In the realm of small engines, grasping the intricate relationships between various elements is crucial for efficient maintenance and operation. These components work in harmony to ensure optimal performance, and recognizing their configurations can greatly aid in troubleshooting and repairs.

Visual aids play an essential role in this process, as they provide a clear representation of how different parts interconnect. By examining these illustrations, one can delve into the specifics of assembly and functionality, ultimately enhancing one’s understanding of the machinery.

As we explore the essential features of these engines, we aim to equip readers with the ultimate knowledge needed for effective service and upkeep. This guide will illuminate the necessary insights for anyone seeking to maintain or repair their equipment with confidence.

Kohler Courage 19 Overview

This section provides a comprehensive look at a specific engine model known for its reliability and performance in various applications. Understanding its features and components can help users maintain and optimize its functionality.

Key Features

- Durable construction for longevity

- Efficient fuel consumption

- Compact design suitable for diverse machinery

Applications

- Lawn mowers

- Garden equipment

- Utility vehicles

Key Features of Kohler Courage 19

This section highlights the standout characteristics of a popular engine model that enhances performance and reliability in various applications. Understanding these features can help users make informed decisions when selecting equipment powered by this specific engine type.

| Feature | Description |

|---|---|

| Power Output | Delivers consistent horsepower, suitable for demanding tasks. |

| Durability | Engine design ensures long-lasting operation under heavy use. |

| Fuel Efficiency | Optimized for reduced fuel consumption, providing cost savings. |

| Easy Maintenance | Accessible components simplify routine upkeep and repairs. |

| Vibration Reduction | Engine technology minimizes vibrations, enhancing operator comfort. |

| Quiet Operation | Designed to operate with reduced noise levels, suitable for residential areas. |

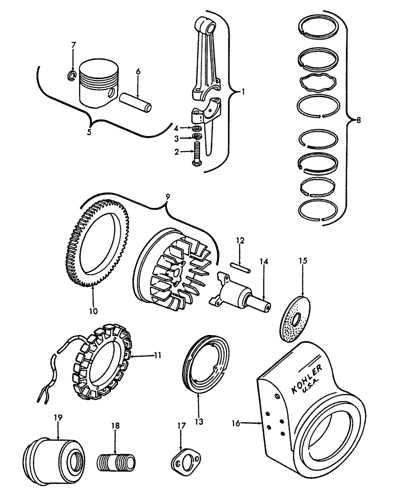

Understanding Engine Components

Engines are intricate machines composed of various elements working in harmony to convert fuel into mechanical energy. A deeper understanding of these components enhances appreciation for their functionality and the overall performance of the engine.

Key Engine Elements

Several critical parts contribute to the efficiency and effectiveness of any engine. These components can be categorized based on their roles in the combustion process, power generation, and overall operation.

| Component | Function |

|---|---|

| Cylinder | Holds the piston and contains the combustion process. |

| Piston | Translates the force from combustion into mechanical motion. |

| Crankshaft | Converts linear motion of the piston into rotational motion. |

| Valves | Regulate the flow of air and fuel into the combustion chamber. |

| Fuel Injector | Sprays fuel into the combustion chamber for optimal burning. |

The Importance of Each Component

Understanding the specific roles of each part is essential for diagnosing issues and optimizing performance. Each element not only contributes individually but also plays a vital role in the synergy that drives the engine’s ultimate efficiency.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your engine requires regular upkeep and attention. Implementing a routine maintenance schedule can significantly enhance performance and prevent potential issues. By focusing on key areas, you can maintain optimal functionality and avoid unnecessary repairs.

Regular Inspection

Performing frequent checks is essential to identify any wear or damage early. Look for signs of leaks, frayed belts, and any irregularities in operation. A proactive approach helps in maintaining peak performance.

Cleaning and Lubrication

Keeping components clean is crucial for smooth operation. Remove dirt and debris from air filters and cooling fins. Additionally, ensuring all moving parts are properly lubricated reduces friction and extends the life of the engine.

| Task | Frequency |

|---|---|

| Check oil level | Every use |

| Clean air filter | Every 10 hours |

| Inspect spark plug | Every season |

| Change oil | Every 50 hours |

Common Issues and Solutions

When dealing with small engine equipment, users often encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems and their potential fixes can greatly enhance the longevity and reliability of your machinery.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine won’t start | Empty fuel tank, clogged fuel line, faulty spark plug | Check and refill fuel, inspect and clean fuel lines, replace spark plug if necessary |

| Loss of power | Dirty air filter, dull blades, improper fuel mixture | Clean or replace air filter, sharpen blades, ensure correct fuel mixture |

| Excessive vibrations | Loose mounting bolts, unbalanced blades, damaged components | Tighten all bolts, check for blade balance, inspect for and replace any damaged parts |

| Overheating | Low oil level, blocked cooling fins, malfunctioning thermostat | Add oil as needed, clear debris from cooling fins, check and replace thermostat |

Importance of Regular Inspections

Conducting routine evaluations is essential for maintaining optimal performance and longevity of any mechanical equipment. These assessments help identify potential issues before they escalate into major problems, ensuring reliable operation and reducing downtime.

