When exploring the elements responsible for transferring power in an automobile, it is essential to grasp how the connection between the engine and the wheels is established. This mechanism plays a pivotal role in ensuring that energy generated by the motor reaches the tires effectively, enabling smooth movement and control of the vehicle.

The setup includes several interconnected elements, each designed to withstand the stresses of operation and to provide reliable performance under various driving conditions. These components work together in harmony, allowing for the efficient transmission of energy from one area of the vehicle to another.

By examining the detailed structure and function of each element in this system, one can gain a better appreciation of how motion is delivered and sustained, especially when dealing with high-torque environments. A deeper look into this arrangement offers insights into the engineering that ensures both durability and performance.

Understanding the Basics of Driveshafts

At the core of many mechanical systems is a component responsible for transferring rotational force between two points. This element plays a critical role in ensuring that power generated from one source is efficiently delivered to another part of the system, enabling smooth operation and consistent performance. The principle behind it involves converting energy into motion, which is essential for a variety of applications in both automotive and industrial contexts.

Key aspects of this element include its ability to handle high torque, maintaining stability even under stress, and providing the necessary flexibility to accommodate movement between connected components. Without it, systems relying on rotational power would lack the efficiency and stability needed to function correctly.

It’s important to understand that this part must be precisely balanced and constructed from durable materials to withstand the forces it encounters. Regular inspection and maintenance of this component are essential to prevent wear and tear, ensuring it continues to perform at optimal levels.

