Understanding the internal structure of modern cooling appliances is essential for those looking to maintain or repair these units. Each system is made up of various interconnected elements that ensure smooth and efficient operation. From the cooling mechanisms to the electrical circuits, these components work together to create an optimal environment for preserving food items. By exploring the arrangement and function of each section, users can gain a better grasp of how everything operates in unison.

The organization of different segments within these cooling systems plays a crucial role in their overall functionality. Whether it’s the temperature control system or the airflow pathways, each part contributes to maintaining a consistent climate within the storage area. Recognizing the placement and role of each element can make the process of troubleshooting and upkeep significantly easier.

Knowing the layout of these mechanisms is not only useful for repairs but also helps in selecting the right replacements when a malfunction occurs. A clear understanding of the physical setup allows owners and technicians to quickly identify areas that may need attention, ensuring the longevity and reliability of the cooling unit. By delving into the structure of these systems, one can achieve a more comprehensive knowledge of how they deliver consistent performance.

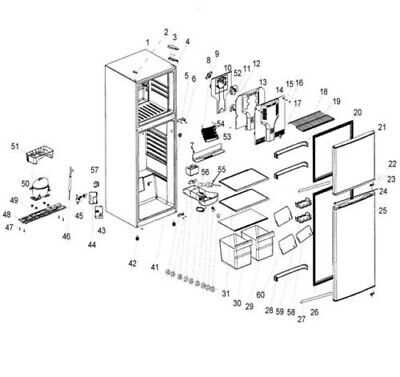

Overview of Common Components

This section focuses on the essential elements typically found in cooling appliances. Understanding each component helps to identify their functions and how they contribute to overall efficiency and performance. Below is a detailed look at some of the most critical parts involved in the cooling process.

Main Cooling Mechanisms

- Cooling Unit: Responsible for lowering the temperature, this unit regulates the environment inside by removing heat.

- Compressor: A key element that circulates the refrigerant through the system, ensuring the transfer of heat away from the interior.

- Evaporator Coils: These coils absorb warmth from the inside, allowing the cooling process to maintain the desired climate.

- Condenser Coils: Located externally, these coils release the accumulated heat into the surrounding air.

Additional Functional Parts

- Thermostat: Regulates the temperature settings, allowing users to maintain consistent cooling levels.

- Defrost System: Prevents frost buildup by periodically warming the interior to melt ice, keeping airflow unrestricted.

- Control Board: Acts as the central unit, managing the various systems and adjusting functions as needed for optimal performance.

