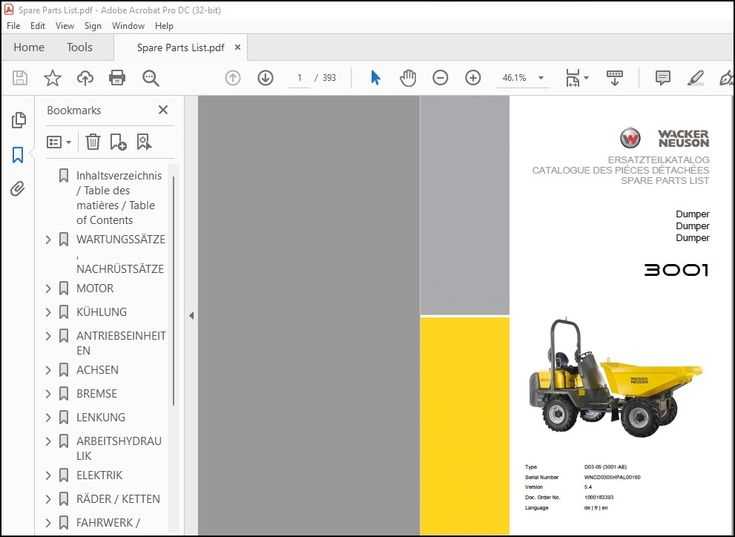

The intricate workings of heavy machinery demand a thorough understanding of their various components and how they fit together. Each element plays a crucial role in ensuring the overall efficiency and performance of the equipment. Grasping the arrangement of these elements is vital for maintenance, troubleshooting, and optimal operation.