Benefits of Regular Evaluations

- Prevention of costly repairs

- Improved safety for operators

- Enhanced efficiency and performance

- Extended lifespan of machinery

Key Areas to Focus On

- Engine functionality and fuel system

- Electrical components and wiring

- Cooling and lubrication systems

- Physical wear and tear of parts

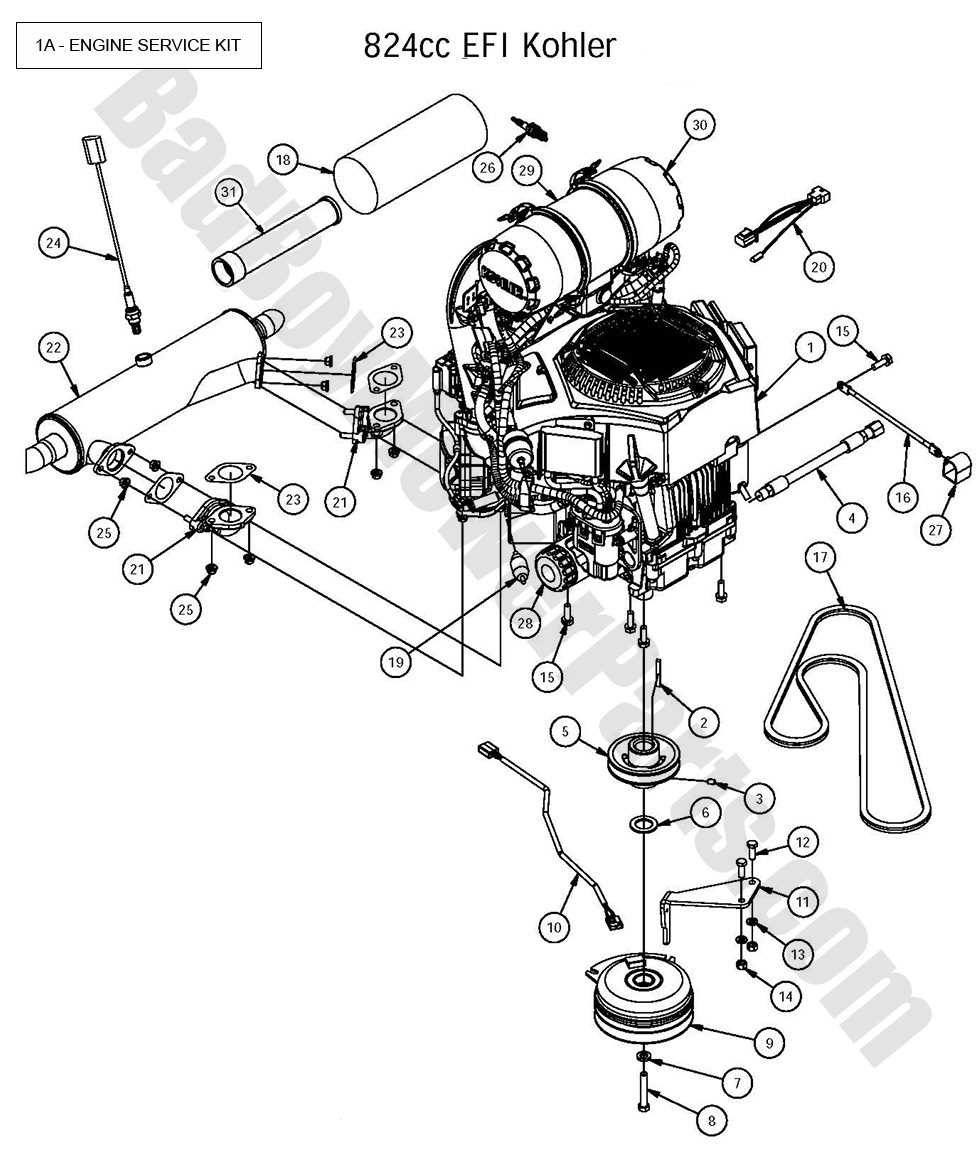

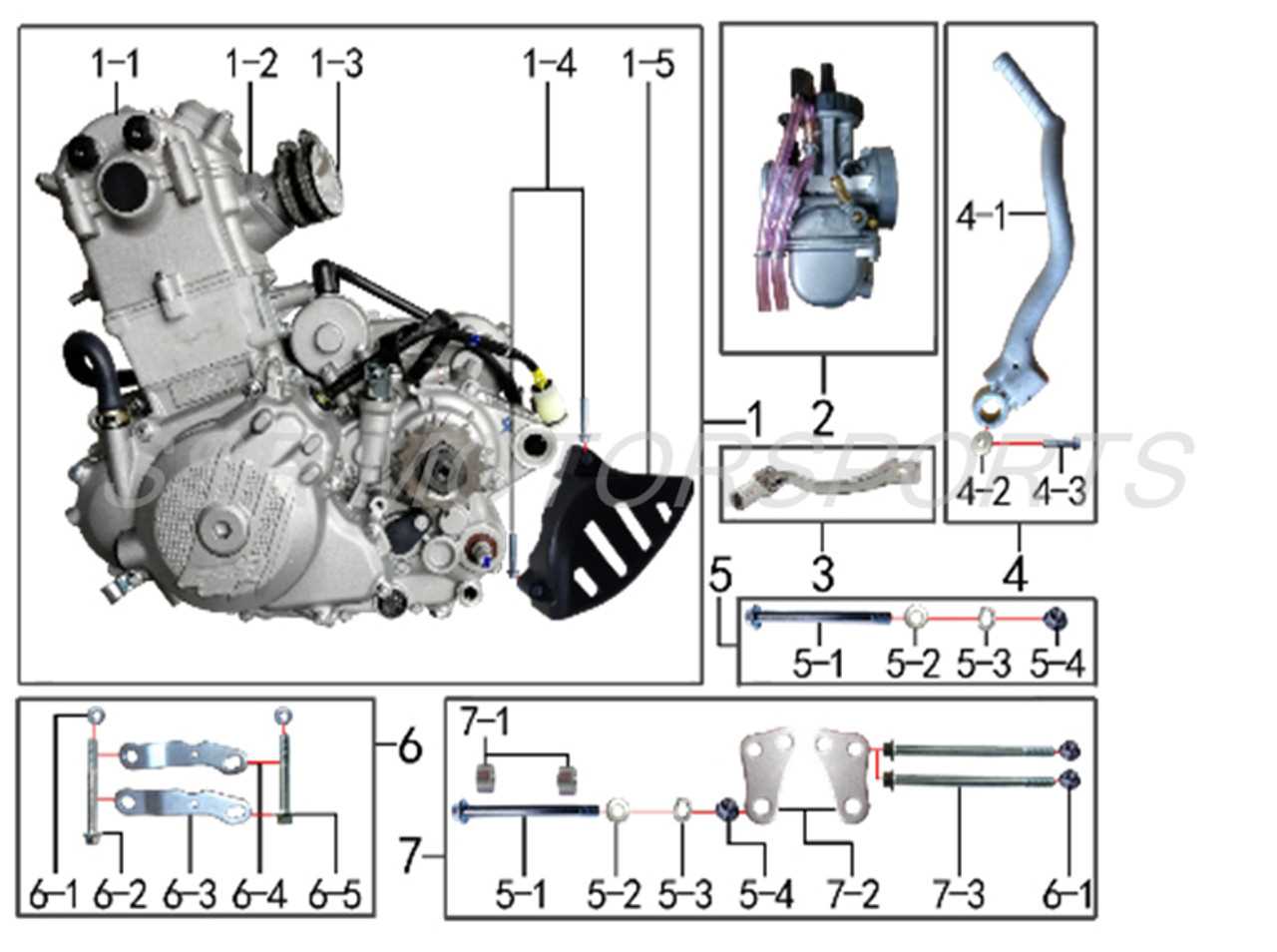

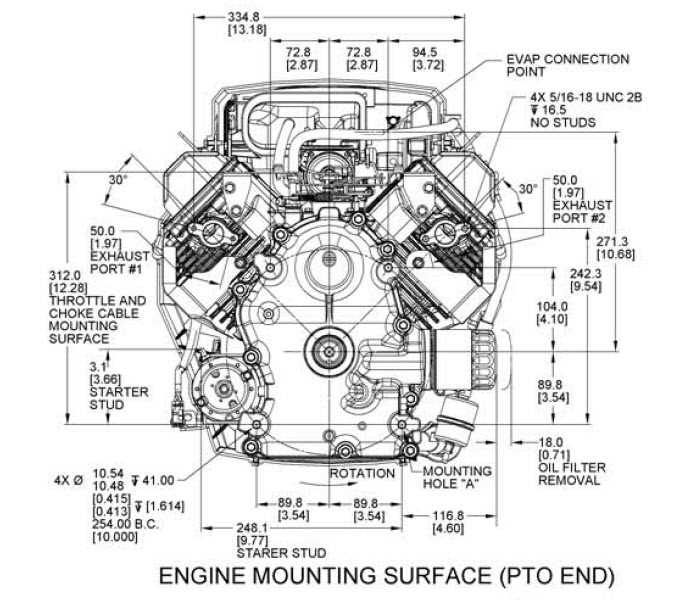

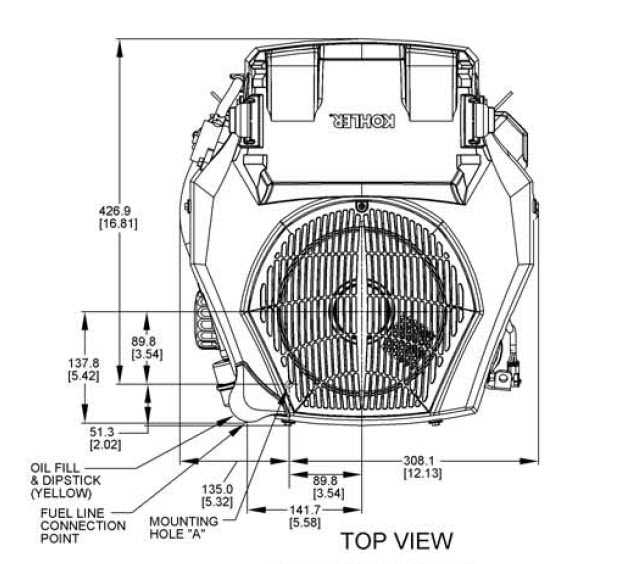

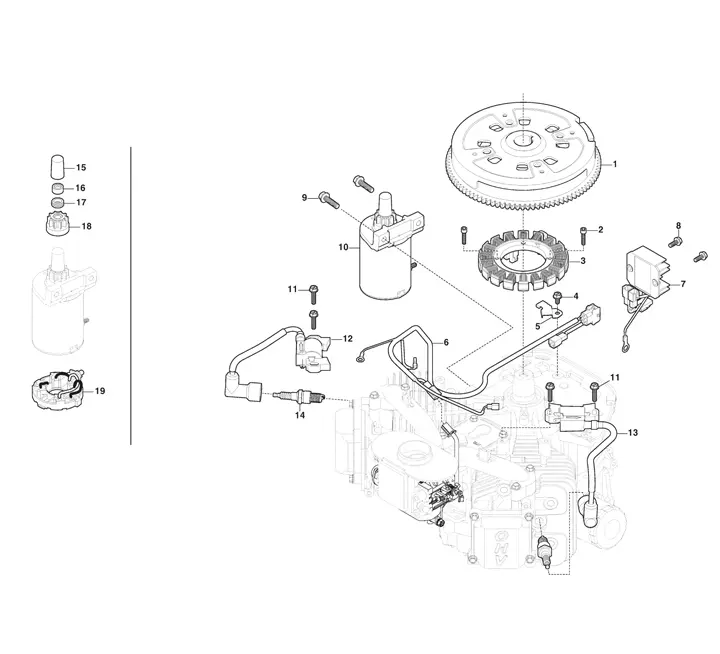