- Sealing Gasket: Ensur

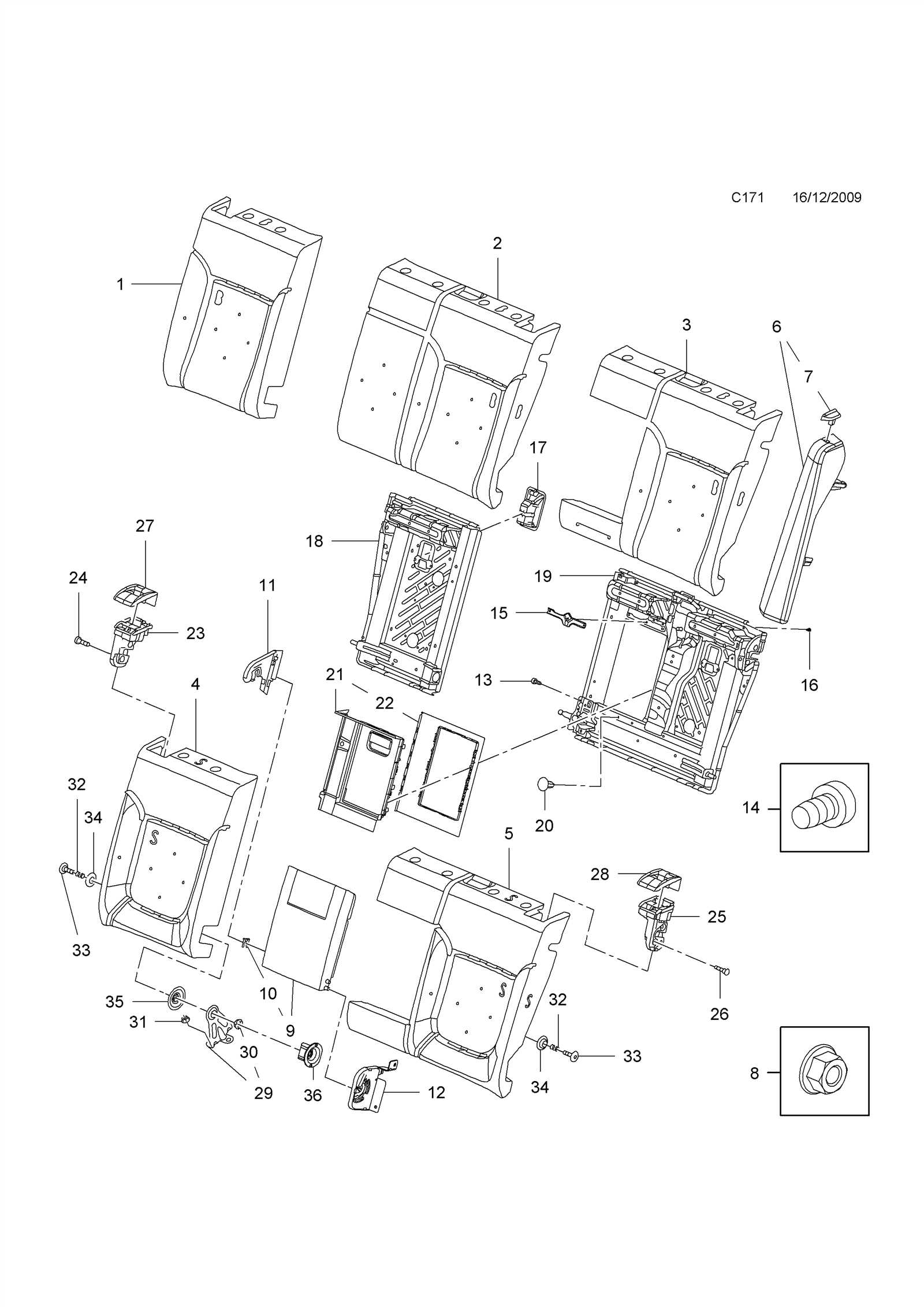

Understanding the Internal Structure

The internal layout is crucial for the efficient operation of cooling devices. By exploring the arrangement of key elements, users can gain a better understanding of how each part contributes to maintaining optimal conditions within the unit. This knowledge is valuable for both routine maintenance and identifying potential issues.

Main Components Overview

The design consists of multiple elements working in harmony. Each element plays a specific role in ensuring a consistent environment. Below is an overview of these core elements:

- Cooling Coils: Responsible for absorbing heat and lowering the temperature inside the space.

- Compressor Unit: Pressurizes the coolant, allowing it to flow through the coils effectively.

- Evaporator: Converts the refrigerant into gas, removing heat from the interior environment.

- Thermostat: Regulates the internal temperature by controlling the cooling cycles.

- Fans: Distribute cool air evenly throughout the compartment, ensuring a stable atmosphere.

Fluid Dynamics and Airflow

The system relies on the seamless movement of fluids and gases to maintain the desired climate. Proper airflow ensures uniform cooling, while the liquid pathways play a key role in heat exchange. Understanding how these processes interact is fundamental for optimizing performance and reducing energy consumption.

- Cooling System Mechanism Explained

The cooling process involves a series of components working together to maintain a consistent environment inside the unit. It operates through a sequence of thermal exchanges, enabling the reduction of internal warmth. Understanding the fundamental principles of this mechanism helps in recognizing how temperature stability is achieved.

At the heart of the system lies a compression process that transforms gaseous matter into a denser form. This pressurized form travels through tubes where it releases warmth to the outside environment. As it moves further, the substance undergoes expansion, turning into a cooler state and absorbing heat from the interior space. This cycle continues, ensuring efficient thermal regulation.

The control system plays a crucial role by adjusting the activity of each phase based on the detected temperature. This ensures that the cooling effect is adapted according to specific conditions, maintaining the desired atmosphere. With each part precisely tuned, the entire setup ensures optimal operation over time, providing a stable and reliable performance.

Key Functions of Cooling Coils

The cooling coils play a crucial role in the process of temperature regulation. These components are designed to transfer thermal energy, allowing for effective heat removal. Their design and functionality ensure the desired internal environment, contributing to the overall system efficiency.

Heat Absorption is one of the primary roles of these coils. As air passes over the coiled surface, warmth is absorbed, and the air becomes cooler. This mechanism aids in maintaining optimal conditions for various stored items, ensuring they remain fresh and safe.