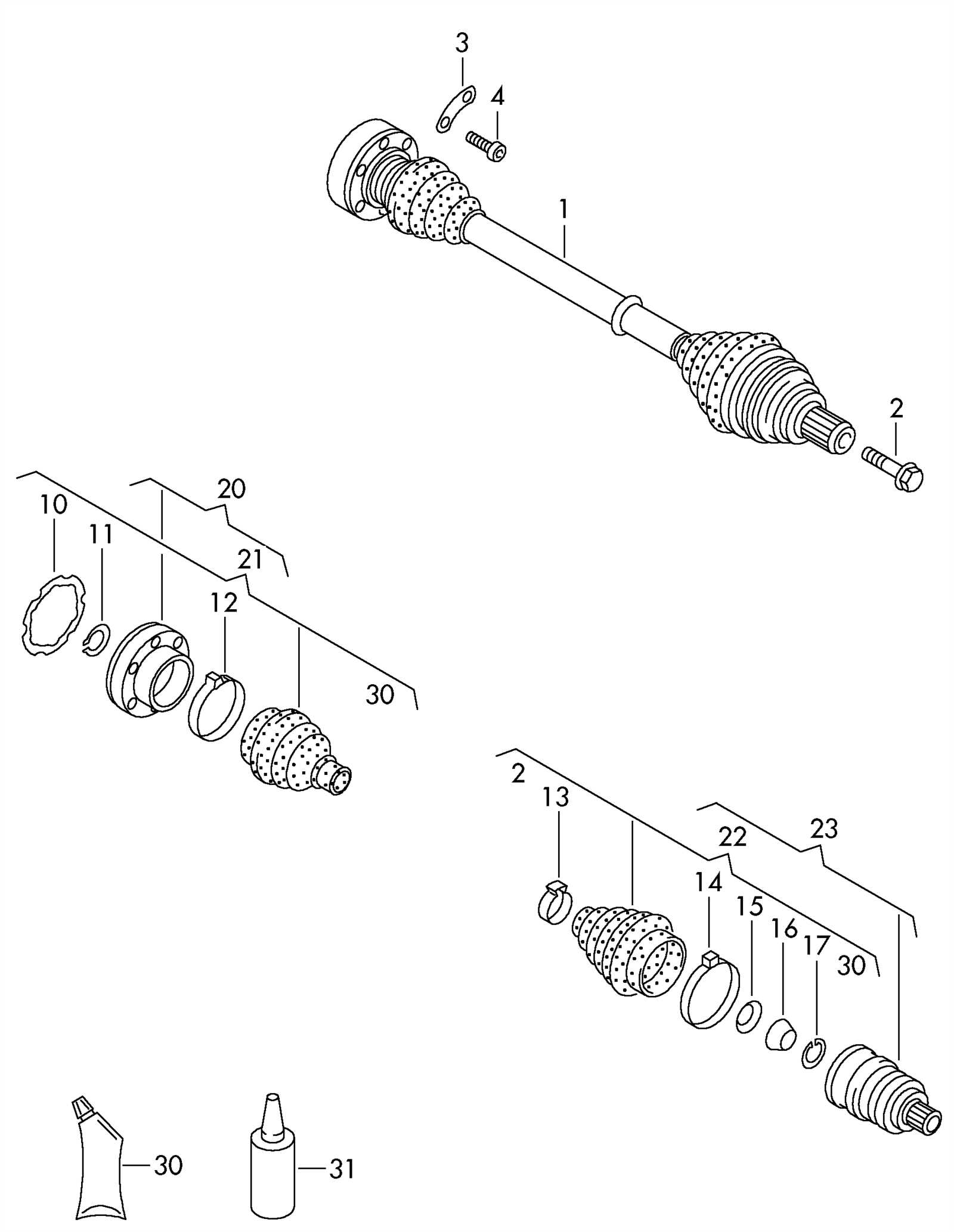

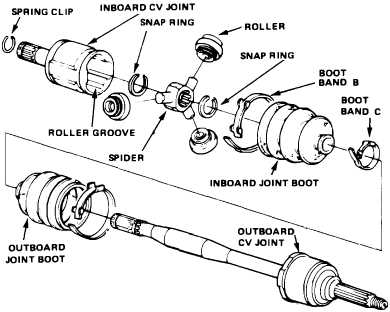

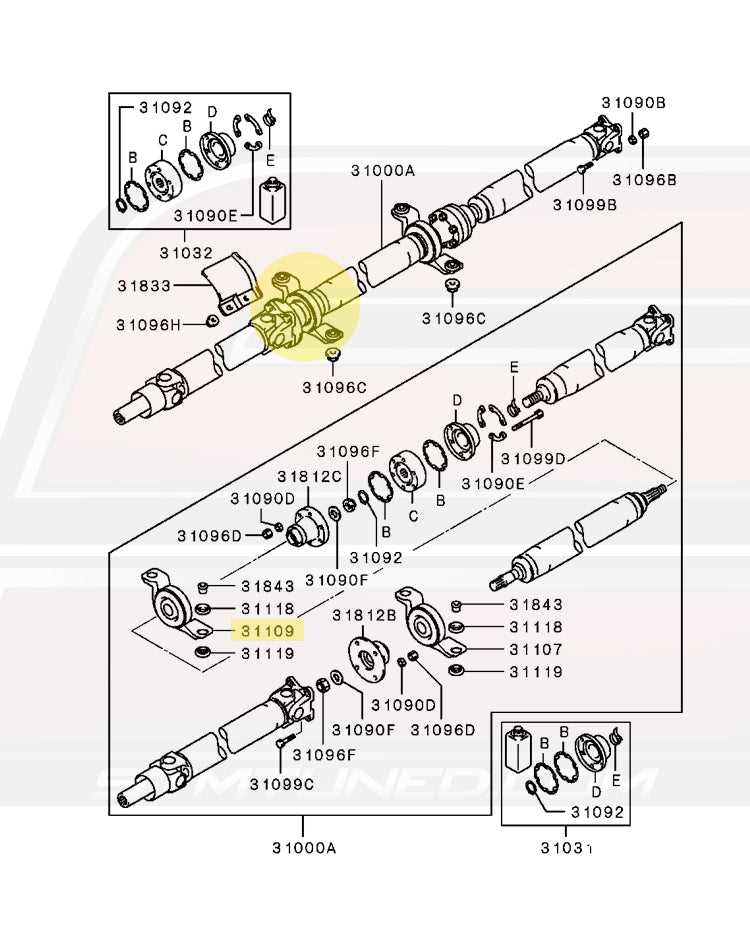

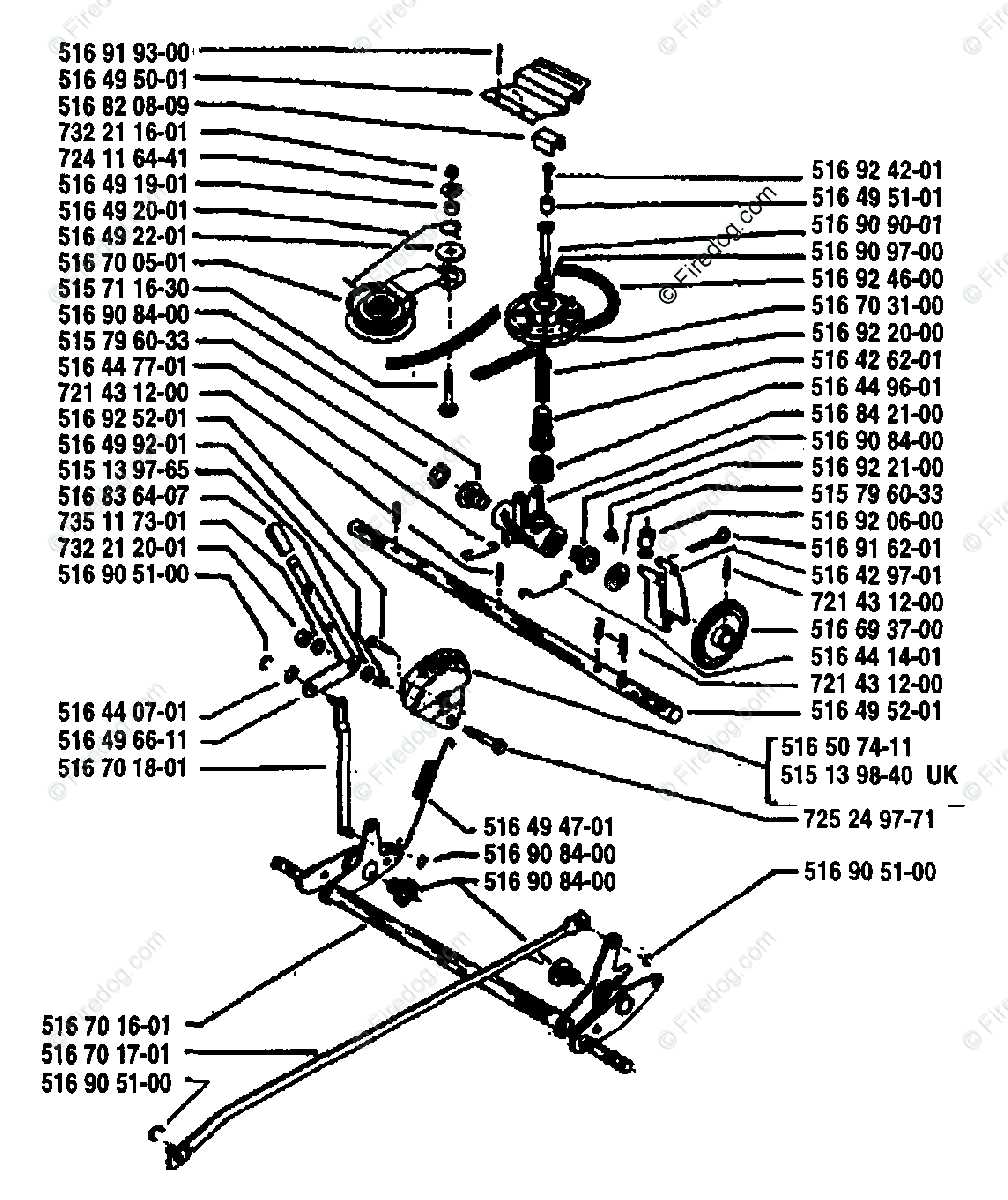

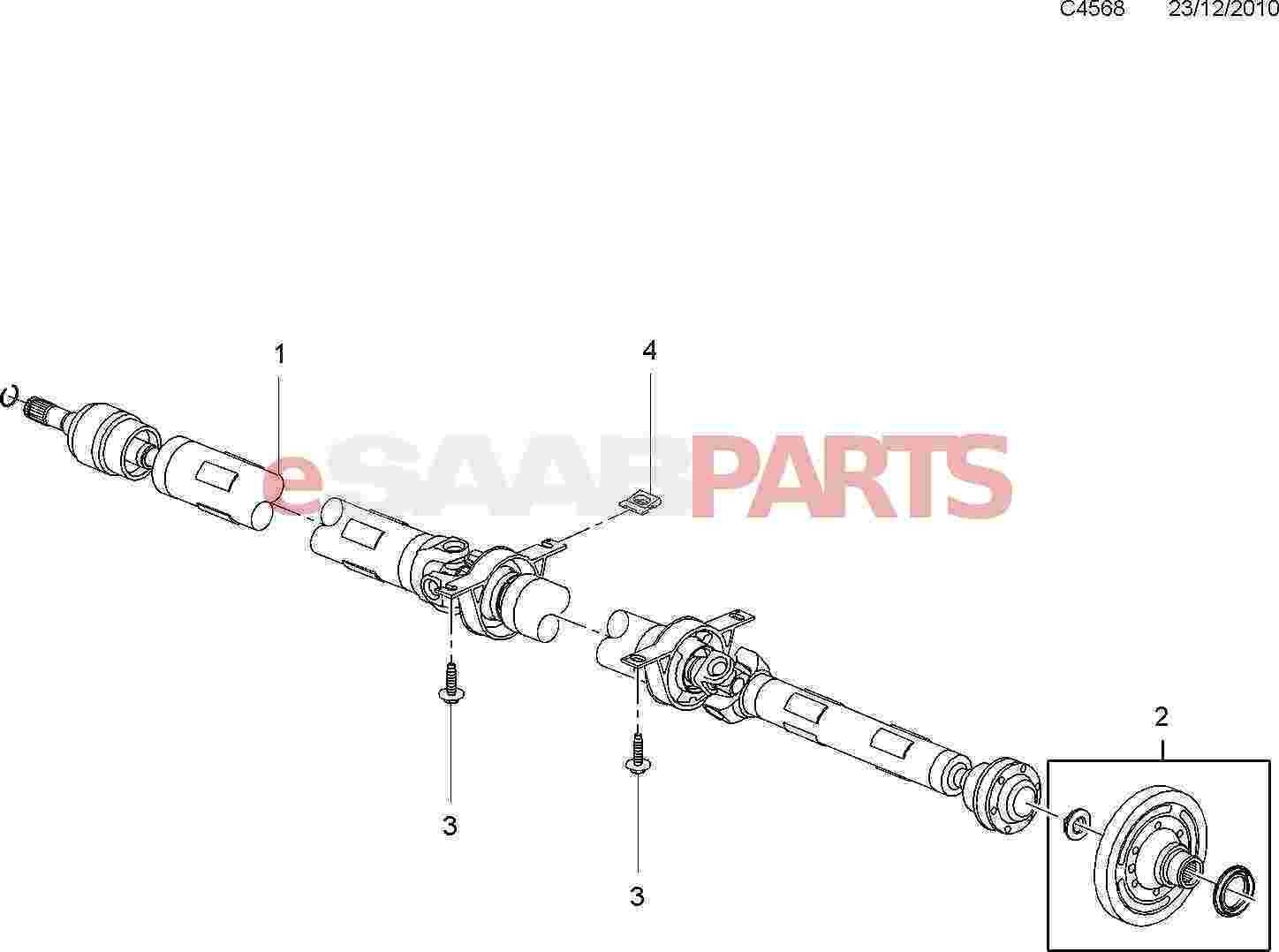

Key Components in a Driveshaft System

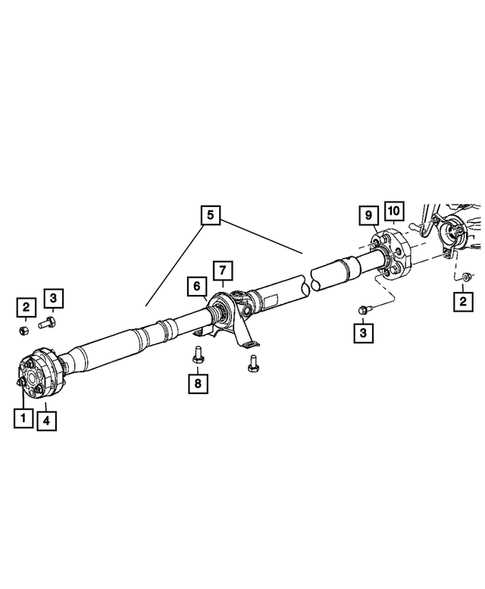

The assembly responsible for transmitting power from the engine to the wheels consists of several essential elements that work in unison. These components ensure smooth power delivery, enabling vehicles to move efficiently. Each part plays a specific role in maintaining balance, flexibility, and stability during operation.

Central Connecting Element

The core of the system is a long, cylindrical structure that connects the power source to the wheels. It is designed to handle high torque and rotational forces, absorbing vibrations and minimizing any potential imbalances during motion. This piece is crucial in transmitting energy without compromising the vehicle’s stability.

