When navigating the world of marine propulsion systems, a thorough comprehension of the intricate components is essential. Each element plays a vital role in ensuring optimal performance and longevity of the system, ultimately impacting your boating experience.

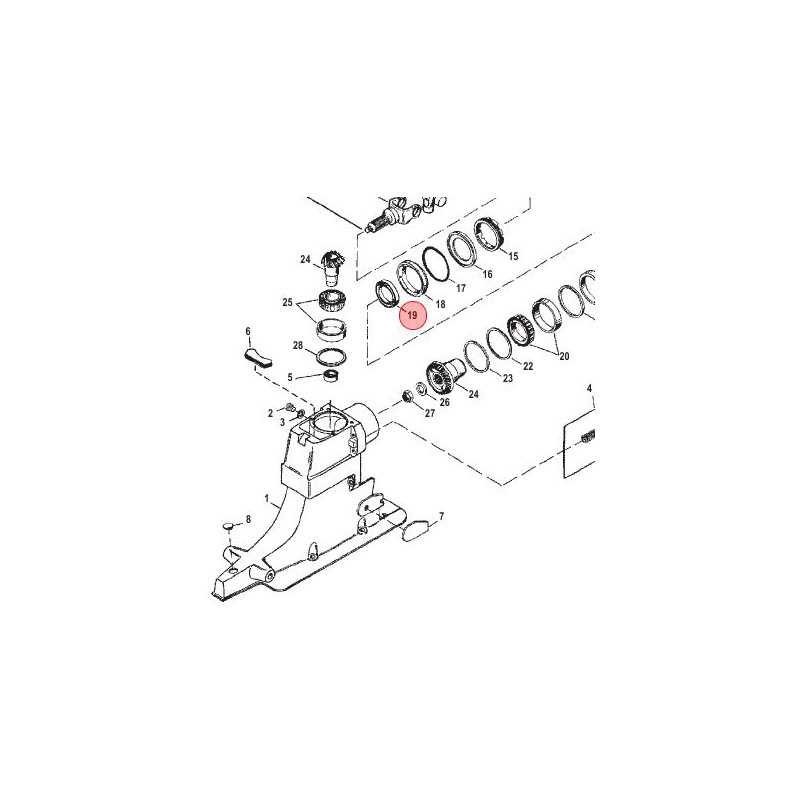

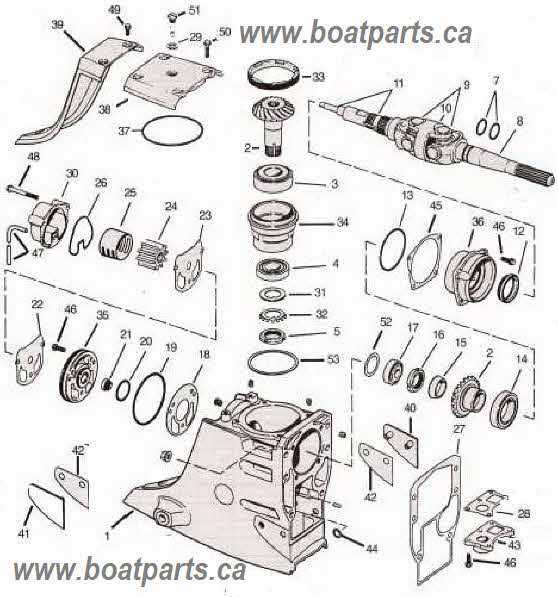

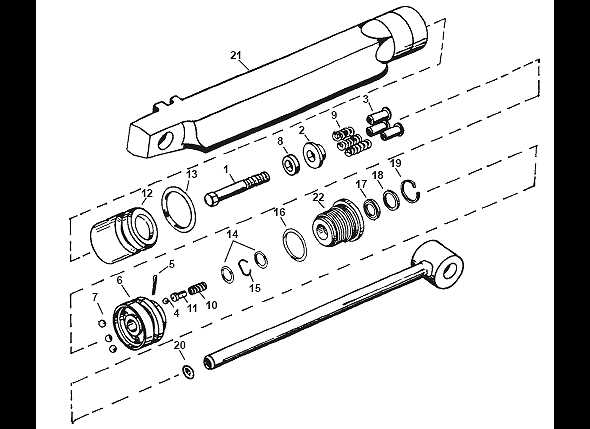

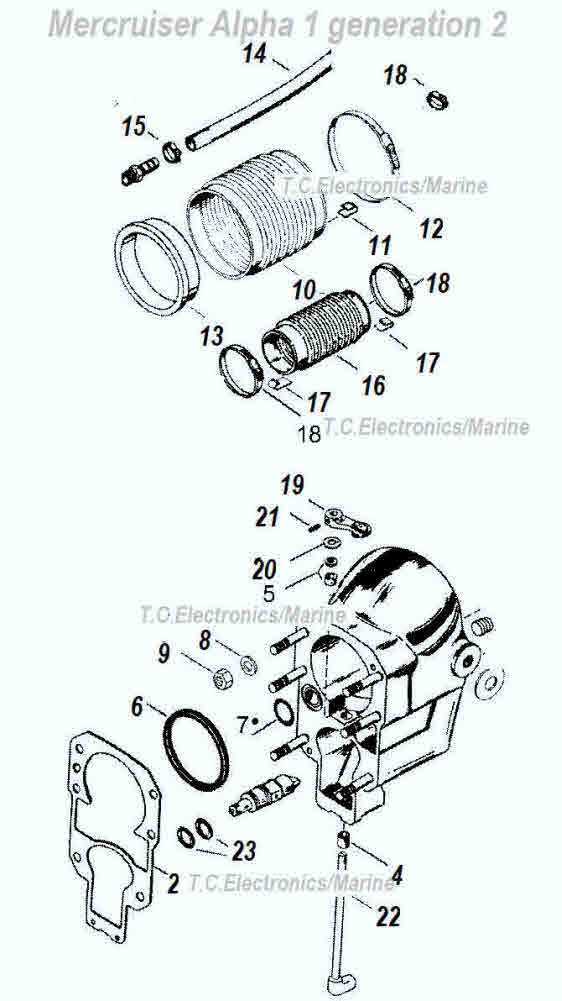

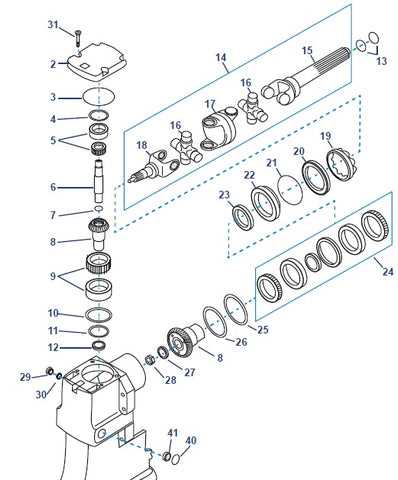

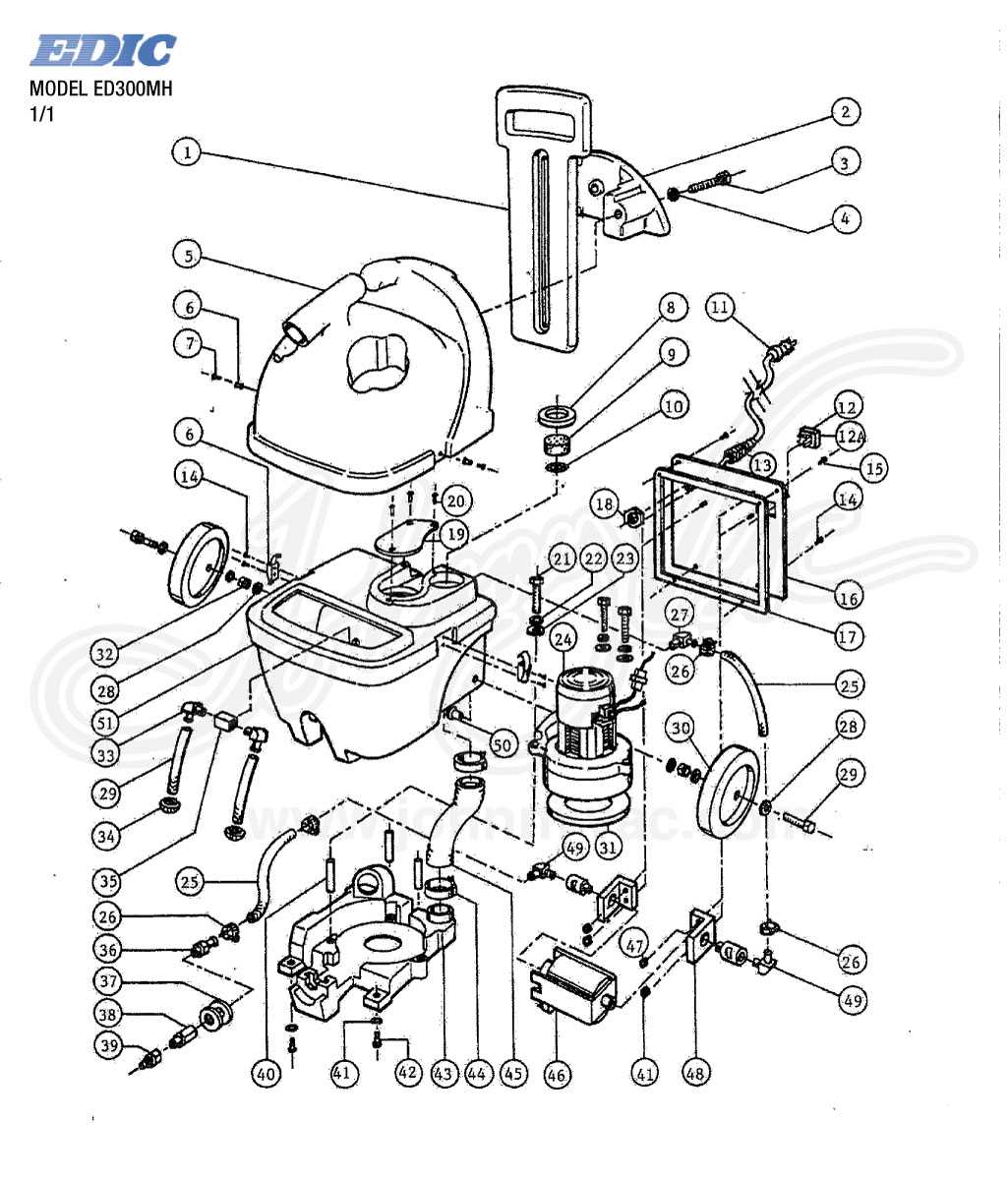

Visual aids can be incredibly helpful in grasping the relationships and functions of various elements. By examining a detailed representation, one can easily identify each part and its significance within the entire assembly.