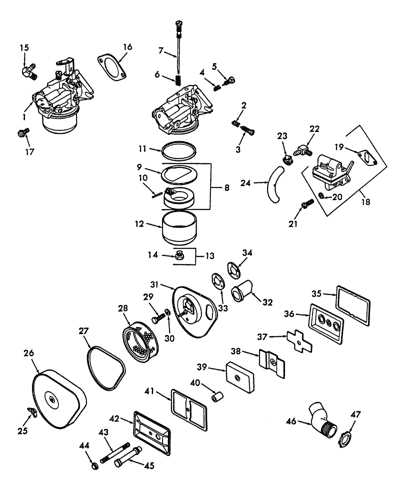

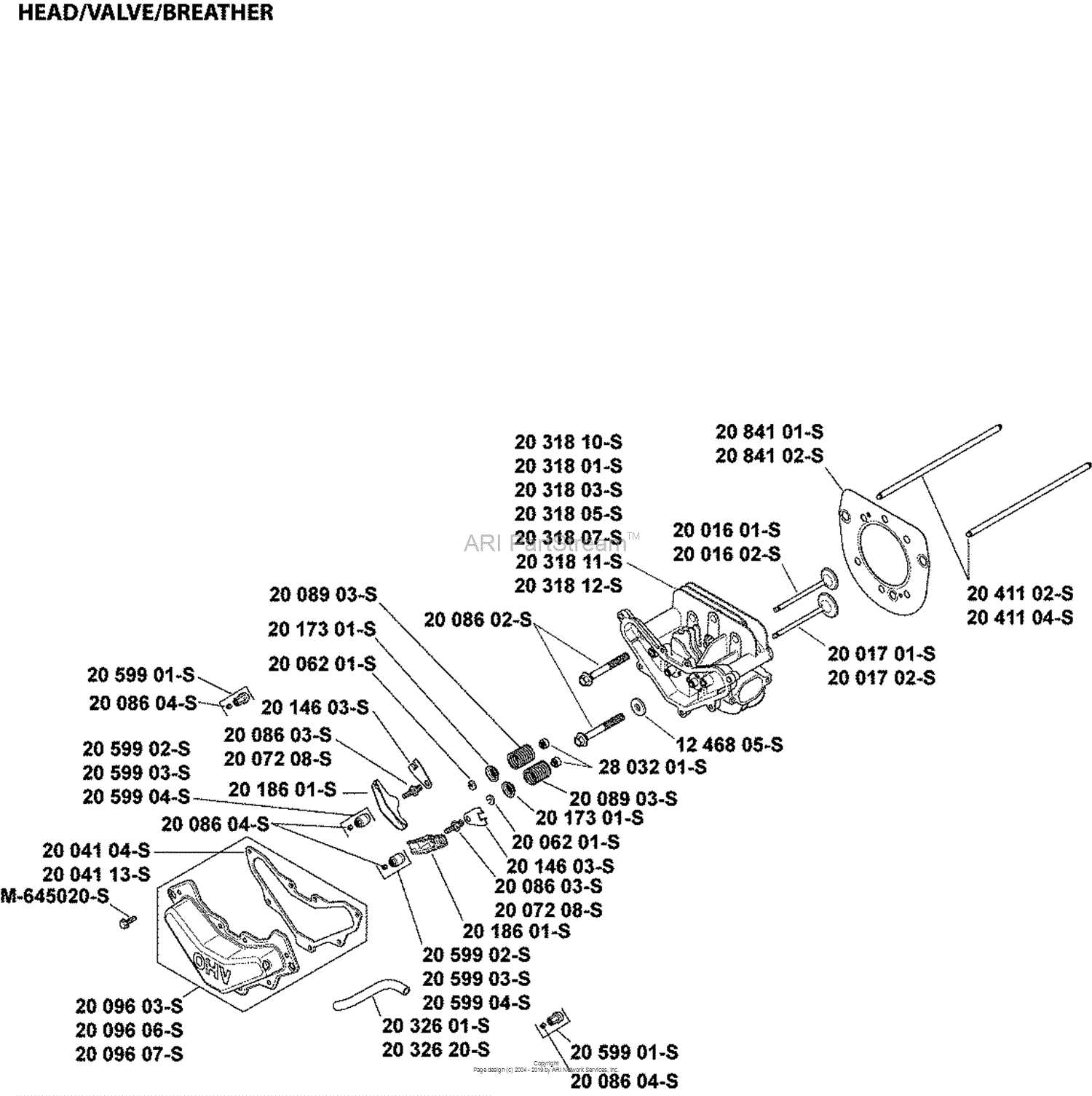

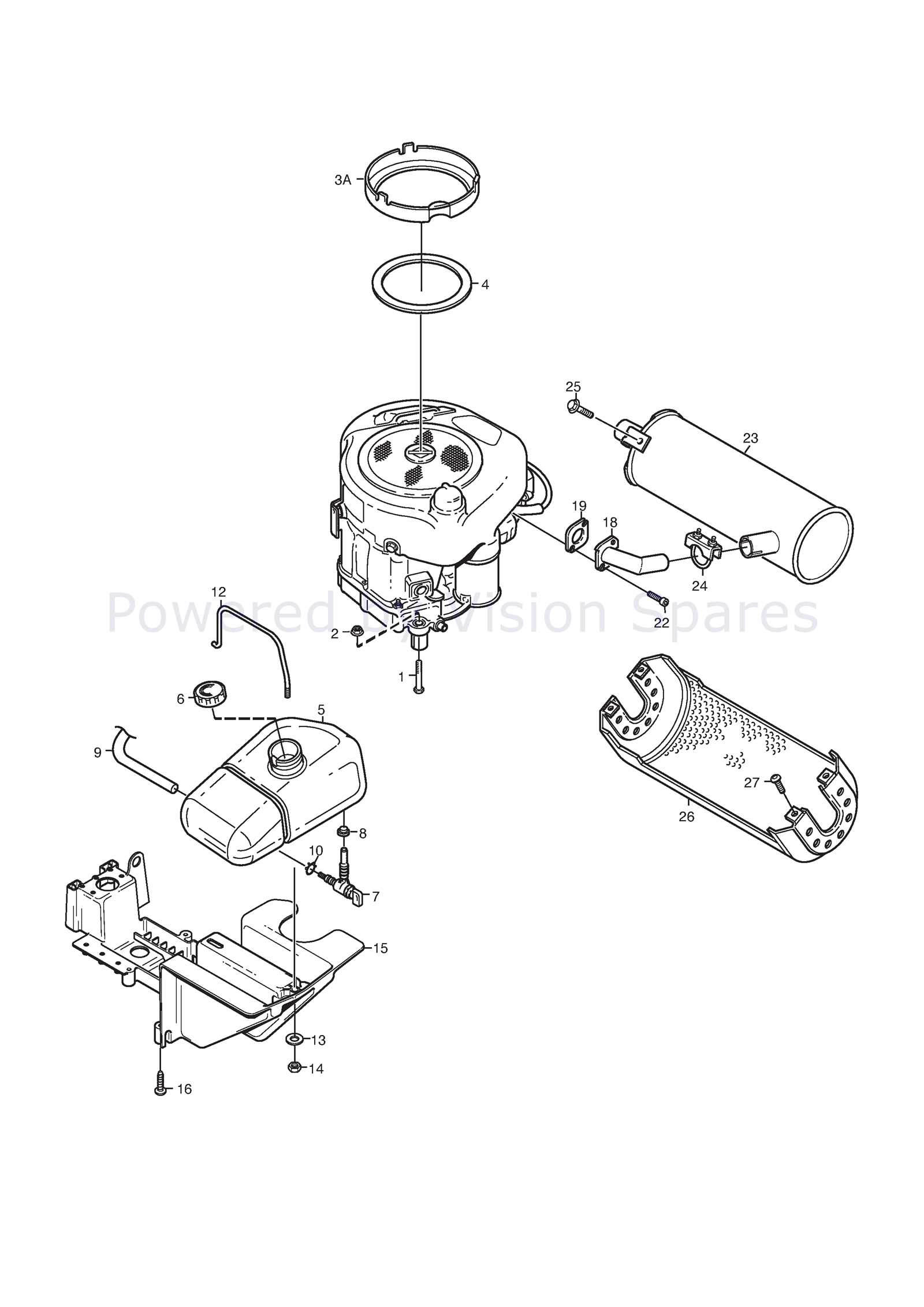

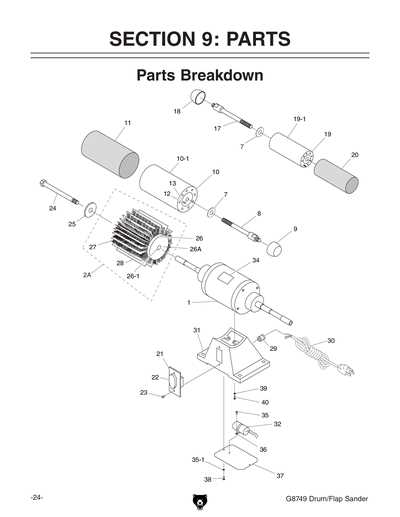

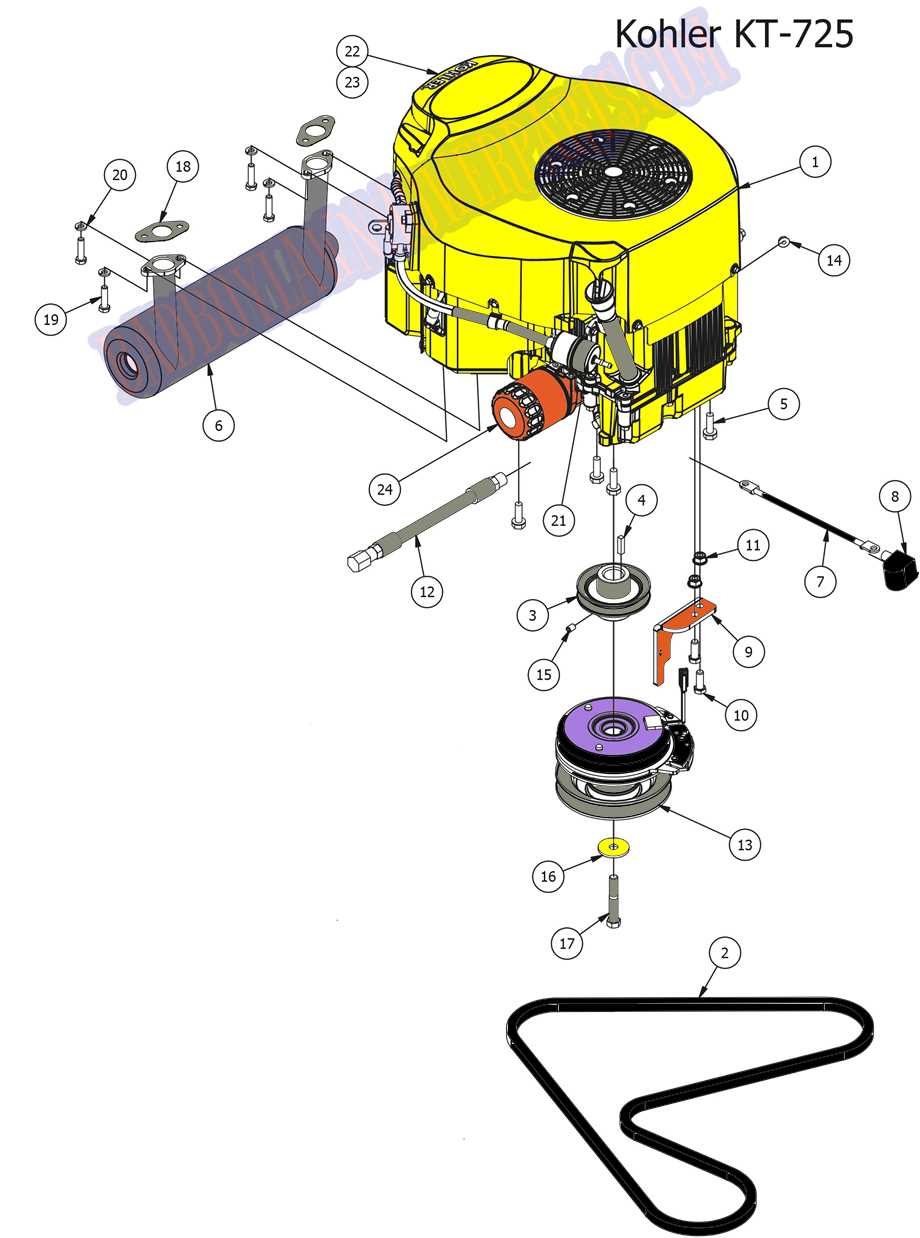

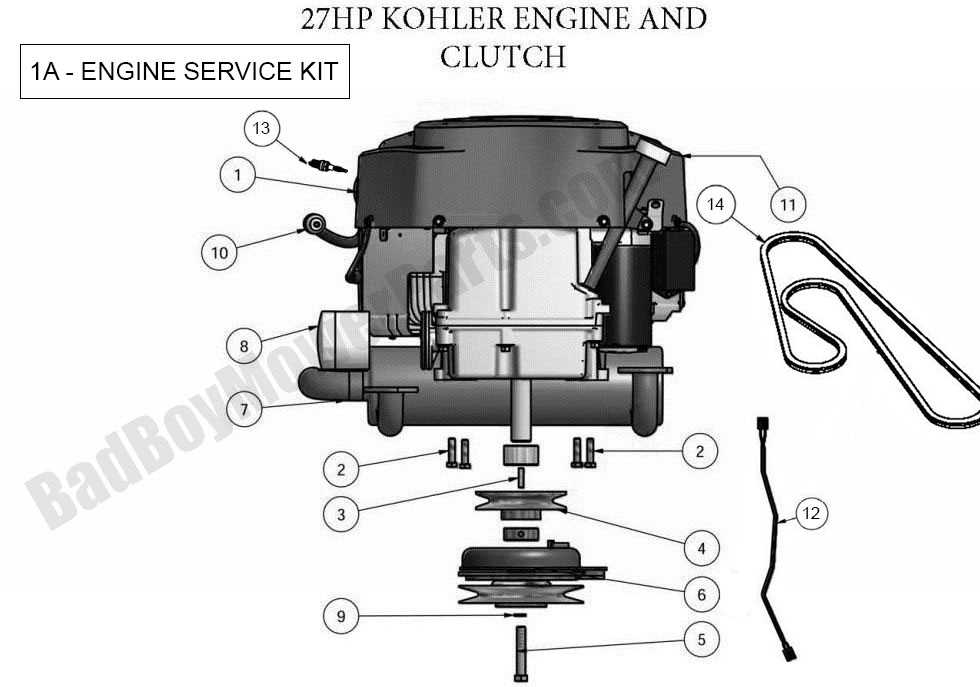

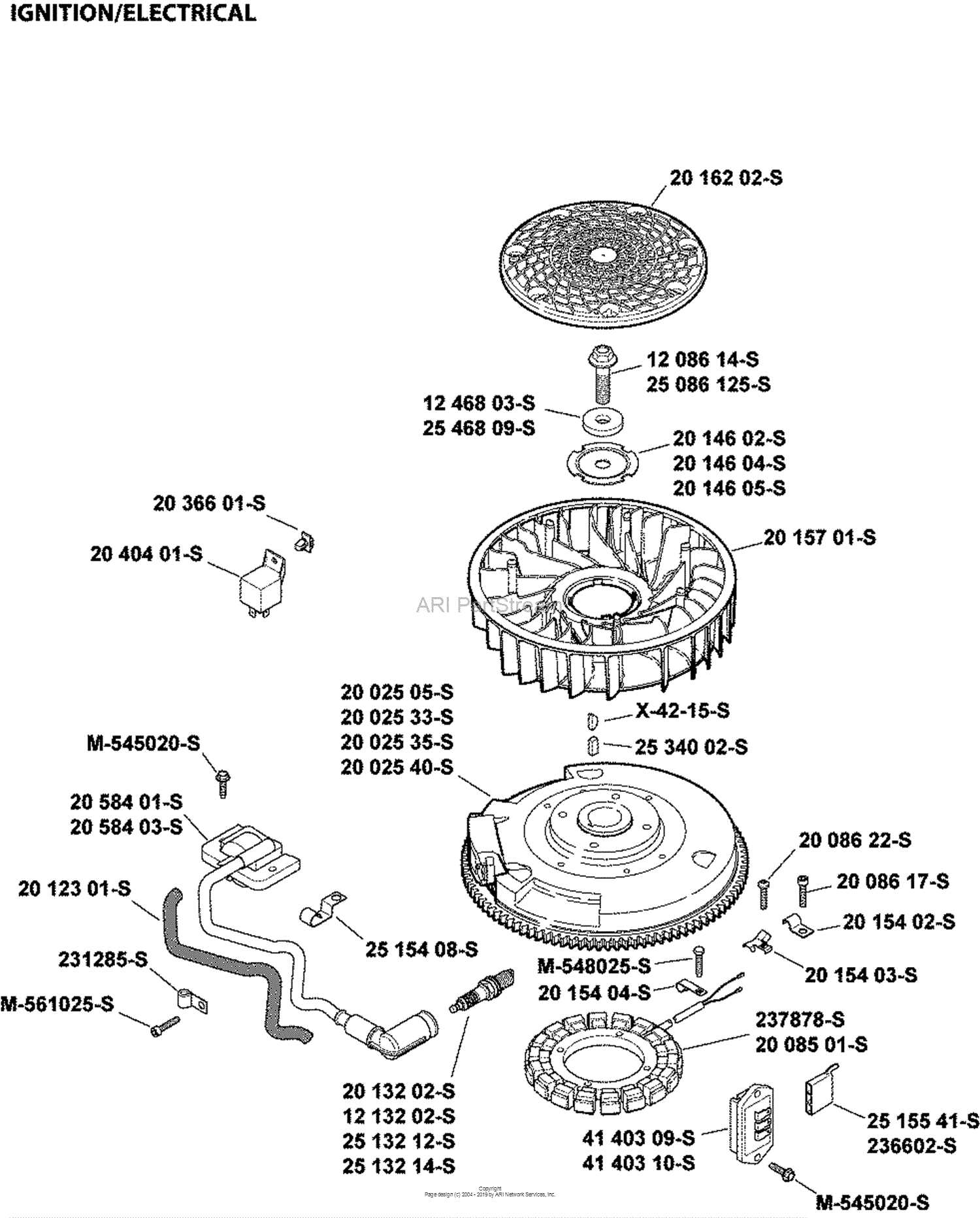

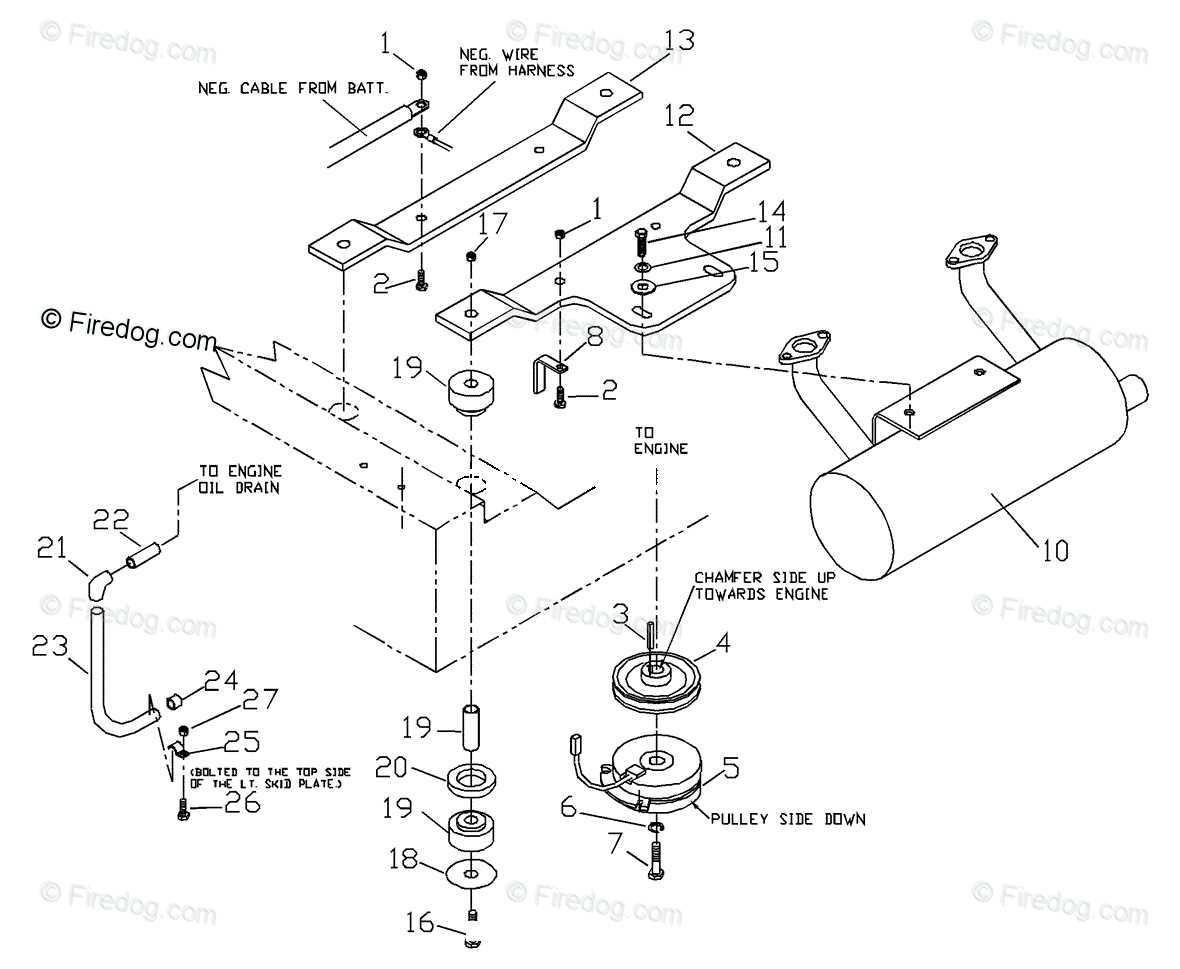

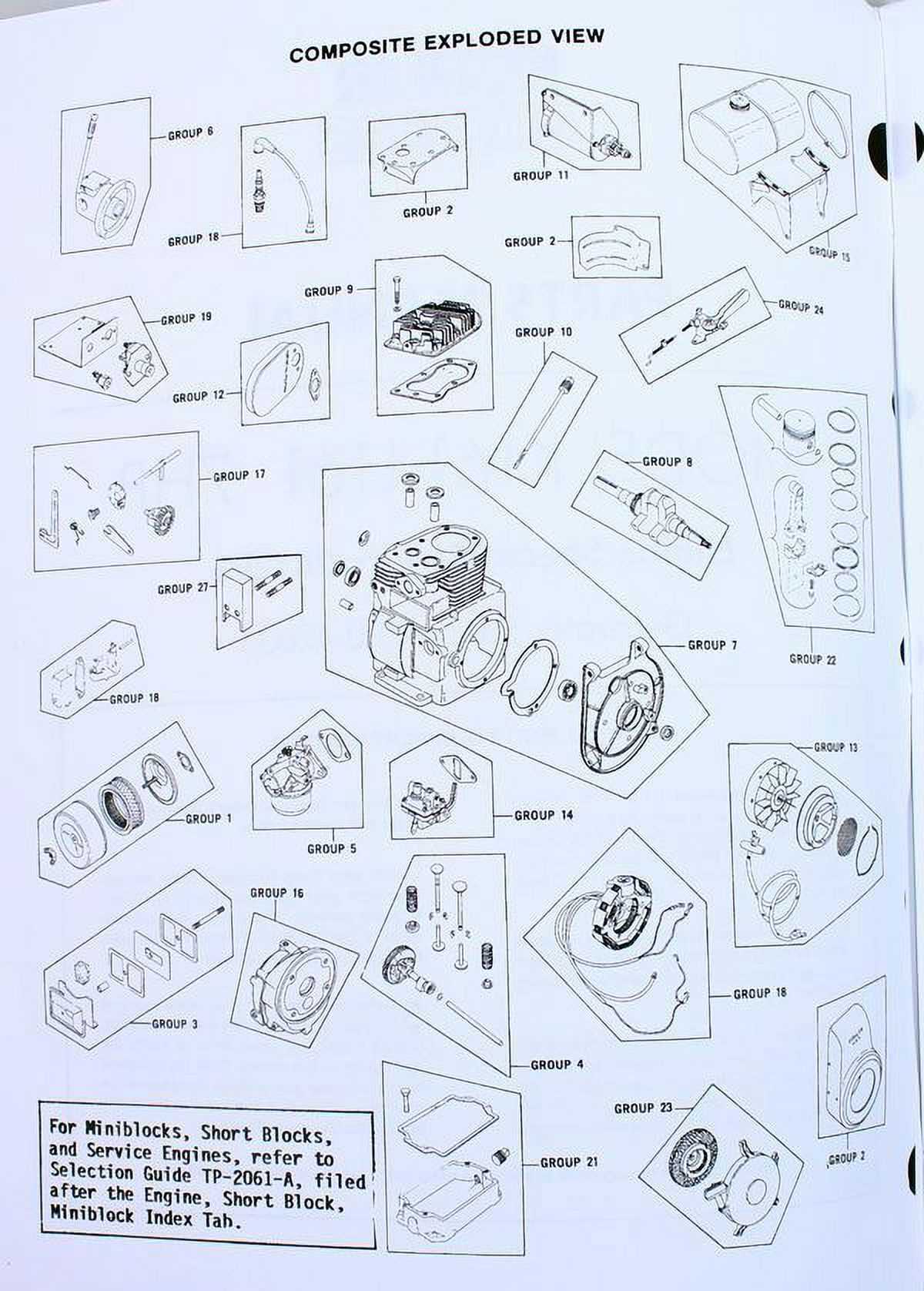

Parts Diagram Explained

Understanding the layout and components of an engine is essential for effective maintenance and troubleshooting. This section aims to clarify the various