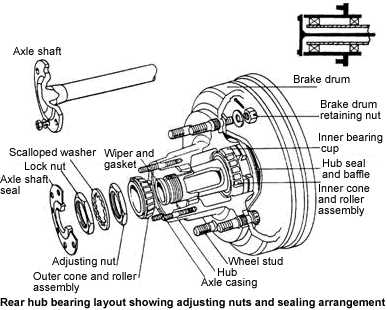

Rotational Support Mechanisms

These include various elements that ensure smooth rotation and alignment. They are critical for supporting the system’s movement, reducing wear, and maintaining proper alignment throughout its operation. Additionally, they contribute to the reduction of vibrations and noise, improving overall

How a Driveshaft Functions in Vehicles

The component that transmits rotational energy from the engine to the wheels plays a crucial role in enabling movement in automobiles. It serves as the link between different mechanical elements that require synchronized motion for the vehicle to operate efficiently. This system ensures that the power generated by the engine is properly delivered to the necessary parts of the vehicle’s undercarriage.

Here are key functions of this system:

- Transfers torque from the engine to the wheels

- Balances rotational forces to avoid vibrations

- Ensures flexibility when the vehicle navigates uneven terrain

- Facilitates smooth power delivery during acceleration and deceleration

In essence, this component ensures the seamless transmission of power, while accommodating for the movement and alignment of various parts of the vehicle’s drivetrain.

Identifying Common Driveshaft Issues

When it comes to vehicle performance and stability, there are several key components that play a crucial role in ensuring smooth operation. Recognizing symptoms of malfunction can prevent further damage and costly repairs. Understanding how these components operate and identifying early signs of wear or failure is essential for maintaining a safe and reliable vehicle.

| Issue | Symptom | Possible Cause | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vibrations while driving | Shaking or wobbling sensation at certain speeds | Imbalance or wear in rotating elements | |||||||||||

| Unusual noises | Clunking or banging when shifting gears | Loose or worn joints in the assembly | |||||||||||

| Difficulty in handling | Reduced control, especially during turns |

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Inspect for wear and damage | Every 10,000 miles | Prevents damage from affecting other components |

| Lubricate the system | Every 15,000 miles | Ensures smooth operation and reduces friction |

| Check for alignment and imbalance | Every 12,000 miles | Prevents excess strain on the system |