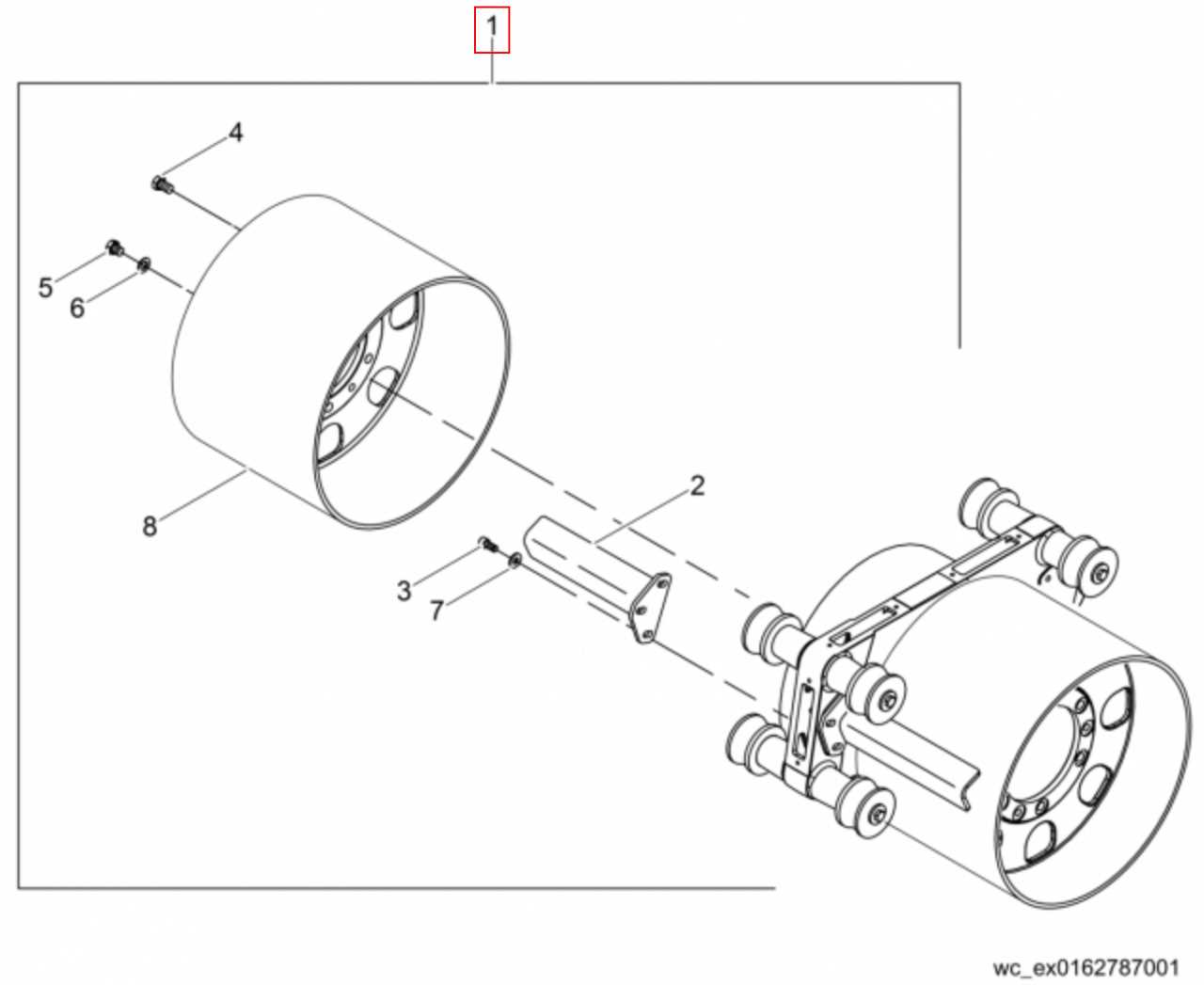

In this section, we will delve into the intricate schematics that illustrate the relationships and functions of different machine elements. By familiarizing ourselves with these layouts, operators and technicians can better navigate repair processes and make informed decisions regarding their machinery.

Moreover, a detailed examination of these illustrations not only aids in the identification of specific components but also enhances the understanding of how they interact. This knowledge ultimately contributes to improved functionality and longevity of the equipment, ensuring that it remains a reliable asset in various applications.

Understanding Wacker Neuson Parts Diagrams

Gaining insights into machinery layouts is essential for efficient maintenance and repair. By familiarizing oneself with visual schematics, users can effectively navigate through various components, ensuring optimal functionality and longevity of equipment.

Importance of Visual Representations

Visual aids serve as crucial tools in understanding intricate systems. They provide clarity, enabling users to identify specific elements quickly. This understanding can ultimately lead to improved troubleshooting and reduced downtime.

How to Utilize Schematics Effectively

To maximize the benefits of these illustrations, users should study each section carefully, cross-referencing with manuals when necessary. This approach not only enhances comprehension but also empowers users to perform repairs with confidence.

Importance of Parts Diagrams in Maintenance

Understanding the intricacies of machinery is vital for effective upkeep. Visual representations serve as essential tools, providing clarity and guidance for technicians during servicing tasks. They facilitate precise identification of components, streamlining the repair process and minimizing downtime.

Enhancing Efficiency

Clear visual aids enable professionals to quickly locate and address issues, ensuring efficient maintenance workflows. This ultimately leads to improved machinery performance and longevity.

Reducing Errors

By utilizing these visuals, technicians can avoid mistakes that may arise from miscommunication or misunderstanding. Accurate depictions foster a deeper understanding of assembly and disassembly, reducing the risk of damage during repairs.

| Benefits | Description |

|---|---|

| Clarity | Provides clear identification of components. |

| Efficiency | Streamlines the repair process. |

| Error Reduction | Minimizes mistakes in servicing tasks. |

How to Access Wacker Neuson Diagrams

Accessing technical illustrations for machinery can significantly enhance your understanding of its components and their functions. These resources provide detailed views that are essential for maintenance and repair tasks. Knowing how to obtain these visuals can ultimately save time and improve efficiency.

Online Resources: Many manufacturers offer digital platforms where you can easily find these illustrations. Look for official websites or authorized dealer portals that provide comprehensive databases.

Manuals and Guides: Hard copies of user manuals often contain these visuals. Ensure to check the documentation that accompanies your machinery, as it can be a valuable reference.

Technical Support: If you encounter difficulties, reaching out to customer support can be beneficial. They can guide you on where to find the necessary resources.

In summary, utilizing online platforms, manuals, and support services will enable you to delve into the intricate details of your equipment effectively.