Moreover, an in-depth exploration of these components allows enthusiasts and professionals alike to make informed decisions regarding maintenance, upgrades, and repairs. Delving into this subject not only enhances knowledge but also fosters a greater appreciation for the engineering behind marine technology.

Understanding Mercruiser Alpha One Gen 1

This section delves into the intricacies of a popular marine propulsion system that has garnered attention for its reliability and performance. Designed to facilitate smooth navigation and power delivery, this equipment is essential for many boaters, providing a blend of efficiency and ease of maintenance.

Components and Functionality

The system comprises various elements that work together harmoniously. Key components include the drive unit, which is responsible for transferring engine power to the propeller, and the gear assembly, which ensures optimal torque management. Understanding these parts enhances the user’s ability to perform maintenance and troubleshoot issues effectively.

Maintenance and Troubleshooting

Regular upkeep is vital for longevity and performance. Routine inspections can help identify wear and tear, preventing more significant problems down the line. Users should pay close attention to signs of corrosion, fluid leaks, and unusual noises, as these may indicate underlying issues. Proper care can significantly extend the lifespan of this marine system.

Key Components of Alpha One Drive

The drive system of a marine vessel is crucial for optimal performance and reliability on the water. Understanding the essential elements that contribute to the functionality of this mechanism is vital for maintenance and troubleshooting. Each component plays a specific role in ensuring smooth operation, effective power transfer, and overall durability.