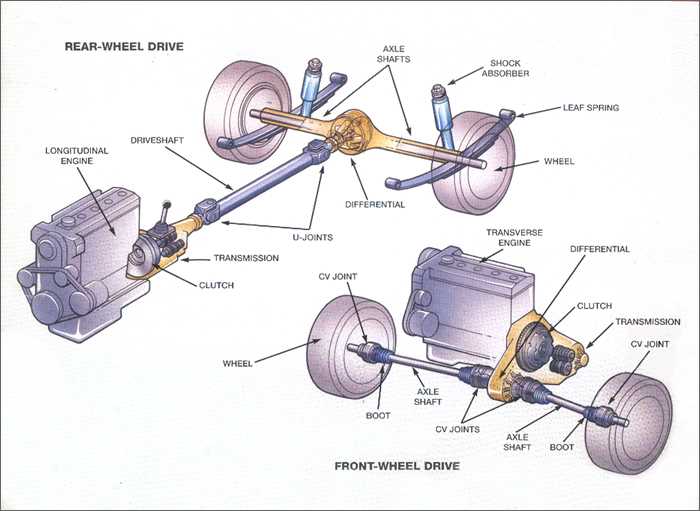

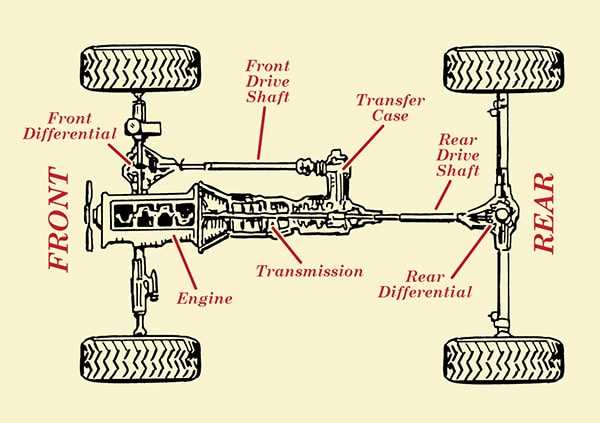

Differences Between Universal Joints and CV Joints

The components responsible for transmitting torque in a vehicle’s drivetrain differ significantly in design and functionality. While both types serve the purpose of connecting rotating elements, they operate in distinct ways and are suited for different driving conditions.

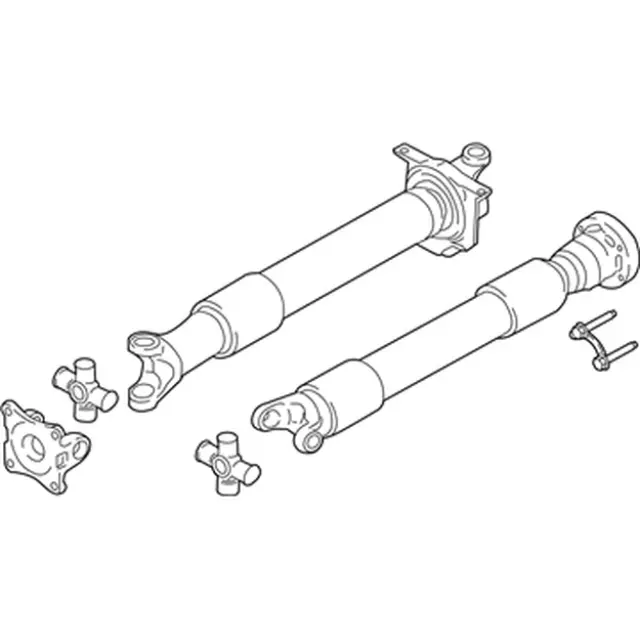

Universal Joints

Universal joints, commonly known as U-joints, are designed to accommodate angular changes in a rotating shaft. These joints provide flexibility and allow for rotational motion to be transmitted even when the connected shafts are not perfectly aligned. However, they have limitations in terms of smoothness at high angles, which can lead to vibrations and wear over time.