The condensation process is another critical aspect of these coils. As the coils cool the air, moisture in the air condenses on their surface. This moisture is then directed away, preventing excess humidity buildup, which is essential for maintaining a balanced atmosphere.

Additionally, energy efficiency is enhanced through their operation. By facilitating the exchange of thermal energy, these coils minimize the effort required by the system to maintain the desired state, leading to reduced energy consumption and improved performance over time.

Identifying Temperature Control Elements

Understanding the mechanisms that regulate internal climate is crucial for ensuring optimal operation. These components maintain a stable environment, allowing the system to adjust to varying conditions and ensure consistent performance.

Key Components for Climate Regulation

- Thermostatic Sensors: These sensors detect variations in internal conditions and relay information to the control unit, which adjusts accordingly.

- Adjustable Dial or Digital Controls: Users can set the desired level using either manual dials or digital interfaces, providing precise adjustments.

- Defrost Timer: This element triggers periodic thawing, preventing frost buildup and ensuring that cooling remains efficient over time.

How Each Element Functions Together

These components work in coordination to maintain consistent cooling. The sensors detect fluctuations, the control adjusts settings, and the defrost timer prevents excessive accumulation, all contributing to a balanced system.

Exploring the Role of Thermostat

The component responsible for maintaining optimal temperature within a cooling unit is crucial for its overall functionality. This device monitors the internal environment and regulates the cooling cycle, ensuring that items remain fresh and at the desired chill level. Understanding its operation provides insights into how temperature control is achieved and maintained effectively.

How the Thermostat Functions

This device operates by sensing the temperature and sending signals to the compressor. When the interior temperature rises above a set threshold, it triggers the compressor to start cooling. Conversely, when the desired temperature is reached, the thermostat instructs the compressor to shut off, thus conserving energy and maintaining efficiency.

Importance of Accurate Calibration

Proper calibration of this device is vital for energy efficiency and preserving the quality of stored items. An incorrectly calibrated unit can lead to excessive energy consumption or inadequate cooling, resulting in spoilage. Regular checks and adjustments can help ensure accurate performance, extending the lifespan of the entire system.