One of the primary elements is the gear assembly, which facilitates the transmission of power from the engine to the propeller. This assembly typically includes various gears designed to withstand high torque and deliver consistent performance under varying conditions. Additionally, the casing protects internal components from water and debris, ensuring longevity and reliability.

The propeller itself is another critical piece, responsible for generating thrust and allowing the vessel to navigate through the water. Its design, including pitch and diameter, significantly influences speed and fuel efficiency. Coupled with the drive shaft, which connects the propeller to the gear assembly, these parts work together to propel the boat effectively.

Seals and bearings also play an essential role in reducing friction and preventing leaks, thereby enhancing the overall efficiency of the drive system. Proper maintenance of these components is necessary to avoid potential failures and costly repairs. Regular inspections can help identify wear and tear, ensuring that the system operates smoothly.

Ultimately, understanding these key components and their functions provides a solid foundation for maintaining the drive system, promoting better performance and reliability on the water.

Importance of Accurate Parts Diagram

Having a precise representation of components is crucial for ensuring proper maintenance and repairs in any mechanical system. A clear illustration not only aids in identifying individual elements but also facilitates understanding their relationships within the overall assembly. This clarity can significantly enhance the efficiency of service procedures and reduce the risk of errors.

Moreover, an accurate visual reference serves as a vital tool for technicians and enthusiasts alike, enabling them to locate specific items swiftly. This becomes particularly important when sourcing replacements or upgrades, as the right fit is essential for optimal performance. Misidentification can lead to complications that may compromise functionality or safety.

Additionally, well-documented schematics often contribute to better communication among team members and with suppliers. When everyone has access to the same detailed information, it fosters a collaborative environment where issues can be resolved more quickly. Ultimately, investing in reliable illustrations can save time and resources, making the entire process more streamlined and effective.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effectively maintaining and repairing mechanical systems. These visual representations provide a detailed overview of components, helping users identify parts, their functions, and how they fit together. Familiarity with these visuals can greatly enhance your troubleshooting skills and efficiency in handling repairs.

Key Elements of Technical Illustrations

When examining these illustrations, focus on the various components depicted. Each element is typically labeled with a reference number that corresponds to a list, providing specific details such as part names and specifications. Pay attention to the orientation and positioning of each piece, as this can indicate how they interact within the overall assembly.

Interpreting Labels and Annotations

Labels often include critical information about sizes, materials, and installation instructions. Understanding these annotations is essential for accurate identification and sourcing of replacements. Additionally, be aware of any directional arrows or notes that highlight assembly sequences or compatibility between parts, as these can influence the effectiveness of repairs.

Common Issues with Alpha One Parts

Understanding the frequent challenges encountered with specific marine components can enhance performance and longevity. Various factors contribute to these problems, ranging from wear and tear to improper maintenance.

Typical Problems

- Corrosion: Exposure to saltwater can lead to significant deterioration.

- Seal Failure: Worn seals often cause leaks and reduced efficiency.

- Overheating: Inefficient cooling systems can result in engine stress.

Maintenance Tips

- Regular Inspections: Check for any signs of wear or damage frequently.

- Use Quality Fluids: Ensure proper lubrication and cooling fluids are utilized.

- Timely Replacements: Replace worn components promptly to avoid larger issues.

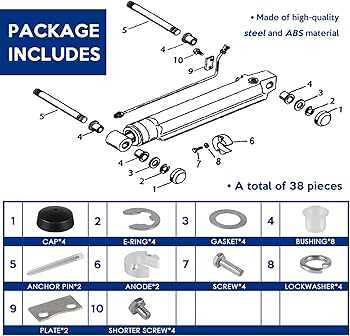

Where to Find Replacement Parts

Finding the right components for your marine engine can be a daunting task. However, knowing where to look can significantly simplify the process. Various sources offer a wide range of options, from new to refurbished items, ensuring you can keep your vessel in prime condition.

Online Retailers

- Major e-commerce platforms like Amazon and eBay provide a vast selection of items.

- Specialized marine supply websites often have specific components tailored for your needs.

- Manufacturer websites may offer direct sales or links to authorized distributors.

Local Sources

- Marine repair shops frequently stock essential components and can assist with installation.

- Boat shows and expos are excellent venues to discover vendors and compare products.