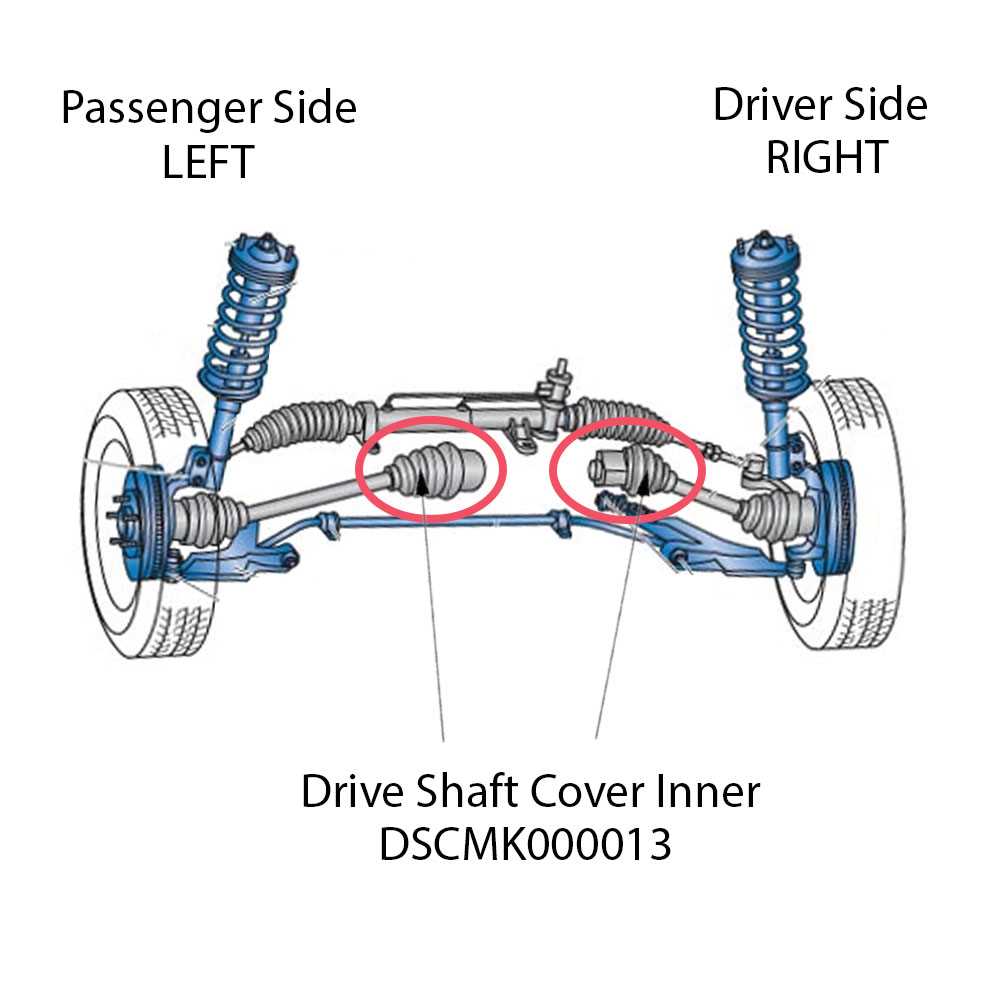

CV Joints

On the other hand, Constant Velocity (CV) joints are engineered to maintain smooth rotational motion even at high angles. They are often used in front-wheel drive systems or all-wheel drive vehicles where precise control over motion is necessary. CV joints are more complex in design, incorporating a set of bearings that enable them to operate with greater efficiency and stability compared to U-joints.

Replacing and Upgrading Driveshaft Components

Upgrading and replacing key components of the rotational system can significantly improve vehicle performance, efficiency, and handling. These components play a crucial role in transferring power from the engine to the wheels, and regular maintenance or enhancement can reduce wear, prevent damage, and optimize driving dynamics.

Choosing the Right Upgrades is essential for those looking to enhance vehicle capabilities. Higher-quality materials, such as stronger alloys or advanced composites, can provide greater durability and performance, especially for high-power setups or off-road driving conditions.

Proper Installation is equally important. Ensuring that the components are correctly aligned and securely fastened will prevent unnecessary stress on other system elements, avoiding potential failure. Professional installation or thorough research is recommended for achieving the best results.