Common Components in Equipment Manuals

Understanding the essential elements of equipment documentation is crucial for effective operation and maintenance. These components provide valuable insights, enabling users to maximize the efficiency and longevity of their machinery.

| Component | Description |

|---|---|

| Specifications | Detailed information about the equipment’s capabilities and requirements. |

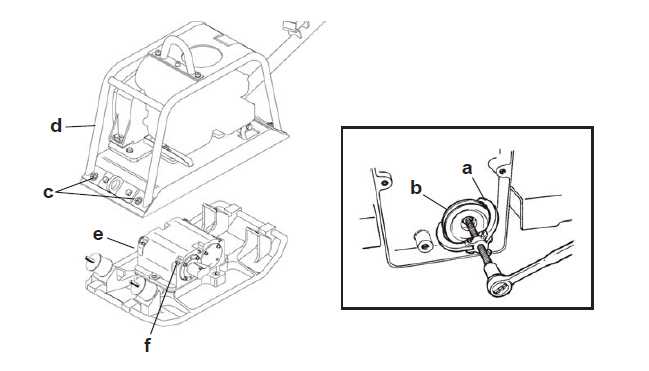

| Assembly Instructions | Guidelines for proper setup and configuration of components. |

| Troubleshooting Guide | Step-by-step procedures to identify and resolve common issues. |

| Maintenance Schedule | Recommended timelines for routine inspections and service tasks. |

| Safety Information | Critical guidelines to ensure safe operation and prevent accidents. |

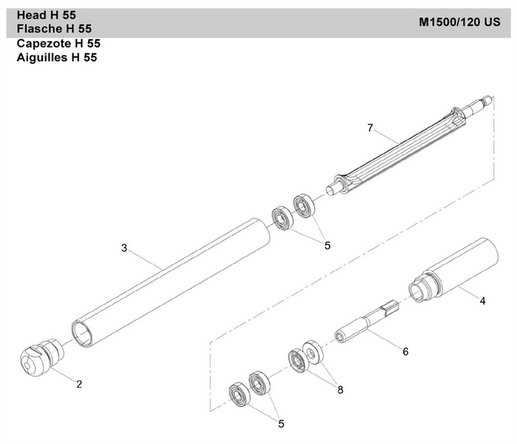

Interpreting Diagrams for Troubleshooting

Understanding visual representations is crucial for effective diagnostics and maintenance. These illustrations serve as guides, allowing technicians to identify components and their relationships within machinery. By familiarizing oneself with these visual tools, one can streamline the process of troubleshooting and enhance problem-solving skills.

To begin, familiarity with symbols and notations is essential. Each representation includes unique icons that denote various elements, such as mechanical parts, electrical connections, and fluid pathways. Recognizing these symbols can significantly reduce the time spent deciphering the information presented.

Next, pay attention to the layout of the visual guide. Components are often arranged in a logical sequence, reflecting their physical arrangement in the equipment. This organization aids in tracing the flow of operations and identifying potential points of failure. When a malfunction occurs, it becomes easier to locate the affected areas by following the paths depicted.

Furthermore, contextual understanding enhances the troubleshooting process. It’s important to consider the operational environment and the specific symptoms being experienced. By correlating these factors with the information in the visual representation, one can make more informed decisions about possible causes and necessary interventions.

Finally, consistent practice with these visual tools will build confidence. Over time, technicians will develop an intuitive sense of how to approach problems, utilizing the illustrations as valuable resources. With each experience, the ability to quickly interpret and act upon the information will improve, leading to more efficient repairs and maintenance.

Benefits of Using Accurate Diagrams

Utilizing precise visual representations in machinery maintenance offers numerous advantages that enhance both efficiency and understanding. These illustrations serve as essential tools for operators and technicians, facilitating easier identification of components and their relationships within complex systems.

Improved Efficiency

Accurate visuals enable quick troubleshooting and repair processes. Technicians can rapidly locate parts, reducing downtime and ensuring that tasks are completed efficiently. Time savings in maintenance translate directly to improved productivity on the job site.