elements involved, their functions, and how they interrelate within the mechanical system.

Each component plays a significant role, contributing to the overall performance and efficiency of the machine. Familiarity with these elements can aid in identifying issues and ensuring optimal functionality.

- Engine Block: The foundation of the engine, housing essential components.

- Cylinder Head: Contains the combustion chamber and valves, crucial for air-fuel mixture and exhaust flow.

- Piston: Moves up and down within the cylinder, facilitating the combustion process.

- Crankshaft: Converts linear motion from the piston into rotational motion, driving the machine.

- Valves: Control the intake and exhaust of gases, vital for efficient operation.

Understanding the arrangement and interaction of these components can simplify repair processes and enhance performance. Knowledge of the mechanical structure leads to better maintenance practices and informed decisions during servicing.

- Regular inspections can prevent major issues.

- Identify worn or damaged components early.

- Use the layout to guide reassembly during repairs.

In summary, a clear grasp of the engine’s architecture enables more effective management, resulting in longer lifespan and better performance of the equipment.

Where to Find Replacement Parts

Locating the necessary components for your engine can be a straightforward process if you know where to look. A variety of resources are available, catering to different preferences and needs. Below are some effective ways to find what you need.

- Official Retailers: Start by checking with authorized dealers. They often stock genuine components that ensure compatibility and reliability.

- Online Marketplaces: Websites like Amazon, eBay, and specialized retailers provide a wide selection. Be sure to read reviews and check seller ratings for quality assurance.

- Local Repair Shops: Many mechanics and service centers maintain inventories of common items. Establishing a relationship with a local shop can also provide insights and recommendations.

- Manufacturer’s Website: Visit the official website for direct access to specifications and ordering options. Many manufacturers have online catalogs and can guide you on compatible items.

- Forums and Online Communities: Engage with enthusiasts and professionals on platforms dedicated to engines. Members often share sources for hard-to-find components and offer advice on installations.

- Salvage Yards: For those on a budget, checking salvage or recycling yards can yield usable parts at a fraction of the cost.

lessCopy code

Utilizing these resources can simplify the process of sourcing the right components, ensuring your engine runs smoothly and efficiently.