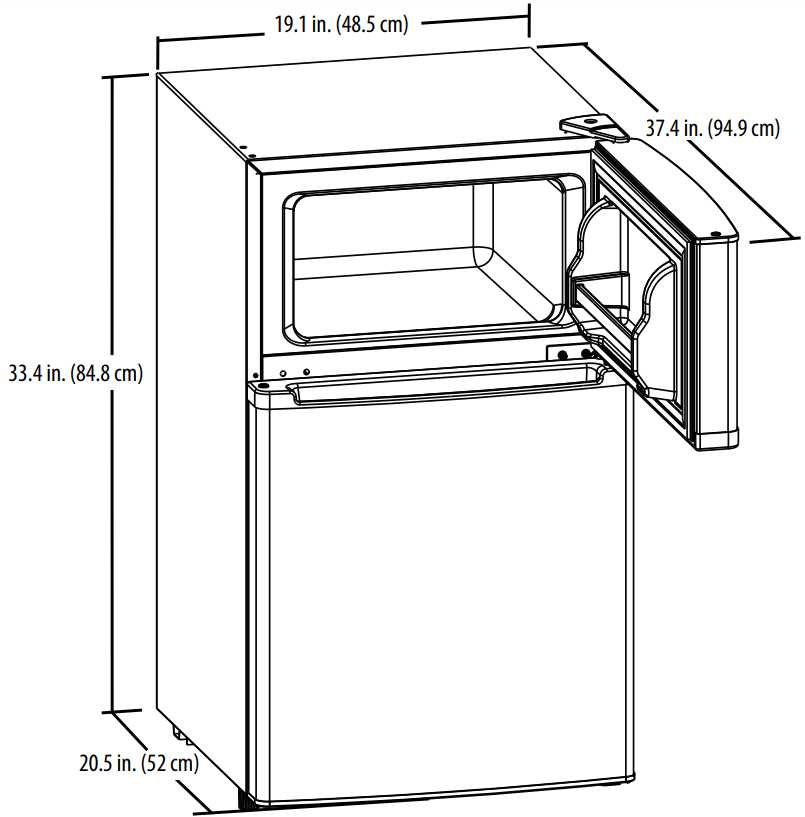

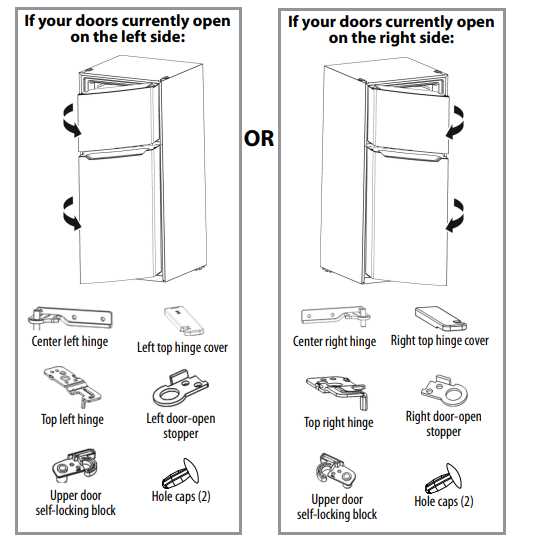

Insignia Refrigerator Door Assembly

The assembly that forms the entrance to your cooling unit is essential for maintaining optimal functionality and efficiency. This structure not only provides access but also plays a crucial role in preserving temperature levels and preventing energy loss.

Components of the Door Assembly

- Outer Panel: The exterior covering that protects internal elements and provides insulation.

- Inner Liner: The inner surface that forms the interior of the door, aiding in thermal efficiency.

- Gasket: The sealing component that ensures a tight closure, preventing air leakage.

- Hinges: Mechanisms that allow the door to pivot smoothly for easy access.

- Handle: The grip that enables effortless opening and closing of the entry.

Importance of Proper Maintenance

Regular upkeep of this assembly is vital for optimal performance. Neglecting maintenance can lead to:

- Increased energy consumption due to poor sealing.

- Temperature fluctuations that affect stored items.

- Wear and tear on hinges and handles, leading to operational issues.

Ensuring all components are in good condition will help enhance the longevity and efficiency of your cooling appliance.

Detailed Look at Door Seals

The effectiveness of any cooling unit heavily relies on its ability to maintain an optimal internal environment. A crucial component in achieving this is the barrier that prevents air exchange between the outside and the inner space. Understanding the significance of this element helps in ensuring energy efficiency and preserving the freshness of stored items.

Functionality and Importance

These barriers play a vital role in insulating the internal chamber. They are designed to create a tight seal that minimizes temperature fluctuations, thereby enhancing the unit’s overall performance. Without a proper seal, cold air can escape, leading to increased energy consumption and a decrease in the efficiency of the appliance.

Maintenance and Replacement

Regular inspection of these components is essential to identify wear and tear. Over time, exposure to moisture and varying temperatures can lead to deterioration. If any signs of damage are noticed, such as cracks or gaps, timely replacement is advised. Proper installation of a new barrier not only restores functionality but also contributes to cost savings in energy bills.

Compressor and Condenser Overview

The components responsible for the refrigeration cycle play a crucial role in maintaining low temperatures. These units work in tandem to facilitate the transfer of heat, ensuring optimal efficiency and performance.

The compressor acts as the heart of the system, circulating the refrigerant and compressing it to a high-pressure state. This process raises the refrigerant’s temperature, allowing it to absorb heat from the surrounding environment. Meanwhile, the condenser serves as a heat exchanger, where the hot refrigerant releases its heat to the outside atmosphere, transforming into a liquid state. Together, these elements are essential for effective cooling and temperature regulation.

Maintaining Compressor Efficiency

Ensuring optimal performance of the cooling unit is crucial for its longevity and functionality. One of the key components in this system is the compressor, which plays a vital role in regulating temperature. To achieve maximum efficiency, it is essential to adopt specific practices that prevent wear and maintain operational effectiveness.

Regular cleaning of the exterior and surrounding areas helps to prevent dust accumulation, which can hinder airflow and lead to overheating. Additionally, checking and ensuring proper insulation around the unit can significantly impact energy consumption and cooling performance. Keeping the condenser coils clean and free of debris is also vital, as this allows for efficient heat dissipation.

Monitoring refrigerant levels is another critical aspect of maintaining efficiency. Low levels can indicate leaks or other issues that need immediate attention. Scheduling routine inspections by a qualified technician ensures that any potential problems are addressed promptly, contributing to the overall health of the system.

Lastly, understanding the signs of wear, such as unusual noises or fluctuations in temperature, can help in identifying when maintenance or repairs are needed. By implementing these practices, the cooling mechanism can operate smoothly, ensuring a consistent and reliable environment.