Enhanced Understanding

These detailed representations promote a deeper comprehension of machinery operations. By providing a clear overview of how different elements interact, users gain confidence in handling equipment. Informed decision-making leads to better maintenance practices and longevity of the machines.

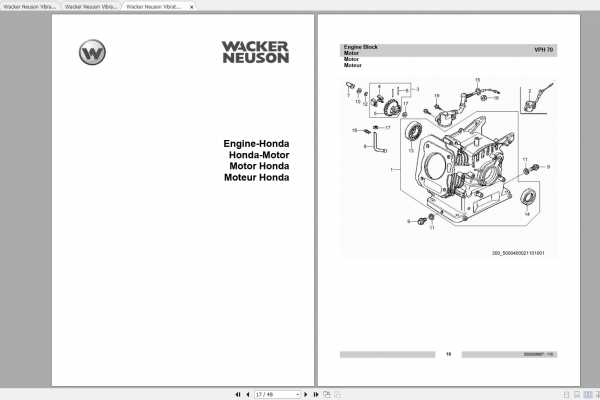

Comparing Diagrams Across Different Models

When examining the layouts of machinery components across various models, it becomes evident that each version showcases unique design elements and configurations. This variation not only highlights the advancements in technology but also reveals how different models address specific operational needs.

Understanding these differences is crucial for professionals who maintain or repair equipment. By analyzing the schematics, one can identify compatibility issues, recognize common features, and pinpoint areas for improvement. Each illustration serves as a guide, offering insights into how parts interact within the machine’s framework.

Furthermore, comparing these layouts can enhance efficiency during maintenance tasks. Technicians can streamline their approach by familiarizing themselves with similar components across models, reducing downtime and minimizing errors. This comparative analysis ultimately contributes to better performance and longevity of the equipment.

Resources for Parts Diagram Reference

When it comes to maintaining and servicing machinery, having access to detailed visual guides is essential. These resources not only enhance understanding but also streamline the repair process, ensuring that every component is identified accurately. For professionals and enthusiasts alike, finding reliable references can make a significant difference in efficiency and effectiveness.

Online Platforms: Numerous websites offer comprehensive catalogs that feature detailed illustrations. These platforms typically provide search functionalities, allowing users to locate specific models and their corresponding schematics quickly.

Manufacturer Websites: The official sites of equipment manufacturers often host valuable resources, including downloadable manuals and visual references. These documents are frequently updated, ensuring that users have the most current information available.

Community Forums: Engaging with online communities can be incredibly beneficial. Many forums host discussions where users share insights, tips, and even custom diagrams that can aid in understanding complex machinery layouts.

Trade Shows and Expos: Attending industry events can provide direct access to representatives who can offer firsthand knowledge and printed materials. Networking at these gatherings can also lead to discovering additional resources.

Local Dealers: Authorized dealers often keep an inventory of reference materials. Visiting or contacting these local businesses can yield useful guides and the chance to consult with knowledgeable staff.

By utilizing these diverse resources, users can enhance their understanding and proficiency in handling machinery, ensuring that repairs and maintenance are conducted with confidence and precision.

Future of Digital Parts Documentation

The landscape of technical documentation is evolving rapidly, driven by advancements in digital technology and the increasing demand for efficiency. As industries continue to embrace digital solutions, the way components and assemblies are documented is set to transform, offering enhanced accessibility and interactivity.

Emerging Trends

- Interactive Visuals: The use of 3D models and augmented reality will allow users to visualize components in a more engaging way, improving understanding and maintenance.

- Cloud-Based Platforms: Storing documentation in the cloud ensures that users can access the latest information from anywhere, facilitating collaboration and reducing downtime.

- Automated Updates: Systems that automatically notify users of changes to documentation will ensure that all stakeholders have the most current information at their fingertips.

Benefits of Digital Transformation

- Enhanced User Experience: Simplified navigation and search functions will make it easier for users to find the information they need.

- Cost Efficiency: Reducing the need for physical documentation can lead to significant savings in printing and distribution costs.

- Real-Time Feedback: Users can provide input on documentation, allowing for continuous improvement and accuracy.

As the shift towards digital documentation accelerates, organizations will need to adapt to these innovations, ensuring they remain competitive and responsive to the needs of their users.