- Local classifieds and forums can lead to opportunities for purchasing used items at a lower cost.

Maintenance Tips for Alpha One Drives

Regular upkeep is essential for ensuring the longevity and efficiency of your marine propulsion system. By following some key practices, you can avoid common pitfalls and maintain optimal performance, enhancing both safety and enjoyment on the water.

1. Check Fluid Levels: Regularly inspect the lubricant in the drive unit. Ensure it is at the correct level and free of contaminants. Old or dirty fluid can lead to increased wear and overheating, compromising the entire system.

2. Inspect the Anodes: Sacrificial anodes play a crucial role in preventing corrosion. Examine these components frequently and replace them as needed to protect your drive from electrolysis damage.

3. Clean the Exterior: Keep the exterior surfaces clean and free from marine growth and debris. This not only improves aesthetics but also helps prevent corrosion and maintains efficient operation.

4. Monitor for Leaks: Regularly inspect for any signs of oil or water leaks. Early detection can prevent more significant issues down the line. Address any leaks promptly to avoid further damage.

5. Service the Propeller: Check the propeller for any signs of damage or wear. Ensure it is securely attached and properly aligned. Any abnormalities can affect performance and fuel efficiency.

6. Schedule Routine Inspections: Periodically have a professional inspect your system. They can provide insights into areas needing attention and ensure everything operates smoothly.

7. Follow Manufacturer Recommendations: Always adhere to the maintenance schedule and guidelines provided by the manufacturer. These recommendations are designed to maximize the lifespan and efficiency of your equipment.

By incorporating these maintenance tips into your routine, you can ensure a reliable and enjoyable boating experience for years to come.

Upgrading Components for Better Performance

Enhancing the efficiency of your vessel can significantly improve both speed and handling. By focusing on key elements of the propulsion system, you can achieve a noticeable boost in performance. This section explores various upgrades that can lead to a more powerful and responsive experience on the water.

Improving the Propeller is often the first step in upgrading performance. Choosing a propeller that matches your engine’s capabilities can optimize thrust and increase top speed. A higher-pitched or different-blade design can provide better acceleration and fuel efficiency, depending on your specific needs.

Upgrading the Exhaust System can also yield impressive results. A high-performance exhaust not only reduces back pressure but enhances the overall sound, contributing to a sportier experience. Additionally, this modification can improve engine efficiency and responsiveness.

Enhancing the Cooling System is essential for maintaining optimal performance, especially under demanding conditions. By installing a more efficient water pump or upgrading the heat exchanger, you can ensure that your engine operates within safe temperature limits, thus prolonging its life and performance.

Refining the Ignition System can lead to more consistent engine starts and smoother operation. High-performance ignition components, such as coils and spark plugs, can result in improved combustion, ultimately translating into enhanced power output and fuel efficiency.

Lastly, upgrading the Fuel System can make a substantial difference. Installing a high-flow fuel pump and performance injectors allows for better fuel delivery, ensuring your engine receives the optimal amount of fuel for maximum power. This can lead to improved acceleration and overall performance.

Incorporating these enhancements can transform your boating experience, making it not only faster but also more enjoyable. Assessing your current setup and investing in the right upgrades can lead to significant gains in both performance and reliability.

Comparing Alpha One to Other Models

When evaluating different drive systems for marine applications, it’s essential to understand the unique characteristics that set each model apart. Each variant offers specific advantages and disadvantages that cater to diverse boating needs. This section explores the distinctions and similarities between various drive configurations, highlighting performance, maintenance, and compatibility aspects.

Performance Features

One key factor in choosing a drive system is performance. Some models are designed for high-speed applications, delivering superior acceleration and handling. Others prioritize fuel efficiency and smooth cruising at lower speeds. Understanding these performance metrics helps boaters select the best option for their specific usage scenarios.

Maintenance and Durability

Maintenance requirements vary significantly among different systems. Some options demand more frequent servicing, while others boast enhanced durability and longevity. It’s crucial for boat owners to assess the maintenance schedule and potential repair costs associated with each model to ensure a hassle-free boating experience. Additionally, compatibility with existing setups can influence the decision, as some configurations integrate seamlessly, while others may require extensive modifications.