

Frequently Asked Questions

This section addresses common inquiries related to the equipment’s functionality and maintenance. Understanding these aspects can enhance user experience and ensure effective operation.

What is the recommended maintenance schedule?

Regular upkeep is essential to prolong the lifespan of the equipment. It is advisable to inspect components periodically and perform necessary maintenance tasks according to the manufacturer’s guidelines.

How do I troubleshoot common issues?

If you encounter difficulties, consulting the user manual can provide troubleshooting steps. Additionally, familiarizing yourself with common symptoms can aid in identifying potential problems and solutions.